Exploring the Latest Developments in Semiconductor Materials

By:Admin

With a history of over 30 years in the semiconductor industry, Semiconductor Manufacturers has established a reputation for delivering high-quality materials that meet the stringent requirements of semiconductor manufacturers. The company's extensive portfolio of materials includes silicon wafers, epitaxial wafers, and advanced packaging materials, all of which play a critical role in the production of cutting-edge electronic devices.

Semiconductor Manufacturers has a strong commitment to research and development, investing heavily in the exploration of new materials and technologies that are designed to push the boundaries of semiconductor capabilities. The company's state-of-the-art research facilities and expert team of scientists and engineers are dedicated to driving innovation and advancing the field of semiconductor technology.

The newly launched product line from Semiconductor Manufacturers incorporates advanced materials that are designed to address the increasing demand for high-performance semiconductor devices. These materials are engineered to deliver superior electrical, thermal, and mechanical properties, enabling semiconductor manufacturers to develop next-generation electronic products that are smaller, faster, and more energy-efficient.

One of the key highlights of Semiconductor Manufacturers' latest product line is its focus on sustainability and environmental responsibility. The company has proactively implemented green manufacturing practices and prioritizes the use of eco-friendly materials in its production processes. This commitment to sustainability is aligned with the growing industry trend towards environmentally conscious practices and supports the company's vision of creating a more sustainable and interconnected world through semiconductor technology.

Furthermore, Semiconductor Manufacturers' advanced materials have been tailored to meet the demands of emerging technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI). These technologies require semiconductor devices with enhanced performance and reliability, and Semiconductor Manufacturers' materials are designed to enable the development of cutting-edge solutions that can power the next wave of connectivity and automation.

In addition to its product innovation, Semiconductor Manufacturers is dedicated to providing exceptional customer support and technical expertise to its global clientele. The company's team of application engineers and technical specialists work closely with customers to understand their specific requirements and offer tailored solutions that meet their unique needs. Semiconductor Manufacturers' commitment to customer satisfaction and collaborative partnerships has positioned the company as a trusted and reliable partner in the semiconductor industry.

As the demand for semiconductor materials continues to grow in tandem with the evolution of electronic devices and technologies, Semiconductor Manufacturers is poised to play a pivotal role in shaping the future of semiconductor technology. With its unwavering commitment to innovation, sustainability, and customer satisfaction, Semiconductor Manufacturers is well-positioned to remain at the forefront of the semiconductor materials industry and contribute to the advancement of electronic devices that power the modern world.

Company News & Blog

Discover the Beauty and Versatility of Glass Block

Title: Innovative Glass Block Enhances Structural Integrity and Architectural Aesthetics for Sustainable Building Design[City, Date] - (Company Name), a global leader in architectural solutions, has unveiled their latest product, an innovative Glass Block that combines cutting-edge technology with unparalleled functionality. This state-of-the-art solution offers architects and construction professionals the perfect balance of structural integrity and artistic appeal, revolutionizing sustainable building design.Designed to meet the ever-evolving needs of the modern construction industry, the (Glass Block) by (Company Name) aims to create visually stunning and energy-efficient spaces while ensuring durability and reliability. With its ingeniously engineered design, this glass block provides an ideal solution for architects, interior designers, and contractors seeking to create sustainable, aesthetically pleasing structures.What sets the (Glass Block) apart is its exceptional strength and versatility. This product is constructed using the highest quality materials to ensure a robust and long-lasting structure, making it suitable for use in both commercial and residential projects. Employing advanced manufacturing techniques, the (Glass Block) offers enhanced resistance to breakage, impacts, and adverse weather conditions while maintaining its transparency and visual appeal.Moreover, this glass block's distinct design features make it an excellent choice for improving energy efficiency within buildings. The advanced insulation capabilities of the (Glass Block) significantly contribute to reducing heating and cooling costs by minimizing heat transfer. This not only enhances the overall comfort level of the space but also promotes sustainability by reducing the building's carbon footprint.The (Glass Block) is available in a wide range of sizes, shapes, and finishes, allowing architects and designers to unleash their creativity and realize their unique visions. Whether it's creating an open-plan office space that maximizes natural light or incorporating an eye-catching feature wall in a residential setting, this glass block offers endless design possibilities.Furthermore, (Company Name) prides itself on delivering high-quality products that align with eco-friendly principles. The (Glass Block) is no exception, as it is designed to meet and exceed industry standards for sustainability. Committed to reducing environmental impact, the company employs sustainable manufacturing practices, ensuring minimal waste generation and maximizing resource efficiency.The development of this groundbreaking glass block is a testament to (Company Name)'s continued commitment to innovation and customer satisfaction. By combining exceptional functionality with exquisite aesthetics, the (Glass Block) has the potential to reshape the way architects and designers approach sustainable building design.As one of the industry leaders, (Company Name) has made significant contributions to architectural advancements. With a wide range of successfully completed projects globally, the company has gained a reputation for delivering excellence and pushing the boundaries of what is possible in the industry.The newly introduced (Glass Block) is set to revolutionize architectural design by providing an attractive and structurally sound material that contributes to more sustainable buildings. With its enhanced strength, energy efficiency, and aesthetic appeal, the (Glass Block) by (Company Name) is poised to become a popular choice among architects, builders, and interior designers alike.In conclusion, (Company Name)'s latest offering, the (Glass Block), showcases their unwavering commitment to innovation, sustainability, and excellence in architectural solutions. With its remarkable strength and design versatility, this glass block offers architects and designers the opportunity to create truly extraordinary structures that merge aesthetic perfection and environmental consciousness.

