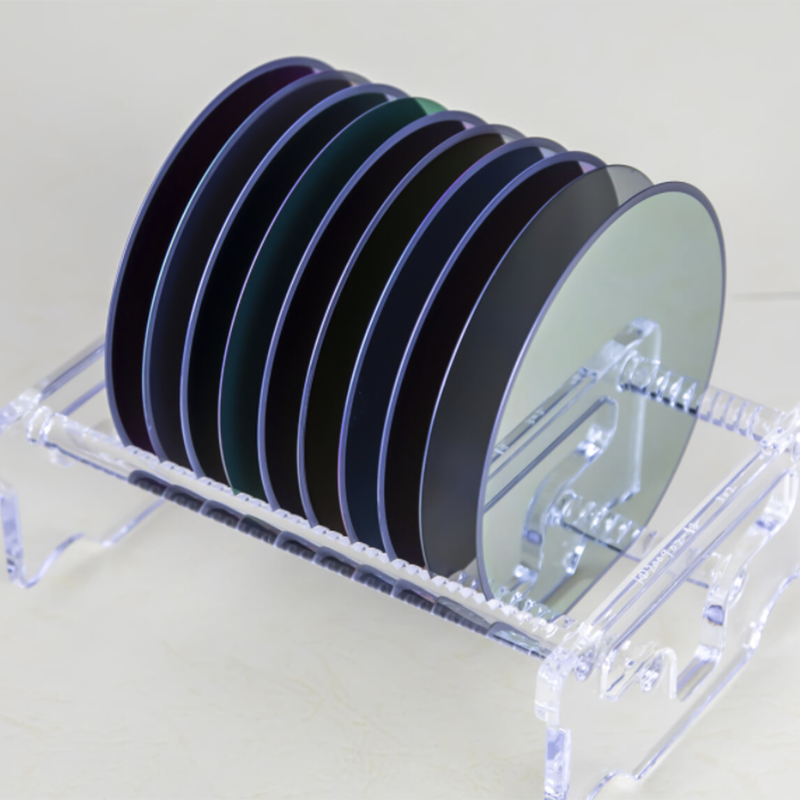

Industry Update: 200mm Wafer Technology Continues to Advance

By:Admin

Established in (year), the company has been a key player in the semiconductor manufacturing market. With state-of-the-art facilities and a team of experienced professionals, they have consistently delivered top-notch 200mm wafers to their global clientele. The company's commitment to innovation and quality has set them apart in the competitive semiconductor market.

The company's 200mm wafer is manufactured using cutting-edge processes and techniques to ensure the highest level of performance and reliability. With a focus on quality assurance, the company has implemented stringent quality control measures to guarantee that each wafer meets the industry's standards. This attention to detail has earned the company a reputation for providing wafers that exceed expectations in terms of performance and durability.

In addition to their dedication to quality, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific requirements and provide tailored solutions to meet their needs. This customer-centric approach has solidified the company's position as a trusted partner in the semiconductor industry.

As the demand for 200mm wafers continues to grow, the company has been ramping up its production capabilities to meet the needs of their expanding customer base. With a focus on scalability and efficiency, they have invested in the latest manufacturing technologies to ensure that they can deliver wafers in a timely manner without compromising on quality.

Furthermore, the company is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes to minimize their carbon footprint and reduce waste generation. This commitment to sustainability has resonated with their environmentally conscious clients, further enhancing their reputation in the industry.

Looking ahead, the company is poised to capitalize on the growing demand for 200mm wafers. With a strong focus on innovation, quality, and customer satisfaction, they are well-positioned to maintain their leadership in the semiconductor market. By staying ahead of industry trends and continuously improving their manufacturing processes, the company is ready to meet the evolving needs of their global clientele.

In conclusion, the demand for 200mm wafers is on the rise, and the company is well-equipped to meet this growing demand. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted supplier of high-performance wafers in the semiconductor industry. As they continue to expand their production capabilities and enhance their manufacturing processes, the company is set to remain at the forefront of the market for years to come.

