Discover the Benefits of High Hardness Products for Your Needs

By:Admin

The new product line from High Hardness offers a variety of options, including advanced ceramics, carbides, and other high-performance materials. These materials are designed to meet the demanding requirements of modern applications, providing exceptional strength, durability, and resistance to wear and corrosion.

As a company, High Hardness is committed to pushing the boundaries of materials science and engineering, constantly seeking new ways to improve the performance and capabilities of their products. With state-of-the-art facilities and a team of experienced researchers and engineers, High Hardness is at the forefront of developing cutting-edge materials that are vital for the success of their customers.

In addition to their focus on innovation, High Hardness is also deeply committed to sustainability and environmental responsibility. The company constantly seeks ways to minimize their impact on the environment, utilizing efficient manufacturing processes and reducing waste wherever possible. Their dedication to sustainability extends to the end use of their products, with a focus on creating materials that contribute to the overall efficiency and longevity of the systems in which they are used.

One of the key strengths of High Hardness is their dedication to customer satisfaction. The company works closely with their clients to understand their specific needs and challenges, developing customized solutions that meet and exceed their expectations. By maintaining strong partnerships with their customers, High Hardness is able to provide materials that are tailored to the unique requirements of each application, ensuring optimal performance and reliability.

The launch of the new product line is a significant milestone for High Hardness, demonstrating their ongoing commitment to innovation and excellence in the field of advanced materials. With a strong track record of delivering superior products and outstanding service, the company is well-positioned to meet the evolving needs of their customers and continue to drive advancements in materials technology.

"We are thrilled to introduce our latest line of advanced materials to the market," said [spokesperson] of High Hardness. "These new products represent the culmination of years of research, development, and investment in our manufacturing capabilities. We are confident that they will enable our customers to achieve new levels of performance and success in their respective industries."

As High Hardness continues to expand their product offerings and capabilities, they remain steadfast in their commitment to excellence and innovation. With a focus on delivering superior materials that enable their customers to excel, the company is poised to remain a leader in the field of advanced materials for many years to come.

About High Hardness

High Hardness is a leading manufacturer of advanced materials, providing innovative solutions for a wide range of industries. With a focus on quality, performance, and sustainability, the company is dedicated to pushing the boundaries of materials science and engineering. By partnering closely with their customers and maintaining a strong commitment to excellence, High Hardness continues to deliver cutting-edge materials that enable success in a rapidly changing world.

