New Breakthrough in Semiconductor Technology: Diamond Wafers Unveiled

By:Admin

Semiconductor technology has advanced rapidly in recent years, with the demand for faster, smaller, and more efficient electronic devices driving continuous innovation. Diamond wafers have emerged as a key component in this evolution, offering superior thermal conductivity, high electron mobility, and exceptional durability.

The company () has established itself as a leader in the production of diamond wafers, utilizing advanced manufacturing processes and cutting-edge technology to deliver high-quality products to its customers. The company's commitment to research and development has enabled it to develop innovative solutions that are driving the adoption of diamond wafers across a wide range of applications.

With a focus on customer satisfaction and technological advancement, () has positioned itself as a trusted partner for semiconductor manufacturers around the world. The company's diamond wafers have been widely acclaimed for their exceptional performance and reliability, making them an ideal choice for demanding semiconductor applications.

One of the key advantages of diamond wafers is their superior thermal conductivity, which allows for more efficient heat dissipation in electronic devices. This not only results in improved performance and reliability but also enables the design of smaller and more compact devices. ()

Additionally, diamond wafers offer high electron mobility, allowing for faster electron movement within the semiconductor material. This enables the development of high-speed, low-power electronic devices that are essential for the continued advancement of technology.

Furthermore, diamond wafers are extremely durable and can withstand harsh operating conditions, making them ideal for applications in aerospace, automotive, and industrial sectors. ()

The company's dedication to quality and innovation has led to the development of diamond wafers that meet the stringent requirements of the semiconductor industry. By leveraging its expertise and state-of-the-art facilities, () has been able to produce diamond wafers with exceptional purity and crystal quality, ensuring consistent and reliable performance in semiconductor devices.

As the demand for faster and more efficient electronic devices continues to grow, the adoption of diamond wafers is expected to increase significantly. () is well-positioned to capitalize on this trend, offering a comprehensive range of diamond wafers to address the evolving needs of its customers.

In addition to its advanced manufacturing capabilities, () is committed to sustainability and environmental responsibility. The company adheres to strict environmental standards in its production processes and works closely with its suppliers to ensure responsible sourcing of raw materials. ()

Looking ahead, () is poised to play a pivotal role in driving the widespread adoption of diamond wafers across various industries. With its focus on innovation, quality, and customer satisfaction, the company is set to continue leading the way in the development and production of diamond wafers that are powering the next generation of electronic devices.

Company News & Blog

Discover the Latest Advances in Silicon Wafer Chip Technology

Silicon Wafer Chips, a cutting-edge technology company based in Silicon Valley, has revolutionized the semiconductor industry with its innovative wafer-chip technology. The company, founded in 2005, has quickly become a leader in producing high-quality silicon wafer chips for a variety of applications, including microprocessors, memory chips, and sensors.Silicon Wafer Chips' state-of-the-art manufacturing facility is equipped with the latest and most advanced semiconductor manufacturing equipment, allowing the company to produce wafers with unparalleled precision and reliability. The company's team of expert engineers and researchers are constantly pushing the boundaries of semiconductor technology, developing new processes and materials to improve the performance and efficiency of their wafer chips.The company's silicon wafer chips are used in a wide range of electronic devices, from smartphones and laptops to automotive systems and industrial machinery. With their superior performance and reliability, Silicon Wafer Chips' products have gained a strong reputation among leading tech companies and manufacturers.One of the key advantages of Silicon Wafer Chips' technology is its ability to produce high-quality wafers at a large scale. The company's manufacturing process is designed to maximize yield and minimize waste, resulting in cost-effective solutions for their customers. This, combined with their commitment to innovation, has made Silicon Wafer Chips a trusted partner for companies looking to incorporate cutting-edge semiconductor technology into their products.In addition to their standard product offerings, Silicon Wafer Chips also provides custom wafer solutions to meet the specific needs of their clients. Their team of engineers and technicians work closely with customers to develop tailored solutions that are optimized for performance, power consumption, and size. This flexibility and commitment to customer satisfaction have set Silicon Wafer Chips apart in the highly competitive semiconductor industry.Furthermore, Silicon Wafer Chips is dedicated to sustainability and environmental responsibility. The company continuously improves its manufacturing processes to minimize its impact on the environment, reducing waste and energy consumption. By investing in green initiatives and eco-friendly technologies, Silicon Wafer Chips is committed to being a responsible corporate citizen.As the demand for advanced semiconductor technology continues to grow, Silicon Wafer Chips is well-positioned to meet the evolving needs of the industry. The company's relentless pursuit of innovation and excellence, combined with their commitment to quality and customer satisfaction, has cemented their position as a leader in the semiconductor market.Looking ahead, Silicon Wafer Chips is actively investing in research and development to bring new breakthroughs in semiconductor technology. With a focus on pushing the boundaries of what is possible, the company is poised to continue driving innovation and shaping the future of the semiconductor industry.In conclusion, Silicon Wafer Chips has established itself as a trailblazer in the semiconductor industry, delivering high-quality, innovative wafer chips to meet the demands of today's tech-driven world. With a strong commitment to sustainability, customer satisfaction, and continuous improvement, the company is well-positioned for long-term success and growth in the rapidly evolving semiconductor market.

