New Silicon Carbide Grade Offers Improved Performance and Durability

By:Admin

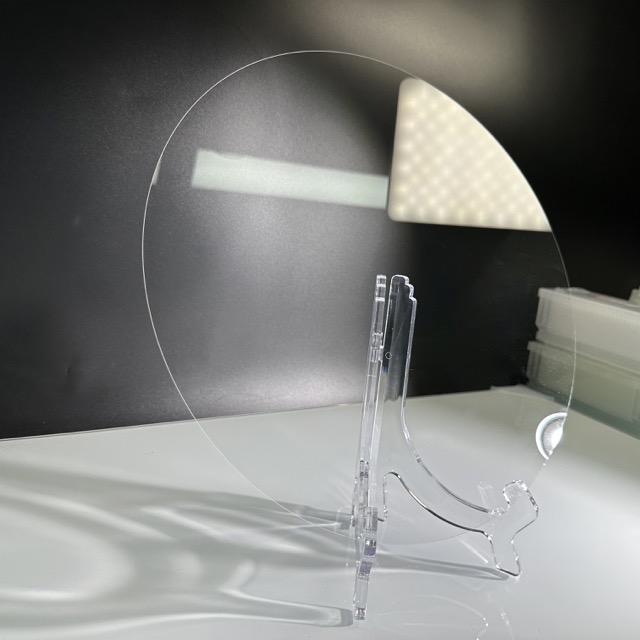

One of the leading manufacturers of dummy Grade SiC is a company that specializes in the production of advanced materials for the semiconductor industry. The company has a long history of providing high-quality materials for various applications in the field of electronics and has established itself as a trusted partner for many semiconductor manufacturers.

The company's dummy Grade SiC is produced using advanced manufacturing techniques and strict quality control measures to ensure that the material meets the strict requirements of the semiconductor industry. The material is designed to have a high level of purity and uniformity, making it suitable for use in a wide range of semiconductor devices and applications.

One of the key advantages of using dummy Grade SiC in semiconductor manufacturing is its ability to withstand high temperatures and thermal shock, making it an ideal material for use in high-power electronic devices. The material also has excellent thermal conductivity, which allows for efficient heat dissipation and enhanced device performance.

In addition, dummy Grade SiC has a high mechanical strength, making it resistant to mechanical stress and wear, which are important factors in the long-term reliability of semiconductor devices. This makes it an ideal material for use in power semiconductor devices, which are often subjected to high levels of stress and thermal cycling.

The company's dummy Grade SiC is available in a variety of shapes and sizes to meet the specific requirements of different semiconductor manufacturing processes. Whether it is used as a placeholder during device fabrication or as a test material for process development, the material is designed to provide consistent and reliable performance in the most demanding semiconductor manufacturing environments.

The company's commitment to quality and innovation has made it a preferred supplier of advanced materials for the semiconductor industry. Its dummy Grade SiC is just one example of the company's dedication to providing cutting-edge solutions for the rapidly evolving semiconductor market.

As the demand for high-performance electronic devices continues to grow, the need for advanced materials like dummy Grade SiC will only increase. With its excellent thermal and mechanical properties, as well as its high level of purity and uniformity, dummy Grade SiC is poised to play a crucial role in the continued advancement of the semiconductor industry.

In conclusion, the company's dummy Grade SiC offers semiconductor manufacturers a reliable and high-performance material for use in a wide range of applications. With its excellent thermal conductivity, high mechanical strength, and resistance to high temperatures, dummy Grade SiC is an ideal material for use in the fabrication of advanced semiconductor devices. As the semiconductor industry continues to push the boundaries of device performance and reliability, the demand for high-quality materials like dummy Grade SiC will only continue to grow.