Discover the Latest Advances in Silicon Wafer Chip Technology

Silicon Wafer Chips, a cutting-edge technology company based in Silicon Valley, has revolutionized the semiconductor industry with its innovative wafer-chip technology. The company, founded in 2005, has quickly become a leader in producing high-quality silicon wafer chips for a variety of applications, including microprocessors, memory chips, and sensors.Silicon Wafer Chips' state-of-the-art manufacturing facility is equipped with the latest and most advanced semiconductor manufacturing equipment, allowing the company to produce wafers with unparalleled precision and reliability. The company's team of expert engineers and researchers are constantly pushing the boundaries of semiconductor technology, developing new processes and materials to improve the performance and efficiency of their wafer chips.The company's silicon wafer chips are used in a wide range of electronic devices, from smartphones and laptops to automotive systems and industrial machinery. With their superior performance and reliability, Silicon Wafer Chips' products have gained a strong reputation among leading tech companies and manufacturers.One of the key advantages of Silicon Wafer Chips' technology is its ability to produce high-quality wafers at a large scale. The company's manufacturing process is designed to maximize yield and minimize waste, resulting in cost-effective solutions for their customers. This, combined with their commitment to innovation, has made Silicon Wafer Chips a trusted partner for companies looking to incorporate cutting-edge semiconductor technology into their products.In addition to their standard product offerings, Silicon Wafer Chips also provides custom wafer solutions to meet the specific needs of their clients. Their team of engineers and technicians work closely with customers to develop tailored solutions that are optimized for performance, power consumption, and size. This flexibility and commitment to customer satisfaction have set Silicon Wafer Chips apart in the highly competitive semiconductor industry.Furthermore, Silicon Wafer Chips is dedicated to sustainability and environmental responsibility. The company continuously improves its manufacturing processes to minimize its impact on the environment, reducing waste and energy consumption. By investing in green initiatives and eco-friendly technologies, Silicon Wafer Chips is committed to being a responsible corporate citizen.As the demand for advanced semiconductor technology continues to grow, Silicon Wafer Chips is well-positioned to meet the evolving needs of the industry. The company's relentless pursuit of innovation and excellence, combined with their commitment to quality and customer satisfaction, has cemented their position as a leader in the semiconductor market.Looking ahead, Silicon Wafer Chips is actively investing in research and development to bring new breakthroughs in semiconductor technology. With a focus on pushing the boundaries of what is possible, the company is poised to continue driving innovation and shaping the future of the semiconductor industry.In conclusion, Silicon Wafer Chips has established itself as a trailblazer in the semiconductor industry, delivering high-quality, innovative wafer chips to meet the demands of today's tech-driven world. With a strong commitment to sustainability, customer satisfaction, and continuous improvement, the company is well-positioned for long-term success and growth in the rapidly evolving semiconductor market.

