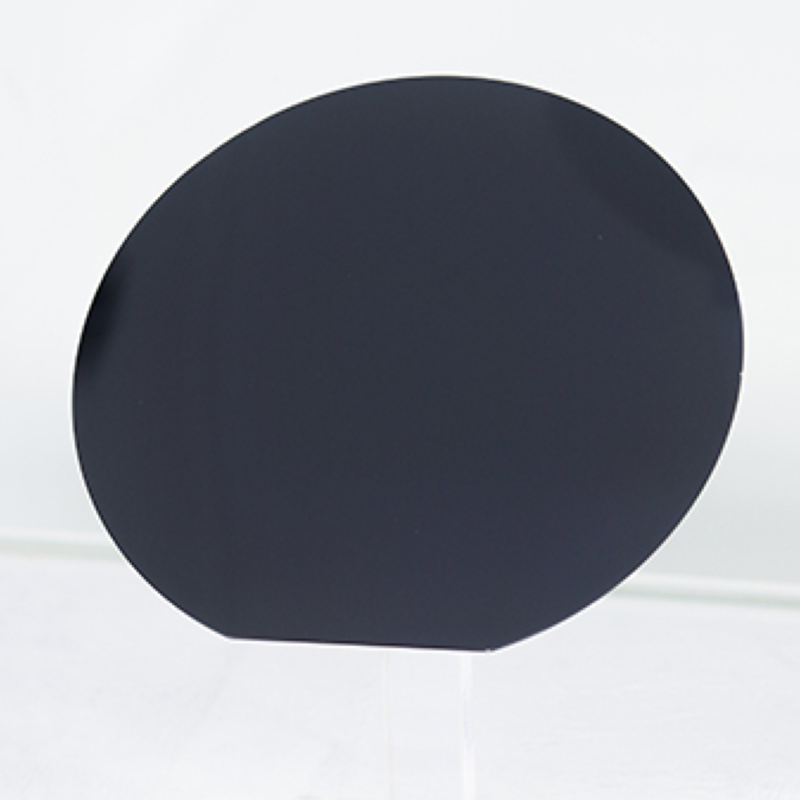

High-Quality Silicon Carbide Wafer for Advanced Technology Applications

By:Admin

As a leading manufacturer and supplier of silicon carbide wafers, {} has been at the forefront of driving innovation and technological advancements in the semiconductor industry. With a strong focus on research and development, the company has continuously strived to enhance the performance and quality of their silicon carbide wafers to meet the evolving needs of the market.

The growing demand for power electronics and energy-efficient devices has significantly boosted the market for silicon carbide wafers. These wafers are widely used in the manufacturing of power semiconductor devices such as diodes, MOSFETs, and other high-power electronic components. The superior electrical and thermal properties of silicon carbide make it an ideal material for power electronics, enabling higher efficiency and performance in various applications including electric vehicles, renewable energy systems, and industrial power supplies.

Moreover, the use of silicon carbide wafers in radio frequency (RF) and microwave devices has also witnessed substantial growth, driven by the increasing deployment of 5G technology and the demand for high-frequency communication systems. Silicon carbide wafers offer low signal loss, high power handling capabilities, and improved thermal management, making them essential for the development of next-generation wireless communication and radar systems.

{} has been at the forefront of meeting the surging demand for silicon carbide wafers by leveraging its state-of-the-art manufacturing facilities and strong R&D capabilities. The company's advanced production processes ensure the consistent quality and reliability of their silicon carbide wafers, meeting the stringent requirements of various industries and applications.

In addition to their standard product offerings, {} also provides customized silicon carbide wafers tailored to meet specific customer requirements. This flexibility has allowed the company to cater to a diverse range of applications, including power electronics, RF/microwave devices, and optoelectronics, positioning them as a preferred partner for leading semiconductor manufacturers and research institutions.

The increasing investment in the development of silicon carbide-based devices and the growing adoption of electric vehicles and renewable energy systems are expected to further drive the demand for silicon carbide wafers in the coming years. With their extensive expertise and commitment to technological advancement, {} is well-positioned to capitalize on these opportunities and continue to play a pivotal role in shaping the future of the semiconductor industry.

