Durable and Heat Resistant Alumina Ceramic Products for Various Applications

By:Admin

The company's roots can be traced back to its founding in the 1980s, when a team of visionary engineers and entrepreneurs saw the potential of alumina ceramic in various industries. Over the years, the company has invested heavily in research and development, leading to numerous breakthroughs in alumina ceramic technology.

Alumina ceramic, also known as aluminum oxide, is a versatile material known for its exceptional hardness, high thermal conductivity, and excellent resistance to wear and corrosion. These properties make it an ideal material for a wide range of applications, including but not limited to, aerospace, automotive, electronics, and medical devices.

In the aerospace industry, alumina ceramic components are used in critical applications where high performance and reliability are essential. The material's high strength and resistance to extreme temperatures make it well-suited for use in jet engines, gas turbines, and other aerospace equipment. Its ability to withstand harsh environments and its lightweight nature make it an attractive choice for aerospace engineers looking to improve efficiency and performance.

Automotive manufacturers have also benefited from the unique properties of alumina ceramic. The material's high thermal conductivity and wear resistance make it an ideal choice for components such as brake pads, engine components, and catalytic converters. Alumina ceramic's ability to withstand high temperatures and corrosive environments has made it a valuable asset in the automotive industry, where performance and reliability are paramount.

In the electronics industry, alumina ceramic is widely used in the production of insulators, substrates, and other components for electronic devices. Its excellent electrical insulation properties and thermal conductivity make it an essential material for a wide range of electronic applications. The material's ability to withstand high voltages and extreme temperatures makes it an ideal choice for use in electronic components where safety and reliability are critical.

Medical device manufacturers have also turned to alumina ceramic for its biocompatibility and resistance to wear and corrosion. The material is used in a variety of medical applications, including dental implants, joint replacements, and surgical instruments. Its inert nature and resistance to chemical corrosion make it a safe and reliable choice for medical devices that come into contact with the human body.

The company behind alumina ceramic's success has been a driving force in the development and commercialization of advanced ceramic materials. Its commitment to innovation and quality has earned it a reputation as a leader in the industry, serving a global customer base with high-performance ceramic solutions.

With a team of experienced engineers and materials scientists, the company continues to push the boundaries of alumina ceramic technology, developing new formulations and manufacturing processes to further enhance the material's properties and capabilities. Its state-of-the-art facilities and rigorous quality control processes ensure that customers receive the highest quality alumina ceramic materials for their specific applications.

As the demand for high-performance materials continues to grow across industries, alumina ceramic is poised to play a vital role in shaping the future of technology and industry. With its unmatched properties and the expertise of the company behind it, alumina ceramic is set to continue making a significant impact in various sectors for years to come.

