New Technology Advancements in Wafer Manufacturing Process

By:Admin

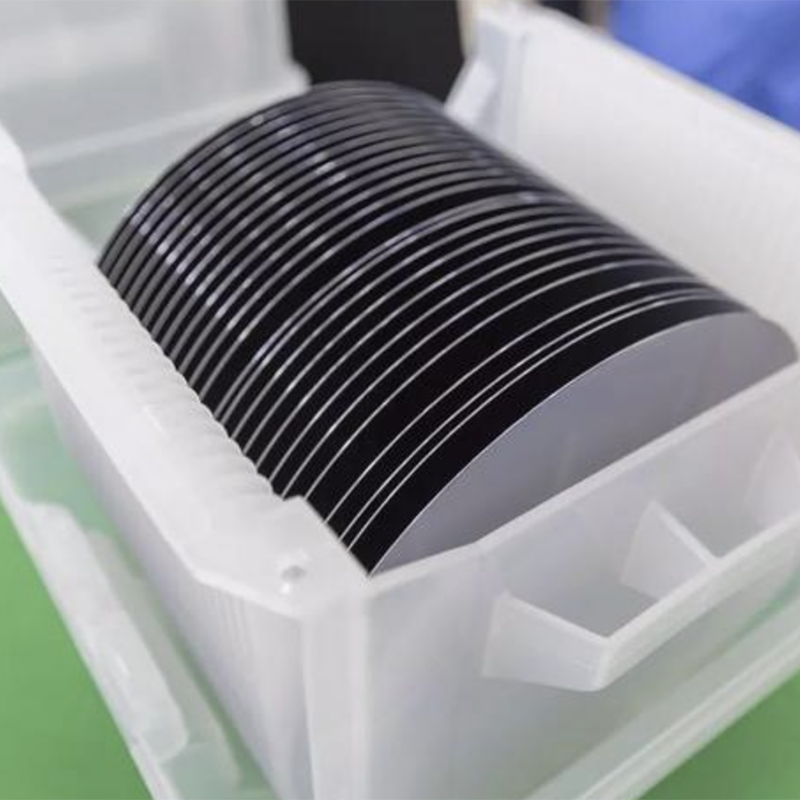

With the increasing demand for smaller, faster, and more power-efficient devices, the semiconductor industry is constantly under pressure to develop new materials and technologies that can keep up with the ever-changing market needs. Pss Wafer has been at the forefront of this technological revolution, and its latest innovation is poised to make a significant impact.

The company's Pss Wafer technology offers a range of benefits that directly address the challenges faced by the semiconductor industry. The unique design and manufacturing process of Pss Wafer enable the production of wafers with enhanced thermal and electrical properties, resulting in higher performance and energy efficiency for semiconductor devices.

Furthermore, Pss Wafer's technology also allows for the integration of multiple functionalities on a single wafer, reducing production costs and enhancing the overall functionality of semiconductor devices. This breakthrough in wafer technology has the potential to significantly impact various industries, including consumer electronics, automotive, telecommunications, and industrial applications.

In addition to its technical capabilities, Pss Wafer has also established itself as a reliable and innovative partner for its customers. The company's commitment to quality, reliability, and customer satisfaction has made it a preferred supplier for leading semiconductor manufacturers worldwide. Pss Wafer's expertise in wafer manufacturing and its dedication to continuous innovation have positioned the company as a key player in the semiconductor industry.

"We are excited to introduce our latest Pss Wafer technology to the market," said a spokesperson for Pss Wafer. "This breakthrough represents a significant advancement in wafer technology and has the potential to redefine the semiconductor industry. We believe that our innovative approach to wafer manufacturing will enable our customers to develop next-generation semiconductor devices that are faster, smaller, and more energy-efficient."

The announcement of Pss Wafer's latest technology comes at a time when the semiconductor industry is experiencing rapid growth and technological advancements. The demand for advanced semiconductor materials and technologies is higher than ever, and Pss Wafer is well-positioned to meet these demands with its cutting-edge wafer technology.

As the semiconductor industry continues to evolve, Pss Wafer remains committed to pushing the boundaries of wafer technology and delivering innovative solutions that drive the industry forward. With its latest breakthrough, the company is poised to make a significant impact on the semiconductor industry and enable the development of next-generation semiconductor devices that will power the technology of the future.

In conclusion, Pss Wafer's latest innovation in wafer technology has the potential to revolutionize the semiconductor industry. With its unique design and manufacturing process, the company is poised to address the growing demand for high-performance, energy-efficient, and cost-effective semiconductor devices. Pss Wafer's commitment to innovation and customer satisfaction has positioned it as a key player in the semiconductor industry, and its latest breakthrough is set to make a lasting impact on the future of semiconductor technology.