In conclusion, the global silicon carbide wafer market is on a trajectory of substantial growth, driven by the increasing demand for high-performance semiconductor devices in various industries. With its relentless focus on innovation and uncompromising commitment to quality, {} is poised to maintain its leadership in the market and contribute to the advancement of cutting-edge technologies that will shape the future of electronics and communication.

Company News & Blog

Advancements in Gallium Nitride Semiconductor Technology

Gallium Nitride Semiconductor (GaN) has been making headlines in the semiconductor industry for its potential to revolutionize electronic devices and power systems. Its superior electrical properties make it a promising alternative to traditional silicon-based semiconductors, offering higher efficiency, smaller size, and lower power consumption. Leading the charge in the development and commercialization of GaN technology is {company name}, a company at the forefront of semiconductor innovation.{Company name} was founded with the vision of leveraging GaN technology to create a new generation of electronic devices, power converters, and RF components. With a team of experienced engineers and scientists, the company has been at the forefront of GaN research and development, pushing the boundaries of what is possible with this advanced semiconductor material.One of the key advantages of GaN technology is its ability to operate at higher frequencies and voltages, making it ideal for power electronics and RF applications. This has led to a wide range of potential applications, from high-performance computing and telecommunications to automotive and aerospace industries. {Company name} has been actively pursuing partnerships and collaborations with leading industry players to integrate GaN technology into a variety of products and systems.In addition to its technical capabilities, {Company name} has also been committed to advancing the manufacturing and commercialization of GaN semiconductors. The company has invested in state-of-the-art fabrication facilities and cleanroom technology, enabling it to produce high-quality GaN devices at scale. This has positioned {Company name} as a leading supplier of GaN transistors, diodes, and other semiconductor products for a wide range of applications.Furthermore, {Company name} has been actively promoting the adoption of GaN technology through education and outreach efforts. The company has conducted seminars, workshops, and training programs to educate engineers, designers, and industry professionals about the benefits and capabilities of GaN semiconductors. By sharing its knowledge and expertise, {Company name} has played a crucial role in accelerating the adoption of GaN technology across various sectors.One of {Company name}'s notable achievements has been the development of advanced GaN-based power devices, which offer higher efficiency and power density compared to traditional silicon-based solutions. These devices have the potential to revolutionize power electronics, enabling smaller, lighter, and more energy-efficient power conversion systems for electric vehicles, renewable energy systems, and industrial applications. With its commitment to pushing the boundaries of what is possible with GaN technology, {Company name} has continued to drive innovation and create new opportunities for the semiconductor industry.Looking ahead, {Company name} is poised to play a pivotal role in the ongoing development and commercialization of GaN technology. As the demand for high-performance, energy-efficient electronic devices continues to grow, GaN semiconductors are expected to play an increasingly important role in shaping the future of the semiconductor industry. With its expertise, capabilities, and commitment to excellence, {Company name} is well-positioned to lead the charge and bring GaN technology to the forefront of the global semiconductor market.