High-quality 300mm Silicon Wafer for Advanced Semiconductor Manufacturing

300mm Silicon Wafer: A Breakthrough in Semiconductor TechnologyThe semiconductor industry has witnessed a significant milestone with the introduction of the 300mm Silicon Wafer by [Company Name]. This breakthrough promises to revolutionize the manufacturing process of semiconductor devices, opening doors to enhanced performance and efficiency.[Company Name] has been a leading player in the semiconductor industry for over two decades. With a strong focus on research and development, the company has consistently pushed the boundaries of technology to bring cutting-edge solutions to the market. The introduction of the 300mm Silicon Wafer is a testament to the company's commitment to innovation and excellence.The 300mm Silicon Wafer holds immense potential for the semiconductor industry. With a larger surface area than traditional wafers, it enables manufacturers to produce more chips per wafer, leading to cost savings and increased efficiency in the production process. This translates to lower manufacturing costs for semiconductor devices, making them more affordable for a wider range of applications.In addition to cost savings, the 300mm Silicon Wafer offers improved performance and reliability. The larger size allows for more transistors to be integrated into a single chip, resulting in higher processing power and enhanced functionality. This is especially significant in the context of emerging technologies such as artificial intelligence, the Internet of Things, and 5G, where the demand for high-performance semiconductor devices is rapidly increasing.Furthermore, the 300mm Silicon Wafer is also expected to drive advancements in semiconductor packaging and interconnect technologies. Its larger size provides more real estate for intricate circuitry and innovative packaging solutions, leading to smaller, faster, and more energy-efficient devices. This has the potential to have a transformative impact on various industries, from consumer electronics to automotive and healthcare.The launch of the 300mm Silicon Wafer is a result of years of research and development by [Company Name]. Leveraging state-of-the-art manufacturing processes and advanced materials, the company has overcome numerous technical challenges to bring this cutting-edge technology to the market. This underscores the company's expertise and capabilities in developing solutions that address the evolving needs of the semiconductor industry.Additionally, [Company Name] is committed to sustainability and environmental responsibility in its business practices. The 300mm Silicon Wafer is designed to optimize resource utilization and minimize waste, aligning with the company's commitment to reducing its environmental footprint. By enabling more efficient production processes and reducing energy consumption, the 300mm Silicon Wafer contributes to a more sustainable semiconductor industry.As the demand for high-performance semiconductor devices continues to grow, the introduction of the 300mm Silicon Wafer by [Company Name] marks a significant advancement in the semiconductor industry. With its potential to drive cost savings, performance improvements, and technological innovation, this breakthrough technology is poised to shape the future of semiconductor manufacturing. [Company Name] remains dedicated to pushing the boundaries of technology and delivering solutions that empower the industry to achieve new heights of performance and efficiency.In conclusion, the 300mm Silicon Wafer represents a major leap forward in semiconductor technology, and [Company Name] is at the forefront of this innovation. With its potential to revolutionize semiconductor manufacturing, this breakthrough promises to drive advancements in performance, efficiency, and sustainability, shaping the future of the semiconductor industry. [Company Name]'s commitment to excellence and innovation positions it as a key player in driving the industry forward, and the introduction of the 300mm Silicon Wafer is a testament to the company's leadership in shaping the future of semiconductor technology.

