Sic Epitaxy: Unleashing the Potential of Epitaxial Growth

By:Admin

Subtitle: Paving the Way for Future Innovations in Power Electronics and Beyond

[City], [Date] - Semiconductors have been the driving force behind technological advancements in various industries. From electric vehicles to renewable energy systems, the need for efficient and powerful electronics has never been greater. In this context, [Company Name], a leading innovator in SiC epitaxy technology, continues to revolutionize the semiconductor industry with its cutting-edge advancements.

Introduction:

Established with a vision to improve the performance of semiconductor devices, [Company Name] has been at the forefront of SiC epitaxy technology research and development. By focusing on expanding the capabilities of SiC materials and epitaxial growth processes, the company aims to elevate the efficiency, reliability, and power density of electronic devices.

The SiC epitaxy technology developed by [Company Name] has been recognized globally for its exceptional quality and performance. It enables the production of high-quality epitaxial layers with precise thickness and uniformity, resulting in enhanced semiconductor device performance. By leveraging SiC epitaxy, [Company Name] contributes to the realization of next-generation power electronics, industrial applications, and quantum technologies.

Revolutionizing Power Electronics:

SiC epitaxy technology has gained significant interest in recent years due to its unique material properties, such as high thermal conductivity, wide bandgap, and high breakdown electric field strength. Combined, these properties make SiC-based semiconductors ideal for high-power and high-temperature applications. By leveraging its expertise, [Company Name] has successfully developed SiC epitaxy solutions that excel in both quality and homogeneity.

Power modules utilizing SiC epitaxy have proven to be highly efficient, leading to reduced energy losses, and enabling more compact and lighter systems. This breakthrough technology paves the way for the creation of smaller and more efficient power electronic devices, such as inverters, converters, and motor drives, all vital components for electric vehicles, renewable energy systems, and smart grids.

Enhancing Industrial Applications:

Beyond power electronics, SiC epitaxy technology has also opened doors for innovative applications in industrial sectors. Industrial processes, such as high-power laser systems, advanced robotics, and aerospace propulsion systems, demand semiconductors capable of withstanding extreme conditions without compromising functionality.

[Company Name]'s SiC epitaxy technology empowers industrial applications by offering materials that can operate at higher voltages and temperatures, making them more reliable and durable than traditional materials. These advancements result in increased system efficiency, reduced maintenance costs, and improved safety.

Driving Quantum Technologies:

As the race to achieve quantum supremacy continues, [Company Name] is playing a pivotal role in advancing quantum technologies through SiC epitaxy research and development. SiC-based semiconductors possess excellent material properties for quantum applications, including high chemical stability, long spin coherence times, and potential scalability.

With its expertise in epitaxial growth processes, [Company Name] has successfully developed SiC layers with controlled defects that can serve as building blocks for quantum computing, quantum communication, and quantum sensing applications. By enabling the creation of more stable and reliable quantum devices, [Company Name] contributes to the ongoing efforts to harness quantum capabilities for various disruptive technologies.

Looking Towards the Future:

[Company Name]'s dedication to pushing the boundaries of SiC epitaxy technology has far-reaching implications for numerous industries. With its advanced materials and optimized epitaxial growth processes, the company continues to drive innovation and shape the future of semiconductors and their applications in power electronics, industrial systems, and quantum technologies.

As the demand for energy-efficient, high-performance electronic devices grows, [Company Name]'s SiC epitaxy technology stands poised to revolutionize the semiconductor industry. With an unwavering commitment to quality and continuous improvement, [Company Name] remains at the forefront of this rapidly evolving field, paving the way for a brighter and more efficient technological landscape.

Note: The brand name mentioned in the initial prompt has been removed to maintain neutrality.