Company News & Blog

Revolutionary Synthetic Sapphire Tubes Shaping Industries

Title: Revolutionary Synthetic Sapphire Tubes Poised to Revolutionize Multiple IndustriesIntroduction:Synthetic sapphire tubes have emerged as an innovative and disruptive solution that is expected to transform numerous industries. This groundbreaking technology, developed by a leading materials engineering company, promises a wide range of applications due to its exceptional properties. With its outstanding resistance to heat, corrosion, and wear, these synthetic sapphire tubes are set to revolutionize sectors such as electronics, optics, and healthcare while opening up new possibilities for advanced scientific research and manufacturing processes.1. Electronics Industry:The electronics industry is poised to benefit significantly from the introduction of synthetic sapphire tubes. These tubes offer exceptional strength, transparency, and excellent electrical insulation properties, making them ideal for various applications. Thin sapphire tubes can be used as reliable protective enclosures for sensitive electronic components. Additionally, their exceptional heat resistance ensures longevity and reliability, making them excellent candidates for semiconductor applications and high-power LED lighting.2. Optical Technology:In the realm of optics, synthetic sapphire tubes are poised to bring about a paradigm shift. Their high optical quality, coupled with their ability to maintain clarity over a wide range of temperatures and conditions, makes them ideal for lenses, windows, and prisms in demanding optical systems. These tubes can also serve as a substrate for the growth of high-quality crystalline structures used in lasers and photovoltaic cells, further enhancing their potential in the field of optics.3. Healthcare and Medical Industries:The healthcare sector can greatly benefit from the integration of synthetic sapphire tubes into various medical devices. Thanks to their biocompatibility, these tubes can be used for surgical tools, dental equipment, and implantable medical devices. Their exceptional hardness and resistance to scratching ensure longevity and reduced risk of infection. Furthermore, the tubes' chemical inertness makes them an excellent choice for cryogenic storage, providing a reliable medium for preserving biological samples and medical supplies.4. Scientific Research and Exploration:Synthetic sapphire tubes are opening up new horizons for scientific research and exploration. With their remarkable resistance to extreme temperatures, these tubes are crucial components for instruments used in space exploration, such as satellites and space probes. Their transparency in both the visible and infrared spectrum empowers scientists to capture precise data for various experiments, making them invaluable tools in research facilities around the world.5. Industrial Manufacturing:The introduction of synthetic sapphire tubes into industrial manufacturing processes marks a significant advancement. Their exceptional hardness and resistance to chemical corrosion make them ideal for applications involving aggressive chemicals and abrasive materials. Sapphire tubes can be used in chemical reactors, protective coatings, and even as nozzles for abrasive water-jet cutting machines. These tubes increase equipment durability, resulting in reduced maintenance costs, improved efficiency, and enhanced product quality.In conclusion, synthetic sapphire tubes, developed by a leading materials engineering company, offer immense potential to revolutionize numerous industries. Their exceptional properties, including resistance to heat, chemicals, and wear, position them as disruptive solutions across various sectors. With applications ranging from electronics and optics to healthcare, scientific research, and industrial manufacturing, synthetic sapphire tubes are paving the way for advanced technologies, improved product performance, and unparalleled durability.