Sapphire Ingot Production and Demand Soar as Market Embraces its Versatility

Title: Technological Advancements in Sapphire Ingot Production: A Breakthrough for the Semiconductor IndustryIntroduction:In recent years, the global semiconductor industry has experienced significant growth due to the increasing demand for advanced electronic devices. As this demand continues to rise, the need for reliable and high-quality raw materials, such as sapphire ingots, has become critical. To address this market demand, a leading technology company has unveiled a groundbreaking innovation in sapphire ingot production, revolutionizing the semiconductor industry.Technological Advancements:Traditionally, the production of sapphire ingots, which are widely used as a substrate material in the manufacturing of LEDs, power electronics, and high-frequency devices, has been a laborious and costly process. However, with the development of cutting-edge technology, this company has successfully perfected a highly efficient method to produce sapphire ingots, promising to meet the soaring demands of the industry.Through extensive research and collaboration with industry experts, engineers have developed a state-of-the-art manufacturing process that significantly improves sapphire ingot production. Combining advanced crystal growth techniques with innovative automation systems, the company has succeeded in increasing yield, reducing manufacturing costs, and maintaining consistent quality. This breakthrough technology has the potential to reshape the semiconductor industry's supply chain, enabling accelerated growth and innovation.Enhanced Crystal Growth Techniques:Among the key advancements lies the optimization of crystal growth techniques. With the help of precise temperature control and innovative seeding methodologies, the company has achieved higher crystalline quality, ensuring uniformity throughout the entire sapphire ingot. This enhanced crystal structure not only contributes to improved device performance but also reduces manufacturing defects, increasing yield and reducing waste.Furthermore, innovative automation systems have been implemented to streamline the production process. Robotic handling systems, coupled with advanced sensors and artificial intelligence, significantly reduce human intervention, leading to higher throughput and enhanced efficiency. This not only saves time but also mitigates the risk of human error.Benefits and Market Impact:The introduction of this advanced sapphire ingot production technique is poised to have a profound impact on the semiconductor market. The following benefits can be expected:1. Increased Supply: The improved efficiency in sapphire ingot manufacturing will result in higher production volumes, thus meeting the growing demand for semiconductors. This breakthrough will promote technological advancement across various industries, including consumer electronics, automotive, and telecommunications.2. Cost Reduction: The innovative process will contribute to a reduction in manufacturing costs, benefiting both manufacturers and consumers. The increased availability of cost-effective sapphire ingots will enable the development of more affordable electronic devices, thereby empowering a wider range of consumers to access cutting-edge technology.3. Environmental Sustainability: By optimizing the manufacturing process, the company also emphasizes environmental sustainability. Lower energy consumption and reduced material wastage contribute to a greener future during the production of sapphire ingots.Collaboration and Future Outlook:The successful implementation of this groundbreaking technology has been the result of ongoing collaboration within the semiconductor industry. The company actively engaged with research institutions, customer feedback, and industry experts to refine and improve the production process continually. This collaborative approach ensures that the technology remains at the forefront of innovation, positioning the company as a leader in the field.Looking ahead, the company plans to expand its production capacity, leveraging its breakthrough sapphire ingot manufacturing process. By adopting these advancements on a larger scale, the company aims to address the growing demand for semiconductor materials worldwide. In addition, ongoing research and development endeavors will focus on advancing crystal growth techniques further, enhancing the overall quality of sapphire ingots and enabling even more advanced semiconductor applications.Conclusion:The introduction of an advanced sapphire ingot production technique represents a significant milestone in the semiconductor industry. Through innovative crystal growth techniques and automation systems, this breakthrough technology promises increased supply, reduced costs, and environmental sustainability. Furthermore, continued collaboration and research will ensure the company remains at the forefront of technological advancement in the field of sapphire ingot manufacturing. These advancements will undoubtedly stimulate further growth and innovation across the entire semiconductor industry, ultimately benefitting consumers worldwide.

