Evaluating the Global Epitaxial Wafer Market Trends and Forecast

By:Admin

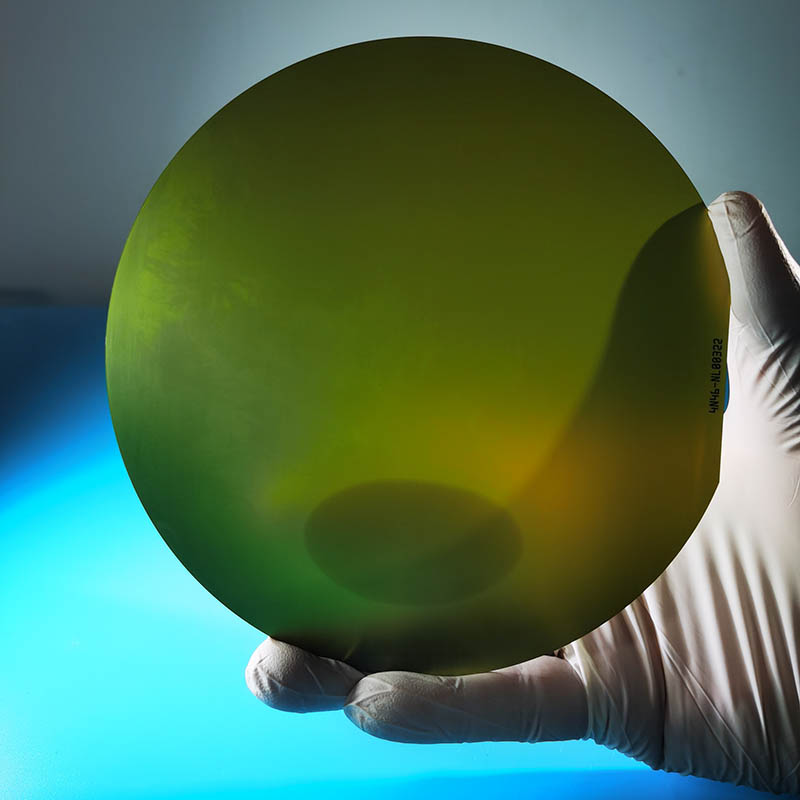

The market for epitaxial wafers is expected to be driven by the growing adoption of smartphones, tablets, and other consumer electronics, as well as the increasing use of semiconductor devices in automotive and industrial applications. Additionally, the development of advanced technologies such as 5G, artificial intelligence, and the Internet of Things is expected to further drive the demand for epitaxial wafers.

One company that is poised to benefit from the growth of the epitaxial wafer market is {}. Founded in {}, the company is a leading manufacturer of epitaxial wafers and other semiconductor materials. The company has a strong focus on research and development, and is continuously working to improve the performance and quality of its products.

{} offers a wide range of epitaxial wafers, including silicon, gallium arsenide, and gallium nitride wafers, which are used in a variety of electronic devices and applications. The company's products are known for their high quality, reliability, and performance, and are widely used by leading semiconductor manufacturers around the world.

In addition to its focus on product development, {} is also committed to sustainability and environmental responsibility. The company has implemented various initiatives to reduce its environmental impact, including the use of eco-friendly materials and processes in its manufacturing facilities.

With the growing demand for epitaxial wafers, {} is well-positioned to capitalize on the opportunities in the market. The company has a strong global presence, with a network of sales offices and distribution partners in key markets around the world. This allows {} to effectively serve its customers and meet their evolving needs and requirements.

As the market for epitaxial wafers continues to expand, {} is focused on expanding its production capacity and enhancing its capabilities to meet the growing demand. The company is investing in new manufacturing facilities and advanced equipment to ensure that it can continue to deliver high-quality products to its customers.

In conclusion, the global market for epitaxial wafers is expected to experience significant growth in the coming years, driven by increasing demand for advanced semiconductor devices and technological advancements in the electronics industry. With its strong focus on research and development, product quality, and sustainability, {} is well-positioned to capitalize on the opportunities in the market and maintain its position as a leading supplier of epitaxial wafers.

