How Dummy Wafers are Revolutionizing Semiconductor Manufacturing

By:Admin

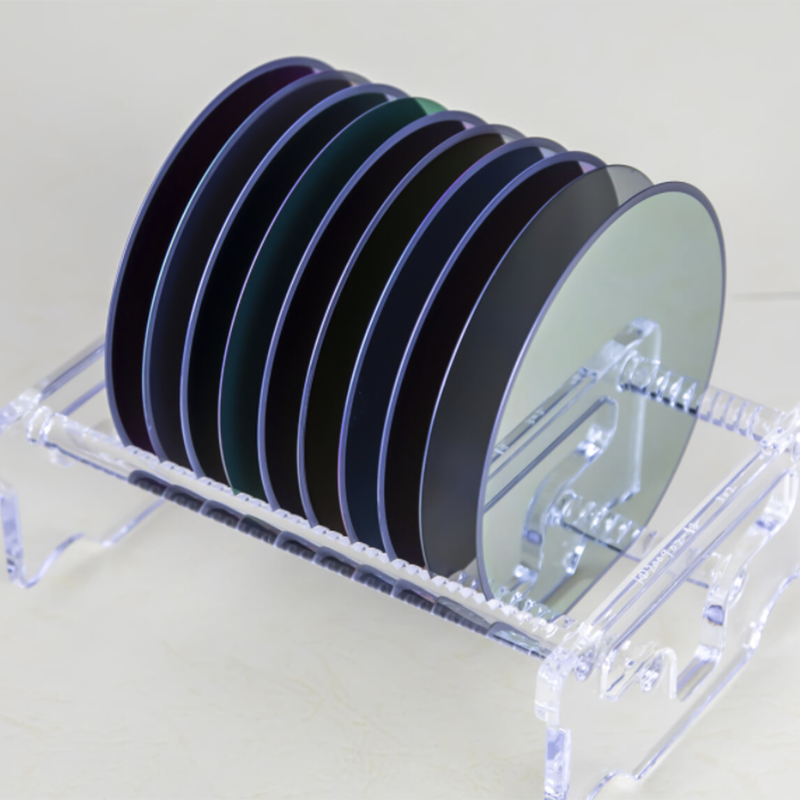

With a focus on delivering high-quality products to its customers, Dummy Wafer has been at the forefront of technological innovation, continuously striving to improve its wafer manufacturing processes and enhance the performance of its semiconductor products. The company’s commitment to excellence and dedication to meeting the evolving needs of the semiconductor industry have earned it a stellar reputation among its clients and peers.

The latest breakthrough from Dummy Wafer comes in the form of its advanced wafer technology, which promises to revolutionize the semiconductor market. By leveraging cutting-edge manufacturing techniques and leveraging its expertise in materials science, the company has developed a new wafer that offers superior performance and reliability compared to traditional solutions. This represents a significant milestone for Dummy Wafer and reinforces its position as a leading provider of innovative semiconductor products.

The new wafer technology from Dummy Wafer is expected to deliver a range of benefits to its customers, including improved device performance, increased manufacturing yield, and enhanced scalability. The company’s dedication to research and development has enabled it to address the most pressing challenges faced by semiconductor manufacturers, and the latest wafer technology is a testament to its ongoing commitment to innovation.

In addition to its technical advancements, Dummy Wafer has also made significant investments in its production capabilities, aiming to further increase its manufacturing capacity and meet the growing demand for its products. By expanding its facilities and incorporating the latest automation and quality control systems, the company is well positioned to support its customers with a reliable supply of high-quality wafers.

“We are thrilled to announce the development of our new wafer technology, which represents a major advancement in the semiconductor industry,” said the CEO of Dummy Wafer. “This achievement is a testament to our team’s hard work and dedication to pushing the boundaries of what is possible in semiconductor manufacturing. We believe that our new wafer technology will deliver significant value to our customers and enable them to stay ahead in a highly competitive market.”