High demand for Wafer in Semiconductor Industry drives market growth

Aln Wafer, a key player in the semiconductor industry, has recently announced the launch of their new product line that is set to revolutionize the electronics market. The company has a proven track record of producing high-quality semiconductor materials and has been a trusted supplier for many leading electronics manufacturers.With a focus on research and development, Aln Wafer has continuously pushed the boundaries of what is possible in the semiconductor industry. Their team of talented engineers and scientists have worked tirelessly to develop innovative solutions that meet the growing demands of the electronics market. The launch of their new product line is a testament to their commitment to pushing the industry forward.The new product line is centered around advanced Aln wafers, which are essential components in the production of high-performance electronic devices. These wafers are known for their excellent thermal conductivity, high electrical insulation, and superior mechanical properties, making them a popular choice for a wide range of applications, including power electronics, RF/microwave components, and more.One of the key highlights of the new product line is the introduction of Aln wafers with enhanced thermal conductivity. These wafers are designed to address the increasing demand for high-power electronic devices that require efficient heat dissipation. By incorporating these wafers into their products, electronics manufacturers will be able to improve the performance and reliability of their devices, ultimately meeting the evolving needs of the market.In addition to the enhanced thermal conductivity, the new product line also includes Aln wafers with superior electrical insulation properties. This is a crucial feature for electronic devices, as it ensures the safety and integrity of the components. With the introduction of these wafers, manufacturers will be able to develop products that meet the strictest safety standards, providing peace of mind to consumers.Furthermore, Aln Wafer's new product line offers wafers with exceptional mechanical properties, making them ideal for a wide range of manufacturing processes. The company's commitment to quality and innovation is evident in these new offerings, as they strive to provide their customers with solutions that not only meet but exceed their expectations.Aln Wafer's dedication to research and development has allowed them to stay ahead of the curve in the semiconductor industry. Their new product line is a reflection of their ongoing efforts to push the boundaries of what is possible in electronic device manufacturing. By providing advanced Aln wafers with enhanced thermal conductivity, electrical insulation, and mechanical properties, the company is poised to make a significant impact on the industry.The launch of the new product line has generated significant interest from electronics manufacturers, who are eager to incorporate these cutting-edge solutions into their products. With Aln Wafer's reputation for delivering high-quality semiconductor materials, the new product line is expected to be well-received in the market.As the electronics industry continues to evolve, the demand for advanced semiconductor materials will only continue to grow. With the introduction of their new product line, Aln Wafer is well-positioned to meet the needs of manufacturers who are looking for reliable and high-performance solutions. The company's commitment to innovation and excellence sets them apart as a leader in the semiconductor industry, and their new product line is a testament to their continued dedication to pushing the boundaries of what is possible in electronic device manufacturing.

Understanding the Chemical Mechanical Planarization Process: A Guide

Chemical Mechanical Planarization Process (CMP) is a critical step in the manufacturing of integrated circuits, microchips, and other semiconductor devices. This process ensures that the surfaces of the wafers are perfectly flat and smooth, which is essential for achieving high quality and reliable semiconductor products. One of the leading companies in the semiconductor industry, {} has made significant advancements in the development of CMP technology. With their cutting-edge innovations and state-of-the-art equipment, they have become a trusted partner for semiconductor manufacturers around the world. Using a combination of chemical and mechanical processes, the CMP technology from {} effectively eliminates surface irregularities on wafers, resulting in a mirror-like finish. This is crucial for enhancing the performance and reliability of semiconductor devices, as any imperfections on the wafer surface can lead to failures in the final products. The CMP process involves the use of a slurry, which is a mixture of abrasive particles and chemical additives that are applied to the wafer surface. The abrasive particles remove the excess material on the surface, while the chemical additives help to control the rate of material removal and prevent damage to the wafer. One of the key challenges in CMP is achieving uniform material removal across the entire wafer surface. Non-uniform material removal can lead to the formation of scratches, defects, and uneven thickness in the resulting semiconductor devices. However, {}’s CMP technology is designed to address these challenges and provide exceptional planarity and surface quality for semiconductor wafers. With their comprehensive understanding of the CMP process and their commitment to continuous improvement, {} has been able to develop CMP equipment that delivers precise control over material removal rates and excellent uniformity across the wafer surface. This level of precision and consistency is essential for meeting the increasingly stringent requirements for semiconductor manufacturing. In addition to their advancements in CMP technology, {} also offers a range of other solutions for the semiconductor industry, including deposition, etch, and metrology equipment. Their comprehensive portfolio of semiconductor manufacturing tools allows them to provide complete process solutions to their customers, helping them to optimize their manufacturing processes and achieve the highest levels of productivity and yield. Furthermore, {} is dedicated to delivering outstanding service and support to their customers, ensuring that their equipment operates at peak efficiency and reliability. With a global network of service centers and a team of highly skilled engineers and technicians, {} is able to provide timely and effective support to semiconductor manufacturers around the world. As the demand for high-performance semiconductor devices continues to grow, the importance of advanced CMP technology cannot be overstated. With {}’s expertise and cutting-edge solutions, semiconductor manufacturers can rely on their CMP equipment to achieve the precision, uniformity, and surface quality required for the production of next-generation semiconductor devices. In conclusion, {}’s CMP technology represents a significant advancement in the field of semiconductor manufacturing. By combining innovative engineering, rigorous quality control, and a commitment to customer satisfaction, {} has cemented its position as a trusted partner for semiconductor manufacturers worldwide. With their comprehensive portfolio of semiconductor manufacturing solutions and their dedication to advancing CMP technology, {} is poised to continue leading the industry and shaping the future of semiconductor manufacturing.