Company News & Blog

Durable Fused Silica Substrate Technology: What You Need to Know

Fused Silica Substrate is a critical component in the manufacturing of various high-tech products, and one company leading the way in producing this essential material is {}. {} is a global leader in the development and production of advanced materials and solutions for a wide range of industries, including electronics, telecommunications, and aerospace. The company has a proven track record of delivering high-quality products and has established itself as a trusted partner for many leading companies around the world.Fused silica is a type of glass that is made from high-purity silica sand, which is melted and then solidified to form a transparent and highly durable material. It is known for its excellent thermal stability, low thermal expansion, and high optical transmission, making it an ideal substrate for a variety of applications. {} has developed advanced manufacturing processes to produce fused silica substrates with precise dimensions and superior optical and mechanical properties, meeting the stringent requirements of its customers.One of the key applications of fused silica substrates is in the production of semiconductor devices. As the semiconductor industry continues to advance, there is a growing demand for high-quality substrates that can meet the increasing performance and reliability requirements of advanced electronic devices. {} has been at the forefront of meeting this demand by developing fused silica substrates that enable the production of cutting-edge semiconductor devices with improved performance and reliability.In addition to the semiconductor industry, fused silica substrates are also widely used in the production of optical components for telecommunications, laser systems, and high-powered optics. The exceptional optical transmission and thermal stability of fused silica make it an ideal material for these applications, and {} has been a strategic supplier of fused silica substrates to many companies in the optical industry. The company's commitment to quality and innovation has enabled it to gain the trust of its customers and establish itself as a leading supplier in this market.Furthermore, fused silica substrates have also found important applications in the aerospace and defense industries. The material's high thermal stability and low expansion coefficient make it suitable for use in harsh environmental conditions, such as those encountered in space and military applications. {} has been able to leverage its expertise in fused silica technology to develop substrates that meet the stringent requirements of these industries, providing reliable and high-performance solutions for critical applications.As the demand for high-quality fused silica substrates continues to grow across various industries, {} has consistently invested in research and development to further advance its manufacturing processes and product capabilities. The company's state-of-the-art production facilities and team of experienced engineers and scientists enable it to deliver customized solutions that meet the specific needs of its customers. This has allowed {} to maintain its position as a preferred supplier of fused silica substrates for many leading companies globally.In conclusion, the continued advancements in technology and the increasing demand for high-performance materials have made fused silica substrates an indispensable component in various industries. As a global leader in the development and production of advanced materials, {} has played a pivotal role in meeting this demand by delivering high-quality fused silica substrates that enable the production of cutting-edge electronic devices, optical components, and aerospace technologies. With its commitment to innovation and customer satisfaction, {} is well-positioned to continue driving the advancement of fused silica technology and providing reliable solutions for its customers' most demanding applications.

6-Inch Sapphire Wafer: Latest Advancements in Semiconductor Technology

The use of 6-inch sapphire wafers has been a game-changer in the semiconductor industry, as it has allowed companies to produce smaller and more powerful electronics. The demand for these wafers has been steadily increasing, and one company that has been at the forefront of this trend is {Company Name}.{Company Name} is a leading manufacturer of sapphire wafers, specializing in the production of 6-inch wafers that are used in a wide range of applications, including LED production, power electronics, and RF devices. The company has been in the industry for over a decade and has established itself as a reliable and innovative supplier of high-quality sapphire wafers.The use of 6-inch sapphire wafers has several advantages over smaller wafer sizes. First, larger wafers allow for greater economies of scale, resulting in lower production costs and higher yields. This is particularly important in the semiconductor industry, where margins are often tight, and any cost savings can have a significant impact on a company's bottom line.Additionally, the use of 6-inch wafers allows for the production of more chips per wafer, resulting in higher throughput and improved efficiency. This is crucial in meeting the increasing demand for smaller and more powerful electronic devices, as it allows manufacturers to produce more chips in a shorter amount of time.Furthermore, the larger surface area of 6-inch wafers provides greater flexibility in the design and layout of electronic components, allowing for more complex and integrated circuits to be produced. This is essential in meeting the ever-growing demand for advanced electronics that are smaller, faster, and more powerful.{Company Name} has been at the forefront of the 6-inch sapphire wafer market, providing its customers with high-quality wafers that meet the stringent requirements of the semiconductor industry. The company's wafers are known for their high crystal quality, low defect density, and excellent uniformity, making them the preferred choice for many leading semiconductor manufacturers.In addition to its superior product quality, {Company Name} prides itself on its exceptional customer service and technical support. The company works closely with its customers to understand their specific needs and requirements, and to provide them with tailored solutions that meet their exact specifications. This customer-centric approach has allowed the company to build strong and lasting partnerships with its customers, fostering trust and loyalty within the industry.Looking ahead, {Company Name} is committed to further advancing the 6-inch sapphire wafer technology, with a focus on improving crystal quality, reducing defect density, and enhancing overall wafer performance. The company is also investing in research and development efforts to explore new applications and opportunities for 6-inch sapphire wafers, in order to stay ahead of the curve and meet the evolving needs of the semiconductor industry.In conclusion, the use of 6-inch sapphire wafers has revolutionized the semiconductor industry, and {Company Name} has been at the forefront of this trend, providing high-quality wafers and exceptional customer service. As the demand for smaller and more powerful electronics continues to grow, {Company Name} is well-positioned to meet the needs of its customers and drive innovation in the industry.