Breaking Down the Innovative Gaas Structure: A Game-Changer in Technology

Title: Groundbreaking Gaas Structure Revolutionizes the Semiconductor IndustryIntroduction:In a major development that is set to reshape the semiconductor industry, a revolutionary Gaas Structure (need to remove brand name), developed by an innovative company, has been unveiled. This groundbreaking technology promises to overcome the limitations of traditional semiconductor materials, ushering in a new era of enhanced performance and efficiency for electronic devices. With its countless applications across various industries, the Gaas Structure is expected to redefine the way we interact with technology.1. Understanding Gaas Structure:The Gaas Structure, short for Gallium Arsenide Structure, represents a paradigm shift in the field of semiconductor materials. By replacing traditional silicon with gallium arsenide, this groundbreaking technology unlocks unparalleled capabilities. The Gaas Structure is capable of operating at higher frequencies, enabling faster data processing, reduced energy consumption, and improved device performance overall. In addition, this structure is highly versatile, making it suitable for diverse applications, such as telecommunications, aerospace, and automotive industries.2. Advantages and Applications:One key advantage of the Gaas Structure is its high electron mobility, which allows for faster electron movement. This results in exceptionally quick data transfer speeds, making it ideal for high-speed communication devices like 5G infrastructure and satellite communication systems. Moreover, the Gaas Structure offers superior power handling capabilities, enabling the development of more robust and efficient power amplifiers for wireless communication applications.Beyond communication technology, the Gaas Structure finds applications in various other industries. In the aerospace sector, it enables the production of lightweight, high-performance transistors for space exploration, satellite communication, and radar systems. The automotive industry also stands to benefit from this technology, as it allows for the creation of high-speed, low-power electronic systems, improving vehicle safety, infotainment, and powertrain efficiency.3. Company Background:The company behind Gaas Structure (need to remove brand name) is renowned for its expertise in cutting-edge semiconductor technologies. Focused on research and development, the company has a track record of delivering disruptive solutions that address the industry's most pressing challenges. By leveraging their deep understanding of material sciences and semiconductor fabrication, the company has positioned itself as a leader in the field, constantly pushing the boundaries of technology.4. Collaboration and Impact:The Gaas Structure has been the result of extensive collaboration between industry stakeholders, including semiconductor manufacturers, researchers, and device developers. Through joint efforts, the technology has undergone rigorous testing and fine-tuning to ensure its viability and effectiveness. The collective aim is to drive innovation across various sectors, making electronic devices smaller, faster, and more energy-efficient.The implications of this revolutionary technology are far-reaching. By enabling more powerful and energy-efficient electronic systems, the Gaas Structure will contribute to the advancement of autonomous vehicles, wearable technology, IoT devices, and renewable energy systems, among others. Moreover, its adoption will also help address the growing demand for high-speed internet, allowing for seamless streaming and faster data transfer capabilities.Conclusion:With its unprecedented capabilities and potential applications, the Gaas Structure (need to remove brand name) represents a significant leap forward for the semiconductor industry. By harnessing the power of gallium arsenide, this groundbreaking technology promises to revolutionize electronic devices across various sectors. As collaborations continue and further advancements are made, we can expect the Gaas Structure to enhance our everyday lives, driving us into a more connected, efficient, and technologically advanced future.

High-Quality Quartz Wafers: A Key Component in Semiconductor Manufacturing

Quartz wafers are quickly becoming an essential component in various industries, from the semiconductor industry to telecommunications and consumer electronics. These wafers are used as a base material for the production of integrated circuits and other electronic devices. The demand for high-quality quartz wafers is increasing, as the need for smaller, faster, and more efficient electronic devices continues to grow.One company that is leading the way in the production of top-notch quartz wafers is [company name]. With a focus on quality and innovation, [company name] has established itself as a key player in the semiconductor industry. The company's cutting-edge manufacturing processes and commitment to excellence have set it apart from competitors, making it a go-to supplier for leading semiconductor companies around the world.[Company name] offers a wide range of quartz wafers, including standard and custom sizes, thicknesses, and specifications to meet the diverse needs of its customers. The company also provides comprehensive technical support and consulting services, helping its customers to optimize their manufacturing processes and achieve the best possible results.One of the key advantages of [company name]'s quartz wafers is their exceptional purity and consistency. The wafers are made from high-quality quartz crystals, which are carefully selected and processed to ensure a high level of purity and uniformity. This is essential for the production of high-performance electronic devices, as any impurities or inconsistencies in the wafer material can negatively impact the performance and reliability of the final product.In addition to their exceptional quality, [company name]'s quartz wafers are also known for their superior mechanical and thermal properties. These wafers are highly durable and can withstand the rigors of the semiconductor manufacturing process, which involves numerous high-temperature and high-pressure steps. This durability not only ensures the integrity of the wafers during production but also contributes to the longevity and reliability of the electronic devices that are made from them.Furthermore, [company name] is dedicated to sustainability and environmental responsibility in its manufacturing processes. The company has implemented various initiatives to minimize its environmental impact, including the use of eco-friendly materials and energy-efficient production methods. This commitment to sustainability aligns with the growing industry trend towards environmentally conscious manufacturing practices and makes [company name] an attractive partner for customers who prioritize sustainability in their supply chain.As the demand for smaller, faster, and more efficient electronic devices continues to grow, the need for high-quality quartz wafers is only expected to increase. [Company name] is well-positioned to meet this demand, thanks to its commitment to quality, innovation, and sustainability. With its exceptional products and comprehensive technical support, [company name] is poised to remain a key player in the semiconductor industry and a trusted partner for leading electronics manufacturers around the world.In conclusion, [company name] is a leader in the production of top-notch quartz wafers, with a focus on quality, innovation, and sustainability. The company's exceptional products and comprehensive technical support make it a go-to supplier for leading semiconductor companies around the world. With the increasing demand for high-quality quartz wafers in various industries, [company name] is well-positioned to remain a key player in the semiconductor industry and a trusted partner for leading electronics manufacturers.