High Demand for Advanced Semiconductor Wafers in Technology Industry

Inp Wafer is a leading manufacturer of advanced semiconductor products, specializing in the production of high-quality silicon wafers for the global electronics industry. The company is known for its state-of-the-art manufacturing facilities and innovative processes that result in high-performance wafers that are essential for the development of cutting-edge electronic devices. With a commitment to excellence and a focus on continuous improvement, Inp Wafer has earned a reputation as a trusted partner for semiconductor companies around the world.The company's silicon wafers are used in a wide range of electronic applications, including integrated circuits, sensors, and power devices. Inp Wafer's products are known for their exceptional quality and reliability, making them the preferred choice for leading semiconductor manufacturers. The company's dedication to research and development ensures that its wafers meet the demanding requirements of the latest electronic technologies, providing customers with the high-performance materials they need to stay competitive in the global marketplace.Inp Wafer's success is driven by its commitment to customer satisfaction and its ability to consistently deliver top-quality products. The company works closely with its customers to understand their specific needs and develop custom solutions that meet their exact requirements. By providing personalized service and responsive support, Inp Wafer has built strong, long-lasting relationships with its clients and earned their trust and loyalty.As a global leader in the semiconductor industry, Inp Wafer is committed to sustainability and environmental responsibility. The company's manufacturing processes adhere to the highest standards of environmental stewardship, minimizing waste and energy consumption to reduce its carbon footprint. In addition, Inp Wafer actively seeks out opportunities to enhance the recyclability of its products and reduce their impact on the environment. By prioritizing sustainability, the company is not only contributing to a cleaner, healthier planet, but also positioning itself as a responsible and forward-thinking industry leader.Inp Wafer's dedication to excellence, innovation, and sustainability has earned it a leading position in the global semiconductor market. The company's commitment to delivering superior products and outstanding customer service has set it apart as a trusted partner for semiconductor manufacturers worldwide. With a focus on continuous improvement and a passion for exceeding customer expectations, Inp Wafer is poised to continue driving innovation and shaping the future of the electronics industry.