Company News & Blog

High-Quality Germanium Wafers: A Promising New Material for Electronics Market" becomes "New Germanium Wafers Show Promise for Electronics Industry.

Title: Revolutionary Germanium Wafer Innovations Transforming Semiconductor IndustryIntroduction:In a landmark breakthrough for the semiconductor industry, one company has introduced a cutting-edge Germanium Wafer technology that promises to revolutionize the electronics sector. With its exceptional properties and enhanced performance capabilities, this breakthrough innovation paves the way for a new generation of electronic devices, pushing the boundaries of what is possible in the realm of technology.Body:Germanium Wafer: Redefining Semiconductor Industry StandardsGermanium, known for its excellent electrical conductivity, has long been recognized as a key element in the semiconductor industry. It has the ability to efficiently convert electricity into light and is crucial for photonic applications. Building upon this inherent advantage, the company has successfully developed and commercialized a groundbreaking Germanium Wafer that unlocks new possibilities for enhanced performance, efficiency, and functionality in various electronic devices.Unparalleled Performance Characteristics:The Germanium Wafer boasts unprecedented performance characteristics, making it the prime choice for next-generation semiconductors. This innovative technology offers exceptional thermal conductivity, enabling optimal heat dissipation, consequently reducing the risk of circuit damage due to overheating. Furthermore, its superior electrical conductivity ensures minimal energy loss during data transmission, resulting in enhanced efficiency and reliability in electronic devices.Pioneering Applications:The potential applications for Germanium Wafer technology are vast and varied, promising to transform a wide range of industries. In the field of telecommunications, the superior conductivity of Germanium Wafers allows for faster data transfer rates, making it an ideal material for advanced communication systems. Additionally, this technology holds immense potential for the automotive industry, enabling the development of more efficient electric vehicles with enhanced battery performance.Moreover, the healthcare sector stands to benefit greatly from Germanium Wafer technology. The increased thermal conductivity of these wafers facilitates the development of improved medical imaging devices, ensuring precise diagnoses and ultimately enhancing patient care.Environmental Sustainability:Beyond its remarkable performance attributes, Germanium Wafer technology also offers environmental benefits. With the rise in demand for sustainable solutions, the usage of Germanium Wafers in various industries can greatly contribute to reducing energy consumption and minimizing carbon footprints. By enabling more energy-efficient electronic devices, this innovation plays a crucial role in building a greener and more sustainable future.Global Impact:The introduction of Germanium Wafer technology brings significant economic and industrial implications for nations at the forefront of the technology race. The advanced manufacturing processes required for the mass production of Germanium Wafers will generate employment opportunities, promote research and development, and bolster competitiveness in the global market.Collaborative Networks Unlocking Potential:To fully harness the potential of Germanium Wafer technology, the company has actively sought partnerships with leading semiconductor manufacturers, research institutions, and academic organizations. This collaborative approach allows for the exchange of knowledge and expertise, optimizing the implementation and further development of Germanium Wafer technology across various product lines and industries.Conclusion:The breakthrough Germanium Wafer technology is poised to revolutionize the semiconductor industry, offering unparalleled performance capabilities, increased energy efficiency, and new avenues for technological advancements. Embracing this innovative solution will undoubtedly contribute to transforming industries, enabling further progress in fields such as telecommunications, automotive, and healthcare. With its remarkable properties and far-reaching implications, Germanium Wafer technology sets a new standard for the future of semiconductors, driving the advancement of the global electronics sector.

Large Crystal Ingot of Lithium Tantalate (LiTaO3) Developed for Advanced Electronics