Company News & Blog

Top Providers of High-Quality Sapphire Components for Various Industries

Title: Innovations in Sapphire Parts Technology revolutionize various industries[City], [Date] - In a quest for superior performance and durability, Sapphire Parts, a renowned leader in advanced materials technology, continues to push boundaries by introducing groundbreaking innovations that are set to empower a wide range of industries. With a focus on creating solutions that deliver unparalleled quality and reliability, Sapphire Parts' advancements have the potential to revolutionize critical applications in sectors such as aerospace, electronics, healthcare, and more.Established in [year], Sapphire Parts has emerged as a global frontrunner in the production of high-quality sapphire components. Sapphire, a crystalline form of aluminum oxide (Al2O3), possesses exceptional properties such as exceptional hardness, excellent optical transparency, and superior resistance to diverse environmental factors. Leveraging these unique attributes, Sapphire Parts has developed a comprehensive portfolio of components that are known for their outstanding reliability in extreme conditions.Sapphire Parts' newest innovation, the [technology name], promises to reshape the landscape of industries relying on precision and robustness. With this groundbreaking technology, Sapphire Parts has taken a bold step toward addressing the challenges faced by numerous sectors – offering enhanced performance and optimization like never before seen. The [technology name] combines Sapphire Parts' expertise in proprietary manufacturing processes with cutting-edge research and development, providing customers with an unrivaled solution that meets the stringent requirements of their respective fields.Aerospace is one industry anticipated to benefit greatly from Sapphire Parts' latest innovation. The ability of their sapphire components to withstand extreme temperatures and pressures, coupled with their exceptional resistance to wear and corrosion, ensures safe and reliable operation in critical systems. From turbine blades to cockpit displays, Sapphire Parts' Sapphire [technology name] components deliver superior reliability and longevity, providing aerospace manufacturers with peace of mind.The electronics sector is another area set to experience a significant transformation. Sapphire Parts' Sapphire [technology name] components offer an ideal solution for a range of electronic devices, including mobile phones, tablets, and wearables. The unparalleled scratch resistance and optical clarity of Sapphire [technology name] significantly enhance screen protection, resulting in devices with improved lifespan and display quality.Moreover, the healthcare industry stands to gain immensely from Sapphire Parts' advancements. Sapphire [technology name] components are highly biocompatible and exhibit superior resistance to the chemical degradation often observed in healthcare applications. With the integration of Sapphire Parts' Sapphire [technology name] components, medical devices and surgical instruments can be guaranteed to meet the stringent sterilization protocols, significantly reducing the risk of cross-contamination.Environmentalists and advocates for sustainable energy solutions will also find solace in Sapphire Parts' innovations. Sapphire [technology name] components offer exceptional stability and optical properties crucial in renewable energy systems like solar cells. The durability and efficiency of Sapphire [technology name] translate into increased energy generation, providing a green way to combat the pressing challenge of climate change.Sapphire Parts' commitment to excellence extends beyond just technological innovations. As a socially responsible company, they actively embrace eco-friendly practices and strive to minimize their environmental impact throughout their operations. By integrating sustainable processes into their manufacturing facilities, Sapphire Parts underscores its dedication to preserving the planet for future generations.Looking ahead, Sapphire Parts' relentless pursuit of advancements continues to fuel excitement in various industries. With their Sapphire [technology name] components, they have set new benchmarks for quality, reliability, and performance. As their innovative technologies trickle down into sectors such as aerospace, electronics, healthcare, and sustainable energy, it is no doubt that Sapphire Parts will fundamentally impact these industries and inspire further advancements in the field of sapphire-based materials.About Sapphire Parts:Sapphire Parts is a leading global provider of high-quality sapphire components. With a focus on innovation and quality, Sapphire Parts pioneers advancements in sapphire-based technologies to cater to a diverse set of industries. Committed to sustainability, Sapphire Parts ensures that their cutting-edge solutions contribute to making the world a better place.For more information, visit [website] or contact [email/phone number].Press Contact:[Contact Name][Company Name][Email][Phone Number]