Sic Wafer Market Trends and Growth Analysis

Sic Wafer, a key player in the semiconductor industry, recently announced a major breakthrough in the development of silicon carbide (SiC) wafers. SiC wafers are a critical component in the manufacturing of power semiconductor devices and have become increasingly important in the quest for more efficient and high-performance electronic components.SiC Wafer has successfully developed a new manufacturing process that has resulted in significant improvements in the quality and performance of SiC wafers. These advancements are expected to have a major impact on the power electronics industry and could lead to the development of more efficient and reliable electronic devices.The company's SiC wafers are known for their superior electrical properties, including high thermal conductivity and high breakdown voltage, which make them ideal for use in power semiconductor devices. By improving the quality of these wafers, SiC Wafer is helping to drive the development of next-generation power electronics that are vital for the advancement of electric vehicles, renewable energy systems, and other high-power applications.Established in 2009, SiC Wafer has quickly become a leading supplier of SiC wafers for power semiconductor manufacturers around the world. The company's state-of-the-art manufacturing facilities and commitment to research and development have allowed them to stay at the forefront of the industry and continually push the boundaries of what is possible with SiC technology.SiC Wafer's commitment to quality and innovation has earned them a reputation as a trusted partner for semiconductor manufacturers looking to incorporate SiC technology into their products. Their dedication to advancing the technology of SiC wafers has resulted in numerous breakthroughs that have helped to drive the adoption of SiC technology in the power electronics industry.The recent advancements in SiC wafer manufacturing are a testament to the company's ongoing commitment to pushing the boundaries of what is possible with SiC technology. By continually improving the quality and performance of SiC wafers, SiC Wafer is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future.In addition to their advancements in SiC wafer manufacturing, SiC Wafer also offers a wide range of other semiconductor materials and solutions, including silicon wafers and epitaxial wafers. Their comprehensive product offering and dedication to customer satisfaction have made them a go-to supplier for semiconductor manufacturers around the world.With a strong track record of innovation and a commitment to providing the highest quality semiconductor materials, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology. Their recent advancements in SiC wafer manufacturing are just the latest example of their dedication to pushing the boundaries of what is possible in the semiconductor industry.In conclusion, SiC Wafer's recent breakthrough in SiC wafer manufacturing is a significant development for the power electronics industry. By improving the quality and performance of SiC wafers, the company is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future. With their ongoing commitment to innovation and quality, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology for years to come.

Sapphire Glass Windows: A Transparent Solution for Enhanced Durability and Clarity

Sapphire Glass Window: The Strength, Durability and Clarity You Need for Your HomeAre you looking for a window that’s built to withstand the test of time? Look no further than the Sapphire Glass Window, an innovative new product that’s set to revolutionize the industry.Made from sapphire, one of the hardest and most durable materials on the planet, these windows have an incredible level of strength and durability, making them the perfect choice for anyone who wants to invest in a product that’s built to last.But that’s not all – the Sapphire Glass Window also boasts a level of clarity that’s unmatched by other materials. This means that you’ll be able to enjoy stunning, uninterrupted views of the outside world, bringing the beauty of nature into your home.So, what makes sapphire such a special material? Well, for starters, it’s incredibly tough. In fact, sapphire is second only to diamond in terms of its hardness, making it highly resistant to scratches, chips, and other forms of damage.Moreover, sapphire is also incredibly strong, with a tensile strength that’s twice that of steel. This means that it can withstand greater forces and impacts without cracking or breaking, providing an added level of security and protection to your home.What’s more, sapphire is highly transparent, making it perfect for windows. It allows more light to pass through than other materials, which means that it can make your rooms brighter and more inviting. Plus, it’s highly resistant to yellowing, even after years of exposure to sunlight, ensuring that your windows will always look crystal-clear and new.But what about the cost, you might ask? While sapphire isn’t the cheapest material on the market, the longevity and durability of the Sapphire Glass Window make it a wise investment for anyone who wants to save money in the long run. Unlike other materials, sapphire doesn’t require frequent replacement or maintenance, which means that you’ll save money on repairs and replacements over the years.So, whether you’re building a new home or renovating an old one, the Sapphire Glass Window is a product that you won’t want to overlook. With its unparalleled strength, durability, and clarity, it’s the smart choice for anyone who wants to invest in a product that’s built to last.