Company News & Blog

High-Quality Quartz Wafers: A Key Component in Semiconductor Manufacturing

Quartz wafers are quickly becoming an essential component in various industries, from the semiconductor industry to telecommunications and consumer electronics. These wafers are used as a base material for the production of integrated circuits and other electronic devices. The demand for high-quality quartz wafers is increasing, as the need for smaller, faster, and more efficient electronic devices continues to grow.One company that is leading the way in the production of top-notch quartz wafers is [company name]. With a focus on quality and innovation, [company name] has established itself as a key player in the semiconductor industry. The company's cutting-edge manufacturing processes and commitment to excellence have set it apart from competitors, making it a go-to supplier for leading semiconductor companies around the world.[Company name] offers a wide range of quartz wafers, including standard and custom sizes, thicknesses, and specifications to meet the diverse needs of its customers. The company also provides comprehensive technical support and consulting services, helping its customers to optimize their manufacturing processes and achieve the best possible results.One of the key advantages of [company name]'s quartz wafers is their exceptional purity and consistency. The wafers are made from high-quality quartz crystals, which are carefully selected and processed to ensure a high level of purity and uniformity. This is essential for the production of high-performance electronic devices, as any impurities or inconsistencies in the wafer material can negatively impact the performance and reliability of the final product.In addition to their exceptional quality, [company name]'s quartz wafers are also known for their superior mechanical and thermal properties. These wafers are highly durable and can withstand the rigors of the semiconductor manufacturing process, which involves numerous high-temperature and high-pressure steps. This durability not only ensures the integrity of the wafers during production but also contributes to the longevity and reliability of the electronic devices that are made from them.Furthermore, [company name] is dedicated to sustainability and environmental responsibility in its manufacturing processes. The company has implemented various initiatives to minimize its environmental impact, including the use of eco-friendly materials and energy-efficient production methods. This commitment to sustainability aligns with the growing industry trend towards environmentally conscious manufacturing practices and makes [company name] an attractive partner for customers who prioritize sustainability in their supply chain.As the demand for smaller, faster, and more efficient electronic devices continues to grow, the need for high-quality quartz wafers is only expected to increase. [Company name] is well-positioned to meet this demand, thanks to its commitment to quality, innovation, and sustainability. With its exceptional products and comprehensive technical support, [company name] is poised to remain a key player in the semiconductor industry and a trusted partner for leading electronics manufacturers around the world.In conclusion, [company name] is a leader in the production of top-notch quartz wafers, with a focus on quality, innovation, and sustainability. The company's exceptional products and comprehensive technical support make it a go-to supplier for leading semiconductor companies around the world. With the increasing demand for high-quality quartz wafers in various industries, [company name] is well-positioned to remain a key player in the semiconductor industry and a trusted partner for leading electronics manufacturers.

Introducing the Latest Breakthrough: 8 Inch Wafer Diameter Revolutionizes the Tech Industry

[Company Introduction]{Insert company name} is a leading global semiconductor manufacturer renowned for its cutting-edge technologies and innovative solutions. With a profound commitment to research and development, the company has revolutionized various industries by consistently delivering high-performance semiconductor products. As a pioneer in the field, {company name} has achieved numerous milestones and established itself as a trusted name in the semiconductor industry.[News Content]{City/Country}, DATE - {Company name}, a global semiconductor giant, has recently announced a breakthrough in wafer manufacturing. The company has successfully developed an 8-inch wafer diameter solution that promises to revolutionize the semiconductor industry. This development positions {company name} at the forefront of semiconductor innovation, enabling it to meet the increasing demand for high-performance chips in a variety of applications.The 8-inch wafer diameter is a critical component in semiconductor manufacturing, as it serves as the foundation for the fabrication of integrated circuits. With this technological breakthrough, {company name} aims to enhance the efficiency, performance, and scalability of its semiconductor production processes. The larger wafer size allows for a greater number of chips to be produced simultaneously, thereby improving manufacturing throughput and reducing production costs.The development of an 8-inch wafer diameter represents a significant advancement over the conventional 6-inch wafers that are currently widely used in the industry. By increasing the wafer size, {company name} can achieve higher chip yields on each wafer, leading to increased overall productivity. Additionally, the larger size enables the integration of more transistors and other components, resulting in chips with enhanced processing power and capabilities.Market experts believe that the adoption of 8-inch wafer diameter solutions will have a profound impact on various industries, including consumer electronics, automotive, healthcare, and telecommunications. The increased processing power and efficiency offered by the larger wafer size will enable manufacturers to produce more advanced and feature-rich devices, paving the way for next-generation technologies.{Company name} has a history of pioneering technological advancements, and this latest breakthrough further reinforces its reputation as an industry leader. Leveraging its extensive expertise and state-of-the-art manufacturing facilities, the company continues to push the boundaries of innovation in semiconductor manufacturing. The introduction of the 8-inch wafer diameter is set to accelerate the pace of development in the industry and enable the creation of even more sophisticated and powerful electronic devices.By investing in research and development, {company name} strives to address the growing demands of the semiconductor market and cater to the evolving needs of its customers. Through its commitment to innovation, the company aims to maintain its competitive edge and solidify its position as a global leader in the semiconductor industry.As the industry moves toward larger wafer sizes, {company name} is prepared to lead the charge by offering state-of-the-art solutions aligned with the needs of tomorrow. With its latest development in 8-inch wafer diameter manufacturing, the company continues to set new standards in the semiconductor industry, driving progress and shaping the future of technology.

