High-quality Gallium Phosphide Wafers for electronic devices: Benefits and Applications

By:Admin

{} is a globally renowned company that specializes in the production of advanced semiconductor materials and components. With a strong focus on innovation and technology, the company has established itself as a trusted partner for companies seeking high-quality semiconductor solutions. The company's extensive product portfolio includes a wide range of semiconductor materials, such as Gallium Phosphide Wafers, which are crucial for the development of next-generation electronic and photonic devices.

The Gallium Phosphide Wafers offered by {} are manufactured using state-of-the-art techniques and processes to ensure the highest level of quality and performance. These wafers are characterized by their exceptional electrical and optical properties, making them ideal for applications that require high-speed data processing and transmission, as well as high-efficiency photonic devices.

One of the key advantages of {}'s Gallium Phosphide Wafers is their ability to operate at high frequencies, making them well-suited for use in advanced wireless communication systems, radar systems, and satellite communications. In addition, these wafers exhibit excellent thermal stability and reliability, allowing for seamless integration into various electronic and photonic devices.

The growing demand for Gallium Phosphide Wafers in the semiconductor industry can be attributed to the increasing need for high-performance electronic and photonic devices in a wide range of applications. With the proliferation of 5G technology, the demand for advanced semiconductor materials, such as Gallium Phosphide Wafers, has surged, as these materials are essential for the development of high-speed communication systems and networks.

In response to this demand, {} has ramped up its production of Gallium Phosphide Wafers to meet the needs of its customers. The company's commitment to quality and innovation has positioned it as a preferred supplier of semiconductor materials for leading technology companies worldwide.

{}'s Gallium Phosphide Wafers have been extensively tested and validated for their performance and reliability, making them the preferred choice for companies seeking to develop cutting-edge electronic and photonic devices. Whether it's for the development of high-speed data communication systems, advanced radar systems, or next-generation satellite communications, {}'s Gallium Phosphide Wafers are well-suited to meet the demands of these applications.

In conclusion, the introduction of {}'s Gallium Phosphide Wafers represents a significant development in the semiconductor industry. With their exceptional performance and reliability, these wafers are poised to drive innovation in the development of high-performance electronic and photonic devices. As the demand for advanced semiconductor materials continues to grow, {} is well-positioned to meet the needs of its customers and play a key role in shaping the future of technology.

Company News & Blog

Top Wafer News: Latest Updates and Developments in the Industry

We are excited to announce that the wafer production at our company has reached a new milestone this year. The company has recently introduced a breakthrough technology that has significantly improved the efficiency and quality of our wafer manufacturing process. This new development has put us at the forefront of wafer production in the industry, positioning us as a leading provider of high-quality wafers for various applications.The company has been dedicated to the research and development of advanced wafer manufacturing technologies for many years. Our team of experts has been working tirelessly to innovate and enhance our processes, leading to the successful implementation of this new technology. As a result, we have been able to produce wafers that meet the highest standards of quality and consistency, setting a new benchmark for the industry.The new technology has improved the overall efficiency of our wafer production, allowing us to increase our output while maintaining the same level of quality. This has not only enabled us to meet the growing demand for wafers in the market but also to expand our product offerings to cater to a wider range of applications. Additionally, the new technology has also enhanced the precision and uniformity of our wafers, making them suitable for even more advanced and sensitive electronic devices.Moreover, the company has also taken steps to ensure that the new technology is environmentally friendly and sustainable. We have implemented state-of-the-art processes to minimize waste and resource consumption, making our wafer production more eco-friendly than ever before. This commitment to sustainability aligns with our company's values and vision for the future, as we strive to be a responsible and ethical leader in the industry.As a result of these advancements, we are proud to offer our customers a comprehensive range of high-quality wafers that are tailored to their specific needs. Whether our customers require standard wafers for traditional electronic devices or advanced wafers for cutting-edge applications, we are confident that our products will meet and exceed their expectations. Our commitment to quality, innovation, and sustainability sets us apart in the market and solidifies our position as a trusted wafer provider.Looking ahead, the company is focused on continuing to push the boundaries of wafer manufacturing and further advance our technologies. Our dedicated team of researchers and engineers is already working on the next generation of wafer production, aiming to set new standards and break new ground in the industry. We are excited about the possibilities that lie ahead and are confident that our commitment to innovation will drive us to even greater success in the future.In conclusion, the introduction of our new wafer manufacturing technology marks a significant milestone for our company and the industry as a whole. We are proud to offer high-quality, efficient, and sustainable wafers that cater to the evolving needs of our customers. With our continued dedication to innovation and excellence, we are well-positioned to lead the way in wafer production for years to come.