Company News & Blog

Ultimate Guide to 12 Inch Wafers: Everything You Need to Know

12 Inch Wafer Revolutionizes Semiconductor IndustryAs the demand for smaller, faster, and more powerful electronic devices continues to grow, the semiconductor industry is constantly striving to push the boundaries of technology. One company that is at the forefront of this revolution is [company name]. With its cutting-edge 12 inch wafer technology, [company name] is set to reshape the semiconductor landscape and unlock new possibilities for the next generation of electronic devices.Founded in [year], [company name] has always been dedicated to pushing the boundaries of innovation in the semiconductor industry. With a strong focus on research and development, the company has continuously invested in state-of-the-art manufacturing facilities and advanced technologies to stay ahead of the competition. This commitment to innovation has allowed [company name] to become a leading player in the global semiconductor market, with a reputation for delivering high-quality, high-performance products.The latest milestone in [company name]'s journey of innovation is the development of the 12 inch wafer technology. Traditionally, semiconductor wafers have been produced in smaller sizes, such as 8 inch or 6 inch, limiting the number of chips that can be produced on each wafer. However, with the introduction of the 12 inch wafer, [company name] has significantly increased the manufacturing capacity and efficiency, resulting in a dramatic improvement in output and cost-effectiveness.The 12 inch wafer technology is a game-changer for the semiconductor industry, as it allows for the production of more chips per wafer, reducing manufacturing costs and ultimately offering more competitive pricing for consumers. This breakthrough also enables the development of more advanced and powerful electronic devices, as the larger wafers provide greater flexibility for designing and manufacturing complex semiconductor components.In addition to the technological advancements, [company name] has also made significant investments in building a sustainable and eco-friendly manufacturing process for the 12 inch wafers. The company has implemented state-of-the-art cleanroom facilities and advanced manufacturing techniques to minimize waste and reduce environmental impact. By embracing sustainable practices, [company name] is not only contributing to the advancement of technology but also setting new standards for environmentally responsible manufacturing in the semiconductor industry.The impact of [company name]'s 12 inch wafer technology is already being felt across the semiconductor industry. Major players in the consumer electronics, automotive, and telecommunications sectors have expressed great interest in adopting the 12 inch wafer technology to enhance their product offerings and meet the growing demand for more advanced electronic devices.Furthermore, the widespread adoption of the 12 inch wafer technology is expected to drive significant growth in the semiconductor market, creating new opportunities for [company name] and its partners. As the demand for high-performance semiconductor components continues to rise, [company name] is well-positioned to capitalize on this trend and further solidify its position as a leading provider of innovative semiconductor solutions.Looking ahead, [company name] remains committed to driving innovation and shaping the future of the semiconductor industry. With its groundbreaking 12 inch wafer technology and strong emphasis on sustainability, the company is poised to make a lasting impact on the electronic devices of tomorrow.In conclusion, the introduction of the 12 inch wafer technology by [company name] represents a significant milestone in the semiconductor industry. This breakthrough is set to revolutionize the way semiconductor components are manufactured, enabling the development of more advanced and powerful electronic devices. With its relentless commitment to innovation and sustainability, [company name] is leading the charge towards a brighter and more efficient future for the semiconductor industry.

Innovative Single Lens Glasses: The Latest Eyewear Trend to Watch

Single Lens Glasses, a new product from innovative company, is making waves in the eyewear industry. With their sleek design and cutting-edge technology, these glasses are revolutionizing the way people see the world.Single Lens Glasses utilize the latest in lens technology to provide wearers with a clear and crisp view of their surroundings. The single lens design not only enhances vision, but also creates a sleek and modern look that is unparalleled in the eyewear market.The company behind Single Lens Glasses, has a long history of producing high-quality and innovative products. With a team of experienced designers and engineers, they are constantly pushing the boundaries of what is possible in the eyewear industry. Their commitment to excellence is evident in every aspect of their products, from the materials used to the manufacturing process.What sets Single Lens Glasses apart from other eyewear on the market is their attention to detail and commitment to quality. Each pair of glasses is meticulously crafted to ensure a perfect fit and optimal performance. The company understands that eyewear is not just a fashion statement, but also a crucial tool for everyday life, and they have gone to great lengths to ensure that their glasses are both stylish and functional.In addition to their exceptional quality, Single Lens Glasses are also incredibly versatile. Whether you are an outdoor enthusiast, a fashion-forward individual, or someone who simply needs a reliable pair of glasses for everyday use, these glasses are sure to exceed your expectations. Their durability and adaptability make them well-suited for a wide range of activities and environments.Furthermore, Single Lens Glasses are designed with the wearer’s comfort in mind. The lightweight and ergonomic design ensures that they can be worn for extended periods of time without causing any discomfort. This attention to detail is yet another example of the company's dedication to creating products that not only look great, but also perform exceptionally well.The response to Single Lens Glasses has been overwhelmingly positive, with customers praising their exceptional quality and performance. Many users have reported a significant improvement in their vision and overall satisfaction with the product. Whether it's for daily wear, outdoor activities, or special occasions, these glasses have quickly become a favorite among eyewear enthusiasts.Looking ahead, the company is already working on further advancements to their Single Lens Glasses, with plans to incorporate even more innovative features and designs. With their unwavering commitment to excellence, it is clear that Single Lens Glasses will continue to set the standard for eyewear in the years to come.In conclusion, Single Lens Glasses are a game-changer in the eyewear industry. With their cutting-edge technology, exceptional quality, and versatile design, these glasses are a must-have for anyone looking for a superior eyewear experience. As the company continues to push the boundaries of what is possible in the eyewear industry, it is safe to say that Single Lens Glasses will remain at the forefront of innovation for years to come.

