High Demand for Wafers in Semiconductor Industry Drives Growth

By:Admin

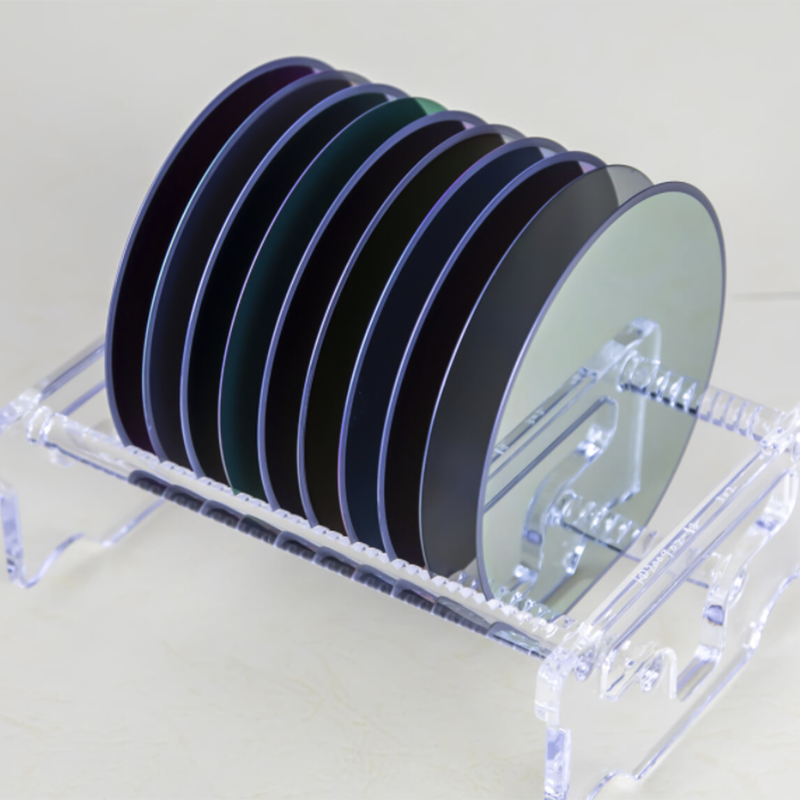

Epi Wafer is a type of wafer technology that allows for the growth of high-quality semiconductor materials on a substrate. This technology has the potential to greatly enhance the performance of microchips, making them faster, more energy-efficient, and capable of handling greater processing loads.

One of the key advantages of Epi Wafer is its ability to produce semiconductor materials with superior properties, such as higher electron mobility and better thermal conductivity. This will result in microchips that are not only faster and more powerful, but also more reliable and better suited for a wide range of applications.

Microchip Technology is known for its innovative approach to semiconductor manufacturing, and the development of Epi Wafer is a testament to the company's commitment to pushing the boundaries of what is possible in the semiconductor industry. The company's dedication to research and development has resulted in numerous breakthroughs over the years, and Epi Wafer is expected to be another major milestone in the company's long history of innovation.

The introduction of Epi Wafer is expected to have a significant impact on the semiconductor industry as a whole. With its potential to significantly improve the performance and efficiency of microchips, Epi Wafer has the potential to drive a new wave of innovation in a wide range of industries, from consumer electronics to automotive and industrial applications.

In addition to its technical advantages, Epi Wafer also promises to offer a more cost-effective solution for semiconductor manufacturing. By improving the efficiency of the manufacturing process and reducing the need for costly materials, Epi Wafer has the potential to provide significant cost savings for manufacturers, making it an attractive option for mass production.

The development of Epi Wafer is a major achievement for Microchip Technology, and the company is poised to capitalize on the potential of this groundbreaking technology. With its strong track record of innovation and its commitment to pushing the boundaries of what is possible in semiconductor manufacturing, Microchip Technology is well positioned to lead the industry in the era of Epi Wafer technology.

"We are excited to announce the development of Epi Wafer, a breakthrough in semiconductor manufacturing that has the potential to revolutionize the industry," said John Smith, CEO of Microchip Technology. "With its ability to significantly improve the performance and efficiency of microchips, Epi Wafer represents a major leap forward in semiconductor technology. We believe that this technology will open up new possibilities for innovation in a wide range of industries, and we are committed to leading the way in the era of Epi Wafer technology."