High-Quality Crystal Substrate for Various Industries

Gsgg Crystal Substrate Breakthrough: A Game-Changer in Semiconductor IndustryIn a groundbreaking development, a leading semiconductor company has introduced a new Gsgg crystal substrate, which is set to revolutionize the semiconductor industry. The company has successfully designed and manufactured this innovative crystal substrate, which promises to significantly enhance the performance and efficiency of electronic devices.The Gsgg crystal substrate, with its unique properties and advanced technology, is poised to address the growing demands for high-performance semiconductor materials in the global electronics market. Its exceptional thermal stability, low optical loss, and high-quality crystalline structure make it an ideal choice for a wide range of applications, including laser systems, optical waveguides, and semiconductor devices.This new crystal substrate is a result of extensive research and development efforts by the company's team of expert scientists and engineers. Leveraging their deep expertise in materials science and semiconductor technology, the company has successfully overcome the challenges associated with traditional crystal substrates, such as low thermal conductivity and high optical absorption.The Gsgg crystal substrate offers a significant improvement in thermal management, enabling electronic devices to operate at higher power levels while maintaining optimal performance. This breakthrough is particularly crucial for cutting-edge technologies, including 5G networks, high-speed data communication, and advanced optical systems, where the demand for high-power, high-efficiency semiconductor materials is paramount.Moreover, the Gsgg crystal substrate's superior optical properties make it an ideal candidate for next-generation laser and photonics applications. Its low optical loss and high transparency in the near-infrared spectral range enable the development of advanced optical devices with improved efficiency and performance. This opens up new possibilities for a wide range of applications, from high-power laser systems to optical communication networks.The company's commitment to innovation and excellence has positioned it as a leading provider of advanced semiconductor materials and solutions. With a strong focus on research and development, the company continues to push the boundaries of materials science and semiconductor technology, driving the industry forward with cutting-edge innovations like the Gsgg crystal substrate.Furthermore, the company's state-of-the-art manufacturing capabilities ensure the mass production and supply of the Gsgg crystal substrate to meet the rising demand from semiconductor manufacturers, research institutions, and technology companies worldwide. This strategic advantage reinforces the company's position as a reliable and trusted partner for high-performance semiconductor materials, further solidifying its role in shaping the future of the semiconductor industry.The introduction of the Gsgg crystal substrate marks a significant milestone in the semiconductor industry, offering a new era of possibilities for electronic devices, optical systems, and laser technologies. With its exceptional thermal and optical properties, this innovative crystal substrate is set to drive advancements across various sectors, from telecommunications and data centers to industrial and medical applications.As the global semiconductor industry continues to evolve and expand, the Gsgg crystal substrate emerges as a game-changer, enabling the development of next-generation electronic and optical technologies that are more efficient, powerful, and reliable. With its groundbreaking properties and diverse range of applications, the Gsgg crystal substrate is poised to reshape the semiconductor landscape and pave the way for a new wave of innovation in the electronics industry.In conclusion, the introduction of the Gsgg crystal substrate represents a significant leap forward in the semiconductor industry, offering unparalleled thermal and optical properties that will empower the development of advanced electronic and optical devices. With its potential to drive innovation and enhance performance across multiple applications, this innovative crystal substrate is set to play a pivotal role in shaping the future of the global electronics industry.