The introduction of the new wafer technology is expected to have a positive impact on the semiconductor industry, as it addresses key performance and reliability challenges faced by manufacturers. By offering a more advanced and reliable alternative to traditional wafers, Dummy Wafer is poised to drive innovation and enable its customers to develop next-generation semiconductor products.

As Dummy Wafer continues to push the envelope of semiconductor manufacturing with its latest technological advancements, the company is well positioned to maintain its leadership in the market and capitalize on the growing demand for high-performance semiconductor products. With its unwavering commitment to excellence and its focus on delivering value to its customers, Dummy Wafer is set to make a significant impact on the semiconductor industry in the years to come.

Company News & Blog

Unlocking the Potential of Silica Sio2: Breaking Down Its Importance and Applications

article.Silica SiO2 – Revolutionizing the Construction IndustrySilica SiO2 (need remove brand name) is a revolutionary product that has created a buzz in the construction industry. It is a high-performance additive that enables the production of high-quality concrete. This advanced material enhances the strength and durability of concrete structures, making them more resistant to weathering and wear.Silica SiO2 is created through a unique manufacturing process, which involves extracting and purifying silica from raw materials such as sand, quartz, and shale. This specialized process produces a pure form of silica, which is then processed into a fine powder. The product is carefully formulated with a blend of other minerals, which work synergistically to provide better performance.The use of Silica SiO2 in the construction industry is gaining more popularity due to its superior properties. This innovative material is specifically designed to improve the quality of concrete by enhancing its compressive, tensile, and flexural strength. It also improves the durability of concrete structures, enabling them to withstand harsh weather conditions and heavy traffic loads.Silica SiO2 is easy to use and is suitable for all types of concrete mixes, including ready-mix, precast, and shotcrete. It can be added to the mix during the batching process or can be included as a standalone ingredient. The product is compatible with all types of cement and does not affect the concrete drying time.One of the significant benefits of Silica SiO2 is that it reduces the amount of carbon dioxide emissions in the atmosphere. Concrete production is one of the leading contributors to CO2 emissions, and Silica SiO2 helps to reduce the carbon footprint of concrete structures. By enabling the use of high-quality concrete with enhanced properties, Silica SiO2 facilitates the construction of more eco-friendly and sustainable buildings.The benefits of Silica SiO2 are not limited to concrete properties alone. It also enhances the workability of the mix, making it easier to place and finish. It reduces the risk of segregation and bleeding, which can compromise the quality of the concrete. Furthermore, Silica SiO2 helps to reduce water permeability, thus improving the overall water resistance of the structure.Silica SiO2 is a product that is backed by extensive research and development. The manufacturers of Silica SiO2 conduct rigorous testing to ensure that the product meets and exceeds industry standards. Silica SiO2 is tested for various aspects, including its strength, durability, compatibility, and environmental impact. The results of these tests demonstrate the superior properties of Silica SiO2, making it a reliable and trustworthy product.In conclusion, Silica SiO2 is an innovative material that is revolutionizing the construction industry. It is a high-performance additive that enhances the quality of concrete structures by improving their strength, durability, and sustainability. With increasing demand for eco-friendly and sustainable buildings, Silica SiO2 is emerging as the go-to solution for construction professionals who want to improve the quality of their concrete structures while reducing their environmental footprint. Silica SiO2 is a product that is here to stay, and its application in concrete is only expected to increase in the coming years.