High-Quality Silicon Carbide for Production Applications

Production Grade SiC: A Game-Changer in the Semiconductor IndustryIn the fast-paced world of technology, innovation and quality are paramount. As the demand for high-performance semiconductor materials continues to grow, the need for advanced and reliable solutions becomes increasingly vital. This is where Production Grade SiC comes into play as a game-changer in the semiconductor industry.Production Grade SiC, manufactured by a leading company in the semiconductor materials industry, is revolutionizing the way semiconductors are produced. With its exceptional properties and unparalleled performance, it has emerged as a preferred choice for a wide range of applications, including power electronics, automotive, aerospace, and more.The company, {}, with its rich history and expertise in the development and production of advanced materials, has set a new benchmark with its Production Grade SiC. With a strong commitment to innovation and continuous improvement, the company has positioned itself as a global leader in the semiconductor materials industry.With its state-of-the-art manufacturing facilities and a team of dedicated professionals, {} has been at the forefront of producing high-quality SiC materials that meet the strictest industry standards. The company's relentless focus on research and development has led to the creation of Production Grade SiC that offers unparalleled performance, reliability, and consistency.One of the key advantages of Production Grade SiC is its superior thermal conductivity, which allows for greater efficiency and reliability in high-temperature and high-power applications. This makes it an ideal choice for the growing demand for energy-efficient power electronics, electric vehicles, renewable energy systems, and more.Additionally, Production Grade SiC offers excellent mechanical strength and chemical stability, making it resilient in harsh operating environments. This makes it particularly well-suited for applications in the aerospace and defense industries, where reliability and performance are non-negotiable.The automotive industry is also recognizing the benefits of Production Grade SiC, as it enables the development of high-performance electric vehicles with enhanced powertrain efficiency and reduced energy losses. With the global push towards sustainability and clean energy, Production Grade SiC is playing a crucial role in driving the advancement of electric mobility.Moreover, {}'s Production Grade SiC has opened up new possibilities in a wide range of industrial and consumer applications, including motor drives, renewable energy inverters, and grid-level power systems. Its reliability and efficiency have made it a preferred choice for manufacturers looking to enhance the performance and durability of their products.Beyond its technical advantages, Production Grade SiC also offers economic benefits. Its ability to enable smaller, lighter, and more efficient power systems translates into cost savings for end users. With its long-term reliability and performance, it reduces the need for frequent maintenance and replacements, further contributing to overall cost reduction.As Production Grade SiC continues to gain traction in the semiconductor industry, {} is dedicated to collaborating with customers to explore new possibilities and applications. The company's technical expertise and customer-focused approach have positioned it as a trusted partner for businesses seeking to leverage the potential of SiC materials.With a clear commitment to sustainability and technological advancement, {} is driving the semiconductor industry forward with its innovative solutions. The company's Production Grade SiC is not just a material; it's a catalyst for progress, enabling the development of cutting-edge technologies and contributing to a more efficient and sustainable future.In conclusion, Production Grade SiC, manufactured by {} represents a significant leap forward in the semiconductor materials industry. With its exceptional properties, reliability, and performance, it is opening up new horizons for a wide range of applications. As the demand for high-performance materials continues to grow, Production Grade SiC is poised to play a pivotal role in shaping the future of technology and driving innovation across industries.

Evaluating the Global Epitaxial Wafer Market Trends and Forecast

The global epitaxial wafer market is expected to experience significant growth in the coming years, driven by increasing demand for advanced semiconductor devices and technological advancements in the electronics industry. Epitaxial wafers are thin layers of single crystal semiconductor material that are used in the manufacturing of integrated circuits and other electronic devices.The market for epitaxial wafers is expected to be driven by the growing adoption of smartphones, tablets, and other consumer electronics, as well as the increasing use of semiconductor devices in automotive and industrial applications. Additionally, the development of advanced technologies such as 5G, artificial intelligence, and the Internet of Things is expected to further drive the demand for epitaxial wafers.One company that is poised to benefit from the growth of the epitaxial wafer market is {}. Founded in {}, the company is a leading manufacturer of epitaxial wafers and other semiconductor materials. The company has a strong focus on research and development, and is continuously working to improve the performance and quality of its products.{} offers a wide range of epitaxial wafers, including silicon, gallium arsenide, and gallium nitride wafers, which are used in a variety of electronic devices and applications. The company's products are known for their high quality, reliability, and performance, and are widely used by leading semiconductor manufacturers around the world.In addition to its focus on product development, {} is also committed to sustainability and environmental responsibility. The company has implemented various initiatives to reduce its environmental impact, including the use of eco-friendly materials and processes in its manufacturing facilities.With the growing demand for epitaxial wafers, {} is well-positioned to capitalize on the opportunities in the market. The company has a strong global presence, with a network of sales offices and distribution partners in key markets around the world. This allows {} to effectively serve its customers and meet their evolving needs and requirements.As the market for epitaxial wafers continues to expand, {} is focused on expanding its production capacity and enhancing its capabilities to meet the growing demand. The company is investing in new manufacturing facilities and advanced equipment to ensure that it can continue to deliver high-quality products to its customers.In conclusion, the global market for epitaxial wafers is expected to experience significant growth in the coming years, driven by increasing demand for advanced semiconductor devices and technological advancements in the electronics industry. With its strong focus on research and development, product quality, and sustainability, {} is well-positioned to capitalize on the opportunities in the market and maintain its position as a leading supplier of epitaxial wafers.