Sic Wafer Market Trends and Growth Analysis

Sic Wafer, a key player in the semiconductor industry, recently announced a major breakthrough in the development of silicon carbide (SiC) wafers. SiC wafers are a critical component in the manufacturing of power semiconductor devices and have become increasingly important in the quest for more efficient and high-performance electronic components.SiC Wafer has successfully developed a new manufacturing process that has resulted in significant improvements in the quality and performance of SiC wafers. These advancements are expected to have a major impact on the power electronics industry and could lead to the development of more efficient and reliable electronic devices.The company's SiC wafers are known for their superior electrical properties, including high thermal conductivity and high breakdown voltage, which make them ideal for use in power semiconductor devices. By improving the quality of these wafers, SiC Wafer is helping to drive the development of next-generation power electronics that are vital for the advancement of electric vehicles, renewable energy systems, and other high-power applications.Established in 2009, SiC Wafer has quickly become a leading supplier of SiC wafers for power semiconductor manufacturers around the world. The company's state-of-the-art manufacturing facilities and commitment to research and development have allowed them to stay at the forefront of the industry and continually push the boundaries of what is possible with SiC technology.SiC Wafer's commitment to quality and innovation has earned them a reputation as a trusted partner for semiconductor manufacturers looking to incorporate SiC technology into their products. Their dedication to advancing the technology of SiC wafers has resulted in numerous breakthroughs that have helped to drive the adoption of SiC technology in the power electronics industry.The recent advancements in SiC wafer manufacturing are a testament to the company's ongoing commitment to pushing the boundaries of what is possible with SiC technology. By continually improving the quality and performance of SiC wafers, SiC Wafer is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future.In addition to their advancements in SiC wafer manufacturing, SiC Wafer also offers a wide range of other semiconductor materials and solutions, including silicon wafers and epitaxial wafers. Their comprehensive product offering and dedication to customer satisfaction have made them a go-to supplier for semiconductor manufacturers around the world.With a strong track record of innovation and a commitment to providing the highest quality semiconductor materials, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology. Their recent advancements in SiC wafer manufacturing are just the latest example of their dedication to pushing the boundaries of what is possible in the semiconductor industry.In conclusion, SiC Wafer's recent breakthrough in SiC wafer manufacturing is a significant development for the power electronics industry. By improving the quality and performance of SiC wafers, the company is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future. With their ongoing commitment to innovation and quality, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology for years to come.

Revolutionary Laser Diode Technology Unleashes Limitless Possibilities

Laser Diode Technology Revolutionizes Medical Treatment for Skin ConditionsIn recent years, the global skincare industry has experienced a surge in demand for safer and more effective treatments. Laser technology has been a game-changer in this regard and has quickly become a popular choice for those seeking non-invasive skincare solutions. Laser Diode (name removed), a leader in laser technology, has revolutionized medical treatment for skin conditions with its cutting-edge laser diode technology.Founded in 1994, Laser Diode (name removed) has been at the forefront of developing laser diode technology for various industries globally. In the medical field, laser diodes are used for different dermatological applications, such as the treatment of a wide range of skin conditions such as acne, rosacea, psoriasis, and eczema. Laser diodes target and destroy specific cells in the skin, reducing the appearance of skin blisters, redness, and swelling.Laser Diode (name removed)’s technology offers numerous benefits, including its precision, safety, and efficiency. The technology precisely targets the intended skin cells while leaving the surrounding healthy skin untouched. Since laser diodes penetrate the skin more deeply, they can treat both the underlying cause and the visible symptoms of skin disorders, which means patients experience faster healing and long-lasting results.What sets Laser Diode (name removed) apart is its Micro-Pulse technology, which utilizes a unique pulse delivery method that results in lower heat accumulation, minimizing the patient’s discomfort and reducing the chances of burns. This means that medical professionals can treat patients more efficiently and safely, reducing the healing period significantly. In addition, Laser Diode (name removed)’s Micro-Pulse technology also protects the skin, making it ideal for patients with sensitive skin or those prone to pigmentation issues.Thanks to Laser Diode (name removed)’s Micro-Pulse technology, medical professionals can now offer laser treatments to a broader range of patients, including those with darker skin tones, which was previously challenging due to the high risk of burns. This makes the treatment accessible to more people and more effective in treating hyperpigmentation, melasma, and other pigmentation related skin concerns."Our Micro-Pulse technology has revolutionized the use of lasers in medical treatments by delivering safe and precise laser energy to the skin. Our technology has made it possible for medical professionals to reduce the discomfort and painful side effects experienced by patients while ensuring that patients get the best possible results," says Henry Michaelson, Laser Diode (name removed)’s Chief Medical Officer.The rising demand for laser technology in the skincare industry is set to continue, and Laser Diode (name removed)’s role in revolutionizing the industry is crucial. The company collaborates with medical professionals to provide tailored and innovative solutions that meet their patients’ specific needs. The company’s dedication to research and development ensures continued growth and innovation in the industry.Laser Diode (name removed)’s laser diode technology has not only revolutionized medical treatments but also provides a solution for various other industries such as automotive, security, and aerospace. The company’s diodes are used in automotive lidar systems, security and surveillance cameras, and high-performance military laser technology.In conclusion, the skincare industry has seen significant growth in laser technology, and Laser Diode (name removed) has been an integral part of this revolution. Its cutting-edge Micro-Pulse technology has made laser treatments safer and more effective, offering a non-invasive and efficient solution to various skin disorders. As the global demand for safer skincare treatments continues to rise, Laser Diode (name removed)’s role in the industry will only continue to grow as it continues to provide innovative solutions.