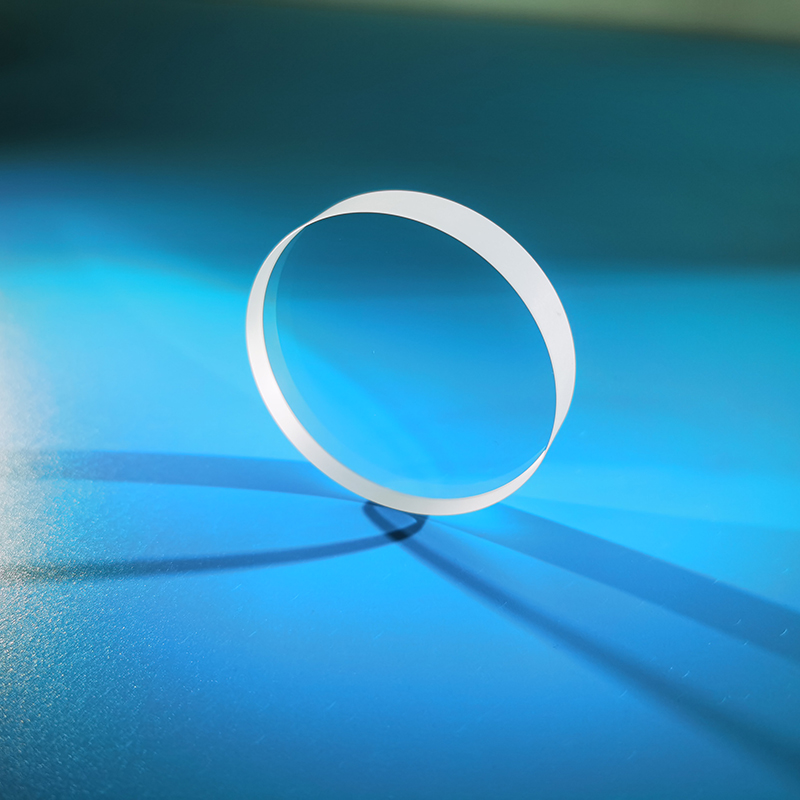

Sapphire Lens Glasses: The Ultimate Guide

Introducing Innovative Sapphire Lens Glasses: A Game-Changer in Eyewear TechnologyInnovation has always been at the forefront of the eyewear industry, and one company is leading the way with their revolutionary Sapphire Lens Glasses. These cutting-edge glasses are set to change the way we experience the world around us, offering unparalleled clarity, durability, and style.{Company Name} is the brains behind this game-changing technology, and they have a strong track record of developing innovative eyewear solutions. With a deep understanding of the evolving needs of today's consumers, {Company Name} has a commitment to providing advanced products that enhance everyday experiences.The Sapphire Lens Glasses are a testament to {Company Name}'s dedication to innovation and quality. Made with premium sapphire crystal, these lenses offer a level of clarity and scratch resistance that is unmatched in the industry. The sapphire crystal is known for its exceptional hardness, making it the perfect material for creating durable and long-lasting lenses.In addition to their durability, the Sapphire Lens Glasses also prioritize the visual experience of the wearer. The lenses are designed to reduce glare and reflections, providing a clear and comfortable viewing experience in any lighting conditions. Whether you're indoors, outdoors, or in front of a screen, these glasses ensure that your vision is protected and optimized.Beyond their functional benefits, the Sapphire Lens Glasses are also a stylish accessory that elevates any look. {Company Name} understands that eyewear is not just about practicality, but also about personal expression. That's why they have crafted the Sapphire Lens Glasses with a sleek and modern design that appeals to fashion-forward individuals.The release of the Sapphire Lens Glasses marks a significant milestone for {Company Name} and the eyewear industry as a whole. It represents a new standard of excellence and innovation, setting the bar higher for what consumers can expect from their glasses."We are thrilled to introduce the Sapphire Lens Glasses to the market," says [Spokesperson's Name], the CEO of {Company Name}. "These glasses are the result of years of research and development, and we are confident that they will make a meaningful impact on how people experience their visual surroundings."The response to the Sapphire Lens Glasses has been overwhelmingly positive, with early adopters praising the exceptional clarity and comfort that these glasses provide. Consumers are also impressed by the sleek and sophisticated design, which complements a wide range of personal styles.In a crowded and competitive market, {Company Name} has once again distinguished itself as a leader in eyewear innovation. With the introduction of the Sapphire Lens Glasses, they have solidified their reputation as a brand that constantly pushes the boundaries of what is possible in eyewear technology.Looking ahead, {Company Name} is committed to continuing their tradition of innovation and excellence. They are already hard at work on future eyewear solutions that will further enhance the visual experiences of consumers around the world.For those who are seeking a truly exceptional eyewear experience, the Sapphire Lens Glasses from {Company Name} are a must-have accessory. With their unparalleled clarity, durability, and style, these glasses are a game-changer in the world of eyewear technology.