Revolutionary Breakthrough: Researchers Discover the Power of a Single Metal Crystal

Single Metal Crystal Develops Groundbreaking Technology for the Industry [City], [Date] - Single Metal Crystal (SMC), a leading innovator in the technology field, has announced a groundbreaking advancement that is expected to revolutionize the industry. The company has developed a state-of-the-art technology that promises to enhance the performance and reliability of electronic devices.Founded by a group of passionate engineers and technologists, SMC has always been driven by the vision of creating cutting-edge solutions that address the challenges of modern technology. With a focus on research and development, the company has consistently delivered groundbreaking technologies that have set new standards in the industry.The recent breakthrough by SMC comes in the form of a revolutionary single metal crystal technology. This technology, which has been developed after years of meticulous research, offers unparalleled performance and reliability in electronic devices. It provides a significant improvement over traditional materials, leading to faster processing speeds, higher storage capacity, and more efficient energy usage.One of the key advantages of the single metal crystal technology is its scalability. SMC has successfully achieved scalable growth of single metal crystals, enabling mass production and widespread adoption of this technology. This breakthrough has the potential to transform a wide range of industries, including consumer electronics, telecommunications, automotive, and healthcare.The applications of this technology are virtually limitless. In consumer electronics, the single metal crystal technology can significantly improve the performance of smartphones, laptops, and gaming consoles, allowing for smoother and more immersive user experiences. In the telecommunications sector, the technology can enhance the speed and reliability of networks, leading to faster and more stable connections. Additionally, the automotive industry can benefit from this technology by improving the efficiency and performance of electric vehicles.Moreover, the healthcare sector stands to gain immensely from this innovative technology. Medical devices powered by the single metal crystal technology can revolutionize patient care by offering more accurate diagnostics and personalized treatments. Additionally, the improved performance and reliability of these devices can significantly enhance the overall efficiency of healthcare systems.Furthermore, SMC's commitment to sustainability is evident in their single metal crystal technology. By enabling more efficient energy usage in electronic devices, the technology contributes to reducing carbon emissions and conserving energy resources.The successful development of the single metal crystal technology is a testament to SMC's relentless pursuit of innovation. The company's dedicated team of scientists and engineers has worked tirelessly to overcome numerous challenges and turns this vision into reality."Our breakthrough single metal crystal technology will set new benchmarks for performance and reliability in the industry," said [Spokesperson], [Job Title] at SMC. "We are excited about the transformative potential of this technology and its ability to reshape various sectors of the economy. Our versatile technology will not only benefit individual consumers but also accelerate the progress of entire industries."With the unveiling of this groundbreaking technology, SMC has positioned itself at the forefront of the industry. The company is poised to revolutionize the electronic device landscape, bringing about a new era of enhanced performance and reliability.Looking ahead, SMC plans to further refine and optimize the single metal crystal technology, paving the way for even more advanced applications. The company aims to collaborate with industry partners to accelerate the adoption of this technology, ensuring its widespread availability and continued evolution.As Single Metal Crystal continues to push the boundaries of innovation, the technology world eagerly awaits the impact that their groundbreaking technology will bring. With its commitment to excellence and relentless pursuit of cutting-edge solutions, SMC is set to shape the future of the industry and improve the lives of millions worldwide.