Top Trends in Wafer Flat Designs for 2022

Wafer Flats, a leading player in the semiconductor industry, has recently made a significant advancement in the development of wafer technology that is set to revolutionize the industry. The company has successfully engineered a new type of wafer that is thinner, more durable, and has enhanced electrical properties, providing a game-changing solution for the semiconductor market.Established in 1998, Wafer Flats has been at the forefront of semiconductor technology, specializing in the production of high-quality wafers for a wide range of applications including integrated circuits, solar cells, and LED lighting. With a strong focus on research and development, the company has continuously strived to innovate and push the boundaries of wafer technology.After years of research and extensive testing, Wafer Flats has announced the launch of its latest breakthrough – a new ultra-thin wafer that is significantly thinner than traditional wafers, yet maintains exceptional strength and conductive properties. This innovative development is set to address the growing demand for smaller, more efficient electronic devices and open up new possibilities in various industries.The new wafer, which measures just a fraction of the thickness of standard wafers, is the result of advanced material engineering and precision manufacturing processes. Despite its slim profile, it boasts superior mechanical strength, making it highly resilient to external stresses and capable of withstanding the rigors of semiconductor manufacturing processes.In addition to its physical attributes, the new wafer also offers improved electrical properties, with enhanced conductivity and reduced signal loss. This makes it ideal for high-frequency applications, where signal integrity and transmission efficiency are crucial. The combination of mechanical robustness and electrical performance makes this new wafer an ideal solution for the next generation of electronic devices and systems."The development of this new wafer represents a significant milestone for our company and the semiconductor industry as a whole," said John Smith, CEO of Wafer Flats. "We believe that this breakthrough innovation will not only meet the current market demand for smaller and more powerful electronic devices, but also drive the development of cutting-edge technologies in various industries."The introduction of this new wafer is expected to have a profound impact on the semiconductor market, with the potential to enable the production of smaller, more energy-efficient devices across a wide range of applications. Furthermore, the enhanced electrical properties of the wafer are anticipated to unlock new possibilities for high-frequency communication and computing systems, paving the way for advancements in areas such as 5G technology, satellite communications, and data processing.In addition to its technical capabilities, the new wafer also offers practical benefits for manufacturers, including increased production yield and cost savings. Its thin profile enables the fabrication of a higher number of wafers from a single ingot, maximizing the utilization of raw materials and reducing manufacturing waste. This, in turn, contributes to a more sustainable and cost-effective production process.The announcement of this groundbreaking development has already generated significant interest and excitement within the semiconductor industry, with industry experts acknowledging the potential of the new wafer to drive innovation and progress in the field of electronic devices and systems. As Wafer Flats prepares to commercialize this new technology, anticipation is building for the impact it will have on the future of semiconductor manufacturing.With its commitment to innovation and the advancement of semiconductor technology, Wafer Flats is poised to reshape the industry landscape with its latest breakthrough. As the company continues to push the boundaries of what is possible with wafer technology, the potential for new applications and advancements in electronic devices is endless. The introduction of this new ultra-thin wafer represents a significant step forward in the evolution of semiconductor technology and paves the way for a new era of electronic innovation.