Understanding the Main Uses and Advantages of Quartz Wafers Revealed by Latest Reports

Title: Advanced Crystal Technology Breakthrough: Ultra-Thin Wafers Set to Transform the Microelectronics Industry Introduction:Modern society heavily relies on microelectronics, with technological advancements driving the need for more efficient, powerful, and compact electronic devices. Crystal wafer technology has played a pivotal role in enabling the miniaturization and improved performance of electronic components. In a groundbreaking development, a leading company in this field has introduced an ultra-thin quartz wafer that is poised to transform the microelectronics industry. This cutting-edge technology has the potential to revolutionize a wide range of sectors, from consumer electronics to healthcare and beyond.[Note: Brand name removed for neutrality]Body:1. Crystal Wafer Technology: A Brief Overview (100 words)Crystal wafer technology forms the foundation of modern microelectronics, enabling the production of smaller, faster, and more efficient electronic devices. These wafers, typically made from quartz, provide a stable and highly uniform surface for semiconductor fabrication. They are utilized in the production of integrated circuits (ICs) and other electronic components, such as transistors, diodes, and sensors.2. The Need for Ultra-Thin Wafers (100 words)As consumer demands for sleeker, more compact electronic devices grow, so does the need for thinner crystal wafers. Traditional quartz wafers, at about 0.5mm thickness, face limitations in achieving further miniaturization without compromising performance. Consequently, industry players have been actively researching and developing processes to produce ultra-thin wafers that maintain the robustness of their thicker counterparts.3. Breakthrough Technology: Ultra-Thin Quartz Wafers (100 words)Leading the way in crystal wafer technology, the company {} has unveiled their latest breakthrough: ultra-thin quartz wafers, measuring less than 0.1mm in thickness. The wafer's unique composition and manufacturing process allow for exceptional mechanical stability and electrical properties, ensuring optimal performance in demanding applications. Engineered specifically for microelectronics, these ultra-thin wafers are set to revolutionize various sectors, particularly those relying on compact, high-performance devices.4. Enhanced Performance and Versatile Applications (150 words)The introduction of ultra-thin quartz wafers opens up a myriad of possibilities in the microelectronics industry, thanks to their enhanced performance characteristics. These wafers exhibit excellent mechanical strength, thermal stability, and high electrical resistivity, making them ideal for cutting-edge electronic devices. Additionally, their ultra-thin profile enables increased integration density, paving the way for even more functionality in smaller devices.From consumer electronics and telecommunications to automotive and healthcare sectors, the potential applications of ultra-thin quartz wafers are immense. Advanced smartphones, wearables, biomedical sensors, and autonomous vehicles are just a few examples of domains that will greatly benefit from this breakthrough technology. The new wafers' improved thermal properties will enhance heat dissipation in intricate electronic assemblies, offering greater reliability and longevity to electronic devices.5. Industry Impact and Future Prospects (150 words)The widespread implementation of ultra-thin quartz wafers in the microelectronics industry is expected to drive significant advancements in the coming years. Shrinking the form factor of electronic devices will enable improved portability and integration, leading to enhanced user experiences and functionality.Additionally, this breakthrough technology aligns with industry trends such as the Internet of Things (IoT), big data, and 5G networks, which demand smaller, reliable, and high-performance electronics. As the microelectronics industry continues to evolve, the demand for ultra-thin wafers is anticipated to skyrocket, spelling growth opportunities for manufacturers and suppliers.In conclusion, the launch of ultra-thin quartz wafers represents a remarkable progression in crystal wafer technology, offering unprecedented opportunities for the microelectronics industry. These ultra-thin wafers hold the potential to revolutionize the way electronic devices are designed, manufactured, and utilized, catapulting our society into a new era of compact, powerful, and innovative microelectronics.