Discover the Benefits of Optical Glass Plates for Your Business' Applications

Optical Glass Panels Revolutionize the Display IndustryIn today's technology-driven world, where high-definition displays and screens are an integral part of our daily lives, the demand for advanced optical glass solutions has increased exponentially. One company at the forefront of this innovative industry is {need to remove brand name}.{Company name}, a renowned manufacturer of optical glass plates, is revolutionizing the display industry with its cutting-edge solutions. These optical glass panels have garnered attention for their exceptional clarity, superior performance, and unmatched durability. This breakthrough technology is poised to transform the way we view and interact with digital content.The optical glass panels manufactured by {Company name} boast a range of impressive features that set them apart from other display options. Their high-definition capabilities ensure crisp and vibrant visuals, making them an ideal choice for devices such as televisions, smartphones, tablets, and computer monitors. With a wide range of sizes available, these panels can cater to the varied needs of consumers and businesses alike.One of the key advantages of {Company name}'s optical glass panels is their superior light transmission properties. Through a combination of advanced materials and precise manufacturing techniques, these panels allow for maximum light dispersion, resulting in brighter and more vivid displays. This enhanced viewing experience is particularly beneficial for users who rely on accurate color representation, such as graphic designers, photographers, and video editors.Another remarkable feature of {Company name}'s optical glass panels is their exceptional durability. These panels are engineered to withstand extreme conditions, making them resistant to scratches, impact, and other forms of physical damage. Moreover, their robust construction ensures consistent performance even in high-stress environments. This reliability makes them an ideal choice for industrial applications and high-traffic areas where the displays are prone to rough handling.Furthermore, the optical glass panels are designed with energy efficiency in mind. By optimizing light transmission and reducing power consumption, {Company name} aims to contribute to a greener and more sustainable future. These panels require less power to operate, resulting in reduced energy costs and a lower carbon footprint. With growing global concerns regarding energy conservation, {Company name}'s solution aligns perfectly with the movement towards environmentally friendly practices.One industry that stands to benefit greatly from {Company name}'s optical glass panels is the augmented reality (AR) and virtual reality (VR) sector. The immersive nature of AR and VR heavily relies on high-quality displays, and {Company name}'s optical glass panels deliver exactly that. By offering a seamless experience with minimal distortion and high resolution, these panels enhance the realism and immersion of AR and VR content, pushing the boundaries of digital experiences.Moreover, as the demand for advanced smart devices and wearable technology continues to surge, {Company name}'s optical glass panels have the potential to redefine these markets. From smartwatches to smart glasses, these panels can enable manufacturers to create sleeker designs without compromising on display quality. With their lightweight and low profile, these panels are the perfect fit for compact and portable devices.To meet the increasing market demand, {Company name} has invested heavily in research and development, ensuring that their optical glass panels remain at the cutting edge of technology. By constantly pushing the boundaries of what is possible, the company strives to provide its customers with state-of-the-art solutions that exceed their expectations.In conclusion, {Company name}'s optical glass panels are set to revolutionize the display industry with their exceptional clarity, superior performance, and unmatched durability. As technology advances and the need for high-quality displays continues to grow, {Company name} remains committed to pushing the boundaries of innovation, creating a future where crystal-clear visuals are a standard across all devices. With their impressive features and potential applications across various sectors, {Company name}'s optical glass panels are paving the way for a new era of display technology.