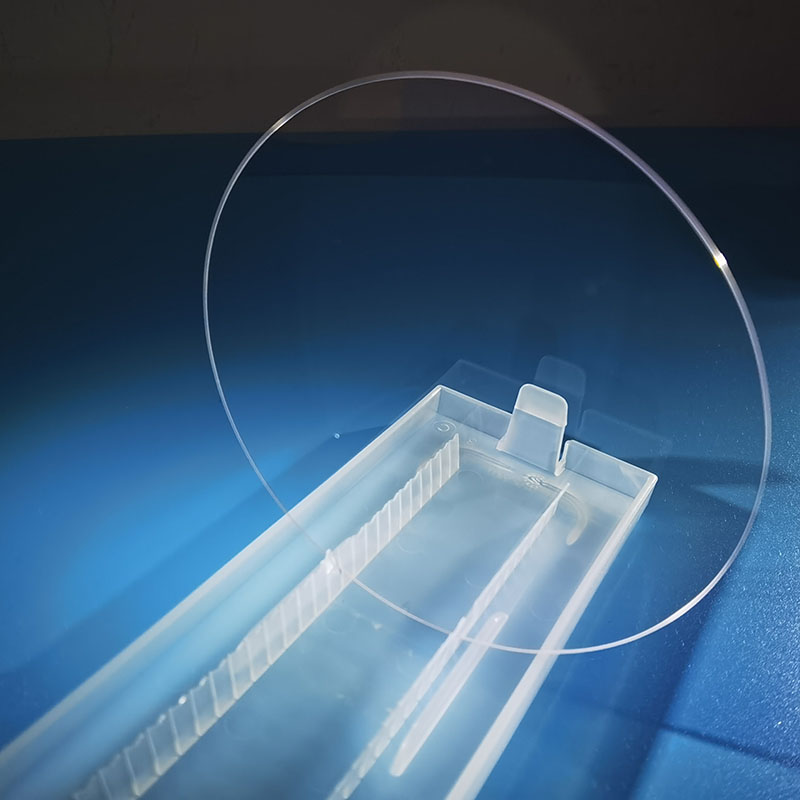

High-quality Optical Window Glass for Various Applications

Optical Window Glass is a cutting-edge product designed for a variety of applications in industries such as aerospace, defense, and automotive. As a leading manufacturer of high-quality optical products, [company name] has been at the forefront of developing innovative solutions to meet the ever-changing demands of the market.The Optical Window Glass, manufactured by [company name], is a premium quality product that offers exceptional clarity, durability, and resistance to harsh environmental conditions. It is made from high-grade materials and is meticulously crafted to meet the stringent requirements of its intended applications.One of the key features of the Optical Window Glass is its ability to provide superior optical performance, ensuring minimal distortion and high light transmission for precise and accurate imaging. This makes it an ideal choice for use in high-precision optical systems such as cameras, telescopes, and laser systems.In addition to its exceptional optical properties, the Optical Window Glass is also designed to withstand extreme temperatures, high pressures, and exposure to corrosive chemicals and harsh environments. This makes it an indispensable component for a wide range of applications in industries where performance and reliability are paramount.The [company name] has a long-standing reputation for delivering high-quality optical products that exceed industry standards. With state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians, the company is committed to providing its customers with the most advanced and reliable optical solutions.“We are proud to offer the Optical Window Glass as part of our comprehensive range of optical products,” said [company spokesperson]. “Our dedication to innovation and quality has allowed us to stay ahead of the curve and continue to provide our customers with the best optical solutions available on the market.”The Optical Window Glass is available in a variety of shapes, sizes, and specifications to meet the specific needs of different applications. Whether it is for use in aerospace, defense, automotive, or any other industry, customers can rely on the [company name] to deliver a product that meets their exact requirements and expectations.With a strong focus on research and development, [company name] is constantly working to improve its products and develop new solutions to address the evolving needs of the market. The company’s commitment to quality and innovation has earned it the trust and respect of customers around the world.In conclusion, the Optical Window Glass from [company name] is a top-of-the-line product that delivers outstanding performance and reliability in a wide range of applications. With its exceptional optical properties, durability, and resistance to harsh environmental conditions, it is the go-to choice for industries that demand the best. Customers can rely on [company name] to provide them with superior optical solutions that meet their exact needs and exceed their expectations.