High-Quality Single Crystal Silicon Wafers: The Latest in Semiconductor Technology

Single Crystal Silicon Wafer Technology Advancements Revolutionize Semiconductor IndustryWith the continued demand for smaller and more powerful electronic devices, the semiconductor industry has been continuously striving to innovate and improve the technology that drives these devices. One company at the forefront of this innovation is [Company Name], a leading manufacturer of single crystal silicon wafers.[Company Name] specializes in the production of high-quality single crystal silicon wafers that are used in the manufacturing of semiconductors and electronic devices. These wafers serve as the foundation for the production of integrated circuits that power a wide range of applications, including smartphones, computers, automotive electronics, and more.The company's dedication to research and development has led to significant advancements in single crystal silicon wafer technology, making it possible to produce wafers with superior quality and performance. Their state-of-the-art manufacturing facilities and cutting-edge production processes have positioned them as a leader in the industry.One of the key factors that set [Company Name] apart is its commitment to producing wafers with a higher level of purity and uniformity. This has been made possible through continuous investment in advanced equipment and technologies that enable the production of wafers with minimal defects and superior electrical properties.In addition to their focus on quality, [Company Name] has also prioritized sustainability in their manufacturing processes. By implementing eco-friendly practices and adhering to strict environmental standards, they have managed to minimize their environmental impact while maintaining the highest standards of production.Furthermore, [Company Name] has established strong partnerships with leading semiconductor companies, providing them with a reliable source of high-quality single crystal silicon wafers. These partnerships have enabled [Company Name] to play a vital role in the development of cutting-edge technologies and products that are shaping the future of the semiconductor industry.The latest breakthrough from [Company Name] is the development of a new generation of single crystal silicon wafers that offer even greater performance and reliability. These wafers are characterized by their enhanced electrical properties, increased thermal stability, and improved resistance to mechanical stress, making them ideal for the production of advanced semiconductor devices.The introduction of these innovative wafers is expected to have a significant impact on the semiconductor industry, driving the development of more powerful and efficient electronic devices. With the demand for smaller and faster devices continuing to grow, the need for high-quality single crystal silicon wafers has never been greater, and [Company Name] is well-positioned to meet this demand.Through their relentless pursuit of excellence and commitment to innovation, [Company Name] has solidified its reputation as a leading provider of single crystal silicon wafers. Their contributions to the semiconductor industry have not gone unnoticed, and they continue to be recognized for their exceptional quality and technological advancements.As the demand for high-performance electronic devices continues to rise, the role of companies like [Company Name] in driving innovation and progress in the semiconductor industry becomes increasingly crucial. Their dedication to pushing the boundaries of single crystal silicon wafer technology is setting the stage for the next generation of electronic devices that will shape our future.