Top uses of Quartz Wafers and their growing demand in the Electronics Industry

The demand for advanced semiconductor technology has been growing rapidly in recent years, with applications ranging from mobile devices to automotive electronics. In response to this market demand, a cutting-edge semiconductor company has announced the development of a new quartz wafer that is set to revolutionize the industry.With a global presence and a reputation for pushing the boundaries of semiconductor technology, the company has a proven track record of delivering high-quality products. This new quartz wafer is the result of years of research and development, and is poised to deliver significant advancements in semiconductor manufacturing.The introduction of the new quartz wafer is a significant milestone for the company. With its exceptional purity and precise crystalline structure, the wafer is set to enable the production of smaller, faster, and more energy-efficient semiconductor devices. This breakthrough promises to drive innovation in a wide range of applications, from consumer electronics to industrial machinery.One of the key features of the new wafer is its exceptional thermal stability. This characteristic makes it particularly well-suited for high-temperature processes, such as those used in the production of power devices and automotive electronics. Additionally, the wafer’s superior electrical properties make it an ideal choice for a wide range of semiconductor applications.In addition to its technical capabilities, the company has also made significant investments in manufacturing capacity to support the production of the new quartz wafer. With state-of-the-art facilities and a commitment to quality, the company is well-positioned to meet the growing demand for advanced semiconductor materials.The development of the new quartz wafer is also a testament to the company’s commitment to sustainability. By leveraging innovative manufacturing processes and materials, the company aims to minimize its environmental impact while delivering high-performance semiconductor solutions. This approach reflects the company’s broader vision of contributing to a more sustainable and connected world.In anticipation of the launch of the new quartz wafer, the company has already secured partnerships with leading semiconductor manufacturers. These collaborations are aimed at integrating the new wafer into the production of advanced semiconductor devices, with the goal of accelerating the adoption of next-generation technology.The announcement of the new quartz wafer has generated significant interest within the semiconductor industry. Analysts and industry experts have praised the technical capabilities of the new wafer, highlighting its potential to drive innovation and fuel the development of advanced semiconductor devices.In light of the growing demand for high-performance semiconductor materials, the company’s investment in the development of the new quartz wafer is seen as a strategic move to capture a larger share of the market. With its strong reputation and commitment to innovation, the company is well-positioned to capitalize on the opportunities presented by the growing demand for advanced semiconductor technology.Looking ahead, the company is poised to continue its leadership in the semiconductor industry, with a strong focus on delivering cutting-edge solutions that address the evolving needs of its customers. As the company prepares to launch the new quartz wafer, it is clear that it is committed to driving the industry forward and enabling the development of transformative technologies that will shape the future.