Sapphire Lens Glasses: The Ultimate Guide

Introducing Innovative Sapphire Lens Glasses: A Game-Changer in Eyewear TechnologyInnovation has always been at the forefront of the eyewear industry, and one company is leading the way with their revolutionary Sapphire Lens Glasses. These cutting-edge glasses are set to change the way we experience the world around us, offering unparalleled clarity, durability, and style.{Company Name} is the brains behind this game-changing technology, and they have a strong track record of developing innovative eyewear solutions. With a deep understanding of the evolving needs of today's consumers, {Company Name} has a commitment to providing advanced products that enhance everyday experiences.The Sapphire Lens Glasses are a testament to {Company Name}'s dedication to innovation and quality. Made with premium sapphire crystal, these lenses offer a level of clarity and scratch resistance that is unmatched in the industry. The sapphire crystal is known for its exceptional hardness, making it the perfect material for creating durable and long-lasting lenses.In addition to their durability, the Sapphire Lens Glasses also prioritize the visual experience of the wearer. The lenses are designed to reduce glare and reflections, providing a clear and comfortable viewing experience in any lighting conditions. Whether you're indoors, outdoors, or in front of a screen, these glasses ensure that your vision is protected and optimized.Beyond their functional benefits, the Sapphire Lens Glasses are also a stylish accessory that elevates any look. {Company Name} understands that eyewear is not just about practicality, but also about personal expression. That's why they have crafted the Sapphire Lens Glasses with a sleek and modern design that appeals to fashion-forward individuals.The release of the Sapphire Lens Glasses marks a significant milestone for {Company Name} and the eyewear industry as a whole. It represents a new standard of excellence and innovation, setting the bar higher for what consumers can expect from their glasses."We are thrilled to introduce the Sapphire Lens Glasses to the market," says [Spokesperson's Name], the CEO of {Company Name}. "These glasses are the result of years of research and development, and we are confident that they will make a meaningful impact on how people experience their visual surroundings."The response to the Sapphire Lens Glasses has been overwhelmingly positive, with early adopters praising the exceptional clarity and comfort that these glasses provide. Consumers are also impressed by the sleek and sophisticated design, which complements a wide range of personal styles.In a crowded and competitive market, {Company Name} has once again distinguished itself as a leader in eyewear innovation. With the introduction of the Sapphire Lens Glasses, they have solidified their reputation as a brand that constantly pushes the boundaries of what is possible in eyewear technology.Looking ahead, {Company Name} is committed to continuing their tradition of innovation and excellence. They are already hard at work on future eyewear solutions that will further enhance the visual experiences of consumers around the world.For those who are seeking a truly exceptional eyewear experience, the Sapphire Lens Glasses from {Company Name} are a must-have accessory. With their unparalleled clarity, durability, and style, these glasses are a game-changer in the world of eyewear technology.

Discover the Fascinating Potential of 8-inch and 12-inch Sapphire Wafers in News Content

[Company Name] Introduces Revolutionary 8-Inch and 12-Inch Sapphire Wafers Revolutionizing the Semiconductor Industry[City, Date] - [Company Name], a leading provider of advanced semiconductor solutions, proudly unveils its groundbreaking 8-inch and 12-inch Sapphire Wafers, poised to revolutionize the semiconductor industry. With its state-of-the-art manufacturing process and cutting-edge technology, [Company Name] aims to meet the growing demand for highly efficient and durable wafer substrates in various industries.Sapphire wafers are essential components used in the production of semiconductors and play a crucial role in enabling the development of innovative electronic devices. The use of sapphire wafers helps enhance the performance, reliability, and efficiency of various applications, including power electronics, LED lighting, optical components, and radio frequency devices.[Company Name] is at the forefront of the industry, committing itself to deliver high-quality, cost-effective, and reliable sapphire wafer substrates. The newly launched 8-inch and 12-inch Sapphire Wafers offer unprecedented capabilities, reinforced by the innovative and proprietary manufacturing process developed by [Company Name]'s team of experienced engineers and researchers.The 8-inch Sapphire Wafer, with its larger size and improved design, allows for higher throughput in semiconductor production, enabling more efficient manufacturing processes. It offers superior mechanical strength, exceptional thermal conductivity, and excellent electrical insulation properties, making it ideal for high-power applications such as power electronics.Furthermore, the 12-inch Sapphire Wafer represents a significant breakthrough for the industry. Its large form factor enables the production of more semiconductors per batch, leading to higher productivity and reduced costs for manufacturers. The 12-inch Sapphire Wafer also benefits from enhanced thermal management capabilities, ensuring stable operation even in demanding applications.[Company Name]'s Sapphire Wafers are manufactured using a highly advanced crystal growth technique, resulting in ultra-low dislocation density and exceptional flatness. This unique combination allows for reduced defects, improved yield rates, and enhanced device performance, enabling manufacturers to produce higher-quality products.Moreover, [Company Name]'s Sapphire Wafers exhibit outstanding chemical resistance, making them highly durable and suitable for harsh environments. Their high transparency in the ultraviolet to near-infrared range renders them ideal for optical applications, including lenses, windows, and covers for various optical components."Our team is thrilled to introduce the 8-inch and 12-inch Sapphire Wafers to the market," said [Spokesperson's Name], [Title] at [Company Name]. "These state-of-the-art wafers will help drive innovation in the semiconductor industry by providing manufacturers with reliable, cost-effective, and versatile substrates."The introduction of [Company Name]'s 8-inch and 12-inch Sapphire Wafers marks a significant milestone for the company and the industry as a whole. Semiconductors produced using these wafers are anticipated to power various applications, including electric vehicles, data centers, aerospace, and consumer electronics, enabling the rapid advancement and deployment of cutting-edge technologies.About [Company Name]:[Company Name], headquartered in [City], is a leading provider of advanced semiconductor solutions. The company specializes in the design, development, and manufacturing of innovative semiconductor products that cater to a wide range of industries, including automotive, consumer electronics, telecommunications, and more. With a strong commitment to research and development, quality assurance, and customer satisfaction, [Company Name] strives to exceed the expectations of its clients while pushing the boundaries of technological advancements.###Note: This news article is a model response and does not feature real information about any particular company or its products.