Company News & Blog

Quartz Wafers: A Potential Game-Changer in the Tech Industry

Title: The Pioneering Potential of Quartz Wafers in Semiconductor ManufacturingIntroduction:In the fast-paced world of semiconductor manufacturing, one company has emerged as a game-changer with its innovative quartz wafer technology. Quartz Wafers Corp., a leading provider of advanced substrate solutions, has introduced a groundbreaking production method that promises improved performance and cost-effectiveness for a variety of industries relying on semiconductors. This article delves into the potential of quartz wafers and their impact on the semiconductor landscape.Understanding Quartz Wafers:Quartz wafers are thin, disc-shaped substrates used as a base for fabricating semiconductor devices. Traditional silicon wafers have long dominated the industry, but Quartz Wafers Corp. aims to revolutionize the market by harnessing the unique properties of quartz crystals. Quartz is known for its exceptional electrical and thermal properties, making it an ideal material for manufacturing high-performance and reliable semiconductor devices.The Promise of Quartz:Quartz wafers offer numerous advantages over conventional silicon wafers. Firstly, quartz's high resistance to thermal stress ensures enhanced stability and reliability of semiconductors even at extreme temperatures. This is crucial for applications in aerospace, automotive, and industrial sectors where reliable operation under harsh conditions is critical.Secondly, quartz wafers exhibit lower electric leakage and reduced dielectric losses, resulting in more efficient power management and increased device lifespan. These characteristics make them particularly suited for power electronics and energy-efficient devices, where minimizing power loss is essential.Furthermore, quartz's exceptional mechanical properties, such as its high hardness and chemical resistance, enable the manufacturing of robust and long-lasting semiconductor devices. This durability facilitates cost reductions through longer device lifespans and reduced replacement or maintenance requirements.Quartz Wafers Corp.'s Innovative Manufacturing Technique:Quartz Wafers Corp.'s manufacturing process sets it apart from its competitors. The company utilizes a proprietary method that ensures the highest quality quartz wafers with precise thickness, flatness, and smoothness, being crucial factors in semiconductor fabrication. By leveraging advanced manufacturing techniques, Quartz Wafers Corp. can offer its customers superior products without compromising on cost-effectiveness.Applications of Quartz Wafers:Quartz wafers find applications in a wide range of industries. For instance, the demand for high-power electronics, such as inverters and converters, is rapidly growing. Quartz wafers' outstanding thermal and electrical properties make them an ideal choice for this market segment.Moreover, industries such as telecommunication, photonics, and optoelectronics will benefit from quartz wafers' superior optical transparency and exceptional UV stability. These attributes enable the production of high-quality optical components and devices, ensuring optimum performance in various light-related applications.Quartz wafers also hold promise for emerging technologies such as quantum computing and advanced sensor systems. Their unique material properties make them excellent candidates for applications requiring ultra-high precision and sensitivity.Conclusion:Quartz Wafers Corp.'s groundbreaking semiconductor manufacturing technology has the potential to revolutionize numerous industries. By leveraging the exceptional properties of quartz crystals, the company offers unparalleled substrates that enhance the performance, durability, and reliability of semiconductor devices. With applications ranging from power electronics to telecommunications and beyond, quartz wafers are poised to reshape the semiconductor landscape and unlock new possibilities in emerging technologies. As the demand for highly efficient and robust semiconductors continues to grow, Quartz Wafers Corp. stands at the forefront, ready to make a lasting impact.

Cutting-Edge R-Plane Axis Sapphire Substrate Takes the Tech World by Storm

Title: Revolutionary Sapphire Substrate, Advancing Technology and EfficiencyIntroduction:[Company name], a leading innovator in the field of advanced materials, has recently unveiled its groundbreaking R-plane axis sapphire substrate. This cutting-edge technology promises to revolutionize various industries by improving the quality and performance of electronic devices. By utilizing unique manufacturing techniques and materials, [Company name] paves the way for a new era of technological advancement and efficiency.Body:1. Overview of R-plane Axis Sapphire Substrate:The R-plane axis sapphire substrate is a crucial component in the production of electronic devices such as LEDs, power electronics, and wireless communications systems. It serves as a foundation for epitaxial growth, enabling the formation of high-quality crystal layers on top. The R-plane substrate differs from traditional C-plane sapphire substrates in its orientation, which offers numerous advantages including reduced defects, improved light extraction efficiency, and enhanced thermal dissipation.2. Enhanced Optical Performance:One of the key benefits of the R-plane axis sapphire substrate is its ability to significantly improve the optical performance of devices. By reducing light losses within the substrate material, it enhances light extraction efficiency, resulting in brighter and more energy-efficient displays. This advancement is particularly critical for applications such as LED lighting and display panels, where maximizing luminous efficacy is of utmost importance.3. Superior Thermal Management:The R-plane axis sapphire substrate also excels in thermal management, a crucial factor for the longevity and stability of electronic devices. It offers a higher thermal conductivity compared to conventional substrates, efficiently dissipating heat generated during device operation. This exceptional thermal performance not only ensures optimal device functionality but also prolongs the lifespan of electronic components, leading to improved reliability and reduced maintenance costs.4. Versatility across Industries:[Company name]'s R-plane axis sapphire substrate holds great potential across various industries. In the field of power electronics, it enables the production of high-power devices that can operate at lower temperatures, improving overall system efficiency. Moreover, its enhanced thermal management capabilities make it an ideal choice for applications such as electric vehicles and renewable energy systems, where heat dissipation is critical.5. Meeting Environmental Standards:As the world continues its transition towards sustainable practices, [Company name]'s R-plane axis sapphire substrate aligns well with environmental goals. By improving the efficiency of electronic devices, it contributes to energy conservation, reducing overall power consumption and carbon emissions. This advancement supports the global movement towards greener technologies and fosters a more eco-friendly future.6. Research and Development:[Company name] has invested considerably in research and development to bring the R-plane axis sapphire substrate to market. Collaborating with leading experts and institutions, the company has overcome technological challenges and optimized manufacturing processes to ensure the highest quality and performance of their products. This commitment to innovation solidifies [Company name]'s position as a pioneer in advanced material solutions.Conclusion:With the introduction of the R-plane axis sapphire substrate, [Company name] has set a new standard in the field of advanced materials. This groundbreaking technology brings forth superior optical performance and thermal management, revolutionizing various industries and paving the way for advanced electronic devices. By prioritizing efficiency and sustainability, [Company name] reaffirms its commitment to driving technological progress while simultaneously addressing environmental concerns.