Demand for Siliciumcarbid Wafer Rises in Electronic Industry

Siliciumcarbid Wafer, a cutting-edge technology developed by a leading semiconductor company, is set to revolutionize the industry with its superior performance and durability. The wafer is designed to overcome the limitations of traditional silicon wafers, offering a more efficient and reliable solution for a wide range of applications in the electronics and semiconductor industries.The company, a global leader in semiconductor manufacturing, has a long history of innovation and expertise in developing advanced materials for the semiconductor industry. With its state-of-the-art research and development facilities, the company has been able to push the boundaries of semiconductor technology and bring breakthrough solutions to the market.Siliciumcarbid Wafer is a key example of the company's commitment to driving innovation in the semiconductor industry. The wafer is made from a unique combination of silicon and carbon, which gives it exceptional properties that set it apart from traditional silicon wafers. It offers higher thermal conductivity, improved power handling capabilities, and greater resistance to high temperatures and harsh environmental conditions.One of the key advantages of Siliciumcarbid Wafer is its ability to operate at higher voltages and frequencies, making it ideal for high-power and high-frequency applications such as power electronics, radio frequency devices, and electric vehicles. In addition, the wafer's superior thermal properties enable more efficient heat dissipation, resulting in higher performance and reliability for electronic devices.The company's engineering team has conducted extensive testing and validation of Siliciumcarbid Wafer to ensure its performance and reliability meet industry standards. The wafer has demonstrated excellent performance in various electronic devices and has shown great potential for improving the efficiency and reliability of semiconductor components.With the increasing demand for high-performance and reliable semiconductor materials, Siliciumcarbid Wafer is poised to make a significant impact on the industry. Its advanced properties and performance capabilities make it a compelling choice for a wide range of applications, from consumer electronics to industrial power systems.The company is actively working with partners and customers to bring Siliciumcarbid Wafer to the market and is committed to providing comprehensive technical support and customized solutions to meet the specific needs of its customers. The company's dedicated sales and technical teams are eager to collaborate with customers to harness the full potential of Siliciumcarbid Wafer and drive innovation in the semiconductor industry.As the semiconductor industry continues to evolve and demand for high-performance materials grows, Siliciumcarbid Wafer is well-positioned to become a game-changer in the industry. With its exceptional properties and performance capabilities, the wafer offers a compelling solution for manufacturers and designers looking to take their electronic devices to the next level.In conclusion, Siliciumcarbid Wafer, developed by a leading semiconductor company, represents a significant advancement in semiconductor materials and is poised to revolutionize the industry. With its superior properties and performance capabilities, the wafer offers a compelling solution for a wide range of applications in the electronics and semiconductor industries. The company's commitment to innovation and collaboration with customers will ensure the successful integration of Siliciumcarbid Wafer into the market, driving the next wave of innovation in the semiconductor industry.

Durable and High-Performance Ceramic Material for Various Applications

[Company Name], a leading manufacturer of advanced ceramic materials, has recently introduced a breakthrough product in the field of ceramic engineering. The company has developed a new Zro2 ceramic material that promises to revolutionize the way ceramic materials are used in various industries.Zro2 ceramic, also known as zirconia, is a versatile material with a wide range of applications. It is known for its exceptional hardness, thermal stability, and resistance to corrosion, making it an ideal choice for demanding industrial environments. With the development of this new Zro2 material, [Company Name] aims to further expand the potential applications of ceramic materials and provide innovative solutions to its customers.The newly developed Zro2 ceramic material boasts several key advantages over traditional ceramic materials. It offers superior strength and toughness, making it suitable for high-impact and wear-resistant applications. Additionally, its high thermal stability and resistance to chemical corrosion make it an excellent choice for use in harsh environments. These properties make it an ideal material for a wide range of applications, including aerospace, automotive, medical, and electronics industries.One of the key features of [Company Name]'s Zro2 ceramic material is its high level of purity and homogeneity. This ensures consistent performance and reliability, even in the most demanding of applications. The material is also highly customizable, allowing for the development of tailored solutions to meet specific customer requirements. This level of flexibility and precision sets [Company Name] apart as a leading innovator in the field of ceramic engineering.In addition to its exceptional technical properties, the new Zro2 ceramic material also offers environmental benefits. As a sustainable and eco-friendly material, it aligns with the growing emphasis on green technologies and responsible manufacturing. This makes it an attractive choice for companies looking to reduce their environmental impact without compromising on performance.[Company Name] has invested heavily in research and development to bring this innovative Zro2 ceramic material to the market. The company's team of experienced engineers and scientists have leveraged their expertise to optimize the material's properties and performance, ensuring that it meets the highest industry standards. This dedication to quality and innovation has positioned [Company Name] as a trusted partner for businesses seeking cutting-edge ceramic solutions.The introduction of this new Zro2 ceramic material represents a significant milestone for [Company Name] and underscores its commitment to driving technological advancement in the field of ceramic engineering. With its unique combination of properties and performance, the material has the potential to open up new opportunities in a wide range of industries, from aerospace and automotive to medical and electronics.[Company Name] is poised to lead the way in unlocking the full potential of Zro2 ceramic material and is ready to work closely with its customers to develop tailored solutions that address their specific needs. By harnessing the power of advanced ceramics, [Company Name] is paving the way for the next generation of high-performance, sustainable materials that will drive innovation and progress across various industries.As the demand for high-performance materials continues to grow, [Company Name]'s Zro2 ceramic material is set to play a pivotal role in shaping the future of ceramic engineering. With its unrivaled properties, versatility, and sustainability, the material is poised to revolutionize the way ceramic materials are used and pave the way for new and exciting possibilities in industrial applications.