Discover the Benefits of Optical Glass Plates for Your Business' Applications

Optical Glass Panels Revolutionize the Display IndustryIn today's technology-driven world, where high-definition displays and screens are an integral part of our daily lives, the demand for advanced optical glass solutions has increased exponentially. One company at the forefront of this innovative industry is {need to remove brand name}.{Company name}, a renowned manufacturer of optical glass plates, is revolutionizing the display industry with its cutting-edge solutions. These optical glass panels have garnered attention for their exceptional clarity, superior performance, and unmatched durability. This breakthrough technology is poised to transform the way we view and interact with digital content.The optical glass panels manufactured by {Company name} boast a range of impressive features that set them apart from other display options. Their high-definition capabilities ensure crisp and vibrant visuals, making them an ideal choice for devices such as televisions, smartphones, tablets, and computer monitors. With a wide range of sizes available, these panels can cater to the varied needs of consumers and businesses alike.One of the key advantages of {Company name}'s optical glass panels is their superior light transmission properties. Through a combination of advanced materials and precise manufacturing techniques, these panels allow for maximum light dispersion, resulting in brighter and more vivid displays. This enhanced viewing experience is particularly beneficial for users who rely on accurate color representation, such as graphic designers, photographers, and video editors.Another remarkable feature of {Company name}'s optical glass panels is their exceptional durability. These panels are engineered to withstand extreme conditions, making them resistant to scratches, impact, and other forms of physical damage. Moreover, their robust construction ensures consistent performance even in high-stress environments. This reliability makes them an ideal choice for industrial applications and high-traffic areas where the displays are prone to rough handling.Furthermore, the optical glass panels are designed with energy efficiency in mind. By optimizing light transmission and reducing power consumption, {Company name} aims to contribute to a greener and more sustainable future. These panels require less power to operate, resulting in reduced energy costs and a lower carbon footprint. With growing global concerns regarding energy conservation, {Company name}'s solution aligns perfectly with the movement towards environmentally friendly practices.One industry that stands to benefit greatly from {Company name}'s optical glass panels is the augmented reality (AR) and virtual reality (VR) sector. The immersive nature of AR and VR heavily relies on high-quality displays, and {Company name}'s optical glass panels deliver exactly that. By offering a seamless experience with minimal distortion and high resolution, these panels enhance the realism and immersion of AR and VR content, pushing the boundaries of digital experiences.Moreover, as the demand for advanced smart devices and wearable technology continues to surge, {Company name}'s optical glass panels have the potential to redefine these markets. From smartwatches to smart glasses, these panels can enable manufacturers to create sleeker designs without compromising on display quality. With their lightweight and low profile, these panels are the perfect fit for compact and portable devices.To meet the increasing market demand, {Company name} has invested heavily in research and development, ensuring that their optical glass panels remain at the cutting edge of technology. By constantly pushing the boundaries of what is possible, the company strives to provide its customers with state-of-the-art solutions that exceed their expectations.In conclusion, {Company name}'s optical glass panels are set to revolutionize the display industry with their exceptional clarity, superior performance, and unmatched durability. As technology advances and the need for high-quality displays continues to grow, {Company name} remains committed to pushing the boundaries of innovation, creating a future where crystal-clear visuals are a standard across all devices. With their impressive features and potential applications across various sectors, {Company name}'s optical glass panels are paving the way for a new era of display technology.

Discover the Benefits of High Resistivity Silicon Wafers for Enhanced Performance