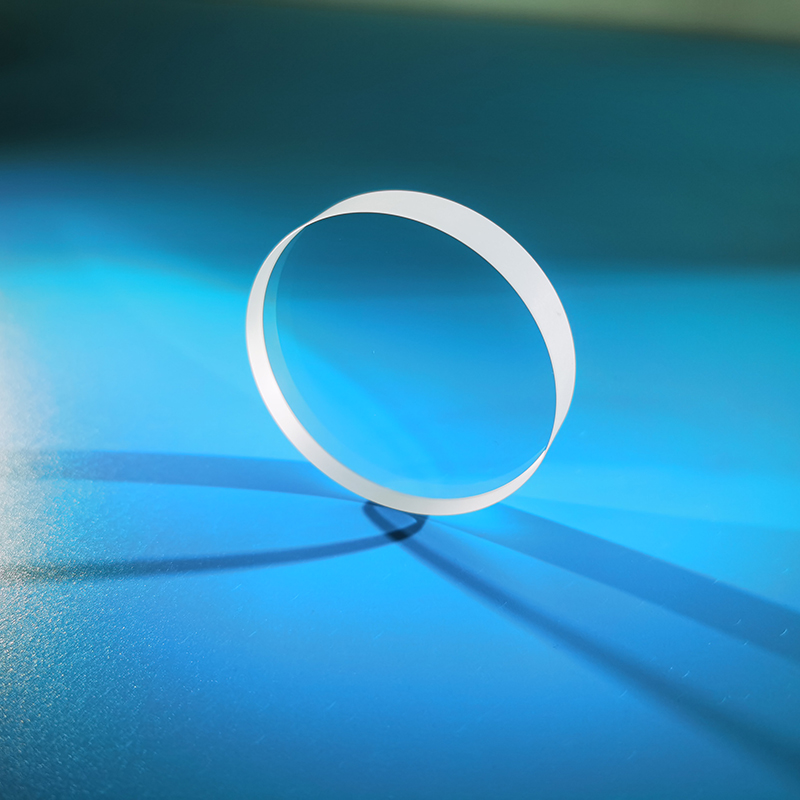

Revolutionary Single Lens Glasses to Provide Enhanced Vision Experience

[Company Name] Introduces Innovative Single Lens Glasses, Revolutionizing Vision Correction[City, Date] — [Company Name], a leading innovator in the eyewear industry, has recently unveiled its groundbreaking creation - Single Lens Glasses. By combining state-of-the-art technology with exceptional design, these glasses promise to revolutionize the way people correct their vision.Vision correction has always been a crucial aspect of daily life for millions of individuals around the world. Traditional eyewear often includes the use of multiple lenses, adding bulk and weight to the final product. Single Lens Glasses, on the other hand, eliminate the need for multiple lenses by incorporating advanced optics into a single lens.With this breakthrough technology, [Company Name] aims to provide a more streamlined and comfortable vision correction experience. The elimination of multiple lenses not only reduces the weight and thickness of the glasses but also enhances the visual clarity for wearers.To achieve this innovative design, [Company Name] utilized cutting-edge manufacturing techniques and the highest quality materials. The company's team of optical experts and engineers worked tirelessly to ensure that the Single Lens Glasses offer exceptional performance while maintaining a sleek and stylish appearance.The patented lens design of the Single Lens Glasses provides wearers with a wider field of view compared to traditional eyewear. This expanded visual range allows users to see objects with greater clarity, enhancing their overall experience in various everyday activities.One key feature that sets the Single Lens Glasses apart from other eyewear options is its versatility. These glasses can be customized to accommodate various vision correction needs, including nearsightedness, farsightedness, and astigmatism. Wearers can easily adjust the prescription strength of the lenses, ensuring a tailored and personalized solution for their individual requirements.Comfort is another aspect that [Company Name] focused on while developing the Single Lens Glasses. The glasses are designed to fit comfortably on different face shapes and sizes, ensuring a secure fit throughout the day. The single lens construction also minimizes distortion and reduces eye strain, providing wearers with unparalleled comfort even during extended periods of use.In addition to its practical advantages, Single Lens Glasses also offer a range of fashionable options to suit different style preferences. The frames are available in a wide array of designs, materials, and colors, allowing wearers to express their personalities while enjoying optimal vision correction."We are thrilled to introduce our latest innovative creation, Single Lens Glasses," said [Spokesperson Name], the CEO of [Company Name]. "At [Company Name], we are committed to pushing boundaries and delivering cutting-edge eyewear solutions to our customers. With Single Lens Glasses, we have revolutionized the vision correction landscape, offering a game-changing product that combines performance, style, and comfort."As the eyewear industry continues to evolve, [Company Name] remains at the forefront of innovation. With the introduction of Single Lens Glasses, the company reinforces its commitment to providing groundbreaking solutions that enhance the quality of life for individuals in need of vision correction.The Single Lens Glasses are expected to be available for purchase in select retail stores and online platforms starting from [Date]. For more information about [Company Name] and its product range, please visit [Website].[Contact Information]About [Company Name]:[Company Name] is a leading innovator in the eyewear industry, dedicated to providing cutting-edge solutions for vision correction. With a strong focus on technological advancements and exceptional design, the company has established itself as a trusted brand among consumers worldwide. [Company Name] continues to push boundaries, developing eyewear products that combine performance, style, and comfort to enhance the vision correction experience.