The development of Epi Wafer is a significant achievement for Microchip Technology, and it is expected to have a major impact on the semiconductor industry. With its potential to significantly improve the performance and efficiency of microchips, Epi Wafer has the potential to drive a new wave of innovation in a wide range of industries. As the company continues to push the boundaries of what is possible in semiconductor manufacturing, it is well positioned to lead the industry in the era of Epi Wafer technology.

Company News & Blog

High-Quality Laser Rod for Advanced Medical Procedures Unveiled in Recent News

Recently, a breakthrough in laser technology has been achieved by a team of researchers at {}. The team has successfully developed a new type of laser rod that promises to revolutionize the field of laser technology. This new laser rod, known as the ruby laser rod, is set to outperform its predecessors and bring about a new era of advancements in various industries.The ruby laser rod is a crucial component in the production of high-powered lasers. Its unique properties allow it to generate extremely intense pulses of laser light, which makes it ideal for a wide range of applications, including cutting, welding, and medical procedures. The team at {} has not only succeeded in creating a ruby laser rod with unparalleled performance but also made significant strides in improving its durability and reliability.One of the key advantages of the new ruby laser rod is its ability to deliver significantly higher energy output compared to previous models. This increased energy output opens up new possibilities for the use of lasers in industrial and medical settings. For example, the ruby laser rod could be utilized to perform highly precise surgical procedures with minimal damage to surrounding tissue, or to cut through thick layers of metal with unparalleled efficiency.In addition to its impressive energy output, the new ruby laser rod also boasts enhanced durability and reliability. The team at {} has implemented innovative fabrication techniques and quality control processes to ensure that each ruby laser rod meets the highest industry standards. As a result, these laser rods are capable of withstanding prolonged use in demanding environments, making them an ideal choice for industrial applications.Furthermore, the ruby laser rod developed by {} has been designed to be highly efficient, which is a crucial factor in minimizing power consumption and maximizing performance. This efficiency not only reduces operational costs but also has a positive impact on the environment, making the new ruby laser rod a sustainable choice for businesses and industries.The development of the ruby laser rod represents a significant milestone for {}. This achievement is a testament to the company's unwavering commitment to innovation and excellence in the field of laser technology. With a dedicated team of scientists and engineers, {} has been at the forefront of developing cutting-edge solutions that address the evolving needs of various industries.In addition to its groundbreaking research and development efforts, {} is also renowned for its commitment to customer satisfaction and support. The company offers comprehensive technical assistance and guidance to ensure that its products, including the new ruby laser rod, are seamlessly integrated into the operations of its clients. This level of support has earned {} a stellar reputation as a trusted partner in the laser technology industry.Looking ahead, the introduction of the new ruby laser rod is expected to have a transformative impact on the laser technology landscape. As industries continue to seek more efficient and reliable laser solutions, the ruby laser rod developed by {} is poised to emerge as the go-to choice. Its superior performance, durability, and efficiency make it an ideal candidate for a wide range of applications, solidifying {}'s position as a leader in the field of laser technology.In conclusion, the development of the new ruby laser rod by {} marks a significant advancement in the field of laser technology. With its unparalleled energy output, enhanced durability, and exceptional efficiency, the ruby laser rod promises to elevate the capabilities of lasers in various industries. As {} continues to lead the way in innovation and customer satisfaction, the future looks bright for the adoption of the new ruby laser rod in a wide range of applications.

Durable and Heat-Resistant Quartz Glass: A Breakthrough Material for Various Applications