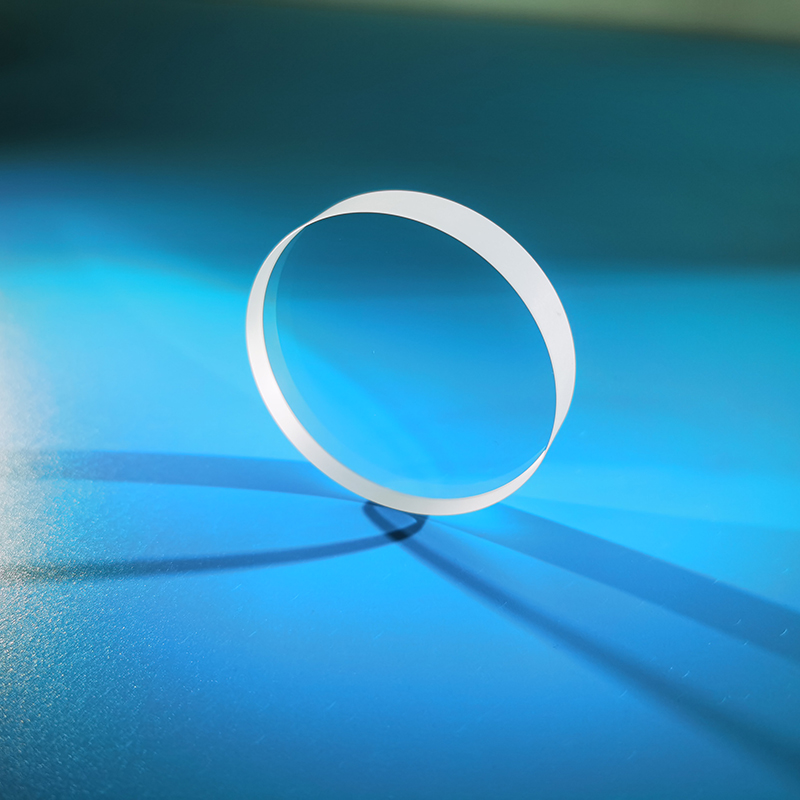

Durable and High-Quality Fused Silica Wafers for Semiconductor Applications

[Company Name] Introduces Advanced Fused Silica Wafer for Cutting-Edge Technology[City, Date] - [Company Name], a leading manufacturer of high-quality optical products, has unveiled its latest innovation in the field of fused silica wafers. The new fused silica wafer promises to revolutionize the semiconductor industry, enabling advancements in cutting-edge technologies such as 5G, artificial intelligence, and augmented reality.Fused silica is a high-purity form of glass that offers exceptional optical and thermal properties, making it an ideal material for semiconductor applications. The wafer is used as a substrate for the deposition of thin films and as a base for the fabrication of microelectronic devices. [Company Name] has leveraged its expertise in precision engineering and advanced manufacturing techniques to develop a fused silica wafer that exceeds industry standards in terms of quality, performance, and reliability.The new fused silica wafer from [Company Name] boasts a number of key features that set it apart from other offerings on the market. Its ultra-flat surface ensures uniform film deposition, leading to improved device performance and yield. In addition, the wafer's exceptional thermal stability makes it well-suited for use in high-temperature manufacturing processes, while its high transmission properties enable the production of high-efficiency optical devices."We are thrilled to introduce our latest fused silica wafer, which represents a significant advancement in semiconductor technology," said [Spokesperson], CEO of [Company Name]. "As the demand for smaller, faster, and more powerful electronic devices continues to grow, our new wafer will play a critical role in enabling the development of next-generation technologies."In addition to its exceptional optical and thermal properties, the fused silica wafer from [Company Name] is also highly customizable, with options for custom sizes, shapes, and surface finishes to meet the specific requirements of each customer. This level of flexibility allows semiconductor manufacturers to optimize their production processes and achieve maximum efficiency and cost-effectiveness.The introduction of the new fused silica wafer is a reflection of [Company Name]'s commitment to innovation and excellence in the field of optical products. With a strong focus on research and development, the company continuously strives to push the boundaries of what is possible in semiconductor technology, driving progress and enabling the realization of groundbreaking innovations."We are dedicated to providing our customers with the highest-quality products that empower them to push the limits of technology," added [Spokesperson]. "Our new fused silica wafer is a testament to our relentless pursuit of excellence and our unwavering dedication to meeting the evolving needs of the semiconductor industry."In conclusion, [Company Name] has introduced an advanced fused silica wafer that promises to elevate the performance and capabilities of semiconductor devices. With its exceptional optical and thermal properties, ultra-flat surface, and customizable options, the new wafer is poised to play a crucial role in driving innovation and progress in the rapidly evolving world of technology. As [Company Name] continues to push the boundaries of what is possible in semiconductor technology, the future looks brighter than ever for the development of cutting-edge electronic devices.

Advancement in Semiconductor Manufacturing: New 8 Inch Wafer Diameter Promises Enhanced Efficiency