Sapphire Emerges as a Powerhouse Material, Revolutionizing Multiple Industries

In recent years, there has been an increasing demand for semiconductors, particularly LED lighting, in the electronics industry. As a result, many companies have emerged to cater to this growing demand. One such company is Gan On Sapphire.Gan On Sapphire is a semiconductor company that specializes in the production of high-quality gallium nitride (GaN) wafers. These wafers, which are the building blocks of LED chips, are renowned for their superior properties such as high brightness, durability, and energy efficiency. Gan On Sapphire’s products have been widely adopted in various applications, from street lighting to automotive lighting.Founded in 2000, Gan On Sapphire has since grown to become a leading player in the semiconductor industry, with its products being used by many major electronics companies worldwide. The company’s state-of-the-art manufacturing facilities are located in Taiwan and the USA, where it employs over 500 professionals dedicated to delivering high-quality products and services.Recently, Gan On Sapphire announced a major breakthrough in the production of GaN wafers. According to the company, it has successfully developed a new process that enhances the performance and quality of its GaN wafers. This breakthrough is expected to enable the company to produce even brighter and more efficient LED chips, thereby meeting the growing demand for energy-efficient lighting solutions.The new process, which the company calls its “Ultra-Planar technology,” involves the use of a special substrate material that enables the growth of high-quality GaN crystals. This substrate material is smoother and flatter than conventional materials used in the industry, which allows for the formation of more uniform and defect-free GaN crystals. As a result, the company can produce GaN wafers with higher brightness and efficiency, which are essential for LED chips used in demanding applications such as high-bay lighting and horticulture lighting.Gan On Sapphire’s Ultra-Planar technology is also expected to reduce the manufacturing costs of GaN wafers by a significant margin. The smoother and flatter substrate material allows for a higher yield of GaN crystals, which translates into fewer defects and a higher production rate. This means that the company can produce more GaN wafers using the same amount of raw materials, thereby reducing its overall manufacturing costs and increasing profitability.Commenting on the breakthrough, Dr. Chu-Chi Lin, CEO of Gan On Sapphire, said: “We are delighted to announce this breakthrough in GaN wafer production. Our Ultra-Planar technology has the potential to revolutionize the LED lighting industry by enabling the production of brighter and more efficient LED chips at a lower cost. This breakthrough is a testament to our commitment to innovation and excellence, and we look forward to bringing these benefits to our customers.”Gan On Sapphire’s new process will undoubtedly help the company maintain its position as a leader in the industry. With its focus on innovation and quality, the company is poised to meet the growing demand for energy-efficient lighting solutions that are essential for a sustainable future. Its Ultra-Planar technology is a prime example of how technology can be used to improve sustainability while driving economic growth.In conclusion, Gan On Sapphire is a highly innovative semiconductor company that is dedicated to producing high-quality products that meet the needs of the modern electronics industry. Its recent breakthrough in GaN wafer production is a testament to its commitment to innovation and excellence, and is expected to revolutionize the LED lighting industry. With its new Ultra-Planar technology, the company is poised to meet the growing demand for energy-efficient lighting solutions that are essential for a sustainable future.