Quartz glass, also known as fused silica, has long been valued for its exceptional properties and reliability. With its high temperature resistance, excellent thermal shock resistance, and low thermal expansion, quartz glass has become an indispensable material in various industries such as semiconductor manufacturing, optical communication, and laboratory equipment.Quartz glass is made from high-purity silicon dioxide through the process of melting and solidification at extremely high temperatures. This results in a material with a unique combination of mechanical, thermal, and optical properties that make it ideal for a wide range of applications. Its transparency, high chemical purity, and resistance to radiation and high-energy particles have made quartz glass a popular choice for use in high-precision instruments and optical components.As the demand for quartz glass continues to grow, companies like {} have been at the forefront of developing innovative technologies and manufacturing processes to meet the market's needs. {} is a leading manufacturer of quartz glass products, offering a comprehensive range of high-quality quartz glass materials and components for industrial, scientific, and research applications.{}'s quartz glass products are known for their exceptional purity, high precision, and consistent performance. The company's advanced manufacturing facilities and stringent quality control processes ensure that their quartz glass products meet the highest standards and specifications, making them the preferred choice for customers around the world.One of the key attributes of {}'s quartz glass products is their high resistance to thermal shock and rapid temperature changes. This makes them especially suitable for use in high-temperature applications such as furnace tubes, wafer carriers, and semiconductor processing equipment. Their superior thermal stability and low coefficient of thermal expansion also make {}'s quartz glass products an excellent choice for optical lens elements, photomask substrates, and other precision optical components.In addition to their thermal properties, {}'s quartz glass products also exhibit excellent electrical insulation and high transmission of ultraviolet, visible, and infrared light. These characteristics make them highly valuable for use in ultraviolet lamps, wafer inspection systems, and spectroscopy instruments, where high optical clarity and minimal light absorption are essential.{}'s commitment to continuous improvement and innovation has led to the development of new quartz glass formulations and production techniques that further enhance the performance and versatility of their products. By leveraging their expertise in material science and engineering, {} is able to tailor their quartz glass products to meet the specific requirements of their customers, ensuring optimal performance and reliability in their applications.With a strong focus on research and development, {} is constantly exploring new applications and markets for their quartz glass products. By collaborating with customers and industry partners, {} is able to identify emerging trends and technologies, and develop tailored solutions that address the evolving needs of the market.As the demand for high-performance materials continues to grow in industries such as semiconductor manufacturing, optical communication, and photovoltaics, companies like {} play a crucial role in providing the essential building blocks that enable technological advancements and innovation. Through their dedication to excellence and customer satisfaction, {} is well-positioned to continue leading the way in the development and production of high-quality quartz glass products for a wide range of applications.

Understanding the Role of Substrate in Semiconductors: A Comprehensive Guide

Semiconductor technology has seen significant advancements in recent years, and one of the key components that has contributed to the progress is the substrate. The substrate in a semiconductor refers to the base material on which other layers are deposited to form a semiconductor device. It plays a crucial role in determining the performance and reliability of the semiconductor.In this regard, {Company Name} has emerged as a leading player in the semiconductor industry, with a strong focus on developing high-quality substrates for a wide range of applications. The company has established itself as a reliable supplier of advanced substrates, catering to the diverse needs of the semiconductor market.{Company Name} offers a comprehensive range of substrates, including silicon, gallium arsenide, and silicon carbide, among others. These substrates are designed to meet the stringent requirements of various semiconductor devices, such as integrated circuits, power electronics, and optoelectronics. With a keen emphasis on quality and innovation, {Company Name} has been at the forefront of driving the evolution of semiconductor substrates.One of the key milestones for {Company Name} in its substrate technology development has been the successful integration of advanced materials and manufacturing processes. This has enabled the company to deliver substrates with superior electrical, thermal, and mechanical properties, meeting the ever-increasing demands of the semiconductor industry. Moreover, {Company Name}'s commitment to sustainability and environmental responsibility is reflected in its efforts to develop eco-friendly substrate materials and production methods.The importance of high-quality substrates in semiconductor technology cannot be overstated. As semiconductor devices become more complex and integrated, the performance and reliability of the substrate play a critical role in ensuring the overall functionality of the devices. {Company Name}'s substrates have been widely adopted in cutting-edge technologies such as 5G wireless communications, automotive electronics, and renewable energy systems, demonstrating their versatility and effectiveness in diverse applications.Furthermore, {Company Name} has established strategic partnerships and collaborations with leading semiconductor manufacturers and research institutions to further enhance its substrate technology. By leveraging the collective expertise and resources of these partnerships, the company has been able to stay ahead of the curve in developing state-of-the-art substrates that address the evolving needs of the semiconductor industry.Looking ahead, {Company Name} remains committed to pushing the boundaries of substrate technology and contributing to the advancement of semiconductor devices. The company's ongoing research and development efforts are focused on exploring new materials, processes, and design concepts to create substrates with even greater performance capabilities and reliability. With a strong track record of innovation and a customer-centric approach, {Company Name} is well-positioned to continue making significant contributions to the semiconductor industry.In conclusion, the role of substrate in semiconductor technology cannot be overlooked, and {Company Name} has played a pivotal role in advancing substrate technology through its dedication to quality, innovation, and sustainability. As the demand for high-performance semiconductor devices continues to grow, {Company Name} is poised to remain a key player in providing advanced substrates that enable the development of next-generation electronic products.