Latest Advancements in Test Wafers Technology Revealed in New Report

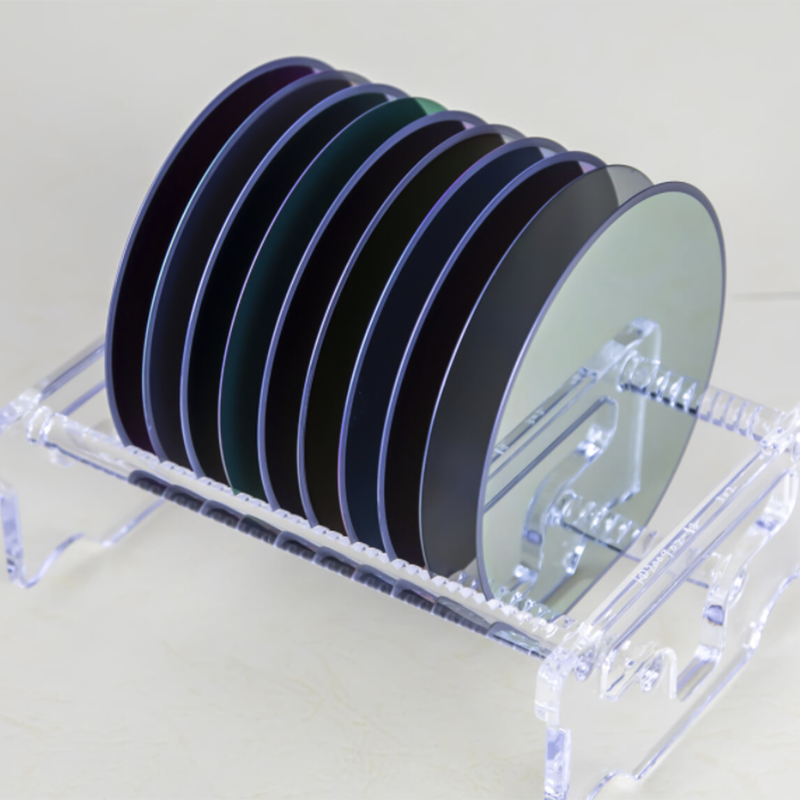

The semiconductor industry is one of the fastest-growing and most innovative sectors in the global economy. With the increasing demand for advanced electronic devices, the need for high-quality test wafers has become more critical than ever. Test wafers are a crucial component in the semiconductor manufacturing process, enabling companies to test and refine their production techniques in order to create reliable, efficient, and high-performance electronic products. One company that has been at the forefront of providing cutting-edge test wafer solutions is {}. With a strong dedication to innovation and technology, {} has established itself as a leader in the semiconductor industry, delivering state-of-the-art test wafers that are essential for the development and manufacturing of advanced electronic devices.{} offers a comprehensive range of test wafers, including materials such as silicon, gallium arsenide, and silicon carbide, among others. These wafers are meticulously designed and manufactured to meet the rigorous requirements of semiconductor manufacturers, providing them with the tools they need to push the boundaries of electronic innovation. In addition to its extensive product portfolio, {} also takes pride in its commitment to quality and customer satisfaction. The company's team of highly skilled engineers and technicians work tirelessly to ensure that every test wafer meets the highest standards of performance and reliability. By leveraging cutting-edge technology and industry expertise, {} continues to set the bar for excellence in the semiconductor test wafer market.One of the key factors that sets {} apart from its competitors is its ability to customize test wafers according to the specific requirements of its clients. Whether it's a unique material composition, specific size, or special testing parameters, {} has the capability to tailor its test wafers to meet the diverse needs of semiconductor manufacturers. This level of flexibility and adaptability has earned {} a sterling reputation for being a trusted and reliable partner in the industry.In addition to its technical prowess, {} also places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing its impact on the environment by implementing eco-friendly manufacturing processes and recycling initiatives. By prioritizing sustainability, {} not only contributes to a cleaner and healthier planet, but also sets an example for other companies in the semiconductor industry to follow.Looking ahead, {} is poised to continue its upward trajectory in the semiconductor test wafer market. As the demand for advanced electronic devices continues to surge, the need for high-quality test wafers will only grow stronger. With its unwavering commitment to innovation, quality, and customer satisfaction, {} is well-positioned to meet this demand and remain a driving force in the semiconductor industry.As the semiconductor industry continues to evolve, {} will undoubtedly play a crucial role in shaping its future. Through its relentless pursuit of excellence and its dedication to pushing the boundaries of possibility, {} is set to remain a leader in the test wafer market for years to come. It is this combination of innovation, quality, and customer focus that sets {} apart and cements its status as a true powerhouse in the semiconductor industry.