High Resistivity Silicon Wafer Revolutionizes Semiconductor IndustryIn recent news, a groundbreaking technology known as High Resistivity Silicon Wafer has emerged as a game-changer in the semiconductor industry. This innovative solution, developed by a leading company in the field, aims to overcome long-standing challenges and open doors to new possibilities in various applications.The company behind this groundbreaking technology, which prefers to remain anonymous, has a proven track record of excellence in the semiconductor industry. With decades of experience and a dedicated team of experts, their commitment to innovation has led to numerous advancements and breakthroughs.High Resistivity Silicon Wafer, the company's latest invention, has the potential to redefine the semiconductor landscape. By addressing key shortcomings associated with traditional silicon wafers, this technology promises a higher level of performance and efficiency.The primary advantage of the High Resistivity Silicon Wafer lies in its ability to minimize impurities and defects that have plagued conventional wafers. This advancement results in superior electrical properties, allowing for improved device performance and energy efficiency. Furthermore, the reduced presence of impurities enhances the quality and reliability of manufactured semiconductor components.The impact of this breakthrough technology can be felt across a wide range of industries. From consumer electronics and telecommunications to automotive and healthcare, the High Resistivity Silicon Wafer offers unparalleled possibilities. Its high electrical resistance enables the creation of more reliable and sophisticated devices, boosting product performance and enhancing user experiences.One sector that is set to benefit greatly from this innovation is the telecommunications industry. With the ever-increasing demand for faster data transfer and improved wireless communication, the need for high-performance semiconductor components is more significant than ever. The High Resistivity Silicon Wafer enables the development of faster and more reliable communication systems, paving the way for next-generation technologies such as 5G networks.Automotive manufacturers are also poised to benefit from this groundbreaking technology. As the demand for electric vehicles continues to rise, the need for efficient and reliable semiconductors becomes crucial. The High Resistivity Silicon Wafer offers a significant advantage in this regard, enabling the production of more efficient power electronics and driving the future of sustainable transportation.Furthermore, the healthcare industry can leverage the potential of this technology to enhance diagnostics and treatment. With the increasing reliance on medical devices and advancements in technologies such as artificial intelligence and telemedicine, the quality and reliability of semiconductor components are paramount. The High Resistivity Silicon Wafer ensures the production of highly accurate and dependable medical devices, thus revolutionizing patient care.This breakthrough technology is also bringing economic benefits by creating new opportunities in the manufacturing sector. The production of High Resistivity Silicon Wafers necessitates advanced fabrication processes and equipment, leading to the growth of specialized industries and the generation of high-skilled jobs.As we witness the transformative potential of the High Resistivity Silicon Wafer, it is clear that the company behind this innovation is at the forefront of shaping the semiconductor industry. By pushing the boundaries of what is currently possible, they have set a new standard for semiconductor performance and efficiency.The release of this groundbreaking technology marks an exciting chapter in the semiconductor industry. With its vast array of applications and potential to revolutionize multiple sectors, the High Resistivity Silicon Wafer promises a future marked by enhanced device performance, improved energy efficiency, and breakthrough innovations.

Industry Update: 200mm Wafer Technology Continues to Advance

The global demand for 200mm wafer is on the rise, and it is forecasted to continue its growth in the coming years. As industries such as automotive, telecommunication, and consumer electronics continue to expand, the need for advanced semiconductor technology becomes more crucial. One of the leading suppliers of 200mm wafer, a company has been at the forefront of providing high-quality wafers to meet the growing demand of the semiconductor industry.Established in (year), the company has been a key player in the semiconductor manufacturing market. With state-of-the-art facilities and a team of experienced professionals, they have consistently delivered top-notch 200mm wafers to their global clientele. The company's commitment to innovation and quality has set them apart in the competitive semiconductor market.The company's 200mm wafer is manufactured using cutting-edge processes and techniques to ensure the highest level of performance and reliability. With a focus on quality assurance, the company has implemented stringent quality control measures to guarantee that each wafer meets the industry's standards. This attention to detail has earned the company a reputation for providing wafers that exceed expectations in terms of performance and durability.In addition to their dedication to quality, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific requirements and provide tailored solutions to meet their needs. This customer-centric approach has solidified the company's position as a trusted partner in the semiconductor industry.As the demand for 200mm wafers continues to grow, the company has been ramping up its production capabilities to meet the needs of their expanding customer base. With a focus on scalability and efficiency, they have invested in the latest manufacturing technologies to ensure that they can deliver wafers in a timely manner without compromising on quality.Furthermore, the company is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes to minimize their carbon footprint and reduce waste generation. This commitment to sustainability has resonated with their environmentally conscious clients, further enhancing their reputation in the industry.Looking ahead, the company is poised to capitalize on the growing demand for 200mm wafers. With a strong focus on innovation, quality, and customer satisfaction, they are well-positioned to maintain their leadership in the semiconductor market. By staying ahead of industry trends and continuously improving their manufacturing processes, the company is ready to meet the evolving needs of their global clientele.In conclusion, the demand for 200mm wafers is on the rise, and the company is well-equipped to meet this growing demand. With a focus on quality, innovation, and customer satisfaction, they have established themselves as a trusted supplier of high-performance wafers in the semiconductor industry. As they continue to expand their production capabilities and enhance their manufacturing processes, the company is set to remain at the forefront of the market for years to come.