Demand for Siliciumcarbid Wafer Rises in Electronic Industry

Siliciumcarbid Wafer, a cutting-edge technology developed by a leading semiconductor company, is set to revolutionize the industry with its superior performance and durability. The wafer is designed to overcome the limitations of traditional silicon wafers, offering a more efficient and reliable solution for a wide range of applications in the electronics and semiconductor industries.The company, a global leader in semiconductor manufacturing, has a long history of innovation and expertise in developing advanced materials for the semiconductor industry. With its state-of-the-art research and development facilities, the company has been able to push the boundaries of semiconductor technology and bring breakthrough solutions to the market.Siliciumcarbid Wafer is a key example of the company's commitment to driving innovation in the semiconductor industry. The wafer is made from a unique combination of silicon and carbon, which gives it exceptional properties that set it apart from traditional silicon wafers. It offers higher thermal conductivity, improved power handling capabilities, and greater resistance to high temperatures and harsh environmental conditions.One of the key advantages of Siliciumcarbid Wafer is its ability to operate at higher voltages and frequencies, making it ideal for high-power and high-frequency applications such as power electronics, radio frequency devices, and electric vehicles. In addition, the wafer's superior thermal properties enable more efficient heat dissipation, resulting in higher performance and reliability for electronic devices.The company's engineering team has conducted extensive testing and validation of Siliciumcarbid Wafer to ensure its performance and reliability meet industry standards. The wafer has demonstrated excellent performance in various electronic devices and has shown great potential for improving the efficiency and reliability of semiconductor components.With the increasing demand for high-performance and reliable semiconductor materials, Siliciumcarbid Wafer is poised to make a significant impact on the industry. Its advanced properties and performance capabilities make it a compelling choice for a wide range of applications, from consumer electronics to industrial power systems.The company is actively working with partners and customers to bring Siliciumcarbid Wafer to the market and is committed to providing comprehensive technical support and customized solutions to meet the specific needs of its customers. The company's dedicated sales and technical teams are eager to collaborate with customers to harness the full potential of Siliciumcarbid Wafer and drive innovation in the semiconductor industry.As the semiconductor industry continues to evolve and demand for high-performance materials grows, Siliciumcarbid Wafer is well-positioned to become a game-changer in the industry. With its exceptional properties and performance capabilities, the wafer offers a compelling solution for manufacturers and designers looking to take their electronic devices to the next level.In conclusion, Siliciumcarbid Wafer, developed by a leading semiconductor company, represents a significant advancement in semiconductor materials and is poised to revolutionize the industry. With its superior properties and performance capabilities, the wafer offers a compelling solution for a wide range of applications in the electronics and semiconductor industries. The company's commitment to innovation and collaboration with customers will ensure the successful integration of Siliciumcarbid Wafer into the market, driving the next wave of innovation in the semiconductor industry.