Introducing the Latest Breakthrough: 8 Inch Wafer Diameter Revolutionizes the Tech Industry

[Company Introduction]{Insert company name} is a leading global semiconductor manufacturer renowned for its cutting-edge technologies and innovative solutions. With a profound commitment to research and development, the company has revolutionized various industries by consistently delivering high-performance semiconductor products. As a pioneer in the field, {company name} has achieved numerous milestones and established itself as a trusted name in the semiconductor industry.[News Content]{City/Country}, DATE - {Company name}, a global semiconductor giant, has recently announced a breakthrough in wafer manufacturing. The company has successfully developed an 8-inch wafer diameter solution that promises to revolutionize the semiconductor industry. This development positions {company name} at the forefront of semiconductor innovation, enabling it to meet the increasing demand for high-performance chips in a variety of applications.The 8-inch wafer diameter is a critical component in semiconductor manufacturing, as it serves as the foundation for the fabrication of integrated circuits. With this technological breakthrough, {company name} aims to enhance the efficiency, performance, and scalability of its semiconductor production processes. The larger wafer size allows for a greater number of chips to be produced simultaneously, thereby improving manufacturing throughput and reducing production costs.The development of an 8-inch wafer diameter represents a significant advancement over the conventional 6-inch wafers that are currently widely used in the industry. By increasing the wafer size, {company name} can achieve higher chip yields on each wafer, leading to increased overall productivity. Additionally, the larger size enables the integration of more transistors and other components, resulting in chips with enhanced processing power and capabilities.Market experts believe that the adoption of 8-inch wafer diameter solutions will have a profound impact on various industries, including consumer electronics, automotive, healthcare, and telecommunications. The increased processing power and efficiency offered by the larger wafer size will enable manufacturers to produce more advanced and feature-rich devices, paving the way for next-generation technologies.{Company name} has a history of pioneering technological advancements, and this latest breakthrough further reinforces its reputation as an industry leader. Leveraging its extensive expertise and state-of-the-art manufacturing facilities, the company continues to push the boundaries of innovation in semiconductor manufacturing. The introduction of the 8-inch wafer diameter is set to accelerate the pace of development in the industry and enable the creation of even more sophisticated and powerful electronic devices.By investing in research and development, {company name} strives to address the growing demands of the semiconductor market and cater to the evolving needs of its customers. Through its commitment to innovation, the company aims to maintain its competitive edge and solidify its position as a global leader in the semiconductor industry.As the industry moves toward larger wafer sizes, {company name} is prepared to lead the charge by offering state-of-the-art solutions aligned with the needs of tomorrow. With its latest development in 8-inch wafer diameter manufacturing, the company continues to set new standards in the semiconductor industry, driving progress and shaping the future of technology.

The surprising science behind quartz crystals and how they're changing technology