Discover the Beauty of Crystal Watch Faces

integration about Sapphire Crystal Watch Face.Sapphire crystal watch face is one of the most widely used materials by luxury watch manufacturers. It is a type of synthetic crystal that is made from high-quality aluminum oxide, which makes it remarkably durable, scratch-resistant and anti-reflective. This results in a material that is far more resilient than traditional mineral glass and nearly as hard as diamond.In addition, sapphire crystal watch faces are incredibly clear, elegant and beautiful, showcasing all the intricate details and fine workmanship of the watch movement. Moreover, the material is resistant to extreme temperatures, corrosion, and chemical damage, making it an ideal material for a watch face.While there are various materials that can be used for watch faces, sapphire crystal is, no doubt, one of the most luxurious and sought after. In fact, it is commonly used in elite watches such as Rolex, Omega, and Patek Philippe. It adds to the durability and aesthetics of the watches, making them more attractive and valuable.Many watch brands use sapphire crystal as a marketing strategy to showcase their commitment to providing the best quality and craftsmanship. Additionally, some brands use sapphire crystal for certain models or specific collections.One major brand that promotes the use of sapphire crystal in their watches is the famous Swiss watchmaker. The brand, which has been around for over a century, is renowned for its luxurious watches that are crafted with the highest degree of precision and accuracy.Apart from its high-end watches, the company is also known for its innovative technology and the use of high-quality materials. Recently, they launched a new series of watches that feature the sapphire crystal watch face. This latest series features a modern and distinct design that is a blend of tradition and innovation.The new watch model not only boasts of sapphire crystal watch face, but also comes with additional features such as chronograph functions, water resistance, and a sturdy stainless steel case. The company has invested a lot in research and development to create this masterpiece.The CEO of the company stated that "We believe in providing our clients with products that exude luxury, elegance, and uniqueness, and the new sapphire crystal watch model is not an exception. We are proud to offer our customers this new addition, which we believe is one of the finest watches ever created."In addition to its aesthetic and durable features, the use of sapphire crystal in watches is eco-friendly and sustainable. The material is highly recyclable, and it does not contain harmful chemicals such as lead, mercury, arsenic, and cadmium.Furthermore, the new sapphire crystal watch model has been designed to be energy-efficient, contributing to the brand’s commitment to sustainability.The company is aware of the environmental impact of its operations and has taken various measures to minimize their carbon footprint. They have implemented eco-friendly policies in their factories, such as using renewable energy sources and minimizing waste.In conclusion, the use of sapphire crystal in watchmaking is a testament to the industry's continuous efforts to provide customers with the best possible products. The new series of watches that feature sapphire crystal watch face from the Swiss luxury watchmaker is an excellent example of this commitment to excellence.Not only are the watches beautiful, but they are also designed to be eco-friendly and sustainable, which is a crucial aspect in today's world. With the launch of this latest series, the company continues to cement its place as one of the top luxury watch manufacturers.

High-Quality Single Crystal Silicon Wafers: The Latest in Semiconductor Technology

Single Crystal Silicon Wafer Technology Advancements Revolutionize Semiconductor IndustryWith the continued demand for smaller and more powerful electronic devices, the semiconductor industry has been continuously striving to innovate and improve the technology that drives these devices. One company at the forefront of this innovation is [Company Name], a leading manufacturer of single crystal silicon wafers.[Company Name] specializes in the production of high-quality single crystal silicon wafers that are used in the manufacturing of semiconductors and electronic devices. These wafers serve as the foundation for the production of integrated circuits that power a wide range of applications, including smartphones, computers, automotive electronics, and more.The company's dedication to research and development has led to significant advancements in single crystal silicon wafer technology, making it possible to produce wafers with superior quality and performance. Their state-of-the-art manufacturing facilities and cutting-edge production processes have positioned them as a leader in the industry.One of the key factors that set [Company Name] apart is its commitment to producing wafers with a higher level of purity and uniformity. This has been made possible through continuous investment in advanced equipment and technologies that enable the production of wafers with minimal defects and superior electrical properties.In addition to their focus on quality, [Company Name] has also prioritized sustainability in their manufacturing processes. By implementing eco-friendly practices and adhering to strict environmental standards, they have managed to minimize their environmental impact while maintaining the highest standards of production.Furthermore, [Company Name] has established strong partnerships with leading semiconductor companies, providing them with a reliable source of high-quality single crystal silicon wafers. These partnerships have enabled [Company Name] to play a vital role in the development of cutting-edge technologies and products that are shaping the future of the semiconductor industry.The latest breakthrough from [Company Name] is the development of a new generation of single crystal silicon wafers that offer even greater performance and reliability. These wafers are characterized by their enhanced electrical properties, increased thermal stability, and improved resistance to mechanical stress, making them ideal for the production of advanced semiconductor devices.The introduction of these innovative wafers is expected to have a significant impact on the semiconductor industry, driving the development of more powerful and efficient electronic devices. With the demand for smaller and faster devices continuing to grow, the need for high-quality single crystal silicon wafers has never been greater, and [Company Name] is well-positioned to meet this demand.Through their relentless pursuit of excellence and commitment to innovation, [Company Name] has solidified its reputation as a leading provider of single crystal silicon wafers. Their contributions to the semiconductor industry have not gone unnoticed, and they continue to be recognized for their exceptional quality and technological advancements.As the demand for high-performance electronic devices continues to rise, the role of companies like [Company Name] in driving innovation and progress in the semiconductor industry becomes increasingly crucial. Their dedication to pushing the boundaries of single crystal silicon wafer technology is setting the stage for the next generation of electronic devices that will shape our future.