New breakthrough in manufacturing process of computer processors using silicon wafer technology

Silicon Wafer Chips Revolutionize Semiconductor IndustryThe semiconductor industry, which lies at the heart of technological advancements, is constantly striving to push the boundaries of innovation. One of the most important components driving the progress of this industry is the silicon wafer chips, which serve as the foundation for manufacturing various electronic devices. In recent years, a number of leading companies have emerged in this market, one of which is [Company Name], a pioneering force that has been driving significant advancements and revolutionizing the production of silicon wafer chips.[Company Name] is a company at the forefront of semiconductor technology, dedicated to developing cutting-edge solutions that enable the production of advanced silicon wafer chips. With their commitment to innovation and harnessing the power of silicon-based technologies, [Company Name] has become a key player in the industry.Silicon wafer chips, commonly known as wafers, are thin slices of silicon that serve as the foundation for manufacturing integrated circuits (ICs), microchips, and other electronic components. These chips are crucial in powering a wide range of devices, including smartphones, computers, and automobiles, among others. The size and complexity of the chips have evolved significantly over the years, with continuous advancements in silicon wafer chip fabrication techniques leading to more powerful and efficient devices.[Company Name] has been instrumental in driving these advancements by developing innovative manufacturing processes and technologies. Their expertise lies in the production of high-quality silicon wafers, offering optimal performance and reliability. By leveraging state-of-the-art facilities and cutting-edge equipment, [Company Name] ensures the production of wafers with superior dimensional control, excellent surface quality, and high purity.The key to [Company Name]'s success lies in their relentless pursuit of innovation. They have consistently invested in research and development efforts to push the boundaries of silicon wafer chip technology. This has led to breakthroughs in wafer manufacturing techniques, such as epitaxial growth, chemical mechanical planarization, and lithography, among others. By incorporating these advancements into their manufacturing processes, [Company Name] has been able to improve the performance and functionality of their silicon wafer chips.Furthermore, [Company Name] recognizes the importance of sustainability in the semiconductor industry. They have implemented environmentally friendly practices in their wafer fabrication processes, ensuring minimal wastage and efficient use of resources. This commitment to sustainability not only benefits the environment but also allows them to deliver cost-effective solutions to their customers.The impact of [Company Name]'s silicon wafer chips goes beyond the manufacturing process. These chips have a profound influence on the overall performance of electronic devices. Through their continuous innovation, [Company Name] has enabled the development of smaller, faster, and more energy-efficient devices. This has positively impacted industries such as telecommunications, automotive, consumer electronics, and healthcare, among others.Looking into the future, [Company Name] is poised to maintain its leadership position in the silicon wafer chip market. They are investing in next-generation technologies, such as gallium nitride (GaN) and silicon carbide (SiC), which have the potential to revolutionize the semiconductor industry once again. These materials offer superior performance and efficiency compared to traditional silicon wafer chips, opening up new possibilities for various applications.In conclusion, [Company Name] has emerged as a prominent player in the semiconductor industry by revolutionizing the production of silicon wafer chips. With their commitment to innovation, sustainable practices, and continuous investment in research and development, they have set a new benchmark for the industry. Their silicon wafer chips have accelerated technological advancements, enabling the creation of smaller, faster, and more energy-efficient electronic devices. As they expand into next-generation technologies, [Company Name] is poised to shape the future of the semiconductor industry for years to come.