Discover the Benefits of Optical Glass Plates for Your Business' Applications

Optical Glass Panels Revolutionize the Display IndustryIn today's technology-driven world, where high-definition displays and screens are an integral part of our daily lives, the demand for advanced optical glass solutions has increased exponentially. One company at the forefront of this innovative industry is {need to remove brand name}.{Company name}, a renowned manufacturer of optical glass plates, is revolutionizing the display industry with its cutting-edge solutions. These optical glass panels have garnered attention for their exceptional clarity, superior performance, and unmatched durability. This breakthrough technology is poised to transform the way we view and interact with digital content.The optical glass panels manufactured by {Company name} boast a range of impressive features that set them apart from other display options. Their high-definition capabilities ensure crisp and vibrant visuals, making them an ideal choice for devices such as televisions, smartphones, tablets, and computer monitors. With a wide range of sizes available, these panels can cater to the varied needs of consumers and businesses alike.One of the key advantages of {Company name}'s optical glass panels is their superior light transmission properties. Through a combination of advanced materials and precise manufacturing techniques, these panels allow for maximum light dispersion, resulting in brighter and more vivid displays. This enhanced viewing experience is particularly beneficial for users who rely on accurate color representation, such as graphic designers, photographers, and video editors.Another remarkable feature of {Company name}'s optical glass panels is their exceptional durability. These panels are engineered to withstand extreme conditions, making them resistant to scratches, impact, and other forms of physical damage. Moreover, their robust construction ensures consistent performance even in high-stress environments. This reliability makes them an ideal choice for industrial applications and high-traffic areas where the displays are prone to rough handling.Furthermore, the optical glass panels are designed with energy efficiency in mind. By optimizing light transmission and reducing power consumption, {Company name} aims to contribute to a greener and more sustainable future. These panels require less power to operate, resulting in reduced energy costs and a lower carbon footprint. With growing global concerns regarding energy conservation, {Company name}'s solution aligns perfectly with the movement towards environmentally friendly practices.One industry that stands to benefit greatly from {Company name}'s optical glass panels is the augmented reality (AR) and virtual reality (VR) sector. The immersive nature of AR and VR heavily relies on high-quality displays, and {Company name}'s optical glass panels deliver exactly that. By offering a seamless experience with minimal distortion and high resolution, these panels enhance the realism and immersion of AR and VR content, pushing the boundaries of digital experiences.Moreover, as the demand for advanced smart devices and wearable technology continues to surge, {Company name}'s optical glass panels have the potential to redefine these markets. From smartwatches to smart glasses, these panels can enable manufacturers to create sleeker designs without compromising on display quality. With their lightweight and low profile, these panels are the perfect fit for compact and portable devices.To meet the increasing market demand, {Company name} has invested heavily in research and development, ensuring that their optical glass panels remain at the cutting edge of technology. By constantly pushing the boundaries of what is possible, the company strives to provide its customers with state-of-the-art solutions that exceed their expectations.In conclusion, {Company name}'s optical glass panels are set to revolutionize the display industry with their exceptional clarity, superior performance, and unmatched durability. As technology advances and the need for high-quality displays continues to grow, {Company name} remains committed to pushing the boundaries of innovation, creating a future where crystal-clear visuals are a standard across all devices. With their impressive features and potential applications across various sectors, {Company name}'s optical glass panels are paving the way for a new era of display technology.

Top Test Wafers for Semiconductor Testing: A Comprehensive Guide

The demand for semiconductor chips has been on the rise in recent years, driven by the increasing use of technology in various industries. As a result, companies specializing in the production of semiconductor testing equipment and materials have found themselves in a lucrative and competitive market. One such company is {Company Name}, a leading provider of advanced test wafer solutions for the semiconductor industry.{Company Name} has been at the forefront of innovation in the semiconductor testing industry, developing cutting-edge test wafers that have set new standards for quality and performance. The company's commitment to research and development has allowed it to stay ahead of the competition and consistently deliver products that meet the demanding requirements of semiconductor manufacturers.One of {Company Name}'s flagship products is its advanced test wafer, which is designed to simulate the behavior of a fully processed semiconductor wafer. This allows semiconductor manufacturers to test their equipment and processes in a controlled environment, ensuring that they can achieve high yields and production efficiency. The test wafer is instrumental in the development and calibration of semiconductor manufacturing equipment, making it an essential tool for companies looking to stay competitive in the industry.In addition to its advanced test wafers, {Company Name} also offers a range of specialized materials and equipment for semiconductor testing, including advanced metrology tools and inspection systems. These products are designed to help semiconductor manufacturers maintain the quality and consistency of their production processes, ultimately leading to improved yields and reduced costs.Recently, {Company Name} announced the launch of its newest generation of test wafers, which are designed to support the latest advancements in semiconductor technology. These test wafers feature enhanced capabilities for simulating the behavior of advanced semiconductor devices, allowing manufacturers to test their processes for producing cutting-edge chips with confidence and precision.The new test wafers from {Company Name} are designed to meet the stringent requirements of the semiconductor industry, including the need for high-purity materials, precise dimensional control, and advanced testing capabilities. The company's investment in research and development has resulted in a product that is not only technologically advanced but also cost-effective, offering semiconductor manufacturers a compelling value proposition.In addition to the technical capabilities of its test wafers, {Company Name} is known for its commitment to customer service and support. The company works closely with its clients to understand their specific needs and develop customized solutions that address their unique challenges. This collaborative approach has earned {Company Name} a reputation as a trusted partner in the semiconductor industry, with many leading manufacturers relying on its expertise to optimize their testing processes.As the demand for semiconductor chips continues to grow, {Company Name} is well-positioned to capitalize on the opportunities in the market. The company's relentless focus on innovation and quality has allowed it to maintain a leadership position in the semiconductor testing industry, and its latest generation of test wafers is a testament to its ongoing commitment to excellence. With a strong track record of success and a proven ability to deliver value to its customers, {Company Name} is poised to remain a key player in the semiconductor testing industry for years to come.