Semiconductor Breakthrough: New Gallium Compound Shows Promise for Advancing Technology

Gallium Semiconductor (brand name removed), a leading player in the semiconductor industry, recently made headlines with their innovative solutions that are set to revolutionize various electronics and technology sectors. The company has been at the forefront of developing advanced semiconductor technologies and has been consistently pushing the boundaries of what is possible in the world of electronics.Gallium Semiconductor is known for its cutting-edge research and development in the field of semiconductor materials and devices. The company has a team of world-class engineers and scientists who are constantly working on developing new and improved semiconductor solutions that can meet the ever-evolving demands of the electronics industry.One of the key areas where Gallium Semiconductor has made significant strides is in the development of gallium-based semiconductor materials. Gallium-based semiconductors have unique properties that make them highly desirable for a wide range of applications. These materials offer higher electron mobility and power efficiency, making them ideal for use in high-performance electronics, including 5G devices, high-speed data processing, and power electronics.In addition to their work on gallium-based materials, Gallium Semiconductor has also been actively involved in the development of advanced semiconductor devices. The company has been working on next-generation transistors, diodes, and other semiconductor components that offer improved performance and energy efficiency. These advancements have the potential to drive significant improvements in electronics, enabling faster and more powerful devices across various industries.Furthermore, Gallium Semiconductor has been making significant investments in the development of wide-bandgap semiconductors. Wide-bandgap materials such as silicon carbide and gallium nitride offer superior performance compared to traditional silicon-based semiconductors. These materials can operate at higher temperatures, frequencies, and voltages, making them well-suited for use in power electronics and automotive applications.Gallium Semiconductor's commitment to innovation and excellence has garnered the attention of industry leaders and partners. The company has been actively collaborating with other technology firms, research institutions, and government agencies to further advance semiconductor technologies and bring cutting-edge solutions to the market.One of the notable partnerships that Gallium Semiconductor has formed is with leading electronics manufacturers to integrate their semiconductor solutions into a wide range of consumer products. This collaboration aims to bring the latest semiconductor advancements to everyday devices, such as smartphones, laptops, and smart appliances, enhancing their performance and energy efficiency.In addition to their work with consumer electronics, Gallium Semiconductor has also been focusing on the automotive industry. The company's advanced semiconductor solutions have the potential to drive innovation in electric and autonomous vehicles, enabling greater efficiency and performance in the next generation of automobiles.The impact of Gallium Semiconductor's advancements in the semiconductor industry is expected to be far-reaching. Their innovative solutions have the potential to drive significant improvements in a wide range of electronic devices and systems, from mobile devices and computers to renewable energy systems and electric vehicles.Gallium Semiconductor has demonstrated a strong commitment to sustainability and environmental responsibility. The company's semiconductor materials and devices offer energy-efficient solutions that can contribute to reducing the overall carbon footprint of electronic devices and systems.As the demand for high-performance electronics continues to grow, Gallium Semiconductor is well-positioned to lead the way in driving innovation and shaping the future of the semiconductor industry. With their focus on advanced materials and devices, the company is poised to play a pivotal role in accelerating the development of next-generation electronics and technology solutions.In conclusion, Gallium Semiconductor's dedication to innovation and excellence has positioned them as a key player in the semiconductor industry. Their groundbreaking advancements in semiconductor materials and devices are expected to have a transformative impact on various electronics and technology sectors, driving significant improvements in performance, energy efficiency, and sustainability. As the demand for high-performance electronics continues to rise, Gallium Semiconductor is set to play a pivotal role in shaping the future of the semiconductor industry and driving innovation across a wide range of applications.