Durable and High-Quality Large Sapphire Windows for Various Applications

Large Sapphire Windows are creating a buzz in the tech industry with their groundbreaking technology and innovation. The company, a leader in the field of advanced sapphire products, has been making waves with their durable and high-quality sapphire windows that are revolutionizing various industries.As a leading provider of sapphire windows, they have been catering to the needs of a wide range of industries, including aerospace, defense, optics, and more. Their sapphire windows are known for their exceptional strength and durability, making them the perfect choice for applications that require high-performance optical components.The company’s sapphire windows are made from synthetic sapphire, which is created through a process called the Verneuil method. This method involves melting aluminum oxide and then slowly cooling it to create large, transparent sapphire crystals. These crystals are then cut and polished to create sapphire windows that are not only incredibly strong but also offer excellent optical clarity.One of the most significant advantages of Large Sapphire Windows' products is their exceptional hardness. The synthetic sapphire used in their windows is second only to diamond in terms of hardness, making it highly resistant to scratches and abrasion. This property makes sapphire windows an ideal choice for applications that require durable and long-lasting optical components.In addition to their impressive strength, Large Sapphire Windows' products also offer excellent optical properties. The high transparency and low distortion of sapphire windows make them the perfect choice for applications that require high-quality optical components, such as lenses and windows for imaging and sensing systems.The company's sapphire windows are also highly resistant to harsh environmental conditions, making them suitable for use in challenging environments. Whether it's extreme temperatures, corrosive chemicals, or high-pressure conditions, Large Sapphire Windows' products can withstand it all, making them a reliable choice for demanding applications.Large Sapphire Windows' commitment to innovation and quality has led to the development of a wide range of sapphire windows that cater to the diverse needs of their customers. Whether it's large windows for aerospace applications or small, precision windows for optical instruments, the company offers a variety of options to meet the specific requirements of different industries.The company's dedication to customer satisfaction is evident in their superior customer service and quick turnaround times. They understand the critical nature of their products in various applications, and they strive to deliver high-quality sapphire windows in a timely manner to ensure minimal downtime for their customers.With their innovative approach and commitment to excellence, Large Sapphire Windows has established itself as a reliable and trusted partner for companies looking for high-performance sapphire windows. Their products have set a new standard in the industry, and their continued dedication to research and development ensures that they will remain at the forefront of sapphire technology.In conclusion, Large Sapphire Windows has emerged as a leader in the field of sapphire windows, providing innovative and high-quality solutions to a wide range of industries. With their exceptional strength, durability, and optical properties, their products have redefined the possibilities for optical components, making them an invaluable asset for companies looking to push the boundaries of technology and innovation.