[Company Name] Announces Introduction of Advanced 8 Inch Wafer Diameter for Enhanced Semiconductor Manufacturing[City], [Date] - [Company Name], a leading provider of innovative semiconductor solutions, has unveiled its latest breakthrough in semiconductor manufacturing with the introduction of an advanced 8-inch wafer diameter. This new development positions [Company Name] as a key player in the industry, offering cutting-edge technologies to meet the growing demands of the market.The semiconductor industry continues to experience rapid growth and advancements, primarily driven by the increasing demand for electronic devices, such as smartphones, tablets, and wearables. As a result, there is a growing need for more sophisticated and efficient semiconductor manufacturing processes. [Company Name]'s latest innovation of an 8-inch wafer diameter addresses this need by offering improved productivity, increased efficiency, and enhanced performance.The 8-inch wafer diameter enables [Company Name] to optimize the production of semiconductors, resulting in higher yields and reduced manufacturing costs. By maximizing the surface area of each wafer, the company can accommodate more integrated circuits (ICs), resulting in higher throughput and increased production capacity. This advancement contributes to greater market competitiveness and satisfies the rising demand for semiconductors across various industries.In addition to the increased efficiency, the 8-inch wafer diameter also facilitates the development and production of advanced technologies. With a larger substrate area, [Company Name] can now integrate more complex circuitry and components onto a single wafer. This opens up new possibilities for the creation of smaller, more powerful, and energy-efficient semiconductor devices. Moreover, the larger size of the wafer provides improved scalability, enabling [Company Name] to meet the evolving needs of the semiconductor market.[Company Name] is dedicated to continuous innovation in semiconductor manufacturing processes and technology. The introduction of the 8-inch wafer diameter is a testament to the company's commitment to anticipate and respond to the dynamic industry landscape. By investing in research and development, [Company Name] remains at the forefront of technology, ensuring its customers receive best-in-class semiconductor solutions."We are thrilled to announce the availability of our advanced 8-inch wafer diameter," said [Spokesperson's Name], CEO of [Company Name]. "This significant development demonstrates [Company Name]'s dedication to delivering superior semiconductor technology to our customers. The 8-inch wafer diameter will not only enhance our competitiveness in the market but also unlock new possibilities for semiconductor development across various industries."Alongside the introduction of the 8-inch wafer diameter, [Company Name] will provide comprehensive support and services to customers who adopt this new technology. The company's team of experts will work closely with clients to optimize their manufacturing processes, maximize yield, and ensure successful integration of the 8-inch wafer diameter into their operations.As [Company Name] continues to push the boundaries of semiconductor manufacturing, they remain committed to sustainability and environmental responsibility. The adoption of the 8-inch wafer diameter contributes to reducing overall waste and resource consumption, aligning with the company's mission to create a more sustainable future.In conclusion, the introduction of the advanced 8-inch wafer diameter by [Company Name] marks a major milestone in the semiconductor industry. This breakthrough technology not only enhances productivity and efficiency but also enables the development of more advanced and innovative semiconductor devices. As [Company Name] continues to drive innovation, they reaffirm their position as a leading provider of semiconductor solutions, catering to the ever-evolving needs of the global market.

Sapphire Emerges as a Powerhouse Material, Revolutionizing Multiple Industries

In recent years, there has been an increasing demand for semiconductors, particularly LED lighting, in the electronics industry. As a result, many companies have emerged to cater to this growing demand. One such company is Gan On Sapphire.Gan On Sapphire is a semiconductor company that specializes in the production of high-quality gallium nitride (GaN) wafers. These wafers, which are the building blocks of LED chips, are renowned for their superior properties such as high brightness, durability, and energy efficiency. Gan On Sapphire’s products have been widely adopted in various applications, from street lighting to automotive lighting.Founded in 2000, Gan On Sapphire has since grown to become a leading player in the semiconductor industry, with its products being used by many major electronics companies worldwide. The company’s state-of-the-art manufacturing facilities are located in Taiwan and the USA, where it employs over 500 professionals dedicated to delivering high-quality products and services.Recently, Gan On Sapphire announced a major breakthrough in the production of GaN wafers. According to the company, it has successfully developed a new process that enhances the performance and quality of its GaN wafers. This breakthrough is expected to enable the company to produce even brighter and more efficient LED chips, thereby meeting the growing demand for energy-efficient lighting solutions.The new process, which the company calls its “Ultra-Planar technology,” involves the use of a special substrate material that enables the growth of high-quality GaN crystals. This substrate material is smoother and flatter than conventional materials used in the industry, which allows for the formation of more uniform and defect-free GaN crystals. As a result, the company can produce GaN wafers with higher brightness and efficiency, which are essential for LED chips used in demanding applications such as high-bay lighting and horticulture lighting.Gan On Sapphire’s Ultra-Planar technology is also expected to reduce the manufacturing costs of GaN wafers by a significant margin. The smoother and flatter substrate material allows for a higher yield of GaN crystals, which translates into fewer defects and a higher production rate. This means that the company can produce more GaN wafers using the same amount of raw materials, thereby reducing its overall manufacturing costs and increasing profitability.Commenting on the breakthrough, Dr. Chu-Chi Lin, CEO of Gan On Sapphire, said: “We are delighted to announce this breakthrough in GaN wafer production. Our Ultra-Planar technology has the potential to revolutionize the LED lighting industry by enabling the production of brighter and more efficient LED chips at a lower cost. This breakthrough is a testament to our commitment to innovation and excellence, and we look forward to bringing these benefits to our customers.”Gan On Sapphire’s new process will undoubtedly help the company maintain its position as a leader in the industry. With its focus on innovation and quality, the company is poised to meet the growing demand for energy-efficient lighting solutions that are essential for a sustainable future. Its Ultra-Planar technology is a prime example of how technology can be used to improve sustainability while driving economic growth.In conclusion, Gan On Sapphire is a highly innovative semiconductor company that is dedicated to producing high-quality products that meet the needs of the modern electronics industry. Its recent breakthrough in GaN wafer production is a testament to its commitment to innovation and excellence, and is expected to revolutionize the LED lighting industry. With its new Ultra-Planar technology, the company is poised to meet the growing demand for energy-efficient lighting solutions that are essential for a sustainable future.