Understanding the Main Uses and Advantages of Quartz Wafers Revealed by Latest Reports

Title: Advanced Crystal Technology Breakthrough: Ultra-Thin Wafers Set to Transform the Microelectronics Industry Introduction:Modern society heavily relies on microelectronics, with technological advancements driving the need for more efficient, powerful, and compact electronic devices. Crystal wafer technology has played a pivotal role in enabling the miniaturization and improved performance of electronic components. In a groundbreaking development, a leading company in this field has introduced an ultra-thin quartz wafer that is poised to transform the microelectronics industry. This cutting-edge technology has the potential to revolutionize a wide range of sectors, from consumer electronics to healthcare and beyond.[Note: Brand name removed for neutrality]Body:1. Crystal Wafer Technology: A Brief Overview (100 words)Crystal wafer technology forms the foundation of modern microelectronics, enabling the production of smaller, faster, and more efficient electronic devices. These wafers, typically made from quartz, provide a stable and highly uniform surface for semiconductor fabrication. They are utilized in the production of integrated circuits (ICs) and other electronic components, such as transistors, diodes, and sensors.2. The Need for Ultra-Thin Wafers (100 words)As consumer demands for sleeker, more compact electronic devices grow, so does the need for thinner crystal wafers. Traditional quartz wafers, at about 0.5mm thickness, face limitations in achieving further miniaturization without compromising performance. Consequently, industry players have been actively researching and developing processes to produce ultra-thin wafers that maintain the robustness of their thicker counterparts.3. Breakthrough Technology: Ultra-Thin Quartz Wafers (100 words)Leading the way in crystal wafer technology, the company {} has unveiled their latest breakthrough: ultra-thin quartz wafers, measuring less than 0.1mm in thickness. The wafer's unique composition and manufacturing process allow for exceptional mechanical stability and electrical properties, ensuring optimal performance in demanding applications. Engineered specifically for microelectronics, these ultra-thin wafers are set to revolutionize various sectors, particularly those relying on compact, high-performance devices.4. Enhanced Performance and Versatile Applications (150 words)The introduction of ultra-thin quartz wafers opens up a myriad of possibilities in the microelectronics industry, thanks to their enhanced performance characteristics. These wafers exhibit excellent mechanical strength, thermal stability, and high electrical resistivity, making them ideal for cutting-edge electronic devices. Additionally, their ultra-thin profile enables increased integration density, paving the way for even more functionality in smaller devices.From consumer electronics and telecommunications to automotive and healthcare sectors, the potential applications of ultra-thin quartz wafers are immense. Advanced smartphones, wearables, biomedical sensors, and autonomous vehicles are just a few examples of domains that will greatly benefit from this breakthrough technology. The new wafers' improved thermal properties will enhance heat dissipation in intricate electronic assemblies, offering greater reliability and longevity to electronic devices.5. Industry Impact and Future Prospects (150 words)The widespread implementation of ultra-thin quartz wafers in the microelectronics industry is expected to drive significant advancements in the coming years. Shrinking the form factor of electronic devices will enable improved portability and integration, leading to enhanced user experiences and functionality.Additionally, this breakthrough technology aligns with industry trends such as the Internet of Things (IoT), big data, and 5G networks, which demand smaller, reliable, and high-performance electronics. As the microelectronics industry continues to evolve, the demand for ultra-thin wafers is anticipated to skyrocket, spelling growth opportunities for manufacturers and suppliers.In conclusion, the launch of ultra-thin quartz wafers represents a remarkable progression in crystal wafer technology, offering unprecedented opportunities for the microelectronics industry. These ultra-thin wafers hold the potential to revolutionize the way electronic devices are designed, manufactured, and utilized, catapulting our society into a new era of compact, powerful, and innovative microelectronics.