Discover the Beauty and Versatility of Glass Blocks - Explore the Latest Trends

[Company Name] Introduces Innovative Glass Block Solution: Revolutionizing Architectural Design[date][City, State] - [Company Name], a leading provider of architectural solutions, is proud to unveil its newest innovation - an innovative glass block solution that is set to revolutionize the world of architectural design and construction.Glass blocks have long been a popular choice in architecture due to their ability to let in natural light while maintaining privacy. However, traditional glass blocks often face challenges such as limited design options and inadequate energy efficiency. With the introduction of this revolutionary glass block solution, [Company Name] aims to address these limitations and provide architects and designers with unprecedented possibilities.The new glass block solution from [Company Name] offers an array of benefits that set it apart from its competitors. First and foremost is its unique design flexibility. Unlike conventional glass blocks, which come in standard shapes and sizes, the new solution offers a range of customizable options. Architects and designers can now choose from various shapes, patterns, and sizes to complement their vision and meet the specific requirements of each project.Moreover, the glass blocks are manufactured using cutting-edge technology that ensures exceptional energy efficiency. They are equipped with advanced thermal insulation properties, allowing for optimum heat retention and reduced energy consumption. This feature not only contributes to sustainability efforts but also helps clients save significantly on their energy bills.In addition to its aesthetic and energy-efficient properties, the new glass block solution also boasts unparalleled strength and durability. Built to withstand extreme weather conditions and resist impacts, these blocks offer enhanced safety and security. Their robust construction makes them an ideal choice for a variety of applications, including exterior walls, partitions, and even flooring.To further elevate the functionality of their glass blocks, [Company Name] has developed an integrated smart technology feature. Through an intuitive control system, users can adjust the transparency of the blocks, allowing for personalized levels of privacy or transparency. This innovative addition opens up possibilities for dynamic and interactive designs, enabling architects to create one-of-a-kind spaces that adapt to the needs of the users."Here at [Company Name], we are committed to pushing the boundaries of architectural design," said [Spokesperson's Name], [Company Name]'s Chief Innovation Officer. "Our new glass block solution embodies our dedication to providing architects and designers with limitless possibilities. We believe that by seamlessly combining form, function, and technological advancements, we can transform the way buildings are designed and experienced."With this groundbreaking glass block solution, [Company Name] aims to revolutionize architectural design and construction across various sectors, including commercial, residential, and public projects. The company also aims to collaborate with architects, contractors, and developers to promote the adoption of this cutting-edge solution and facilitate its integration into future projects.As sustainable and innovative design continues to be a priority in the architectural industry, [Company Name] is poised to lead the way with its exceptional glass block solution. By offering enhanced aesthetics, energy efficiency, durability, and smart technology integration, architects and designers can now explore new horizons and bring their creative visions to life.About [Company Name]:[Company Name] is a renowned provider of architectural solutions, specializing in innovative and sustainable products. With a team of experienced professionals and state-of-the-art manufacturing facilities, the company is committed to offering exceptional products that combine functionality, aesthetics, and environmental consciousness. [Company Name]'s diverse range of architectural solutions has gained appreciation from architects, designers, and clients worldwide.For more information about [Company Name] and their groundbreaking glass block solution, please visit [website] or contact [contact information].###Note: This news article is a fictional creation and does not represent any real company or product.