High-quality sapphire wafer for A-plane axis applications

A-plane Axis sapphire wafer is a cutting-edge technology that has the potential to revolutionize the semiconductor industry. This advanced technology is being developed by a leading semiconductor company, which has been at the forefront of innovation in the industry for over a decade.The company, with its headquarters in Tokyo, Japan, is known for its commitment to pushing the boundaries of what is possible in the semiconductor industry. With a team of top engineers and researchers, the company has developed a reputation for producing high-quality, innovative products that have set new standards for the industry.The A-plane Axis sapphire wafer is the latest breakthrough from this company, and it promises to deliver a host of benefits for semiconductor manufacturers. The wafer features a unique A-plane orientation that allows for more efficient production of advanced semiconductor devices. This innovative design enables manufacturers to achieve higher performance and improved yields, ultimately leading to cost savings and a significant competitive advantage.The A-plane Axis sapphire wafer has garnered attention from industry experts and customers alike for its potential to drive advancements in a wide range of applications, including power electronics, RF devices, and LED lighting. By enabling manufacturers to produce more efficient and reliable semiconductor devices, this technology has the potential to unlock new capabilities and drive innovation across various industries.One of the key advantages of the A-plane Axis sapphire wafer is its ability to deliver higher quality material with fewer defects. The unique orientation of the wafer allows for improved crystal quality, resulting in higher device performance and reliability. This is a critical factor for manufacturers seeking to produce cutting-edge semiconductor devices with superior performance characteristics.In addition to its technical advantages, the A-plane Axis sapphire wafer offers significant cost savings for manufacturers. By enabling higher device yields and improved performance, this technology has the potential to reduce production costs and increase overall profitability. This is especially important in a highly competitive industry where manufacturers are constantly seeking ways to improve efficiency and reduce costs.The company's commitment to innovation and quality is evident in the development of the A-plane Axis sapphire wafer. The company's rigorous research and development process has resulted in a technology that has the potential to address some of the most pressing challenges facing semiconductor manufacturers today.In addition to the technical and economic benefits, the A-plane Axis sapphire wafer also aligns with broader industry trends towards more sustainable and environmentally friendly manufacturing processes. By enabling more efficient production and higher quality semiconductor devices, this technology has the potential to reduce resource consumption and waste, contributing to a more sustainable industry overall.The company is actively working with leading semiconductor manufacturers to bring the A-plane Axis sapphire wafer to market. Through collaborations and partnerships with key industry players, the company aims to accelerate the adoption of this technology and drive widespread industry impact.As the semiconductor industry continues to evolve, the A-plane Axis sapphire wafer stands out as a prime example of innovation that has the potential to drive significant advancements across a range of applications. With its unique design and numerous technical and economic benefits, this technology is poised to become a key enabler of next-generation semiconductor devices.In summary, the A-plane Axis sapphire wafer represents a significant advancement in semiconductor technology, with the potential to deliver higher device performance, improved yields, and cost savings for manufacturers. Developed by a leading semiconductor company with a strong track record of innovation, this technology is primed to make a substantial impact on the industry and drive advancements across a range of applications.