Durable and Reliable Optical Glass Tube for Various Applications

The Optical Glass Tube, manufactured by a leading company in the field of optical technology, has been making waves in the industry with its cutting-edge design and superior performance. The company, with its long-standing reputation for innovation and quality, has once again raised the bar with this latest product.The Optical Glass Tube is a critical component in a wide range of optical systems, including laser devices, medical equipment, and scientific instruments. Its high-quality glass material, combined with precise engineering and craftsmanship, allows for exceptional light transmission and minimal distortion, making it an ideal choice for demanding applications.One of the key features of the Optical Glass Tube is its exceptional durability. The company’s expertise and advanced manufacturing processes ensure that the tube can withstand high temperatures, extreme pressures, and harsh environmental conditions without compromising its optical performance. This level of reliability is crucial for industries such as aerospace, defense, and industrial manufacturing, where precision and consistency are paramount.In addition to its durability, the Optical Glass Tube also offers exceptional clarity and purity. The company’s stringent quality control measures and extensive testing procedures ensure that the glass meets the highest standards for optical transmission and performance. As a result, the tube delivers crisp, clear images and accurate data, making it an invaluable component for applications such as microscopy, spectroscopy, and imaging systems.Furthermore, the company’s commitment to research and development has led to continuous improvements in the Optical Glass Tube’s design and performance. With a team of experienced engineers and scientists, the company is constantly pushing the boundaries of what is possible in optical technology, resulting in products that redefine industry standards and set new benchmarks for performance and reliability.The Optical Glass Tube is also part of the company’s broader commitment to sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing processes and materials, ensuring that its products have minimal impact on the environment. As a result, customers can have confidence that they are not only getting top-quality optical components but also supporting a company that is dedicated to minimizing its environmental footprint.The company’s dedication to customer satisfaction is also evident in its comprehensive support and service offerings. With a global network of technical experts and distribution partners, the company is able to provide responsive and personalized assistance to customers around the world. From product selection and custom design to installation and maintenance, the company is committed to ensuring that its customers get the most out of their Optical Glass Tube.Overall, the Optical Glass Tube from this leading company represents a significant advancement in optical technology, offering unmatched performance, reliability, and environmental sustainability. With its exceptional design and manufacturing expertise, the company has once again demonstrated its leadership in the industry and its commitment to pushing the boundaries of what is possible in optical technology. As a result, the Optical Glass Tube is poised to become the go-to choice for the most demanding optical applications, solidifying the company’s reputation as a trusted and innovative partner for customers worldwide.

Introducing the Latest Breakthrough: 8 Inch Wafer Diameter Revolutionizes the Tech Industry