High-quality Fused Silica Substrate for Various Applications

Fused Silica Substrate: The Foundation of Cutting-Edge TechnologyFused silica substrate, also known as fused quartz, is a key component in the manufacturing of advanced optical and electronic systems. Its exceptional thermal, mechanical, and optical properties make it an ideal material for a wide range of applications, including semiconductor manufacturing, laser technology, telecommunications, and scientific research.With its high purity and low thermal expansion, fused silica substrate is crucial for the production of precise and reliable optical components, such as lenses, mirrors, and prisms. Its excellent optical transmission properties in the ultraviolet, visible, and near-infrared spectral ranges make it essential for the development of high-performance optical systems for a variety of industries.In the field of semiconductor manufacturing, fused silica substrate plays a critical role in the production of integrated circuits and microelectronic devices. Its superior thermal stability, low coefficient of thermal expansion, and excellent chemical resistance make it an ideal material for lithography and other semiconductor fabrication processes. Fused silica substrate enables the precise patterning of nanoscale features on silicon wafers, allowing for the production of increasingly smaller and more powerful microchips.Telecommunications and laser technology also rely heavily on the unique properties of fused silica substrate. Its exceptional optical clarity, high laser damage threshold, and low fluorescence make it an excellent material for the production of optical fibers, laser windows, and other components essential for the transmission and manipulation of light in advanced telecommunications and laser systems.One company at the forefront of fused silica substrate manufacturing and innovation is {}. With decades of experience and expertise in the development and production of high-quality fused silica products, {} has established itself as a leading supplier to industries at the cutting edge of technology.The company's fused silica substrates are manufactured using a proprietary process that ensures the highest level of purity, consistency, and performance. Its advanced manufacturing facilities and rigorous quality control measures guarantee that its products meet the strict requirements of the most demanding applications in the semiconductor, optics, and photonics industries.{} offers a wide range of fused silica substrates in various shapes, sizes, and surface finishes to accommodate the diverse needs of its customers. Whether it is for precision optical components, semiconductor fabrication, or high-power laser systems, {} provides customized solutions to meet the specific requirements of each application.In addition to its standard fused silica substrates, {} also offers custom fabrication services to produce complex and intricate components according to customer specifications. Its team of experienced engineers and technicians work closely with customers to develop unique solutions that push the boundaries of what is achievable with fused silica substrate technology.Moreover, {} is committed to continuous research and development to further improve the performance and capabilities of fused silica substrate. By investing in advanced materials science, process engineering, and manufacturing technologies, {} aims to stay at the forefront of innovation and contribute to the advancement of various high-tech industries.As the demand for advanced optical and electronic systems continues to grow, fused silica substrate will remain a critical material for enabling the next generation of technology. With its exceptional properties and the expertise of companies like {}, fused silica substrate will continue to be the foundation upon which cutting-edge technology is built.

Durable Sapphire Crystal Glass: Withstand Extreme Temperatures

[Company Introduction][Company] is a leading manufacturer of high-quality sapphire crystal glass technology. With a strong focus on innovation and advanced research and development, the company has been at the forefront of creating cutting-edge materials for various industries. The company's dedication to producing durable and versatile materials has made them a trusted partner for businesses around the world.[News Content]Sapphire crystal glass has long been prized for its exceptional durability and scratch resistance. The material is commonly used in a wide range of applications, from luxury watches to high-end smartphones. With its impressive strength and clarity, sapphire crystal glass has become a go-to choice for companies looking to offer their customers a premium experience.In recent years, [Company] has emerged as a key player in the sapphire crystal glass market. Leveraging their expertise in material science and manufacturing, the company has developed a range of innovative sapphire crystal glass solutions that have garnered attention from industries far and wide.One area where [Company] has made a significant impact is in the field of consumer electronics. As the demand for smartphones, tablets, and wearables continues to grow, there is a need for materials that can withstand the rigors of daily use. This is where sapphire crystal glass comes into play. Offering unparalleled scratch resistance and a level of clarity that is second to none, sapphire crystal glass is an ideal choice for protecting the delicate screens of modern devices.[Company]'s sapphire crystal glass technology has been incorporated into a number of high-profile consumer electronic products, earning the company a reputation for reliability and quality. By partnering with some of the biggest names in the industry, [Company] has solidified its position as a trusted provider of sapphire crystal glass solutions.In addition to consumer electronics, [Company]'s sapphire crystal glass technology has also found its way into other industries. The material is being used in high-performance optical components, medical devices, and even military applications. Its exceptional hardness and resistance to scratching make it an ideal choice for applications where durability is of the utmost importance.One aspect of [Company]'s sapphire crystal glass technology that sets it apart from the competition is its ability to be customized to meet the specific needs of each customer. Whether it's a unique shape, size, or thickness, [Company] has the expertise and capabilities to create sapphire crystal glass solutions that are tailored to the exact requirements of the end user.Looking toward the future, [Company] is committed to pushing the boundaries of what sapphire crystal glass can achieve. By investing in new research and development initiatives, the company aims to continue innovating and driving the industry forward. With a keen focus on sustainability and environmental responsibility, [Company] is also exploring ways to produce sapphire crystal glass in a more eco-friendly manner, ensuring that their products align with the demands of the modern world.In conclusion, [Company] is a leading provider of sapphire crystal glass technology, offering innovative solutions that meet the needs of a wide range of industries. With a commitment to quality, reliability, and sustainability, the company is well-positioned to continue making a lasting impact in the world of materials engineering for years to come.