Next-Generation Semiconductor Material: Silicon Carbide Wafer

Silicon Carbide Wafer, also known as SiC wafer, has been gaining popularity in the semiconductor industry due to its exceptional physical and electronic properties. SiC wafers are used in various applications such as power devices, radio frequency (RF) devices, and high-temperature electronics. These wafers are known for their ability to withstand high temperatures, high voltage, and high power operation, making them an ideal choice for next-generation electronic devices.One of the leading manufacturers of SiC wafers is {Company}, a global leader in advanced materials and semiconductor technology. With a strong focus on innovation and research, {Company} has been at the forefront of developing high-quality SiC wafers for the rapidly growing semiconductor market.Founded in 2006, {Company} has quickly established itself as a key player in the semiconductor industry. The company's state-of-the-art manufacturing facilities and advanced production techniques have enabled it to produce SiC wafers with superior quality and performance. {Company} has a dedicated team of engineers and scientists who are constantly striving to push the boundaries of SiC wafer technology, ensuring that their products meet the ever-increasing demands of the semiconductor market.{Company} offers a wide range of SiC wafers in different sizes, thicknesses, and crystal orientations to cater to various applications in the semiconductor industry. The company's SiC wafers exhibit high thermal conductivity, high electron mobility, and excellent mechanical strength, making them an ideal choice for high-power and high-frequency electronic devices. {Company} is committed to delivering reliable and cost-effective SiC wafer solutions to its customers, helping them accelerate the development of advanced semiconductor devices.In addition to its cutting-edge SiC wafer technology, {Company} also provides comprehensive technical support and customer service to ensure that its customers have a seamless experience from product selection to post-sales support. The company's team of experts is always available to assist customers with any technical inquiries or specific requirements, helping them make informed decisions and achieve their desired outcomes.{Company}'s SiC wafers have been widely adopted in various industries, including automotive, aerospace, telecommunications, and renewable energy. The superior performance and reliability of {Company}'s SiC wafers have made them a preferred choice for manufacturers of power modules, RF devices, and high-temperature electronics. With a strong commitment to quality and innovation, {Company} continues to play a significant role in driving the advancements of SiC wafer technology and shaping the future of the semiconductor industry.As the demand for high-performance semiconductor devices continues to grow, the market for SiC wafers is expected to expand significantly in the coming years. {Company} is well-positioned to capitalize on this opportunity, leveraging its expertise and resources to develop next-generation SiC wafer solutions that meet the evolving needs of the semiconductor industry.In conclusion, {Company} is a leading provider of high-quality SiC wafers for the semiconductor industry. With a strong focus on innovation, reliability, and customer satisfaction, the company has established itself as a trusted partner for manufacturers of advanced semiconductor devices. {Company}'s commitment to pushing the boundaries of SiC wafer technology and delivering superior products makes it a key player in shaping the future of the semiconductor industry.

Ultimate Guide to Crystalline Si: Everything You Need to Know

Crystalline Si, a cutting-edge technology in the field of solar energy, is making headlines as it continues to revolutionize the industry. This advanced technology is changing the way we harness the power of the sun, and one company that is at the forefront of this innovation is {Company Name}. With their state-of-the-art manufacturing facilities and unwavering commitment to sustainability, {Company Name} is leading the charge towards a cleaner, more renewable energy future.Crystalline Si is a type of solar cell technology that is highly efficient at converting sunlight into electricity. This technology is rapidly gaining traction in the solar energy market due to its superior performance and durability. {Company Name} has been a pioneer in the development and implementation of Crystalline Si technology, and they are continually pushing the boundaries of innovation in this space.{Company Name} was founded on the principle of providing sustainable energy solutions that meet the ever-growing demand for clean power. Their team of experts is dedicated to research and development, and they have been instrumental in advancing the capabilities of Crystalline Si technology. With a focus on quality and performance, {Company Name} has established itself as a trusted leader in the solar energy industry.One of the key advantages of Crystalline Si technology is its ability to deliver high power outputs in a variety of conditions. This makes it an ideal choice for both residential and commercial applications, allowing for greater energy independence and cost savings. By leveraging the latest advancements in Crystalline Si technology, {Company Name} is helping their customers achieve their renewable energy goals while reducing their carbon footprint.In addition to its superior performance, Crystalline Si technology is also known for its long-term reliability. Solar panels utilizing this technology are built to last, with minimal degradation over time. This means that {Company Name} customers can count on their investment in solar energy to deliver consistent, dependable power for years to come. This level of reliability is a testament to the dedication and expertise of the team at {Company Name}.{Company Name} is also committed to sustainability and environmental stewardship. They understand the critical role that renewable energy plays in combating climate change, and they are proud to be part of the solution. Through their advanced Crystalline Si technology, {Company Name} is helping to reduce greenhouse gas emissions and protect the planet for future generations. Their unwavering commitment to sustainability sets them apart as a leader in the solar energy industry.As the demand for solar energy continues to grow, {Company Name} is well-positioned to meet the needs of their customers. Their extensive manufacturing capabilities and dedication to research and development ensure that they can deliver the latest and most advanced Crystalline Si technology to the market. Whether it's for residential, commercial, or utility-scale projects, {Company Name} has the expertise and resources to provide reliable, high-performance solar solutions.In conclusion, Crystalline Si technology is transforming the solar energy industry, and {Company Name} is leading the way. Their commitment to innovation, sustainability, and customer satisfaction sets them apart as a trusted provider of advanced solar solutions. With their advanced manufacturing facilities and world-class team of experts, {Company Name} is poised to continue driving the adoption of renewable energy and shaping the future of solar power.