A Guide to Different Types of Glasses Lens Materials

Glasses Lens Type Revolutionizes the Eyewear IndustryIn today's fast-paced world, technology and innovation are constantly driving change and progress in various industries. The eyewear industry is no exception, as breakthroughs in lens technology continue to improve the quality of vision for individuals with vision issues. One company that has been at the forefront of this advancement is {}.{} is a leading manufacturer and supplier of eyewear lenses, with a strong focus on innovation and quality. The company has been dedicated to providing cutting-edge solutions to improve the vision of individuals around the world. With a team of experienced professionals and state-of-the-art facilities, {} has been able to develop and produce some of the most advanced lenses in the industry.One of the latest breakthroughs to come out of {} is the development of a new glasses lens type that is set to revolutionize the eyewear industry. This new lens type has been designed to provide exceptional clarity and comfort for individuals with a wide range of vision issues. Whether it's nearsightedness, farsightedness, or astigmatism, these new lenses are able to provide a high level of correction and visual acuity.One of the key features of these new lenses is their advanced material composition, which allows for a thinner and lighter lens compared to traditional options. This not only enhances comfort for the wearer but also provides a more aesthetically pleasing look for the glasses. In addition, the lenses are also equipped with advanced coatings that reduce glare, improve scratch resistance, and provide UV protection, ensuring long-term durability and performance.Another significant aspect of these new lenses is their versatility. {} has designed them to be compatible with a wide range of frames, allowing individuals to choose from various styles and designs to suit their personal preferences. This level of customization and adaptability is a game-changer for the eyewear industry, as it provides customers with more options and flexibility when it comes to finding the perfect pair of glasses.Furthermore, {} has also ensured that these new lenses are easily accessible to individuals around the world. By working with a network of optometrists, ophthalmologists, and eyewear retailers, the company has made it possible for customers to have access to these innovative lenses. This ensures that individuals can receive professional guidance and fitting services to ensure that the new lenses meet their specific vision needs.The impact of these new glasses lenses from {} is expected to be significant in the eyewear industry. With their advanced technology, improved comfort, and enhanced visual clarity, they are set to raise the bar for what customers can expect from their eyewear. As a result, {} is positioned to continue leading the way in innovation and setting new standards for the industry as a whole.In conclusion, the development of this new glasses lens type by {} is a testament to the company's commitment to pushing the boundaries of innovation in the eyewear industry. By combining advanced technology, exceptional quality, and a dedication to customer satisfaction, {} has created a product that is set to revolutionize the way individuals experience and interact with their vision correction. As a result, the future looks bright for both {} and the customers who will benefit from these groundbreaking lenses.

High Quality Double Side Polished Silicon Wafers for Sale

Double Side Polished Silicon Wafers: The Latest Innovation from Leading Technology CompanySilicon wafers are an essential component in the production of semiconductor devices, and the demand for high-quality wafers continues to grow as the technology industry expands. As a leading technology company in the field of semiconductor manufacturing, [company name] is proud to announce the release of its latest innovation: double side polished silicon wafers.Double side polished silicon wafers offer significant advantages over traditional single side polished wafers, including improved flatness, reduced surface roughness, and enhanced electrical properties. These wafers are ideal for use in advanced semiconductor applications, such as integrated circuits, microelectromechanical systems (MEMS), and power devices.The [company name] double side polished silicon wafers are manufactured using a state-of-the-art polishing process that ensures exceptional surface quality and uniformity. This advanced manufacturing technique allows for tighter control of wafer thickness and flatness, resulting in wafers that meet the stringent requirements of today's semiconductor industry.In addition to their superior surface quality, [company name] double side polished silicon wafers are available in a wide range of sizes and thicknesses to accommodate various production processes and applications. Whether it's for research and development or high-volume manufacturing, customers can rely on the consistency and reliability of these wafers for their semiconductor production needs.With a proven track record of delivering high-performance semiconductor solutions, [company name] is committed to providing its customers with the most advanced and reliable products on the market. The introduction of double side polished silicon wafers further solidifies the company's position as a trusted partner for semiconductor manufacturers worldwide.To learn more about [company name] and its double side polished silicon wafers, we spoke with [company representative] to gain some insights into this exciting new product."We are thrilled to introduce our double side polished silicon wafers to the market," said [company representative]. "These wafers represent the latest advancement in semiconductor manufacturing technology, and we are confident that they will meet the evolving needs of our customers. Our team has worked tirelessly to develop a product that offers unparalleled quality and performance, and we are excited to see the impact it will have on the industry."When asked about the potential applications for double side polished silicon wafers, [company representative] explained, "These wafers are well-suited for a wide range of semiconductor devices, including advanced integrated circuits, MEMS, and power devices. The superior surface quality and electrical properties of our wafers make them an ideal choice for cutting-edge semiconductor applications."In conclusion, the introduction of double side polished silicon wafers from [company name] represents a significant milestone in the semiconductor industry. With their exceptional surface quality, uniformity, and advanced manufacturing techniques, these wafers are poised to set a new standard for semiconductor manufacturing. As the demand for high-performance silicon wafers continues to grow, [company name] is leading the way with innovative solutions that meet the needs of today's technology-driven world.