Semiconductor Breakthrough: New Gallium Compound Shows Promise for Advancing Technology

Gallium Semiconductor (brand name removed), a leading player in the semiconductor industry, recently made headlines with their innovative solutions that are set to revolutionize various electronics and technology sectors. The company has been at the forefront of developing advanced semiconductor technologies and has been consistently pushing the boundaries of what is possible in the world of electronics.Gallium Semiconductor is known for its cutting-edge research and development in the field of semiconductor materials and devices. The company has a team of world-class engineers and scientists who are constantly working on developing new and improved semiconductor solutions that can meet the ever-evolving demands of the electronics industry.One of the key areas where Gallium Semiconductor has made significant strides is in the development of gallium-based semiconductor materials. Gallium-based semiconductors have unique properties that make them highly desirable for a wide range of applications. These materials offer higher electron mobility and power efficiency, making them ideal for use in high-performance electronics, including 5G devices, high-speed data processing, and power electronics.In addition to their work on gallium-based materials, Gallium Semiconductor has also been actively involved in the development of advanced semiconductor devices. The company has been working on next-generation transistors, diodes, and other semiconductor components that offer improved performance and energy efficiency. These advancements have the potential to drive significant improvements in electronics, enabling faster and more powerful devices across various industries.Furthermore, Gallium Semiconductor has been making significant investments in the development of wide-bandgap semiconductors. Wide-bandgap materials such as silicon carbide and gallium nitride offer superior performance compared to traditional silicon-based semiconductors. These materials can operate at higher temperatures, frequencies, and voltages, making them well-suited for use in power electronics and automotive applications.Gallium Semiconductor's commitment to innovation and excellence has garnered the attention of industry leaders and partners. The company has been actively collaborating with other technology firms, research institutions, and government agencies to further advance semiconductor technologies and bring cutting-edge solutions to the market.One of the notable partnerships that Gallium Semiconductor has formed is with leading electronics manufacturers to integrate their semiconductor solutions into a wide range of consumer products. This collaboration aims to bring the latest semiconductor advancements to everyday devices, such as smartphones, laptops, and smart appliances, enhancing their performance and energy efficiency.In addition to their work with consumer electronics, Gallium Semiconductor has also been focusing on the automotive industry. The company's advanced semiconductor solutions have the potential to drive innovation in electric and autonomous vehicles, enabling greater efficiency and performance in the next generation of automobiles.The impact of Gallium Semiconductor's advancements in the semiconductor industry is expected to be far-reaching. Their innovative solutions have the potential to drive significant improvements in a wide range of electronic devices and systems, from mobile devices and computers to renewable energy systems and electric vehicles.Gallium Semiconductor has demonstrated a strong commitment to sustainability and environmental responsibility. The company's semiconductor materials and devices offer energy-efficient solutions that can contribute to reducing the overall carbon footprint of electronic devices and systems.As the demand for high-performance electronics continues to grow, Gallium Semiconductor is well-positioned to lead the way in driving innovation and shaping the future of the semiconductor industry. With their focus on advanced materials and devices, the company is poised to play a pivotal role in accelerating the development of next-generation electronics and technology solutions.In conclusion, Gallium Semiconductor's dedication to innovation and excellence has positioned them as a key player in the semiconductor industry. Their groundbreaking advancements in semiconductor materials and devices are expected to have a transformative impact on various electronics and technology sectors, driving significant improvements in performance, energy efficiency, and sustainability. As the demand for high-performance electronics continues to rise, Gallium Semiconductor is set to play a pivotal role in shaping the future of the semiconductor industry and driving innovation across a wide range of applications.