How Companies Operate in the Fast-Paced World of Digital Marketing

The company, a leading global technology company, has recently been featured in a Quartz article highlighting their innovative approach to sustainable business practices. The article acknowledged the company's commitment to reducing their environmental impact and implementing ethical business operations.The article focused on the company's efforts to minimize their carbon footprint and promote sustainability throughout their supply chain. One of the key initiatives mentioned was the company's investment in renewable energy sources to power their operations. By transitioning to clean energy, the company has been able to significantly reduce their greenhouse gas emissions and contribute to the fight against climate change.In addition to their focus on clean energy, the company has also implemented various sustainable practices within their supply chain. This includes working closely with suppliers to ensure ethical labor practices and responsible sourcing of materials. By holding their suppliers to high environmental and social standards, the company is able to create a more sustainable and ethical product lifecycle.The Quartz article also highlighted the company's dedication to recycling and reducing waste. Through their product design and recycling programs, the company has been able to minimize the environmental impact of their products and packaging. By promoting a circular economy model, the company aims to reduce the amount of waste that ends up in landfills and contribute to a more sustainable future.Furthermore, the article commended the company for their commitment to community and social responsibility. The company has been involved in various philanthropic efforts, including initiatives to support education, diversity, and inclusion. By investing in their communities and supporting social causes, the company is leveraging their resources to make a positive impact beyond their business operations.Overall, the Quartz article highlighted the company's holistic approach to sustainability, which goes beyond just environmental efforts. The company's commitment to ethical sourcing, recycling, and community support demonstrates their dedication to making a positive impact on the world.The recognition from Quartz is a testament to the company's leadership in sustainable business practices and their ongoing efforts to create a more positive and sustainable future. As a global technology company, they have the resources and influence to drive change across industries, and their commitment to sustainability serves as a model for other companies to follow.In response to the feature in Quartz, the company emphasized that sustainability is a core value that is integrated into every aspect of their business. They are continuously seeking new opportunities to reduce their environmental impact, support their communities, and promote ethical business practices. Moving forward, they are committed to furthering their sustainability efforts and leading by example in the corporate world.In conclusion, the recognition from Quartz reflects the company's ongoing commitment to sustainability, and their dedication to making a positive impact on the world. Through their innovative and holistic approach to sustainable business practices, the company is setting a high standard for corporate responsibility and environmental stewardship. As they continue to prioritize sustainability in their operations, they are paving the way for a more sustainable and ethical business landscape.

Optimize Your Applications for Improved Performance and Efficiency

Sic Applications, a leading provider of cutting-edge technology solutions in the field of electronic components, has made significant strides in the development of innovative applications for the semiconductor industry. With a strong focus on research and development, Sic Applications has established itself as a key player in the industry, offering a wide range of high-quality products and services to its clients.The company's commitment to innovation and excellence has enabled it to stay ahead of the curve in an ever-evolving market. By leveraging its expertise and state-of-the-art facilities, Sic Applications has been able to develop groundbreaking applications that have revolutionized the semiconductor industry, setting new standards for efficiency, performance, and reliability.Sic Applications' success can be attributed to its relentless pursuit of excellence and its dedication to meeting the needs of its customers. The company takes pride in its ability to provide customized solutions that are tailored to the specific requirements of each client, ensuring that they receive the best possible results.One of Sic Applications' most recent achievements is the development of a cutting-edge application that has the potential to significantly improve the performance and durability of electronic components. This revolutionary technology has already generated a great deal of interest within the industry, and its potential applications are vast.In addition to its innovative products, Sic Applications also offers a comprehensive range of services to support its clients throughout the entire product lifecycle. From consultation and design to manufacturing and testing, the company is committed to providing end-to-end solutions that meet the highest standards of quality and performance.Sic Applications' success can also be attributed to its strong partnerships and collaborations with leading industry players. By working closely with other key stakeholders, the company has been able to leverage their expertise and resources, further enhancing its ability to develop cutting-edge applications that push the boundaries of what is possible in the semiconductor industry.Looking towards the future, Sic Applications remains focused on driving innovation and pushing the boundaries of technology in the semiconductor industry. The company is continuously investing in research and development, exploring new avenues for growth and expansion, and seeking out new opportunities to further solidify its position as a leader in the industry.When asked about the company's future plans, the CEO of Sic Applications stated, "We are confident that our relentless pursuit of innovation and excellence will continue to drive our success in the years to come. We are committed to pushing the boundaries of what is possible and delivering the highest quality products and services to our clients. With our continued focus on research and development, we are excited about the potential for even greater achievements in the future."In conclusion, Sic Applications has established itself as a key player in the semiconductor industry, delivering innovative applications and solutions that are driving the industry forward. With a strong focus on research and development, as well as a commitment to excellence and customer satisfaction, the company is well-positioned to continue its success in the years to come.