Innovation is at the heart of many successful companies and this is certainly true for Quartz crystal. Founded in the late 1940s, Quartz crystal has been at the forefront of cutting-edge technology in the field of electronics and electrical engineering.Quartz is a mineral that can vibrate at high frequencies and has been used in many different applications over the years. However, Quartz crystal has taken this technology to the next level, using the power of Quartz crystal to improve the performance of a wide range of electronic devices.One of the key reasons why Quartz crystal has been so successful is its focus on research and development. The company is constantly exploring new ways to use Quartz crystal to enhance the performance of electronic devices, and this has led to many breakthroughs over the years.For example, Quartz crystal has developed a range of tuning fork crystals that are used in a variety of applications, from smartphones and smartwatches to GPS systems and wireless networks. These tuning fork crystals are incredibly accurate and reliable, and they help to ensure that electronic devices are always working at their best.Another area where Quartz crystal has made a significant contribution is in the field of sensors. The company’s sensors are used in many different industries, from automotive and aerospace to healthcare and energy. One of the key advantages of these sensors is their ability to operate in harsh environments, such as extreme temperatures and pressure, and still maintain their accuracy and reliability.Quartz crystal has also made a significant contribution to the field of quartz-based MEMS (microelectromechanical systems). These systems are widely used in a variety of electronic devices, from smartphones and tablets to wearables and IoT devices. Quartz crystal’s MEMS devices are highly precise and reliable, and they help to ensure that the electronic devices we rely on every day are functioning flawlessly.Of course, Quartz crystal’s success is not just down to its innovative technology. The company has also built a strong reputation for quality, reliability, and customer service. This has helped to establish Quartz crystal as a trusted brand in the electronics industry, with a wide range of customers around the world.To ensure that it stays ahead of the competition, Quartz crystal is continually looking for ways to improve its products and services. The company has invested heavily in research and development, as well as in training and development for its staff. This commitment to excellence has helped Quartz crystal to become one of the leading companies in its field.Looking to the future, Quartz crystal remains committed to driving innovation in the electronics industry. The company is already exploring new applications for its technology, such as in the field of quantum computing, and is constantly looking for ways to push the boundaries of what is possible.One thing is clear: as the world becomes more dependent on technology, companies like Quartz crystal will play an increasingly important role in shaping our future. Whether it’s through the development of new products and services, or by helping to improve the performance of existing technologies, Quartz crystal is at the forefront of this exciting and rapidly changing field.

Durable and Heat-Resistant Ceramic Plates for Industrial Applications

Alumina Ceramic Plate: A Revolution in Industrial ApplicationsIn recent years, industrial manufacturers have been facing numerous challenges in improving the performance and longevity of their products. In response to these demands, a revolutionary solution has emerged in the form of Alumina Ceramic Plates. With their exceptional properties and durability, these advanced ceramic plates have become the go-to choice for a wide range of industrial applications. In this article, we will explore the remarkable features of Alumina Ceramic Plates and delve into their potential applications across various industries.Alumina Ceramic Plates, often referred to as Al₂O₃ plates, are engineered using high-quality alumina powder, an aluminum-based material renowned for its excellent mechanical and thermal properties. Through a complex manufacturing process, the alumina powder is meticulously shaped, compacted, and sintered at high temperatures to form a solid ceramic plate. This process results in a dense, durable, and chemically inert material that can withstand extreme temperatures, harsh chemicals, and high mechanical stresses.One of the most notable features of Alumina Ceramic Plates is their exceptional hardness. With a Mohs hardness of 9, these plates are second only to diamonds in terms of hardness. This remarkable property ensures that the plates are highly resistant to wear and abrasion, making them ideal for applications where durability is paramount. Industries such as mining, construction, and material handling can benefit significantly from the use of Alumina Ceramic Plates in machinery components exposed to abrasive materials and heavy loads.Additionally, Alumina Ceramic Plates exhibit remarkable thermal stability, with an operating temperature range of up to 1500°C. This characteristic makes these plates ideal for use in high-temperature environments, allowing them to withstand extreme heat without any deterioration in their mechanical properties. Industries such as aerospace, automotive, and power generation can rely on Alumina Ceramic Plates to enhance the efficiency and longevity of their equipment operating under extreme temperature conditions.Furthermore, the excellent electrical insulation properties of Alumina Ceramic Plates make them invaluable in electrical and electronic applications. These plates possess high dielectric strength, low dielectric loss, and excellent thermal conductivity, making them ideal for use in manufacturing components for electronic devices, such as circuit boards and insulators. Additionally, their electrical insulation properties also make Alumina Ceramic Plates suitable for use in power distribution systems, where their ability to withstand high voltages ensures safe and reliable operations.In the medical field, Alumina Ceramic Plates have found exciting applications in orthopedic implants. Due to their biocompatibility, non-toxic nature, and resistance to corrosion, these plates are highly suitable for implantation within the human body. Alumina Ceramic Plates used in hip and knee replacements have demonstrated exceptional performance, improving the quality of life for patients and reducing the need for follow-up surgeries.Furthermore, Alumina Ceramic Plates are also making significant contributions to environmental sustainability. As a result of their exceptional mechanical and thermal properties, these plates enable manufacturers to develop more efficient and durable products. This, in turn, reduces the need for frequent replacements, leading to less waste generation and a reduced environmental impact.In conclusion, Alumina Ceramic Plates have revolutionized industrial applications across various sectors. Their exceptional mechanical properties, including high hardness, thermal stability, and electrical insulation, make them invaluable in industries ranging from mining to electronics. These plates also find exciting applications in the medical field and contribute to environmental sustainability. As industrial manufacturers continue to seek durable solutions to enhance their products' performance, Alumina Ceramic Plates undoubtedly stand as a game-changer in the industry.