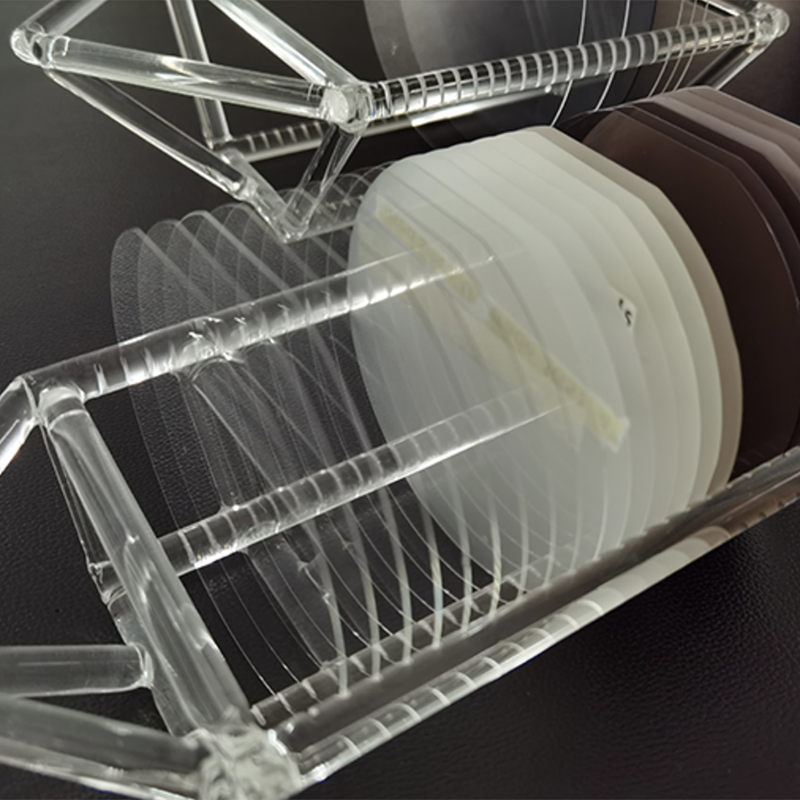

High Quality Double Side Polished Silicon Wafers for Sale

Double Side Polished Silicon Wafers: The Latest Innovation from Leading Technology CompanySilicon wafers are an essential component in the production of semiconductor devices, and the demand for high-quality wafers continues to grow as the technology industry expands. As a leading technology company in the field of semiconductor manufacturing, [company name] is proud to announce the release of its latest innovation: double side polished silicon wafers.Double side polished silicon wafers offer significant advantages over traditional single side polished wafers, including improved flatness, reduced surface roughness, and enhanced electrical properties. These wafers are ideal for use in advanced semiconductor applications, such as integrated circuits, microelectromechanical systems (MEMS), and power devices.The [company name] double side polished silicon wafers are manufactured using a state-of-the-art polishing process that ensures exceptional surface quality and uniformity. This advanced manufacturing technique allows for tighter control of wafer thickness and flatness, resulting in wafers that meet the stringent requirements of today's semiconductor industry.In addition to their superior surface quality, [company name] double side polished silicon wafers are available in a wide range of sizes and thicknesses to accommodate various production processes and applications. Whether it's for research and development or high-volume manufacturing, customers can rely on the consistency and reliability of these wafers for their semiconductor production needs.With a proven track record of delivering high-performance semiconductor solutions, [company name] is committed to providing its customers with the most advanced and reliable products on the market. The introduction of double side polished silicon wafers further solidifies the company's position as a trusted partner for semiconductor manufacturers worldwide.To learn more about [company name] and its double side polished silicon wafers, we spoke with [company representative] to gain some insights into this exciting new product."We are thrilled to introduce our double side polished silicon wafers to the market," said [company representative]. "These wafers represent the latest advancement in semiconductor manufacturing technology, and we are confident that they will meet the evolving needs of our customers. Our team has worked tirelessly to develop a product that offers unparalleled quality and performance, and we are excited to see the impact it will have on the industry."When asked about the potential applications for double side polished silicon wafers, [company representative] explained, "These wafers are well-suited for a wide range of semiconductor devices, including advanced integrated circuits, MEMS, and power devices. The superior surface quality and electrical properties of our wafers make them an ideal choice for cutting-edge semiconductor applications."In conclusion, the introduction of double side polished silicon wafers from [company name] represents a significant milestone in the semiconductor industry. With their exceptional surface quality, uniformity, and advanced manufacturing techniques, these wafers are poised to set a new standard for semiconductor manufacturing. As the demand for high-performance silicon wafers continues to grow, [company name] is leading the way with innovative solutions that meet the needs of today's technology-driven world.