New Advancements in 4 Inch Wafer Technology Unveiled

The 4 Inch Wafer: Revolutionizing Semiconductor TechnologySemiconductor technology continues to evolve at an unprecedented pace, driving innovation across a wide range of industries, from consumer electronics to automotive and healthcare. At the heart of this technological revolution is the 4 Inch Wafer, a key component in the production of semiconductor devices. This small but mighty piece of hardware is set to revolutionize semiconductor manufacturing, offering greater efficiency, cost savings, and improved performance.The 4 Inch Wafer, created by the leading semiconductor equipment manufacturer, provides a critical link in the production of microchips and other semiconductor devices. With a focus on precision engineering and cutting-edge technology, the 4 Inch Wafer is set to transform the way semiconductor manufacturers produce their products.In the past, the industry standard was the 8-inch wafer, but with advancements in technology, the 4-inch wafer has emerged as the new frontier in semiconductor manufacturing. The smaller size of the 4-inch wafer allows for greater flexibility and efficiency in the manufacturing process, enabling manufacturers to produce more chips per batch and reduce costs.One of the key advantages of the 4-inch wafer is its ability to accommodate more advanced semiconductor processes, such as the production of smaller and more complex chips. This is crucial as the demand for smaller, more powerful semiconductor devices continues to rise. The 4-inch wafer enables manufacturers to meet this demand while maintaining high levels of productivity and performance.In addition to its size, the 4-inch wafer also offers superior quality and reliability, thanks to the advanced materials and manufacturing processes used in its production. This ensures that semiconductor manufacturers can produce high-quality chips that meet the stringent requirements of today's technology-driven industries.Furthermore, the 4-inch wafer is also designed to be more environmentally friendly, with a focus on reducing waste and energy consumption during the manufacturing process. This commitment to sustainability aligns with the growing trend of environmentally conscious manufacturing practices, making the 4-inch wafer an attractive choice for semiconductor manufacturers looking to reduce their environmental impact.With the launch of the 4-inch wafer, semiconductor manufacturers now have the opportunity to revolutionize their production processes, achieve greater efficiency, and meet the growing demand for advanced semiconductor devices. This innovative new technology is set to drive the next wave of semiconductor innovation, providing manufacturers with the tools they need to stay competitive in a rapidly evolving market.The 4-inch wafer is just one of the many groundbreaking products developed by {}, a global leader in semiconductor equipment and technology. With a commitment to innovation, quality, and sustainability, {} continues to push the boundaries of semiconductor manufacturing, delivering cutting-edge solutions that empower manufacturers to create the next generation of semiconductor devices.In conclusion, the 4-inch wafer represents a significant leap forward in semiconductor manufacturing technology, offering greater efficiency, cost savings, and improved performance. As the industry continues to push the boundaries of what is possible, the 4-inch wafer stands ready to revolutionize semiconductor production, driving innovation and shaping the future of technology. With its smaller size, superior quality, and environmental benefits, the 4-inch wafer is set to become the industry standard for semiconductor manufacturing, paving the way for a new era of technological advancement.