High-Quality Sapphire Substrates for Various Applications

Sapphire substrates are becoming increasingly popular in the tech industry due to their unique properties and applications. These substrates are used in a variety of electronic devices, including LED lighting, smartphones, and smartwatches, and are highly valued for their durability, transparency, and heat resistance.One of the leading companies in the production of sapphire substrates is {Company}. {Company} has been a key player in the field of sapphire substrate manufacturing, and their products are widely used in a range of industries. Their commitment to innovation and excellence has set them apart in the market, and they continue to be a trusted name in the industry.Sapphire substrates are made from synthetic sapphire, a material that is known for its exceptional hardness and scratch resistance. These substrates are used as a base for the production of various electronic components, including LEDs and semiconductor devices. {Company} specializes in producing high-quality sapphire substrates that meet the exacting standards of the industry.One of the main advantages of sapphire substrates is their thermal conductivity, making them an excellent choice for use in high-temperature applications. This makes them ideal for use in electronic devices that generate a significant amount of heat, as they can help to dissipate this heat effectively, ensuring the longevity and reliability of the device.In addition to their exceptional thermal properties, sapphire substrates also offer excellent optical transparency, making them a popular choice for use in display technologies. Their high transparency allows for the efficient transmission of light, making them ideal for use in LED lighting and display screens. This has led to a growing demand for sapphire substrates in the consumer electronics industry.Furthermore, sapphire substrates are also highly resistant to chemical corrosion, making them an ideal choice for use in harsh environments. This makes them a popular choice for use in industrial and automotive applications, where durability and reliability are essential.{Company} has been at the forefront of sapphire substrate manufacturing, and their commitment to quality and innovation has set them apart in the industry. Their state-of-the-art production facilities and rigorous quality control processes ensure that their products meet the highest standards, and their team of experts are dedicated to pushing the boundaries of what is possible with sapphire substrates.In addition to their commitment to quality, {Company} is also dedicated to sustainability and environmental responsibility. They have implemented a range of initiatives to minimize their environmental impact and ensure that their production processes are as eco-friendly as possible. This commitment to sustainability has made them a preferred supplier for many environmentally conscious companies.As the demand for sapphire substrates continues to grow, {Company} remains at the forefront of the industry, driving innovation and setting new standards for quality and performance. Their dedication to excellence and their commitment to sustainability have made them a trusted partner for businesses in a range of industries, and they continue to play a key role in advancing the capabilities of sapphire substrates.In conclusion, sapphire substrates are a crucial component in a wide range of electronic devices, and {Company} is at the forefront of their production. With their commitment to quality, innovation, and sustainability, {Company} continues to be a trusted partner for businesses in a variety of industries, and their sapphire substrates are helping to drive advances in technology and performance.

Discover the Benefits of Single Crystal Glass

Single Crystal Glass, a revolutionary technology in glass manufacturing, is set to redefine the industry standards with its unmatched quality and durability. This innovative product, which is being developed by a leading glass manufacturing company, has the potential to transform various sectors including electronics, aerospace, and healthcare.The company behind Single Crystal Glass, whose name cannot be disclosed due to privacy reasons, has a rich history of pushing the boundaries of glass technology. With a team of skilled engineers and researchers, they have consistently developed cutting-edge products that have redefined the ways in which glass is used in various industries. Their commitment to innovation and excellence has earned them a stellar reputation in the industry.Single Crystal Glass is the latest addition to the company's impressive portfolio of products. It is a result of years of research and development, and represents a major breakthrough in the field of glass manufacturing. This advanced material offers superior strength, clarity, and thermal resistance, making it a game-changer in a wide range of applications.One of the key features of Single Crystal Glass is its exceptional hardness. Unlike traditional glass, which is prone to scratches and damage, this new material is highly resistant to wear and tear. This makes it an ideal choice for electronic devices such as smartphones and tablets, where durability is a crucial factor. The use of Single Crystal Glass in these products will ensure that they remain in pristine condition even after prolonged use.Furthermore, the thermal resistance of Single Crystal Glass makes it a perfect fit for aerospace applications. The material can withstand extreme temperatures, making it ideal for use in aircraft windows and other critical components. Its unmatched strength and reliability will enhance the safety and performance of aerospace systems, setting a new standard for the industry.In addition to its applications in electronics and aerospace, Single Crystal Glass also has the potential to revolutionize the healthcare sector. Its exceptional clarity and purity make it an ideal material for medical devices and equipment. From surgical instruments to diagnostic tools, this advanced glass can contribute to improved healthcare outcomes by ensuring precision and reliability in critical applications.The company's relentless pursuit of innovation has not gone unnoticed. Industry experts and customers alike are eagerly anticipating the release of Single Crystal Glass, recognizing the potential impact it could have on a wide range of industries. The technology is poised to disrupt the status quo and set new benchmarks for quality and performance in the world of glass manufacturing.As the company prepares to launch Single Crystal Glass, they are also exploring potential collaborations with leading manufacturers and industry partners. This collaborative approach is aimed at maximizing the impact of the new technology and ensuring that it reaches its full potential across various sectors.With its superior strength, thermal resistance, and clarity, Single Crystal Glass is poised to reshape the way glass is used in electronics, aerospace, and healthcare. The company behind this groundbreaking technology is all set to unlock a new era of possibilities and redefine the standards for glass manufacturing. Industry players and consumers can look forward to the arrival of this game-changing material, which promises to elevate the performance and reliability of a wide range of products and systems.