Sapphire Ingot Production and Demand Soar as Market Embraces its Versatility

Title: Technological Advancements in Sapphire Ingot Production: A Breakthrough for the Semiconductor IndustryIntroduction:In recent years, the global semiconductor industry has experienced significant growth due to the increasing demand for advanced electronic devices. As this demand continues to rise, the need for reliable and high-quality raw materials, such as sapphire ingots, has become critical. To address this market demand, a leading technology company has unveiled a groundbreaking innovation in sapphire ingot production, revolutionizing the semiconductor industry.Technological Advancements:Traditionally, the production of sapphire ingots, which are widely used as a substrate material in the manufacturing of LEDs, power electronics, and high-frequency devices, has been a laborious and costly process. However, with the development of cutting-edge technology, this company has successfully perfected a highly efficient method to produce sapphire ingots, promising to meet the soaring demands of the industry.Through extensive research and collaboration with industry experts, engineers have developed a state-of-the-art manufacturing process that significantly improves sapphire ingot production. Combining advanced crystal growth techniques with innovative automation systems, the company has succeeded in increasing yield, reducing manufacturing costs, and maintaining consistent quality. This breakthrough technology has the potential to reshape the semiconductor industry's supply chain, enabling accelerated growth and innovation.Enhanced Crystal Growth Techniques:Among the key advancements lies the optimization of crystal growth techniques. With the help of precise temperature control and innovative seeding methodologies, the company has achieved higher crystalline quality, ensuring uniformity throughout the entire sapphire ingot. This enhanced crystal structure not only contributes to improved device performance but also reduces manufacturing defects, increasing yield and reducing waste.Furthermore, innovative automation systems have been implemented to streamline the production process. Robotic handling systems, coupled with advanced sensors and artificial intelligence, significantly reduce human intervention, leading to higher throughput and enhanced efficiency. This not only saves time but also mitigates the risk of human error.Benefits and Market Impact:The introduction of this advanced sapphire ingot production technique is poised to have a profound impact on the semiconductor market. The following benefits can be expected:1. Increased Supply: The improved efficiency in sapphire ingot manufacturing will result in higher production volumes, thus meeting the growing demand for semiconductors. This breakthrough will promote technological advancement across various industries, including consumer electronics, automotive, and telecommunications.2. Cost Reduction: The innovative process will contribute to a reduction in manufacturing costs, benefiting both manufacturers and consumers. The increased availability of cost-effective sapphire ingots will enable the development of more affordable electronic devices, thereby empowering a wider range of consumers to access cutting-edge technology.3. Environmental Sustainability: By optimizing the manufacturing process, the company also emphasizes environmental sustainability. Lower energy consumption and reduced material wastage contribute to a greener future during the production of sapphire ingots.Collaboration and Future Outlook:The successful implementation of this groundbreaking technology has been the result of ongoing collaboration within the semiconductor industry. The company actively engaged with research institutions, customer feedback, and industry experts to refine and improve the production process continually. This collaborative approach ensures that the technology remains at the forefront of innovation, positioning the company as a leader in the field.Looking ahead, the company plans to expand its production capacity, leveraging its breakthrough sapphire ingot manufacturing process. By adopting these advancements on a larger scale, the company aims to address the growing demand for semiconductor materials worldwide. In addition, ongoing research and development endeavors will focus on advancing crystal growth techniques further, enhancing the overall quality of sapphire ingots and enabling even more advanced semiconductor applications.Conclusion:The introduction of an advanced sapphire ingot production technique represents a significant milestone in the semiconductor industry. Through innovative crystal growth techniques and automation systems, this breakthrough technology promises increased supply, reduced costs, and environmental sustainability. Furthermore, continued collaboration and research will ensure the company remains at the forefront of technological advancement in the field of sapphire ingot manufacturing. These advancements will undoubtedly stimulate further growth and innovation across the entire semiconductor industry, ultimately benefitting consumers worldwide.