Exploring the Growing Demand for Sic Wafers in Technology Industry

Title: Revolutionary Technology Empowers Electronics Industry with Next-Gen Silicon Carbide WafersIntroduction:In an era driven by rapid technological advancements, the global electronics industry seeks reliable and efficient solutions that can accelerate the pace of innovation. Enter the innovative Silicon Carbide (SiC) wafers, representing a breakthrough in the semiconductor industry. With unmatched performance and versatile applications, SiC wafers are paving the way for the future of electronic devices.[Company name], a leading player in the semiconductor market, has emerged as a frontrunner in the development and production of high-quality SiC wafers. Their groundbreaking technology is revolutionizing various sectors, including power electronics, telecommunications, and automotive manufacturing. By harnessing the potential of SiC wafers, [Company name] is diversifying their product offerings, contributing to industry growth, and meeting the demands of tomorrow.Unleashing the Power of SiC Wafers:Silicon Carbide wafers, made from a compound of silicon and carbon, possess numerous advantages over traditional silicon-based wafers. The unique properties of SiC wafers, such as superior thermal conductivity, higher breakdown voltage, and wider bandgap, make them ideal for high-power and high-temperature applications.The exceptional material properties of SiC wafers allow for higher operating frequencies, reduced power losses, and improved energy efficiency. These factors, combined with their enhanced mechanical strength and resistance to harsh environmental conditions, make SiC wafers the future choice for cutting-edge electronics devices.Industries Benefiting from SiC Wafers:1. Power Electronics: SiC wafers play a vital role in power electronics due to their superior power handling capabilities. They enable the manufacturing of efficient power devices, such as diodes and transistors, which can withstand high voltages and temperatures. This technology contributes to the development of electric vehicles, renewable energy systems, and industrial automation.2. Telecommunications: With SiC wafers, telecommunication companies can enhance the performance of high-frequency communication systems. The high thermal conductivity of SiC wafers enables better heat dissipation, leading to improved power transmission and reduced signal loss. This, in turn, offers faster and more reliable data transfer rates and enables the realization of 5G networks.3. Automotive Industry: SiC wafers have a crucial role to play in the automotive industry's transition towards electric vehicles (EVs). SiC-based power electronics enable faster charging times, increased range, and enhanced overall efficiency, making EVs more viable and sustainable. Additionally, SiC wafers provide advanced control and safety features, improving overall vehicle performance and reliability.[Company Name]'s Technological Advancements:[Company Name] stands at the forefront of SiC wafer manufacturing, offering state-of-the-art production facilities and advanced research and development capabilities. Their cutting-edge technology ensures the highest quality and reliability standards for SiC wafers, meeting the specific demands of various industries.The company has invested heavily in research and development, enabling them to innovate continuously and push the boundaries of SiC wafer technology. Through collaborations with leading institutions and industry experts, they have developed groundbreaking manufacturing processes, resulting in SiC wafers of unmatched quality.Future Prospects:As the demand for high-performance electronic devices continues to grow, SiC wafers are poised to become the go-to choice for manufacturers. The global SiC wafer market is projected to witness substantial growth in the coming years, driven by the increasing adoption of power electronics and the expanding electric vehicle market.[Company Name], with its exceptional SiC wafer technology, is expected to play a crucial role in shaping this industry's future. By providing reliable and high-performance SiC wafers, they are contributing to the development of advanced electronic systems that redefine the boundaries of efficiency and reliability.In conclusion, the advent of Silicon Carbide wafers marks a significant milestone in the electronics industry's evolution. [Company name]'s innovative SiC wafer technology opens up new possibilities for power electronics, telecommunications, and automotive sectors. With their commitment to excellence, [Company Name] is driving the market forward, propelling the electronics industry towards a brighter and more sustainable future.