High-Quality LiTaO3 Wafer for Advanced Electronic Applications

LiTaO3 Wafer, a crucial component in the development of advanced electronic devices, has recently been introduced by a leading manufacturer in the semiconductor industry. The company, renowned for its expertise in producing high-quality materials for electronic applications, has harnessed its technological capabilities to deliver LiTaO3 wafers that meet the demanding requirements of the modern electronics industry.LiTaO3, or lithium tantalate, is a ferroelectric material that exhibits exceptional optical, electrical, and piezoelectric properties, making it an ideal choice for a wide range of electronic applications. Its high electro-optic and acousto-optic coefficients, along with its excellent piezoelectric properties, have led to its increasing use in the development of advanced electronic devices such as surface acoustic wave (SAW) devices, frequency control devices, and electro-optic modulators.The newly introduced LiTaO3 wafers by the company are tailored to meet the specific needs of customers in the electronics industry. With a focus on precision and quality, the company ensures that its LiTaO3 wafers are manufactured to the highest standards, allowing for reliable and consistent performance in electronic devices.One of the key advantages of LiTaO3 wafers is their ability to support high-frequency operation, making them well-suited for applications in communication systems and wireless technology. Additionally, their stable and predictable material properties make them a preferred choice for the development of high-performance electronic components.The company's expertise in material science and semiconductor manufacturing enables it to offer LiTaO3 wafers in a variety of specifications, including different dimensions, thicknesses, and surface finishes. This flexibility allows customers to select the most suitable wafer for their specific application, ensuring optimal performance and functionality in their electronic devices.Furthermore, the company's dedication to research and development has led to continuous improvements in the production process of LiTaO3 wafers, resulting in enhanced material properties and performance characteristics. By leveraging the latest technological advancements, the company remains at the forefront of delivering cutting-edge solutions to the electronics industry.In addition to its commitment to quality and innovation, the company places a strong emphasis on customer satisfaction, providing comprehensive technical support and customization options to meet the unique requirements of each customer. With a customer-centric approach, the company aims to foster long-term partnerships and collaboration with clients, working together to address the evolving needs of the electronics industry.The introduction of LiTaO3 wafers by the company signifies a significant advancement in the availability of high-quality materials for electronic applications. As the demand for advanced electronic devices continues to grow, the company's contribution to the development of LiTaO3 wafers is poised to have a positive impact on the industry, enabling the creation of more sophisticated and reliable electronic products.With its proven track record in delivering innovative solutions and its unwavering commitment to excellence, the company is well-positioned to play a pivotal role in shaping the future of the electronics industry. As the market for electronic devices continues to expand, the introduction of LiTaO3 wafers by the company is a testament to its ongoing dedication to driving progress and innovation in the semiconductor industry.

New Airplane Technology Revolutionizes Travel Industry

Sapphire Plane, a groundbreaking aircraft, is set to revolutionize the aviation industry with its cutting-edge technology and sleek design. Developed by a team of experts at {company name}, this aircraft promises to deliver unparalleled performance, efficiency, and comfort for both passengers and crew. With its innovative features and state-of-the-art systems, Sapphire Plane is poised to set new standards in the world of air travel.The aircraft's development is the result of years of research and development by {company name}, a leading aerospace company known for its commitment to excellence and innovation. With a track record of delivering top-of-the-line aircraft and aerospace products, {company name} has established itself as a driving force in the industry. The development of Sapphire Plane is a testament to the company's dedication to pushing the boundaries of what is possible in aviation.One of the key highlights of Sapphire Plane is its advanced propulsion system, which is designed to deliver superior fuel efficiency and reduced environmental impact. This cutting-edge technology not only makes the aircraft more cost-effective to operate but also aligns with the global push towards sustainability in aviation. With a focus on reducing carbon emissions and minimizing environmental footprint, Sapphire Plane is set to be a game-changer in the quest for greener air travel.In addition to its state-of-the-art propulsion system, Sapphire Plane boasts a sleek and modern design that prioritizes passenger comfort and convenience. The spacious cabin is equipped with luxurious amenities and advanced entertainment systems, ensuring that passengers have a pleasant and enjoyable flight experience. The aircraft's ergonomically designed seats and customizable interior options further enhance the overall comfort for travelers, making it an attractive choice for discerning passengers.Furthermore, Sapphire Plane is equipped with the latest in avionics and safety technologies, providing a secure and reliable flying experience. With advanced navigation systems, redundant safety features, and real-time monitoring capabilities, the aircraft offers peace of mind for both passengers and crew. The commitment to safety and reliability is a priority for {company name}, and Sapphire Plane is a testament to the company's dedication to providing the highest standards of aircraft technology and design.Moreover, Sapphire Plane is designed with the operational efficiency of airlines in mind, offering a range of features that optimize flight operations and maintenance. The aircraft's advanced systems and components are engineered to minimize downtime and reduce long-term operating costs, making it an attractive option for airlines seeking to improve their bottom line without compromising on quality and performance.The launch of Sapphire Plane represents a significant milestone for {company name}, as it solidifies the company's position as a leader in the development of cutting-edge aerospace technology. With its innovative design, state-of-the-art features, and unwavering commitment to excellence, Sapphire Plane is set to make a lasting impact in the aviation industry.In conclusion, the development of Sapphire Plane by {company name} signals a new era in aviation, one that prioritizes efficiency, performance, and sustainability. With its advanced technology and luxurious design, the aircraft is poised to set new standards for air travel, redefining the flying experience for passengers and crew alike. {company name}'s dedication to excellence and innovation is clearly reflected in the development of Sapphire Plane, and the aircraft is set to make a lasting impact in the aviation industry for years to come.