[Company Introduction]{Insert company name} is a leading global semiconductor manufacturer renowned for its cutting-edge technologies and innovative solutions. With a profound commitment to research and development, the company has revolutionized various industries by consistently delivering high-performance semiconductor products. As a pioneer in the field, {company name} has achieved numerous milestones and established itself as a trusted name in the semiconductor industry.[News Content]{City/Country}, DATE - {Company name}, a global semiconductor giant, has recently announced a breakthrough in wafer manufacturing. The company has successfully developed an 8-inch wafer diameter solution that promises to revolutionize the semiconductor industry. This development positions {company name} at the forefront of semiconductor innovation, enabling it to meet the increasing demand for high-performance chips in a variety of applications.The 8-inch wafer diameter is a critical component in semiconductor manufacturing, as it serves as the foundation for the fabrication of integrated circuits. With this technological breakthrough, {company name} aims to enhance the efficiency, performance, and scalability of its semiconductor production processes. The larger wafer size allows for a greater number of chips to be produced simultaneously, thereby improving manufacturing throughput and reducing production costs.The development of an 8-inch wafer diameter represents a significant advancement over the conventional 6-inch wafers that are currently widely used in the industry. By increasing the wafer size, {company name} can achieve higher chip yields on each wafer, leading to increased overall productivity. Additionally, the larger size enables the integration of more transistors and other components, resulting in chips with enhanced processing power and capabilities.Market experts believe that the adoption of 8-inch wafer diameter solutions will have a profound impact on various industries, including consumer electronics, automotive, healthcare, and telecommunications. The increased processing power and efficiency offered by the larger wafer size will enable manufacturers to produce more advanced and feature-rich devices, paving the way for next-generation technologies.{Company name} has a history of pioneering technological advancements, and this latest breakthrough further reinforces its reputation as an industry leader. Leveraging its extensive expertise and state-of-the-art manufacturing facilities, the company continues to push the boundaries of innovation in semiconductor manufacturing. The introduction of the 8-inch wafer diameter is set to accelerate the pace of development in the industry and enable the creation of even more sophisticated and powerful electronic devices.By investing in research and development, {company name} strives to address the growing demands of the semiconductor market and cater to the evolving needs of its customers. Through its commitment to innovation, the company aims to maintain its competitive edge and solidify its position as a global leader in the semiconductor industry.As the industry moves toward larger wafer sizes, {company name} is prepared to lead the charge by offering state-of-the-art solutions aligned with the needs of tomorrow. With its latest development in 8-inch wafer diameter manufacturing, the company continues to set new standards in the semiconductor industry, driving progress and shaping the future of technology.

Discover the Latest Advancements in Wafer Window Technology

Mgo Wafer Windows Revolutionize the Window Industry[Company Name], a leading innovative materials technology company, has recently introduced a revolutionary product that is set to transform the window industry. Mgo Wafer Windows, a groundbreaking development in window technology, promise increased durability, enhanced thermal insulation, and improved soundproofing. With their innovative design and advanced properties, these windows are poised to become the go-to choice for architects, builders, and homeowners alike.Traditional windows have long been plagued by issues such as susceptibility to damage, limited insulation capabilities, and poor soundproofing. [Company Name] recognized these pain points and embarked on a mission to develop a solution that would alleviate these problems. The result of their relentless research and development efforts is the Mgo Wafer Windows – a product that promises to revolutionize the way we think about and experience windows.One of the key advantages of Mgo Wafer Windows is their exceptional durability. Unlike traditional windows, which are prone to cracks, discoloration, and warping over time, Mgo Wafer Windows are composed of magnesium oxide, a material known for its high strength and resistance to wear and tear. This superior durability ensures that the windows retain their aesthetic appeal and functionality for extended periods, saving homeowners from the hassle and cost of regular replacements.Furthermore, Mgo Wafer Windows excel in thermal insulation, offering a significant improvement over conventional windows. These windows feature advanced insulation properties that minimize heat transfer, resulting in reduced energy consumption for heating or cooling buildings. As a result, homeowners can enjoy a more comfortable and energy-efficient living environment while simultaneously reducing their carbon footprint.Another area where Mgo Wafer Windows shine is soundproofing. The advanced design of these windows incorporates multiple layers of sound-dampening materials, effectively reducing noise pollution from outside sources. This is particularly beneficial for urban areas, where excessive noise can negatively impact the quality of life. Mgo Wafer Windows provide the peace and tranquility that homeowners desire, allowing them to relax and unwind without disturbances.Additionally, Mgo Wafer Windows offer an array of customizable options, ensuring they seamlessly blend with various architectural styles. Homeowners and architects can choose from a wide range of sizes, shapes, and designs to meet their unique preferences and requirements. This versatility allows for creativity in design and enhances the overall aesthetics of any building or space.In terms of installation and maintenance, Mgo Wafer Windows provide added convenience. The lightweight nature of magnesium oxide makes these windows easy to handle and install, saving time and effort during the construction process. Moreover, the low maintenance requirements of Mgo Wafer Windows help homeowners avoid constant upkeep and reduce long-term costs associated with repairs.With the introduction of Mgo Wafer Windows, [Company Name] has disrupted the traditional window industry and set new standards for excellence. These windows promise remarkable durability, energy efficiency, enhanced soundproofing, and aesthetic versatility – a combination of features that makes them an ideal choice for both residential and commercial buildings.As the demand for sustainable and efficient building materials continues to grow, Mgo Wafer Windows position [Company Name] at the forefront of innovation in the window industry. With a commitment to excellence and a focus on customer satisfaction, [Company Name] is poised to lead the charge in transforming the way we view and experience windows. The advent of Mgo Wafer Windows marks a crucial milestone in the progression of architecture and construction, and it is only a matter of time before these windows become the new industry standard.