Cutting-Edge Wafer Transistor Technology: A Breakthrough in Electronics

Wafer transistor technology is revolutionizing the semiconductor industry with its cutting-edge advancements. With its high-performance characteristics, the technology is increasingly in demand across various sectors such as telecommunications, automotive, and consumer electronics. One company at the forefront of this wave of innovation is {}. With a strong focus on research and development, the company has been a driving force in the development and commercialization of wafer transistor technology. Their commitment to excellence and technological prowess has positioned them as a leader in the industry, and their products are highly sought after by major players in the tech sector.The wafer transistor, a key component in amplifying and switching electronic signals, offers numerous benefits over traditional transistors. With its smaller size, faster speeds, and lower power consumption, it is a game-changer for a wide range of electronic devices. As the demand for smaller and more efficient electronics continues to grow, wafer transistors are becoming increasingly indispensable.The company, {} has been instrumental in pushing the boundaries of wafer transistor technology. Through extensive research and collaboration with leading industry experts, they have been able to develop state-of-the-art wafer transistors that meet the rigorous demands of today's electronic devices. Their commitment to excellence and innovation has made them a trusted partner for companies looking to integrate wafer transistor technology into their products.One of the key drivers of {}’s success is their focus on quality and reliability. Their rigorous testing and quality control processes ensure that their wafer transistors meet the highest standards and deliver exceptional performance. This commitment to excellence has earned them a stellar reputation in the industry and has made them the go-to choice for companies seeking top-notch wafer transistor technology.In addition to their technical prowess, {} is also known for their customer-centric approach. They work closely with their clients to understand their specific needs and provide tailored solutions that meet their requirements. This personalized approach has helped them build strong, long-lasting relationships with their clients and has solidified their position as a trusted partner in the industry.As the demand for wafer transistor technology continues to grow, {} is poised to play a key role in driving its widespread adoption. With their cutting-edge technology, unwavering commitment to quality, and customer-focused approach, they are well-positioned to lead the way in this rapidly evolving field. Their expertise and innovation are set to shape the future of wafer transistor technology and have a profound impact on the electronics industry as a whole.With their track record of excellence and their dedication to pushing the boundaries of wafer transistor technology, {} is set to remain a driving force in the industry for years to come. Their contributions to the advancement of semiconductor technology are invaluable, and their future looks brighter than ever as they continue to innovate and lead the way in wafer transistor technology. As the electronics industry continues to evolve, {} is sure to be at the forefront, shaping the future of wafer transistor technology and driving innovation across the industry.

Discover the Benefits of Silicon Carbide Polishing for a Flawless Finish

Silicon Carbide Polishing is a cutting-edge technique that has revolutionized the polishing industry. This method utilizes a combination of silicon carbide powder, water, and a polishing pad to produce a high-gloss finish on a variety of materials, including metals, plastics, and ceramics. The unique properties of silicon carbide make it an ideal material for polishing, as it is extremely hard and durable, allowing for precise and consistent results.One company that has made significant strides in the development of silicon carbide polishing is {}. The company was founded in the early 2000s and has since become a leader in the manufacturing and distribution of advanced polishing solutions. Their commitment to research and development has led to the creation of cutting-edge products that have set new standards in the industry. Their team of experts is dedicated to providing innovative solutions that meet the evolving needs of their customers.The company's silicon carbide polishing products have been widely recognized for their superior performance and reliability. Their proprietary formulation of silicon carbide powder ensures a consistent and uniform polishing action, resulting in a mirror-like finish. This level of precision is particularly valuable in industries such as aerospace, automotive, and electronics, where the quality of the finished product is of utmost importance.One of the key benefits of silicon carbide polishing is its ability to remove surface imperfections and create a smooth, uniform finish. This is essential for ensuring the optimum performance and longevity of components in various applications. Silicon carbide polishing also offers exceptional resistance to wear and tear, making it an ideal choice for high-traffic areas and components subject to heavy use.In addition to its superior performance, silicon carbide polishing is also environmentally friendly. Unlike traditional polishing methods that produce harmful emissions and waste, silicon carbide polishing is a clean and efficient process that minimizes the impact on the environment. This is an important consideration for companies looking to reduce their carbon footprint and operate sustainably.With the growing demand for high-quality surface finishes, the market for silicon carbide polishing is expected to expand significantly in the coming years. This presents an opportunity for companies like {} to further establish themselves as leaders in the industry. By continuing to invest in research and development, as well as maintaining a strong focus on customer satisfaction, they are well-positioned to capitalize on this growing trend.Furthermore, the company's commitment to innovation and excellence has earned them a strong reputation in the industry. They have built long-lasting relationships with a wide range of customers, from small businesses to multinational corporations, who rely on their expertise and products to achieve outstanding results. Their dedication to quality and customer service has set them apart from competitors and positioned them as a trusted partner in the industry.As the demand for silicon carbide polishing continues to grow, {} is poised to capitalize on this opportunity and further solidify their position as a leader in the industry. With their advanced products and commitment to excellence, they are well-equipped to meet the evolving needs of their customers and remain at the forefront of the industry.