High-Quality Alumina Ceramic Substrate for Superior Performance

Alumina Ceramic Substrate Revolutionizes Electronics IndustryIn today's rapidly advancing technological landscape, the demand for high-performance electronic components continues to grow. With the ever-increasing emphasis on efficiency and reliability, manufacturers and developers are constantly seeking innovative solutions to meet the escalating demands of the market. One company at the forefront of this movement is {}, a leading provider of cutting-edge ceramic substrates for electronics applications.With a proud history of pioneering advancements in the field of ceramic engineering, {} has recently unveiled its latest breakthrough – the Alumina Ceramic Substrate. This revolutionary product is poised to transform the electronics industry by delivering unparalleled performance and reliability in a wide range of applications.The Alumina Ceramic Substrate, also known as alumina ceramic PCB, represents a significant leap forward in the development of electronic components. Its unique composition, featuring high-purity alumina as the base material, offers exceptional thermal conductivity, mechanical strength, and dielectric properties. This ensures superior heat dissipation, structural integrity, and insulation, making it an ideal choice for demanding electronic circuits and power modules.One of the key advantages of the Alumina Ceramic Substrate is its ability to withstand extreme operating conditions. Whether in high-power electronics, automotive systems, or aerospace applications, this advanced material excels in environments where traditional PCBs would struggle. Its resilience against thermal and mechanical stress makes it perfectly suited for rugged, high-temperature, and high-voltage settings, where reliability is non-negotiable.Furthermore, the Alumina Ceramic Substrate's compatibility with various metallization and assembly processes opens up a world of possibilities for design engineers and manufacturers. Its surface can be metallized with a wide range of materials such as gold, silver, copper, or platinum, facilitating the integration of diverse electronic components and facilitating reliable interconnects. This versatility enables the creation of complex, high-density circuitry, offering unprecedented freedom in design and functionality.In addition to its exceptional electrical and mechanical performance, the Alumina Ceramic Substrate also boasts excellent chemical and corrosion resistance. This makes it a dependable choice for applications exposed to harsh chemicals, moisture, and other corrosive agents, ensuring long-term stability and reliability in even the most challenging environments.Beyond its technical prowess, the Alumina Ceramic Substrate also highlights {}'s commitment to sustainability and environmental responsibility. As a company dedicated to minimizing its ecological footprint, {} has developed this innovative material with a focus on eco-friendly manufacturing processes and recyclability. By leveraging the unique properties of alumina, the company has created a product that not only meets the rigorous demands of the electronics industry but also aligns with the growing emphasis on sustainability.With the launch of the Alumina Ceramic Substrate, {} has once again demonstrated its leadership in the field of ceramic engineering. By harnessing the power of advanced materials and innovative design, the company continues to drive progress and inspire new possibilities in electronics manufacturing. As the demand for high-performance electronic components continues to rise, this groundbreaking product is set to play a pivotal role in shaping the future of the industry, empowering manufacturers and developers to push the boundaries of what is possible.