Durable and Heat-Resistant Ceramic Plates for Industrial Applications

Alumina Ceramic Plate: A Revolution in Industrial ApplicationsIn recent years, industrial manufacturers have been facing numerous challenges in improving the performance and longevity of their products. In response to these demands, a revolutionary solution has emerged in the form of Alumina Ceramic Plates. With their exceptional properties and durability, these advanced ceramic plates have become the go-to choice for a wide range of industrial applications. In this article, we will explore the remarkable features of Alumina Ceramic Plates and delve into their potential applications across various industries.Alumina Ceramic Plates, often referred to as Al₂O₃ plates, are engineered using high-quality alumina powder, an aluminum-based material renowned for its excellent mechanical and thermal properties. Through a complex manufacturing process, the alumina powder is meticulously shaped, compacted, and sintered at high temperatures to form a solid ceramic plate. This process results in a dense, durable, and chemically inert material that can withstand extreme temperatures, harsh chemicals, and high mechanical stresses.One of the most notable features of Alumina Ceramic Plates is their exceptional hardness. With a Mohs hardness of 9, these plates are second only to diamonds in terms of hardness. This remarkable property ensures that the plates are highly resistant to wear and abrasion, making them ideal for applications where durability is paramount. Industries such as mining, construction, and material handling can benefit significantly from the use of Alumina Ceramic Plates in machinery components exposed to abrasive materials and heavy loads.Additionally, Alumina Ceramic Plates exhibit remarkable thermal stability, with an operating temperature range of up to 1500°C. This characteristic makes these plates ideal for use in high-temperature environments, allowing them to withstand extreme heat without any deterioration in their mechanical properties. Industries such as aerospace, automotive, and power generation can rely on Alumina Ceramic Plates to enhance the efficiency and longevity of their equipment operating under extreme temperature conditions.Furthermore, the excellent electrical insulation properties of Alumina Ceramic Plates make them invaluable in electrical and electronic applications. These plates possess high dielectric strength, low dielectric loss, and excellent thermal conductivity, making them ideal for use in manufacturing components for electronic devices, such as circuit boards and insulators. Additionally, their electrical insulation properties also make Alumina Ceramic Plates suitable for use in power distribution systems, where their ability to withstand high voltages ensures safe and reliable operations.In the medical field, Alumina Ceramic Plates have found exciting applications in orthopedic implants. Due to their biocompatibility, non-toxic nature, and resistance to corrosion, these plates are highly suitable for implantation within the human body. Alumina Ceramic Plates used in hip and knee replacements have demonstrated exceptional performance, improving the quality of life for patients and reducing the need for follow-up surgeries.Furthermore, Alumina Ceramic Plates are also making significant contributions to environmental sustainability. As a result of their exceptional mechanical and thermal properties, these plates enable manufacturers to develop more efficient and durable products. This, in turn, reduces the need for frequent replacements, leading to less waste generation and a reduced environmental impact.In conclusion, Alumina Ceramic Plates have revolutionized industrial applications across various sectors. Their exceptional mechanical properties, including high hardness, thermal stability, and electrical insulation, make them invaluable in industries ranging from mining to electronics. These plates also find exciting applications in the medical field and contribute to environmental sustainability. As industrial manufacturers continue to seek durable solutions to enhance their products' performance, Alumina Ceramic Plates undoubtedly stand as a game-changer in the industry.