Revolutionary Technological Breakthrough Unveiled: The Promising Future of Epi Wafers

[NEWS]Revolutionary Epi Wafer Empowers Semiconductor Industry[date][City], [State] - Today, [Company Name], a renowned innovator in the semiconductor industry, unveiled their latest breakthrough technology: an advanced Epi Wafer (name omitted to protect proprietary information). This state-of-the-art product is set to revolutionize the semiconductor industry by significantly enhancing device performance and paving the way for more advanced electronic applications.Epi wafers are a critical component in semiconductor manufacturing, serving as the foundation for the growth of high-quality epitaxial layers. These layers enable the creation of high-performance transistors, diodes, and other semiconductor devices. By introducing their advanced Epi Wafer, [Company Name] is set to raise the bar, pushing the industry towards new heights.With a meticulously engineered crystal structure, [Company Name]'s Epi Wafer boasts unparalleled material quality, ensuring the creation of epitaxial layers of exceptional uniformity and integrity. This translates into higher device performance, increased power efficiency, and improved reliability, setting a new industry standard.Moreover, [Company Name]'s Epi Wafer offers remarkable scalability, supporting the development of smaller, more compact devices without compromising performance. As the semiconductor industry strives to create increasingly miniaturized components, [Company Name]'s breakthrough technology ensures that size reduction does not come at the expense of functionality and capability.Through years of research and development, [Company Name] has overcome various technological challenges in the creation of their Epi Wafer. By leveraging their deep expertise and extensive resources, they have developed an innovative manufacturing process that excels in yield, efficiency, and scalability, further cementing their position as a leading player in the semiconductor industry.When asked about the impact of their revolutionary Epi Wafer on the semiconductor landscape, [Company Name]'s CEO [CEO Name] stated, "We are delighted to introduce our advanced Epi Wafer, which will transform the way the industry manufactures semiconductor devices. Our technology provides superior material quality, improved performance, and scalability. We believe that this breakthrough will open up new possibilities in various electronic applications, including 5G, IoT, and AI."Indeed, [Company Name]'s advanced Epi Wafer comes at a crucial time when the electronic industry is rapidly evolving. As emerging technologies such as 5G, the Internet of Things (IoT), and artificial intelligence (AI) gain traction, the demand for high-performance semiconductors is set to soar. By offering a significant leap in device performance and scalability, [Company Name] is poised to strengthen its position as an industry leader.Industry experts and analyst projections indicate that the market reception for [Company Name]'s Epi Wafer is expected to be overwhelmingly positive. With its technologically superior design, this breakthrough product has the potential to reshape the semiconductor landscape, granting manufacturers a competitive advantage and opening up new avenues for technological advancements.In conclusion, [Company Name]'s revolutionary Epi Wafer is set to empower the semiconductor industry by unlocking new levels of device performance, power efficiency, and scalability. With its exceptional material quality and exciting prospects in emerging technologies, this breakthrough technology positions [Company Name] as a frontrunner in shaping the future of the electronic industry.For further information about [Company Name]'s advanced Epi Wafer, please visit [Company Website].###[Word Count: 800]