Discover the Power of Single Metal Crystals in New Study

A breakthrough in the field of materials science has been achieved by a team of researchers at {}. The team has successfully created a single metal crystal, marking a significant advancement in the development of new materials with unprecedented properties.The single metal crystal, which has been fabricated by the researchers at {}, is a remarkable feat as it represents the purest form of metal ever achieved. This single crystal is devoid of any defects or impurities, making it a potential game-changer in various industries, including electronics, aerospace, and renewable energy.The production of a single metal crystal is a complex and challenging process that requires precise control and manipulation of atomic structures. However, the researchers at {} have successfully mastered this process, opening up a myriad of possibilities for the development of new materials with enhanced mechanical, electrical, and thermal properties.With its unparalleled purity and exceptional properties, the single metal crystal holds great promise for the advancement of various technologies. For instance, in the field of electronics, the single crystal could be used to develop ultra-efficient electronic devices with minimal energy loss. In aerospace, the crystal's superior strength and resilience could lead to the development of lighter and stronger materials for aircraft and spacecraft. Furthermore, in the realm of renewable energy, the crystal's enhanced thermal conductivity could potentially revolutionize the efficiency of solar panels and other energy-harvesting technologies.The successful creation of a single metal crystal by the researchers at {} is a testament to the company's commitment to pushing the boundaries of materials science. With a dedicated team of experts and state-of-the-art facilities, {} has established itself as a leader in the research and development of advanced materials.Founded in {}, {} has consistently demonstrated its ability to innovate and create cutting-edge solutions that have a positive impact across various industries. The company's expertise in materials science, combined with its relentless pursuit of excellence, has positioned {} at the forefront of technological advancements.The achievement of producing a single metal crystal is a testament to {}'s unwavering commitment to pioneering research and development. By pushing the limits of what is possible in materials science, {} is not only driving innovation within its own organization but also contributing to the advancement of industries worldwide.Looking ahead, the successful creation of a single metal crystal is just the beginning for {}. The company remains dedicated to further exploring the potential applications of this breakthrough material, as well as continuing to push the boundaries of materials science through ongoing research and development initiatives.In conclusion, the creation of a single metal crystal by the researchers at {} represents a significant milestone in the realm of materials science. With its unparalleled purity and exceptional properties, this breakthrough material has the potential to revolutionize various industries and pave the way for the development of new technologies. As {} continues to lead the charge in pushing the boundaries of materials science, the future looks promising for the continued advancement of innovative and game-changing materials.