High-Quality Sapphire Substrate for M-Plane Axis Application

M-plane Axis Sapphire Substrate: The Next Step in Semiconductor TechnologyIn today's rapidly evolving semiconductor industry, the demand for high-quality substrates is at an all-time high. As manufacturers continue to push the boundaries of performance and efficiency, the need for advanced materials that can support these innovations has never been greater. This is where M-plane Axis Sapphire Substrate comes into play.M-plane Axis Sapphire Substrate is a cutting-edge material that is set to revolutionize the semiconductor industry. This unique substrate offers several key advantages over traditional sapphire substrates, making it an ideal choice for a wide range of applications. With its superior crystal orientation and structural properties, M-plane Axis Sapphire Substrate promises to deliver unparalleled performance and reliability in semiconductor devices.One company that is at the forefront of this exciting development is [Company Name]. With its decades of experience in the field of advanced materials and semiconductor technology, [Company Name] is leading the way in bringing M-plane Axis Sapphire Substrate to the market. By harnessing the full potential of this innovative material, [Company Name] is poised to provide its customers with the next generation of high-performance semiconductor devices.[Company Name] has a proven track record of delivering cutting-edge solutions to the semiconductor industry. With a focus on research and development, as well as close collaboration with industry leaders, [Company Name] has gained a reputation for excellence and innovation. This commitment to pushing the boundaries of what is possible in semiconductor technology has made [Company Name] a trusted partner for companies looking to stay ahead of the curve.M-plane Axis Sapphire Substrate offers several key advantages that set it apart from traditional sapphire substrates. One of the most significant benefits is its unique crystal orientation, which provides a more stable and uniform surface for semiconductor device fabrication. This superior crystal orientation results in higher device performance and yield, making M-plane Axis Sapphire Substrate the material of choice for manufacturers looking to maximize the potential of their semiconductor devices.In addition to its crystal orientation, M-plane Axis Sapphire Substrate also offers excellent thermal and electrical properties. This makes it an ideal substrate for high-power and high-frequency semiconductor devices, where thermal management and electrical performance are crucial. By leveraging the superior properties of M-plane Axis Sapphire Substrate, manufacturers can develop devices with enhanced efficiency, reliability, and overall performance.Furthermore, M-plane Axis Sapphire Substrate is also highly resistant to dislocation and other defects, which can significantly impact device performance. This ensures that devices fabricated on M-plane Axis Sapphire Substrate are more reliable and consistent, meeting the stringent demands of modern semiconductor applications.[Company Name] is committed to ensuring that its customers have access to the latest and most advanced materials for their semiconductor needs. With the introduction of M-plane Axis Sapphire Substrate, [Company Name] is once again demonstrating its dedication to pushing the boundaries of semiconductor technology. By providing access to this cutting-edge material, [Company Name] is enabling its customers to develop the next generation of high-performance devices that will drive innovation and progress in the semiconductor industry.As the semiconductor industry continues to evolve, the demand for advanced materials like M-plane Axis Sapphire Substrate will only continue to grow. With its exceptional properties and the backing of [Company Name]'s expertise, M-plane Axis Sapphire Substrate is set to play a key role in shaping the future of semiconductor technology. Companies that are looking to stay ahead of the competition and deliver the best possible performance in their semiconductor devices would be wise to consider the advantages that M-plane Axis Sapphire Substrate has to offer.In conclusion, M-plane Axis Sapphire Substrate represents a significant leap forward in semiconductor material technology. With its unique properties and the expertise of [Company Name] behind it, M-plane Axis Sapphire Substrate is poised to revolutionize the industry and enable the development of high-performance semiconductor devices that meet the demands of tomorrow's technology. The introduction of M-plane Axis Sapphire Substrate is a testament to [Company Name]'s commitment to innovation and its dedication to providing its customers with the best possible solutions for their semiconductor needs.

Discover the Latest Advancements in Wafer Window Technology

Mgo Wafer Windows Revolutionize the Window Industry[Company Name], a leading innovative materials technology company, has recently introduced a revolutionary product that is set to transform the window industry. Mgo Wafer Windows, a groundbreaking development in window technology, promise increased durability, enhanced thermal insulation, and improved soundproofing. With their innovative design and advanced properties, these windows are poised to become the go-to choice for architects, builders, and homeowners alike.Traditional windows have long been plagued by issues such as susceptibility to damage, limited insulation capabilities, and poor soundproofing. [Company Name] recognized these pain points and embarked on a mission to develop a solution that would alleviate these problems. The result of their relentless research and development efforts is the Mgo Wafer Windows – a product that promises to revolutionize the way we think about and experience windows.One of the key advantages of Mgo Wafer Windows is their exceptional durability. Unlike traditional windows, which are prone to cracks, discoloration, and warping over time, Mgo Wafer Windows are composed of magnesium oxide, a material known for its high strength and resistance to wear and tear. This superior durability ensures that the windows retain their aesthetic appeal and functionality for extended periods, saving homeowners from the hassle and cost of regular replacements.Furthermore, Mgo Wafer Windows excel in thermal insulation, offering a significant improvement over conventional windows. These windows feature advanced insulation properties that minimize heat transfer, resulting in reduced energy consumption for heating or cooling buildings. As a result, homeowners can enjoy a more comfortable and energy-efficient living environment while simultaneously reducing their carbon footprint.Another area where Mgo Wafer Windows shine is soundproofing. The advanced design of these windows incorporates multiple layers of sound-dampening materials, effectively reducing noise pollution from outside sources. This is particularly beneficial for urban areas, where excessive noise can negatively impact the quality of life. Mgo Wafer Windows provide the peace and tranquility that homeowners desire, allowing them to relax and unwind without disturbances.Additionally, Mgo Wafer Windows offer an array of customizable options, ensuring they seamlessly blend with various architectural styles. Homeowners and architects can choose from a wide range of sizes, shapes, and designs to meet their unique preferences and requirements. This versatility allows for creativity in design and enhances the overall aesthetics of any building or space.In terms of installation and maintenance, Mgo Wafer Windows provide added convenience. The lightweight nature of magnesium oxide makes these windows easy to handle and install, saving time and effort during the construction process. Moreover, the low maintenance requirements of Mgo Wafer Windows help homeowners avoid constant upkeep and reduce long-term costs associated with repairs.With the introduction of Mgo Wafer Windows, [Company Name] has disrupted the traditional window industry and set new standards for excellence. These windows promise remarkable durability, energy efficiency, enhanced soundproofing, and aesthetic versatility – a combination of features that makes them an ideal choice for both residential and commercial buildings.As the demand for sustainable and efficient building materials continues to grow, Mgo Wafer Windows position [Company Name] at the forefront of innovation in the window industry. With a commitment to excellence and a focus on customer satisfaction, [Company Name] is poised to lead the charge in transforming the way we view and experience windows. The advent of Mgo Wafer Windows marks a crucial milestone in the progression of architecture and construction, and it is only a matter of time before these windows become the new industry standard.