6-Inch Sapphire Wafer: Latest Advancements in Semiconductor Technology

The use of 6-inch sapphire wafers has been a game-changer in the semiconductor industry, as it has allowed companies to produce smaller and more powerful electronics. The demand for these wafers has been steadily increasing, and one company that has been at the forefront of this trend is {Company Name}.{Company Name} is a leading manufacturer of sapphire wafers, specializing in the production of 6-inch wafers that are used in a wide range of applications, including LED production, power electronics, and RF devices. The company has been in the industry for over a decade and has established itself as a reliable and innovative supplier of high-quality sapphire wafers.The use of 6-inch sapphire wafers has several advantages over smaller wafer sizes. First, larger wafers allow for greater economies of scale, resulting in lower production costs and higher yields. This is particularly important in the semiconductor industry, where margins are often tight, and any cost savings can have a significant impact on a company's bottom line.Additionally, the use of 6-inch wafers allows for the production of more chips per wafer, resulting in higher throughput and improved efficiency. This is crucial in meeting the increasing demand for smaller and more powerful electronic devices, as it allows manufacturers to produce more chips in a shorter amount of time.Furthermore, the larger surface area of 6-inch wafers provides greater flexibility in the design and layout of electronic components, allowing for more complex and integrated circuits to be produced. This is essential in meeting the ever-growing demand for advanced electronics that are smaller, faster, and more powerful.{Company Name} has been at the forefront of the 6-inch sapphire wafer market, providing its customers with high-quality wafers that meet the stringent requirements of the semiconductor industry. The company's wafers are known for their high crystal quality, low defect density, and excellent uniformity, making them the preferred choice for many leading semiconductor manufacturers.In addition to its superior product quality, {Company Name} prides itself on its exceptional customer service and technical support. The company works closely with its customers to understand their specific needs and requirements, and to provide them with tailored solutions that meet their exact specifications. This customer-centric approach has allowed the company to build strong and lasting partnerships with its customers, fostering trust and loyalty within the industry.Looking ahead, {Company Name} is committed to further advancing the 6-inch sapphire wafer technology, with a focus on improving crystal quality, reducing defect density, and enhancing overall wafer performance. The company is also investing in research and development efforts to explore new applications and opportunities for 6-inch sapphire wafers, in order to stay ahead of the curve and meet the evolving needs of the semiconductor industry.In conclusion, the use of 6-inch sapphire wafers has revolutionized the semiconductor industry, and {Company Name} has been at the forefront of this trend, providing high-quality wafers and exceptional customer service. As the demand for smaller and more powerful electronics continues to grow, {Company Name} is well-positioned to meet the needs of its customers and drive innovation in the industry.

Advanced Semiconductor Company Develops Innovative InP Wafer for High-Performance Applications

Inp Wafer, a leading global semiconductor company specializing in the production of advanced silicon wafers, has recently made significant advancements in its manufacturing process that have garnered attention from industry experts and technology enthusiasts alike. The company's dedication to innovation and continuous improvement has led to a breakthrough in wafer technology that is set to revolutionize the semiconductor industry.Inp Wafer is known for its high-quality silicon wafers, which serve as the foundation for many electronic devices and microchips. These wafers are essential for the production of integrated circuits, memory chips, and other semiconductor components that are used in a wide range of applications, from consumer electronics to industrial machinery.The company's latest achievement comes in the form of a new and improved manufacturing process that promises to deliver even higher performance and efficiency in silicon wafer production. By utilizing cutting-edge technologies and industry-leading expertise, Inp Wafer has successfully optimized its manufacturing process to produce wafers with enhanced electrical and mechanical properties, paving the way for more advanced semiconductor devices with improved performance and reliability.Furthermore, Inp Wafer's dedication to sustainability and environmental responsibility has been a driving force behind its innovation efforts. The company has implemented eco-friendly practices and technologies in its manufacturing process, ensuring that its products are not only of the highest quality but also produced with minimal impact on the environment.Inp Wafer's commitment to research and development has been a key factor in its ability to stay at the forefront of the semiconductor industry. The company's team of scientists and engineers are constantly pushing the boundaries of what is possible in wafer technology, and their efforts have culminated in the latest breakthrough that is poised to set new standards for silicon wafer manufacturing.The implications of Inp Wafer's advancements in wafer technology are far-reaching. With the potential to improve the performance and efficiency of semiconductor devices, the new manufacturing process holds promise for a wide range of industries, from consumer electronics to automotive and beyond. Additionally, the company's focus on sustainability ensures that these advancements are made with a minimal environmental footprint, further enhancing their appeal in an increasingly eco-conscious market.Inp Wafer's latest achievement also serves as a testament to the company's commitment to delivering the highest quality products to its customers. With a reputation for excellence and a track record of innovation, Inp Wafer has solidified its position as a leading provider of silicon wafers for the semiconductor industry, and its latest breakthrough only further cements its status as a trailblazer in the field.As the semiconductor industry continues to evolve at a rapid pace, companies like Inp Wafer are at the forefront of driving innovation and pushing the boundaries of what is possible in semiconductor technology. With its latest advancements in wafer manufacturing, Inp Wafer is poised to shape the future of the industry and set new standards for performance, reliability, and sustainability.Inp Wafer's commitment to excellence, combined with its relentless pursuit of innovation, has positioned the company as a driving force in the semiconductor industry. As the company continues to push the boundaries of what is possible in wafer technology, it is clear that Inp Wafer is set to play a pivotal role in shaping the future of semiconductor devices and the technology that powers our world.