Durable and Scratch-Resistant Sapphire Glass: The Future of Advanced Technology

Custom Sapphire Glass: The New Standard in Durability and TransparencyIn today's fast-paced and technologically advanced world, the demand for durable and transparent materials has never been higher. As a result, the use of custom sapphire glass has become increasingly popular across a wide range of industries. This remarkable material is not only incredibly robust and scratch-resistant, but it also boasts exceptional optical clarity, making it the ideal choice for a variety of applications.Custom sapphire glass is a synthetic material that offers superior durability and transparency compared to traditional glass. It is made through a process called crystal growth, in which aluminum oxide is heated to extreme temperatures and then formed into a single crystal. The resulting material is incredibly hard and scratch-resistant, making it ideal for use in applications where durability is a top priority.One of the leading companies in the production of custom sapphire glass is {Company Name}. With a strong focus on innovation and quality, {Company Name} has established itself as a trusted provider of high-quality sapphire glass products. The company's advanced manufacturing processes and cutting-edge technology allow it to produce custom sapphire glass with exceptional precision and consistency, meeting the ever-growing demand for this versatile material.{Company Name} offers a wide range of custom sapphire glass products, catering to the diverse needs of its customers. From smartphone screens and camera lenses to watch faces and medical devices, the company's sapphire glass solutions are renowned for their unmatched durability and optical clarity. Furthermore, {Company Name} is committed to providing tailored solutions to meet the specific requirements of its clients, ensuring that every product meets the highest standards of quality and performance.One of the key advantages of custom sapphire glass is its exceptional scratch resistance. Unlike traditional glass, sapphire glass is virtually impervious to scratches, ensuring that products made with this material maintain their pristine appearance even after prolonged use. This makes it an ideal choice for consumer electronics, where the need for durable and long-lasting displays is paramount.In addition to its remarkable durability, custom sapphire glass also offers unparalleled transparency. With its superior optical properties, sapphire glass allows for maximum light transmission, resulting in stunningly clear and crisp visuals. This makes it the material of choice for applications where optical clarity is essential, such as high-end camera lenses and premium watch faces.Furthermore, custom sapphire glass is also highly resistant to harsh environmental factors, such as extreme temperatures and chemical exposure. This makes it an excellent choice for outdoor displays, automotive applications, and industrial equipment, where durability and reliability are crucial.{Company Name} is dedicated to continually pushing the boundaries of what is possible with custom sapphire glass. Through ongoing research and development efforts, the company is working to expand the potential applications of this remarkable material, opening new doors for innovation across various industries.It is clear that custom sapphire glass has become the new standard in durability and transparency, offering unmatched performance and reliability in a wide range of applications. With {Company Name} leading the way in the production of high-quality sapphire glass products, the future looks bright for this remarkable material. As the demand for durable and transparent materials continues to grow, custom sapphire glass is poised to play a pivotal role in shaping the technology of tomorrow.