Newly Developed Polysilicon Wafers Show Promise for Solar Energy Production

article as follows:Polysilicon Wafer - The Revolutionary Energy SolutionRenewable energy has become a buzzword in today's world, and polysilicon wafers have emerged as the revolutionary energy solution. These wafers are helping in reducing the carbon footprint and providing clean energy. Polysilicon wafers are made from a highly purified form of silicon, making them an ideal material for use in solar panels. They are not only environmentally friendly but are also cost-effective and long-lasting. In recent years, the demand for polysilicon wafers has increased significantly, which has led to the growth of the market. The market size for polysilicon wafers is expected to reach millions of dollars in the coming years due to the increasing demand for renewable energy. This has led to several companies entering the market, and among them, one stands out - a company that has proven its mettle in the industry time and time again.Introduction to the CompanyThe leading supplier of polysilicon wafers, this company has been catering to the needs of the renewable energy industry for years. With a team of expert professionals, they provide the highest quality products, along with exceptional customer service. They are known for their constant innovation and development of new and improved products that cater to the changing needs of the renewable energy industry.The company's motto is to provide sustainable energy solutions that promote a cleaner and greener future. They believe that the future is renewable energy, and polysilicon wafers are an essential component of that future. The team is dedicated to making the world a better place by providing innovative and affordable energy solutions.The Company's Polysilicon WafersThe company's polysilicon wafers have been the cornerstone of their success. Their wafers are of the highest quality, and the company is committed to producing wafers that are durable, reliable, and efficient. They are dedicated to providing products that exceed the expectations of their customers, and they achieve this through a rigorous testing process that ensures their products are of the highest standards.Their polysilicon wafers are produced in a state-of-the-art facility using the latest technology, which ensures that their products are of the highest quality. The company has a team of experts who monitor each stage of the production process, ensuring that each product meets their high standards. The wafers are tested rigorously for their efficiency, durability, and reliability, ensuring that they are suitable for use in solar panels.Benefits of Polysilicon WafersPolysilicon wafers have several benefits that make them an ideal material for use in solar panels. They are environmentally friendly, cost-effective, and long-lasting. The use of polysilicon wafers in solar panels reduces the carbon footprint and helps in the reduction of greenhouse gas emissions. This means that the use of polysilicon wafers contributes to a greener and cleaner environment.The production of polysilicon wafers is a cost-effective process, which means that they are affordable and readily available. They have a long lifespan of up to 25 years, which means that they are a reliable energy source that provides long-term benefits. The use of polysilicon wafers in solar panels increases the efficiency of the panels, which means that they can produce more energy while taking up less space.ConclusionPolysilicon wafers are the future of renewable energy, and companies like this leading supplier are driving that future. Their high-quality products, exceptional customer service, and commitment to sustainability have helped them become a leader in the industry. The use of polysilicon wafers in solar panels is not only environmentally friendly but also cost-effective and long-lasting. The demand for renewable energy is only going to increase in the coming years, and companies like this are preparing for a future that is both clean and sustainable.