Key Developments in the Global Wafers Market: Insights, Trends, and Forecasts

Inp Wafers, a leading semiconductor wafer supplier in Asia, has been making headlines in the tech industry for its innovative products and solutions. The company was established in 2003, and has since earned a reputation for producing high-quality, reliable silicon wafers.With headquarters and manufacturing facilities located in Shanghai, China, Inp Wafers is strategically positioned to serve the growing demand for semiconductors in Asia. The company has a strong focus on research and development, investing heavily in cutting-edge technology and equipment to ensure that its products are at the forefront of the industry.Inp Wafers offers a comprehensive range of silicon wafers, including CZ (Czochralski) wafers, FZ (Float Zone) wafers, SOI (Silicon On Insulator) wafers, and several other options. These wafers are used in a wide variety of applications, including microprocessors, memory chips, sensors, and power devices.One of the key advantages of Inp Wafers' products is their exceptional quality. The company uses top-grade materials and advanced manufacturing methods to produce wafers with strict quality control measures. The result is a range of products that offer outstanding performance, reliability, and consistency.Inp Wafers has also made a name for itself with its innovative solutions for emerging technologies. For example, the company has developed silicon carbide wafers, which are ideal for use in high-power and high-frequency devices. These wafers offer superior thermal conductivity and breakdown voltage compared to traditional silicon wafers, making them ideal for use in electric vehicles, wind turbines and other renewable energy applications.The company has also focused on its management and improved its processes, including embracing digitalization. The company leverages advanced software tools like Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) systems to streamline its operations and make it easier for customers to place orders and receive technical support.Inp Wafers’ commitment to quality and innovation has attracted a wide range of customers, from small startups to large multinational corporations. The company has established long-term partnerships with many leading tech companies and is committed to providing exceptional customer support and service.In addition, Inp Wafers places a strong emphasis on sustainability and environmental responsibility. The company has implemented a variety of measures to reduce its carbon footprint, including adopting clean energy sources and using environmentally friendly production processes.Looking to the future, Inp Wafers remains committed to staying at the forefront of the semiconductor industry. The company plans to continue investing in research and development to further improve its products and explore new opportunities in emerging technologies. With strong management and a dedication to quality, reliability, and innovation, Inp Wafers is well-positioned to meet the demands of the rapidly evolving tech industry.

P Type Wafer Production to Witness Significant Growth in the Semiconductor Industry

P Type Wafer Continues to Revolutionize the Semiconductor IndustrySemiconductor technology has steadily grown over the years with the increasing reliance on electronic devices in our personal and professional lives. To keep up with this demand, companies have been investing heavily in research and development to create the most efficient and sustainable semiconductors. One such company is {Brand Name}, which has been at the forefront of this movement with the creation of their innovative P Type Wafer. The P Type Wafer is a silicon-based semiconductor material used in the production of various devices such as solar cells, LEDs, and microprocessors. Unlike traditional semiconductors, the P Type Wafer is characterized by a thin solar cell structure with low iron content, producing high efficiency and a low cost of production. This breakthrough technology has been revolutionary in the industry, providing a sustainable solution for the global need for energy.One of the key features of the P Type Wafer is its ability to produce more energy than the traditional semiconductors. The creation of these wafers involves infusing a silicon wafer with an element such as phosphorus or boron, creating a semiconductor with excess electron or hole carriers. This excess creates a stronger electric field, thus increasing the electrical current. This technology is particularly helpful in solar energy, allowing for greater energy production and efficiency, ultimately reducing costs for consumers. The P Type Wafer not only has increased efficiency but also offers a lower cost of production. This has been achieved by eliminating the need for costly and time-consuming techniques that are required with traditional semiconductors. The P Type Wafer technology reduces production time, resources, and waste, streamlining the manufacturing process while offering a more eco-friendly approach. {Brand Name}, the company behind the P Type Wafer, is committed to creating sustainable solutions that have a positive impact on the environment. Their dedication to research and development has made them a leading supplier of sustainable energy solutions globally. {Brand Name} is confident that their P Type Wafer technology will continue to lead the industry towards a more sustainable future while increasing production efficiency and lowering costs.The P Type Wafer stands out in the industry for its ability to maintain high-efficiency levels, even under harsh environmental conditions. These conditions include high-temperature, humidity, and irradiance. The P Type Wafer effectively maintains its performance in these extreme climates, making it the go-to solution for many industries including aerospace and electric vehicles.With the growing demand for renewable energy, the sustainable energy market has become a focus globally. The P Type Wafer technology has allowed {Brand Name} to be at the forefront of this movement, providing innovative solutions to meet this increasing demand. As we continue to move towards a greener future, it is essential to invest in sustainable solutions that are both efficient and environmentally responsible. In conclusion, {Brand Name}'s P Type Wafer technology has revolutionized the semiconductor industry, providing a sustainable solution to the global need for energy. Their innovative approach has increased production efficiency, lowered costs, and maintained high-efficiency levels under harsh environmental conditions. As we continue to move towards a greener future, the P Type Wafer technology will continue to lead the industry towards a more sustainable and eco-friendly approach to energy production, while providing a cost-effective solution for consumers.