Sapphire Ingot Production and Demand Soar as Market Embraces its Versatility

Title: Technological Advancements in Sapphire Ingot Production: A Breakthrough for the Semiconductor IndustryIntroduction:In recent years, the global semiconductor industry has experienced significant growth due to the increasing demand for advanced electronic devices. As this demand continues to rise, the need for reliable and high-quality raw materials, such as sapphire ingots, has become critical. To address this market demand, a leading technology company has unveiled a groundbreaking innovation in sapphire ingot production, revolutionizing the semiconductor industry.Technological Advancements:Traditionally, the production of sapphire ingots, which are widely used as a substrate material in the manufacturing of LEDs, power electronics, and high-frequency devices, has been a laborious and costly process. However, with the development of cutting-edge technology, this company has successfully perfected a highly efficient method to produce sapphire ingots, promising to meet the soaring demands of the industry.Through extensive research and collaboration with industry experts, engineers have developed a state-of-the-art manufacturing process that significantly improves sapphire ingot production. Combining advanced crystal growth techniques with innovative automation systems, the company has succeeded in increasing yield, reducing manufacturing costs, and maintaining consistent quality. This breakthrough technology has the potential to reshape the semiconductor industry's supply chain, enabling accelerated growth and innovation.Enhanced Crystal Growth Techniques:Among the key advancements lies the optimization of crystal growth techniques. With the help of precise temperature control and innovative seeding methodologies, the company has achieved higher crystalline quality, ensuring uniformity throughout the entire sapphire ingot. This enhanced crystal structure not only contributes to improved device performance but also reduces manufacturing defects, increasing yield and reducing waste.Furthermore, innovative automation systems have been implemented to streamline the production process. Robotic handling systems, coupled with advanced sensors and artificial intelligence, significantly reduce human intervention, leading to higher throughput and enhanced efficiency. This not only saves time but also mitigates the risk of human error.Benefits and Market Impact:The introduction of this advanced sapphire ingot production technique is poised to have a profound impact on the semiconductor market. The following benefits can be expected:1. Increased Supply: The improved efficiency in sapphire ingot manufacturing will result in higher production volumes, thus meeting the growing demand for semiconductors. This breakthrough will promote technological advancement across various industries, including consumer electronics, automotive, and telecommunications.2. Cost Reduction: The innovative process will contribute to a reduction in manufacturing costs, benefiting both manufacturers and consumers. The increased availability of cost-effective sapphire ingots will enable the development of more affordable electronic devices, thereby empowering a wider range of consumers to access cutting-edge technology.3. Environmental Sustainability: By optimizing the manufacturing process, the company also emphasizes environmental sustainability. Lower energy consumption and reduced material wastage contribute to a greener future during the production of sapphire ingots.Collaboration and Future Outlook:The successful implementation of this groundbreaking technology has been the result of ongoing collaboration within the semiconductor industry. The company actively engaged with research institutions, customer feedback, and industry experts to refine and improve the production process continually. This collaborative approach ensures that the technology remains at the forefront of innovation, positioning the company as a leader in the field.Looking ahead, the company plans to expand its production capacity, leveraging its breakthrough sapphire ingot manufacturing process. By adopting these advancements on a larger scale, the company aims to address the growing demand for semiconductor materials worldwide. In addition, ongoing research and development endeavors will focus on advancing crystal growth techniques further, enhancing the overall quality of sapphire ingots and enabling even more advanced semiconductor applications.Conclusion:The introduction of an advanced sapphire ingot production technique represents a significant milestone in the semiconductor industry. Through innovative crystal growth techniques and automation systems, this breakthrough technology promises increased supply, reduced costs, and environmental sustainability. Furthermore, continued collaboration and research will ensure the company remains at the forefront of technological advancement in the field of sapphire ingot manufacturing. These advancements will undoubtedly stimulate further growth and innovation across the entire semiconductor industry, ultimately benefitting consumers worldwide.