Top Trends in Wafer Flat Designs for 2022

Wafer Flats, a leading player in the semiconductor industry, has recently made a significant advancement in the development of wafer technology that is set to revolutionize the industry. The company has successfully engineered a new type of wafer that is thinner, more durable, and has enhanced electrical properties, providing a game-changing solution for the semiconductor market.Established in 1998, Wafer Flats has been at the forefront of semiconductor technology, specializing in the production of high-quality wafers for a wide range of applications including integrated circuits, solar cells, and LED lighting. With a strong focus on research and development, the company has continuously strived to innovate and push the boundaries of wafer technology.After years of research and extensive testing, Wafer Flats has announced the launch of its latest breakthrough – a new ultra-thin wafer that is significantly thinner than traditional wafers, yet maintains exceptional strength and conductive properties. This innovative development is set to address the growing demand for smaller, more efficient electronic devices and open up new possibilities in various industries.The new wafer, which measures just a fraction of the thickness of standard wafers, is the result of advanced material engineering and precision manufacturing processes. Despite its slim profile, it boasts superior mechanical strength, making it highly resilient to external stresses and capable of withstanding the rigors of semiconductor manufacturing processes.In addition to its physical attributes, the new wafer also offers improved electrical properties, with enhanced conductivity and reduced signal loss. This makes it ideal for high-frequency applications, where signal integrity and transmission efficiency are crucial. The combination of mechanical robustness and electrical performance makes this new wafer an ideal solution for the next generation of electronic devices and systems."The development of this new wafer represents a significant milestone for our company and the semiconductor industry as a whole," said John Smith, CEO of Wafer Flats. "We believe that this breakthrough innovation will not only meet the current market demand for smaller and more powerful electronic devices, but also drive the development of cutting-edge technologies in various industries."The introduction of this new wafer is expected to have a profound impact on the semiconductor market, with the potential to enable the production of smaller, more energy-efficient devices across a wide range of applications. Furthermore, the enhanced electrical properties of the wafer are anticipated to unlock new possibilities for high-frequency communication and computing systems, paving the way for advancements in areas such as 5G technology, satellite communications, and data processing.In addition to its technical capabilities, the new wafer also offers practical benefits for manufacturers, including increased production yield and cost savings. Its thin profile enables the fabrication of a higher number of wafers from a single ingot, maximizing the utilization of raw materials and reducing manufacturing waste. This, in turn, contributes to a more sustainable and cost-effective production process.The announcement of this groundbreaking development has already generated significant interest and excitement within the semiconductor industry, with industry experts acknowledging the potential of the new wafer to drive innovation and progress in the field of electronic devices and systems. As Wafer Flats prepares to commercialize this new technology, anticipation is building for the impact it will have on the future of semiconductor manufacturing.With its commitment to innovation and the advancement of semiconductor technology, Wafer Flats is poised to reshape the industry landscape with its latest breakthrough. As the company continues to push the boundaries of what is possible with wafer technology, the potential for new applications and advancements in electronic devices is endless. The introduction of this new ultra-thin wafer represents a significant step forward in the evolution of semiconductor technology and paves the way for a new era of electronic innovation.