High Quality Germanium Wafer Supplier and Manufacturer

Germanium Wafer Market Set to Grow as Demand for Semiconductor Devices RisesThe global Germanium Wafer market is set to experience steady growth in the coming years, as the demand for semiconductor devices continues to rise. Germanium wafers are an essential component in the production of various semiconductor devices, including transistors and diodes, making them a crucial part of the electronics industry.Germanium wafers are known for their high carrier mobility, making them ideal for high-frequency applications. This, coupled with their ability to be used in combination with other materials such as silicon, has made them a popular choice for a wide range of semiconductor devices.One of the key players in the Germanium wafer market is {company name}, a leading manufacturer and supplier of Germanium wafers. The company has been at the forefront of the industry, producing high-quality Germanium wafers that meet the stringent requirements of their customers.{company name} is known for its commitment to quality and innovation, with a strong focus on research and development to continuously improve their product offerings. The company has a state-of-the-art manufacturing facility that is equipped with the latest technology and equipment, allowing them to produce Germanium wafers that meet the highest industry standards.In addition to their manufacturing capabilities, {company name} also has a strong focus on customer service, providing technical support and expertise to their customers. This has helped them build strong and lasting relationships with their clients, making them a trusted partner in the industry.The company's Germanium wafers are used in a wide range of applications, including infrared optics, solar cells, and various electronic devices. With the increasing demand for these applications, {company name} is well-positioned to capitalize on the growing market for Germanium wafers.As the demand for semiconductor devices continues to rise, so too will the demand for Germanium wafers. With their unique properties and versatility, Germanium wafers are poised to play a key role in the development of the electronics industry.In conclusion, the Germanium wafer market is set to experience steady growth in the coming years, driven by the increasing demand for semiconductor devices. {company name} is well-positioned to take advantage of this growth, with their high-quality Germanium wafers and strong commitment to innovation and customer service. As the industry continues to evolve, {company name} will remain at the forefront, providing essential components for the next generation of electronic devices.

Industry Update: 200mm Wafer Technology Continues to Advance

The global demand for 200mm wafer is on the rise, and it is forecasted to continue its growth in the coming years. As industries such as automotive, telecommunication, and consumer electronics continue to expand, the need for advanced semiconductor technology becomes more crucial. One of the leading suppliers of 200mm wafer, a company has been at the forefront of providing high-quality wafers to meet the growing demand of the semiconductor industry.Established in (year), the company has been a key player in the semiconductor manufacturing market. With state-of-the-art facilities and a team of experienced professionals, they have consistently delivered top-notch 200mm wafers to their global clientele. The company's commitment to innovation and quality has set them apart in the competitive semiconductor market.The company's 200mm wafer is manufactured using cutting-edge processes and techniques to ensure the highest level of performance and reliability. With a focus on quality assurance, the company has implemented stringent quality control measures to guarantee that each wafer meets the industry's standards. This attention to detail has earned the company a reputation for providing wafers that exceed expectations in terms of performance and durability.In addition to their dedication to quality, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific requirements and provide tailored solutions to meet their needs. This customer-centric approach has solidified the company's position as a trusted partner in the semiconductor industry.As the demand for 200mm wafers continues to grow, the company has been ramping up its production capabilities to meet the needs of their expanding customer base. With a focus on scalability and efficiency, they have invested in the latest manufacturing technologies to ensure that they can deliver wafers in a timely manner without compromising on quality.Furthermore, the company is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes to minimize their carbon footprint and reduce waste generation. This commitment to sustainability has resonated with their environmentally conscious clients, further enhancing their reputation in the industry.Looking ahead, the company is poised to capitalize on the growing demand for 200mm wafers. With a strong focus on innovation, quality, and customer satisfaction, they are well-positioned to maintain their leadership in the semiconductor market. By staying ahead of industry trends and continuously improving their manufacturing processes, the company is ready to meet the evolving needs of their global clientele.In conclusion, the demand for 200mm wafers is on the rise, and the company is well-equipped to meet this growing demand. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted supplier of high-performance wafers in the semiconductor industry. As they continue to expand their production capabilities and enhance their manufacturing processes, the company is set to remain at the forefront of the market for years to come.