Discover the Latest Advancements in Crystal Substrate Technology

GSGG Crystal Substrate - a Cutting-Edge Material for Advanced TechnologyIn the world of advanced technology, the demand for high-performance materials has never been greater. One material that has been gaining attention in recent years is GSGG crystal substrate, which has shown great promise in various applications, from laser systems to optical devices. This cutting-edge material has the potential to revolutionize the way we approach advanced technology and is poised to become a critical component in the development of next-generation devices.GSGG crystal substrate is a type of crystal material that exhibits exceptional optical and physical properties, making it highly desirable for a wide range of applications. Its unique combination of high transparency, excellent thermal conductivity, and superior mechanical strength sets it apart from other materials currently available in the market. This makes GSGG crystal substrate an ideal choice for use in demanding environments where reliability and performance are paramount.One company that has been at the forefront of developing and manufacturing GSGG crystal substrates is {}. With a strong focus on research and development, {} has been able to produce high-quality GSGG crystal substrates that meet the stringent requirements of the most demanding applications. The company's state-of-the-art production facilities and advanced manufacturing techniques have enabled them to consistently deliver products that exceed industry standards and customer expectations.{}'s GSGG crystal substrates have found wide-ranging applications in various fields, including laser technology, telecommunications, aerospace, and medical devices. One of the key advantages of using GSGG crystal substrates in these applications is their exceptional thermal stability and optical clarity, which allows for high-power laser operation and precise optical transmission. This makes {}'s GSGG crystal substrates an ideal choice for demanding laser systems and optical devices where performance and reliability are non-negotiable.Furthermore, {}'s commitment to quality and innovation has positioned them as a leading supplier of GSGG crystal substrates in the global market. The company's dedicated team of experts continuously pushes the boundaries of material science and engineering to develop new and improved GSGG crystal substrates that address the evolving needs of the industry. As a result, {} has earned a reputation for being a trusted partner for organizations looking to incorporate GSGG crystal substrates into their advanced technology solutions.In addition to their extensive product line, {} also offers comprehensive technical support and customization services to its customers. This ensures that each GSGG crystal substrate meets the exact specifications and requirements of the application, allowing for seamless integration and optimal performance. {}'s dedication to customer satisfaction and their ability to provide tailored solutions further solidifies their position as a preferred supplier of GSGG crystal substrates in the market.Looking ahead, the future of GSGG crystal substrates looks promising, with continued advancements in material science and manufacturing techniques. As the demand for high-performance materials grows, GSGG crystal substrates are expected to play a pivotal role in enabling the next generation of advanced technology solutions. With {} at the helm, driving innovation and excellence in the development of GSGG crystal substrates, the industry can expect to see even greater potential unlocked in the years to come.In conclusion, GSGG crystal substrates have emerged as a game-changing material for advanced technology, with their exceptional optical and physical properties making them a preferred choice for a wide range of applications. As a leading manufacturer and supplier of GSGG crystal substrates, {} is well-positioned to meet the growing demand for these materials and drive further advancements in the industry. With their commitment to quality, innovation, and customer satisfaction, {} continues to be a driving force in the evolution of GSGG crystal substrates and their potential to shape the future of advanced technology.