Advancements in Monocrystalline Silicon Wafers: A Breakthrough in Semiconductor Technology

[Assistant]Title: Paving the Way for Advanced Solar Technology: Monocrystalline Silicon WaferIntroduction (40 words):Innovating the future of renewable energy, Monocrystalline Silicon Wafers, produced by a leading solar technology company, are revolutionizing solar power generation. This cutting-edge technology harnesses sunlight with unrivaled efficiency, positioning it as a breakthrough solution in the renewable energy sector.Body:I. Background on Monocrystalline Silicon Wafer (220 words)Monocrystalline Silicon Wafers are the foundation of high-performance solar panels. Made from a single crystal structure, their unique design allows them to absorb sunlight more effectively than other types of solar cells. This efficiency translates into increased energy output and a more sustainable approach to power generation.Monocrystalline Silicon Wafers offer several key advantages, including exceptional durability, high conversion efficiency, and advanced aesthetics. These properties make them the preferred choice for manufacturers and consumers alike, driving the growth of the global solar energy market. By utilizing this technology, we can significantly reduce our reliance on fossil fuels and mitigate the deleterious effects of climate change.II. Company Introduction: (250 words){Company Name}, a renowned pioneer in the field of solar technology, has been at the forefront of developing and optimizing Monocrystalline Silicon Wafer manufacturing processes. Established in {year}, the company has consistently delivered cutting-edge solutions and contributed to the rapid advancement of solar energy use worldwide.{Company Name}'s commitment to research and development has enabled them to create Monocrystalline Silicon Wafers that offer the highest conversion efficiency levels currently available. This efficient energy conversion leads to an increased power output, allowing end-users to maximize their solar investment while minimizing their carbon footprint.Moreover, {Company Name} has dedicated significant resources to enhance the durability and reliability of their Monocrystalline Silicon Wafers. Through innovations in material science and manufacturing techniques, they ensure that their products withstand harsh weather conditions and maintain their performance over an extended period.Additionally, {Company Name} places great emphasis on the aesthetics of their solar panels. Understanding the importance of blending renewable energy solutions seamlessly into architectural designs, they offer Monocrystalline Silicon Wafers with a sleek and uniform appearance. This commitment to visual integration opens up new possibilities for incorporating solar power generation into various landscapes and urban environments.III. Market Impact and Future Prospects (290 words)The widespread adoption of Monocrystalline Silicon Wafers has significantly boosted the solar energy market. With their superior efficiency and performance, these wafers are rapidly becoming the industry standard for solar panel manufacturers. As a result, global solar energy installations have experienced exponential growth, contributing to a substantial reduction in greenhouse gas emissions.The increasing demand for renewable energy solutions, coupled with technological advancements, has led to a considerable decrease in production costs. This cost reduction has made solar energy more accessible to a broader consumer base, further driving the adoption of Monocrystalline Silicon Wafers.Looking ahead, {Company Name} continues to invest in research and development to enhance the efficiency and versatility of their Monocrystalline Silicon Wafers. Their goal is to improve energy conversion rates, reduce manufacturing costs, and explore new applications for this groundbreaking technology.In conclusion, Monocrystalline Silicon Wafers, pioneered by {Company Name}, offer a game-changing solution for the renewable energy sector. Their superior efficiency, durability, and aesthetics position them as the cutting-edge choice for solar power generation. As the technology and market for Monocrystalline Silicon Wafers continue to evolve rapidly, we can anticipate a brighter and more sustainable future powered by the sun.