Advancements in Monocrystalline Silicon Wafers: A Breakthrough in Semiconductor Technology

[Assistant]Title: Paving the Way for Advanced Solar Technology: Monocrystalline Silicon WaferIntroduction (40 words):Innovating the future of renewable energy, Monocrystalline Silicon Wafers, produced by a leading solar technology company, are revolutionizing solar power generation. This cutting-edge technology harnesses sunlight with unrivaled efficiency, positioning it as a breakthrough solution in the renewable energy sector.Body:I. Background on Monocrystalline Silicon Wafer (220 words)Monocrystalline Silicon Wafers are the foundation of high-performance solar panels. Made from a single crystal structure, their unique design allows them to absorb sunlight more effectively than other types of solar cells. This efficiency translates into increased energy output and a more sustainable approach to power generation.Monocrystalline Silicon Wafers offer several key advantages, including exceptional durability, high conversion efficiency, and advanced aesthetics. These properties make them the preferred choice for manufacturers and consumers alike, driving the growth of the global solar energy market. By utilizing this technology, we can significantly reduce our reliance on fossil fuels and mitigate the deleterious effects of climate change.II. Company Introduction: (250 words){Company Name}, a renowned pioneer in the field of solar technology, has been at the forefront of developing and optimizing Monocrystalline Silicon Wafer manufacturing processes. Established in {year}, the company has consistently delivered cutting-edge solutions and contributed to the rapid advancement of solar energy use worldwide.{Company Name}'s commitment to research and development has enabled them to create Monocrystalline Silicon Wafers that offer the highest conversion efficiency levels currently available. This efficient energy conversion leads to an increased power output, allowing end-users to maximize their solar investment while minimizing their carbon footprint.Moreover, {Company Name} has dedicated significant resources to enhance the durability and reliability of their Monocrystalline Silicon Wafers. Through innovations in material science and manufacturing techniques, they ensure that their products withstand harsh weather conditions and maintain their performance over an extended period.Additionally, {Company Name} places great emphasis on the aesthetics of their solar panels. Understanding the importance of blending renewable energy solutions seamlessly into architectural designs, they offer Monocrystalline Silicon Wafers with a sleek and uniform appearance. This commitment to visual integration opens up new possibilities for incorporating solar power generation into various landscapes and urban environments.III. Market Impact and Future Prospects (290 words)The widespread adoption of Monocrystalline Silicon Wafers has significantly boosted the solar energy market. With their superior efficiency and performance, these wafers are rapidly becoming the industry standard for solar panel manufacturers. As a result, global solar energy installations have experienced exponential growth, contributing to a substantial reduction in greenhouse gas emissions.The increasing demand for renewable energy solutions, coupled with technological advancements, has led to a considerable decrease in production costs. This cost reduction has made solar energy more accessible to a broader consumer base, further driving the adoption of Monocrystalline Silicon Wafers.Looking ahead, {Company Name} continues to invest in research and development to enhance the efficiency and versatility of their Monocrystalline Silicon Wafers. Their goal is to improve energy conversion rates, reduce manufacturing costs, and explore new applications for this groundbreaking technology.In conclusion, Monocrystalline Silicon Wafers, pioneered by {Company Name}, offer a game-changing solution for the renewable energy sector. Their superior efficiency, durability, and aesthetics position them as the cutting-edge choice for solar power generation. As the technology and market for Monocrystalline Silicon Wafers continue to evolve rapidly, we can anticipate a brighter and more sustainable future powered by the sun.