Discover the Benefits of Single Crystal Glass

Single Crystal Glass, a revolutionary technology in glass manufacturing, is set to redefine the industry standards with its unmatched quality and durability. This innovative product, which is being developed by a leading glass manufacturing company, has the potential to transform various sectors including electronics, aerospace, and healthcare.The company behind Single Crystal Glass, whose name cannot be disclosed due to privacy reasons, has a rich history of pushing the boundaries of glass technology. With a team of skilled engineers and researchers, they have consistently developed cutting-edge products that have redefined the ways in which glass is used in various industries. Their commitment to innovation and excellence has earned them a stellar reputation in the industry.Single Crystal Glass is the latest addition to the company's impressive portfolio of products. It is a result of years of research and development, and represents a major breakthrough in the field of glass manufacturing. This advanced material offers superior strength, clarity, and thermal resistance, making it a game-changer in a wide range of applications.One of the key features of Single Crystal Glass is its exceptional hardness. Unlike traditional glass, which is prone to scratches and damage, this new material is highly resistant to wear and tear. This makes it an ideal choice for electronic devices such as smartphones and tablets, where durability is a crucial factor. The use of Single Crystal Glass in these products will ensure that they remain in pristine condition even after prolonged use.Furthermore, the thermal resistance of Single Crystal Glass makes it a perfect fit for aerospace applications. The material can withstand extreme temperatures, making it ideal for use in aircraft windows and other critical components. Its unmatched strength and reliability will enhance the safety and performance of aerospace systems, setting a new standard for the industry.In addition to its applications in electronics and aerospace, Single Crystal Glass also has the potential to revolutionize the healthcare sector. Its exceptional clarity and purity make it an ideal material for medical devices and equipment. From surgical instruments to diagnostic tools, this advanced glass can contribute to improved healthcare outcomes by ensuring precision and reliability in critical applications.The company's relentless pursuit of innovation has not gone unnoticed. Industry experts and customers alike are eagerly anticipating the release of Single Crystal Glass, recognizing the potential impact it could have on a wide range of industries. The technology is poised to disrupt the status quo and set new benchmarks for quality and performance in the world of glass manufacturing.As the company prepares to launch Single Crystal Glass, they are also exploring potential collaborations with leading manufacturers and industry partners. This collaborative approach is aimed at maximizing the impact of the new technology and ensuring that it reaches its full potential across various sectors.With its superior strength, thermal resistance, and clarity, Single Crystal Glass is poised to reshape the way glass is used in electronics, aerospace, and healthcare. The company behind this groundbreaking technology is all set to unlock a new era of possibilities and redefine the standards for glass manufacturing. Industry players and consumers can look forward to the arrival of this game-changing material, which promises to elevate the performance and reliability of a wide range of products and systems.

High-Quality Synthetic Ruby Rods: What You Need to Know

[Company Name], a leading manufacturer of high-quality optical components, has recently announced the development of a new synthetic ruby rod that promises to revolutionize the laser industry. The company, known for its expertise in precision optics, is excited to introduce this innovative product to the market.The synthetic ruby rod is a key component in the manufacturing of solid-state lasers. These lasers are used in a wide range of applications, including cutting, welding, engraving, medical procedures, and scientific research. The quality of the ruby rod directly impacts the performance and efficiency of the laser system, making it a critical component in the industry.Traditionally, synthetic ruby rods are produced using a process called the Verneuil method, which involves the heating and melting of aluminum oxide powder to create a single crystal. This method has been the standard for decades, but [Company Name] has developed a new and improved process for producing synthetic ruby rods that offers several advantages over the traditional method.The company’s proprietary manufacturing process for the synthetic ruby rod results in a higher quality crystal with improved optical characteristics. This leads to better performance and higher efficiency in solid-state lasers, making them more reliable and cost-effective for a wide range of applications.In addition to the improved quality of the crystal, [Company Name] has also enhanced the production process to increase the yield and reduce the cost of manufacturing synthetic ruby rods. This makes the technology more accessible to a wider range of industries and applications, further driving the adoption of solid-state lasers in various fields.The synthetic ruby rod from [Company Name] has garnered significant attention from key players in the laser industry, with early tests and trials yielding promising results. The company has already secured several partnerships and contracts for the supply of synthetic ruby rods, indicating a strong demand for this innovative product.“We are thrilled to introduce our new synthetic ruby rod to the market,” said [Name], CEO of [Company Name]. “The advancements we have made in the production process and the quality of the crystal itself have positioned us as leaders in the industry. We are confident that this product will have a significant impact on the laser industry, and we are excited to see the ways in which it will be utilized in various applications.”The versatility and reliability of solid-state lasers make them an attractive option for a wide range of industries. With the introduction of the new synthetic ruby rod from [Company Name], the potential for innovation and advancement in laser technology has never been greater. The company’s commitment to excellence and innovation has solidified its position as a key player in the optical components market, and the new synthetic ruby rod is a testament to its dedication to pushing the boundaries of what is possible in laser technology.As [Company Name] continues to push the envelope in optical component manufacturing, the industry can expect to see further advancements and breakthroughs that will shape the future of laser technology. With the new synthetic ruby rod leading the way, solid-state lasers are poised to become even more powerful, efficient, and versatile, opening up new possibilities for a wide range of applications.