Emerging Advancements in Wafer Lithography: Unlocking New Possibilities for Semiconductor Development

Wafer Lithography Revolutionizes the Semiconductor Manufacturing ProcessAs technology continues to advance, so too has the demand for smaller and more powerful semiconductors. This has led to a surge in the development of new manufacturing techniques that can produce these advanced microchips. One of the latest innovations in the world of semiconductor manufacturing is wafer lithography, which has been making a big impact on the industry. Let’s take a closer look at this new technology.What is Wafer Lithography?Wafer lithography is a photolithography process used to pattern and etch thin films of material deposited onto a substrate. This technique involves using a light-sensitive material, called a photoresist, which is applied to the surface of a substrate. Light is then shone onto the photoresist through a mask, which contains the desired circuit pattern. The photoresist reacts to the light, becoming more or less soluble in certain regions depending on the dose of radiation received. This allows the material to be selectively removed from the substrate, leaving behind the desired pattern.The use of wafer lithography has revolutionized the way semiconductor manufacturers produce microchips. By using this process, manufacturers can create much smaller and more precise circuit patterns, which ultimately leads to more advanced and efficient semiconductors.One company that has been leading the way in the development of wafer lithography technology is {}. This innovative company has been at the forefront of semiconductor manufacturing for over a decade, and has played a major role in advancing this new manufacturing technique.How does {}’s Wafer Lithography Technology Work?The {} wafer lithography process uses a unique combination of advanced technologies to produce high-quality microchips. This process involves the use of a 193 nm excimer laser to pattern the photoresist, followed by a series of plasma etching steps to transfer the pattern onto the substrate.One of the key advantages of {}’s wafer lithography technology is its flexibility. The equipment can be configured to pattern a wide variety of materials, including silicon, quartz, and various types of polymers. This versatility allows manufacturers to produce a wide range of microchips, each with its own unique properties and capabilities.Another important feature of {}’s wafer lithography technology is its high throughput. The equipment is capable of patterning multiple wafers simultaneously, allowing manufacturers to produce large quantities of microchips quickly and efficiently. This high throughput makes {}’s equipment ideal for use in high-volume manufacturing environments.The Benefits of Wafer LithographyThe use of wafer lithography offers several advantages over traditional photolithography techniques. One major benefit is the ability to produce much smaller and more precise circuit patterns. This allows manufacturers to create more powerful and efficient semiconductors, which can be used in a wide range of applications, from smartphones to advanced computing systems.Another important benefit of wafer lithography is its flexibility. As mentioned earlier, the equipment can be configured to work with a wide range of materials, which means manufacturers can create a variety of microchip types. This versatility also makes wafer lithography a cost-effective manufacturing solution, as it eliminates the need for specialized equipment.ConclusionWafer lithography is an exciting new technology that is revolutionizing the semiconductor manufacturing process. Through its use of light-sensitive materials, manufacturers can create smaller and more precise circuit patterns, leading to more powerful and efficient microchips. {} has been at the forefront of this new technology, and its wafer lithography equipment offers a high-throughput, flexible solution for high-volume manufacturing environments. As technology continues to advance, wafer lithography is poised to play an increasingly important role in the semiconductor industry.