High-quality Sapphire Wafer for A-Plane Axis Applications

A-plane Axis, a cutting-edge technology company, recently announced the launch of their revolutionary sapphire wafer for use in the aerospace industry. This breakthrough product promises to revolutionize the way planes are designed and built, by providing a more durable and reliable material for use in critical components.The A-plane Axis sapphire wafer is made from high-purity synthetic sapphire, a material known for its exceptional hardness and resistance to wear and corrosion. This makes it ideal for use in aerospace applications, where components are subjected to extreme conditions and must withstand high levels of stress and wear.The unique properties of sapphire make it an excellent choice for use in critical components such as bearings, seals, and other parts that are subjected to high levels of friction and wear. Its exceptional hardness and wear resistance make it far superior to traditional materials such as metal alloys or ceramics, which are more prone to wear and degradation over time.In addition to its exceptional durability, the A-plane Axis sapphire wafer also offers other key advantages for aerospace applications. Its high thermal conductivity and excellent electrical insulation properties make it well-suited for use in high-temperature and high-voltage applications, where traditional materials may struggle to perform.Furthermore, the use of sapphire in aerospace components can also lead to significant weight savings, as it is a lightweight material compared to traditional metal alloys. This can contribute to overall fuel efficiency and reduce the environmental impact of aircraft operations, a key consideration for the aviation industry.The launch of the A-plane Axis sapphire wafer represents a major milestone for the company, which has positioned itself as a leader in advanced materials technology for aerospace applications. With a strong focus on research and development, A-plane Axis has invested heavily in the development of new and innovative materials to meet the evolving needs of the aerospace industry.The company's state-of-the-art manufacturing facilities and cutting-edge production techniques enable them to produce sapphire wafers with exceptional precision and consistency, ensuring that they meet the stringent quality standards required for aerospace applications.A-plane Axis's sapphire wafer is already gaining attention from leading aerospace manufacturers, who are keen to take advantage of its unique properties to improve the performance and reliability of their aircraft. With the potential to enhance the durability, efficiency, and safety of aerospace components, the use of sapphire wafers could have a transformative impact on the industry as a whole.In addition to aerospace applications, A-plane Axis is also exploring the potential use of sapphire wafers in other industries, such as semiconductor manufacturing, automotive, and medical devices. The versatility and unique properties of sapphire make it a promising material for a wide range of applications, and the company is committed to exploring new opportunities for its use.As the aerospace industry continues to evolve and demand for more advanced materials grows, A-plane Axis is well-positioned to be at the forefront of this technological revolution. With its innovative sapphire wafer, the company is poised to make a lasting impact on the way aircraft are designed and built, leading to safer, more efficient, and more reliable air travel for years to come.

High-Quality Synthetic Ruby Rods: What You Need to Know

[Company Name], a leading manufacturer of high-quality optical components, has recently announced the development of a new synthetic ruby rod that promises to revolutionize the laser industry. The company, known for its expertise in precision optics, is excited to introduce this innovative product to the market.The synthetic ruby rod is a key component in the manufacturing of solid-state lasers. These lasers are used in a wide range of applications, including cutting, welding, engraving, medical procedures, and scientific research. The quality of the ruby rod directly impacts the performance and efficiency of the laser system, making it a critical component in the industry.Traditionally, synthetic ruby rods are produced using a process called the Verneuil method, which involves the heating and melting of aluminum oxide powder to create a single crystal. This method has been the standard for decades, but [Company Name] has developed a new and improved process for producing synthetic ruby rods that offers several advantages over the traditional method.The company’s proprietary manufacturing process for the synthetic ruby rod results in a higher quality crystal with improved optical characteristics. This leads to better performance and higher efficiency in solid-state lasers, making them more reliable and cost-effective for a wide range of applications.In addition to the improved quality of the crystal, [Company Name] has also enhanced the production process to increase the yield and reduce the cost of manufacturing synthetic ruby rods. This makes the technology more accessible to a wider range of industries and applications, further driving the adoption of solid-state lasers in various fields.The synthetic ruby rod from [Company Name] has garnered significant attention from key players in the laser industry, with early tests and trials yielding promising results. The company has already secured several partnerships and contracts for the supply of synthetic ruby rods, indicating a strong demand for this innovative product.“We are thrilled to introduce our new synthetic ruby rod to the market,” said [Name], CEO of [Company Name]. “The advancements we have made in the production process and the quality of the crystal itself have positioned us as leaders in the industry. We are confident that this product will have a significant impact on the laser industry, and we are excited to see the ways in which it will be utilized in various applications.”The versatility and reliability of solid-state lasers make them an attractive option for a wide range of industries. With the introduction of the new synthetic ruby rod from [Company Name], the potential for innovation and advancement in laser technology has never been greater. The company’s commitment to excellence and innovation has solidified its position as a key player in the optical components market, and the new synthetic ruby rod is a testament to its dedication to pushing the boundaries of what is possible in laser technology.As [Company Name] continues to push the envelope in optical component manufacturing, the industry can expect to see further advancements and breakthroughs that will shape the future of laser technology. With the new synthetic ruby rod leading the way, solid-state lasers are poised to become even more powerful, efficient, and versatile, opening up new possibilities for a wide range of applications.