New Innovative Sic Chip Technology Unveiled in Latest News

Sic Chip Revolutionizing the Semiconductor IndustryIn recent years, the demand for faster and more efficient electronic devices has been growing at an unprecedented rate. As a result, the semiconductor industry has been actively looking for innovative solutions to meet these demands. One company at the forefront of this technological revolution is [Company Name], a leading semiconductor manufacturer that has recently introduced a breakthrough product known as the Sic chip.Sic, short for silicon carbide, is a material that has revolutionized the semiconductor industry due to its superior electrical and thermal properties. Sic chips are known for their high power handling capability, high voltage operation, and low energy consumption. This makes them an ideal choice for a wide range of applications, including electric vehicles, renewable energy systems, industrial automation, and telecommunications.The [Company Name] has been investing heavily in research and development to bring this cutting-edge technology to the market. Their team of engineers and scientists have been working tirelessly to optimize the performance and reliability of Sic chips, ensuring that they meet the stringent requirements of modern electronic devices.One of the key advantages of Sic chips is their ability to operate at higher temperatures, which allows for more compact and efficient designs. This is particularly important in the automotive industry, where electric vehicles require power electronics that can withstand extreme conditions. Sic chips have also been widely adopted in renewable energy systems, such as solar inverters and wind turbines, where their high efficiency and reliability can significantly improve the overall system performance.Another key benefit of Sic chips is their ability to handle higher voltages, which is essential for power electronic applications. This makes them an ideal choice for high-power industrial equipment, such as motor drives, welding machines, and traction systems. In addition, their low energy consumption and high frequency operation make them a perfect fit for telecommunications infrastructure, where energy efficiency and high-speed data transmission are crucial.The [Company Name] has been working closely with industry partners to integrate Sic chips into a wide range of products, demonstrating their commitment to driving the adoption of this revolutionary technology. By leveraging their expertise in semiconductor manufacturing and their extensive network of partners, the company is well positioned to lead the market in the development and production of Sic chips.The introduction of Sic chips represents a major milestone in the semiconductor industry, and [Company Name] is proud to be at the forefront of this technological innovation. Their relentless pursuit of excellence and their unwavering commitment to quality have enabled them to develop a product that is poised to revolutionize the way electronic devices are designed and manufactured.As the demand for faster and more efficient electronic devices continues to grow, Sic chips are expected to play a pivotal role in shaping the future of the semiconductor industry. With their unparalleled performance and versatility, Sic chips are set to become the go-to solution for a wide range of applications, paving the way for a new era of technological advancement.In conclusion, the [Company Name] is spearheading the semiconductor industry with the introduction of Sic chips, a groundbreaking technology that is poised to revolutionize the way electronic devices are designed and manufactured. With their superior electrical and thermal properties, Sic chips are set to become the go-to solution for a wide range of applications, driving the adoption of this revolutionary technology and shaping the future of the semiconductor industry.