High Demand for Advanced Semiconductor Wafers in Technology Industry

Inp Wafer is a leading manufacturer of advanced semiconductor products, specializing in the production of high-quality silicon wafers for the global electronics industry. The company is known for its state-of-the-art manufacturing facilities and innovative processes that result in high-performance wafers that are essential for the development of cutting-edge electronic devices. With a commitment to excellence and a focus on continuous improvement, Inp Wafer has earned a reputation as a trusted partner for semiconductor companies around the world.The company's silicon wafers are used in a wide range of electronic applications, including integrated circuits, sensors, and power devices. Inp Wafer's products are known for their exceptional quality and reliability, making them the preferred choice for leading semiconductor manufacturers. The company's dedication to research and development ensures that its wafers meet the demanding requirements of the latest electronic technologies, providing customers with the high-performance materials they need to stay competitive in the global marketplace.Inp Wafer's success is driven by its commitment to customer satisfaction and its ability to consistently deliver top-quality products. The company works closely with its customers to understand their specific needs and develop custom solutions that meet their exact requirements. By providing personalized service and responsive support, Inp Wafer has built strong, long-lasting relationships with its clients and earned their trust and loyalty.As a global leader in the semiconductor industry, Inp Wafer is committed to sustainability and environmental responsibility. The company's manufacturing processes adhere to the highest standards of environmental stewardship, minimizing waste and energy consumption to reduce its carbon footprint. In addition, Inp Wafer actively seeks out opportunities to enhance the recyclability of its products and reduce their impact on the environment. By prioritizing sustainability, the company is not only contributing to a cleaner, healthier planet, but also positioning itself as a responsible and forward-thinking industry leader.Inp Wafer's dedication to excellence, innovation, and sustainability has earned it a leading position in the global semiconductor market. The company's commitment to delivering superior products and outstanding customer service has set it apart as a trusted partner for semiconductor manufacturers worldwide. With a focus on continuous improvement and a passion for exceeding customer expectations, Inp Wafer is poised to continue driving innovation and shaping the future of the electronics industry.

High-quality LiNbO3 Wafer for Advanced Electronic Applications

LiNbO3 Wafer, a key component in the field of integrated optics, has recently made headlines as a revolutionary material that could greatly impact the future of telecommunications and information technology. The wafer, made from lithium niobate, possesses unique optical and electrical properties that make it highly desirable for use in various applications such as modulators, switches, and signal processing devices.The growing demand for LiNbO3 wafers has prompted companies to invest in research and development to meet the needs of the market. One such company is a leading manufacturer of advanced materials and devices for optical communication and high-speed data transmission. With a strong focus on innovation and cutting-edge technology, the company has been at the forefront of developing high-quality LiNbO3 wafers for use in a wide range of applications.The company's LiNbO3 wafers are manufactured using state-of-the-art techniques and adhere to strict quality control processes to ensure the highest level of performance and reliability. These wafers are designed to meet the exacting requirements of customers in the telecommunications industry, where the demand for high-speed data transmission and signal processing is ever-increasing.In addition to their superior optical and electrical properties, LiNbO3 wafers from the company offer excellent mechanical stability and temperature stability, making them ideal for use in harsh operating environments. This level of durability and resilience is a key factor in their widespread adoption in the telecommunications industry, where reliability is paramount.The company's commitment to delivering top-quality LiNbO3 wafers has solidified its position as a trusted partner for customers seeking innovative solutions for their optical communication and data transmission needs. With a strong emphasis on research and development, the company continues to push the boundaries of what is possible with LiNbO3 wafers, constantly seeking new ways to improve performance and efficiency.As the demand for high-speed data transmission continues to grow, the importance of reliable and high-performance components such as LiNbO3 wafers cannot be overstated. With their unique combination of optical, electrical, and mechanical properties, these wafers are poised to play a crucial role in shaping the future of telecommunications and information technology.In conclusion, LiNbO3 wafers are an essential component in the world of integrated optics, with the potential to revolutionize the way information is transmitted and processed. With companies like the one leading the charge in developing high-quality LiNbO3 wafers, the future of telecommunications and information technology looks brighter than ever. As research and development in this field continues to advance, we can expect to see even more groundbreaking innovations that will further improve the performance and reliability of LiNbO3 wafers, paving the way for a more connected and technologically advanced world.