LiTaO3 Ingot: A Next-Generation Material for the FutureIn today's fast-paced world, technology has become an integral part of our daily lives. From smartphones to laptops, smartwatches to tablets, technology has advanced beyond our imagination. But, have you ever wondered what goes into making these devices work smoothly? The answer lies in the materials used to create them. One such material is LiTaO3 Ingot.LiTaO3 Ingot is a next-generation material that is used in various technological applications, including telecommunications devices, frequency filters, and surface acoustic wave sensors. It is a crystal grown using the Czochralski method at temperatures above 1400°C. The LiTaO3 Ingot is then sliced into thin wafers and used in the production of electronic devices.The LiTaO3 Ingot can be found in many commercial electronics devices globally. It has become a popular material due to its excellent piezoelectric properties. Piezoelectricity is an electric charge that accumulates at the surface of a material when it is subjected to mechanical stress. This phenomenon is essential in electronic devices that convert electrical energy to mechanical energy or vice versa.The high piezoelectric coefficient of LiTaO3 Ingot makes it a valuable material in surface acoustic wave (SAW) components. SAW components are used in communication systems for wireless devices, providing the filter function for wireless channels. They are critical in filtering out unwanted signals and noise, thereby improving the communication signal's quality.Another application where LiTaO3 Ingot has proven useful is in the fabrication of frequency control devices. Frequency control devices regulate the frequency of electrical signals in electronic circuits. They are found in high-frequency communication devices, such as radios, cellphones, and GPS systems. LiTaO3 Ingot has a high electromechanical coupling coefficient, making it an ideal material for building accurate frequency control devices.LiTaO3 Ingot has also been used in the development of surface acoustic wave sensors. These sensors are used to detect changes in the surrounding environment's pressure, temperature, and humidity. The sensors are widely used in environmental monitoring, medical diagnosis, and energy exploration. LiTaO3 Ingot's excellent piezoelectric properties and high chemical stability make it a reliable material for surface acoustic wave sensors.{Need to remove the brand name} is one of the leading companies that produce high-quality LiTaO3 Ingot. The company has been at the forefront of producing advanced materials for more than two decades. Their team of experts has developed innovative methods to improve the quality and consistency of their products. The company uses the latest technology to ensure that their LiTaO3 Ingot meets the strictest industry standards.{Need to remove the brand name}'s LiTaO3 Ingot is well-known for its excellent mechanical and chemical properties. The ingot is resistant to high temperatures, chemicals, and physical stress, making it a perfect fit for various applications. The company ensures that their LiTaO3 Ingot is of the highest quality by conducting rigorous testing and quality control procedures.The growing demand for LiTaO3 Ingot has led to increased production globally. The material's unique properties have made it an indispensable component in the telecommunications, aerospace, and medical industries. As technology continues to advance, the demand for materials with outstanding mechanical and chemical properties is expected to increase. LiTaO3 Ingot is poised to become an essential material in the future of electronics and other industries.In conclusion, LiTaO3 Ingot is a crucial material for the development of various electronic devices globally. Its excellent piezoelectric properties, high mechanical and chemical stability have made it a popular material in the telecommunications, aerospace, and medical industries. {Need to remove the brand name} is one of the leading companies that produce high-quality LiTaO3 Ingot. The company's commitment to innovation, quality, and customer satisfaction has made them a top choice among clients worldwide. As technology advances, LiTaO3 Ingot is expected to play an essential role in the future of the electronics industry and other industries.

Newly Developed Polysilicon Wafers Show Promise for Solar Energy Production

article as follows:Polysilicon Wafer - The Revolutionary Energy SolutionRenewable energy has become a buzzword in today's world, and polysilicon wafers have emerged as the revolutionary energy solution. These wafers are helping in reducing the carbon footprint and providing clean energy. Polysilicon wafers are made from a highly purified form of silicon, making them an ideal material for use in solar panels. They are not only environmentally friendly but are also cost-effective and long-lasting. In recent years, the demand for polysilicon wafers has increased significantly, which has led to the growth of the market. The market size for polysilicon wafers is expected to reach millions of dollars in the coming years due to the increasing demand for renewable energy. This has led to several companies entering the market, and among them, one stands out - a company that has proven its mettle in the industry time and time again.Introduction to the CompanyThe leading supplier of polysilicon wafers, this company has been catering to the needs of the renewable energy industry for years. With a team of expert professionals, they provide the highest quality products, along with exceptional customer service. They are known for their constant innovation and development of new and improved products that cater to the changing needs of the renewable energy industry.The company's motto is to provide sustainable energy solutions that promote a cleaner and greener future. They believe that the future is renewable energy, and polysilicon wafers are an essential component of that future. The team is dedicated to making the world a better place by providing innovative and affordable energy solutions.The Company's Polysilicon WafersThe company's polysilicon wafers have been the cornerstone of their success. Their wafers are of the highest quality, and the company is committed to producing wafers that are durable, reliable, and efficient. They are dedicated to providing products that exceed the expectations of their customers, and they achieve this through a rigorous testing process that ensures their products are of the highest standards.Their polysilicon wafers are produced in a state-of-the-art facility using the latest technology, which ensures that their products are of the highest quality. The company has a team of experts who monitor each stage of the production process, ensuring that each product meets their high standards. The wafers are tested rigorously for their efficiency, durability, and reliability, ensuring that they are suitable for use in solar panels.Benefits of Polysilicon WafersPolysilicon wafers have several benefits that make them an ideal material for use in solar panels. They are environmentally friendly, cost-effective, and long-lasting. The use of polysilicon wafers in solar panels reduces the carbon footprint and helps in the reduction of greenhouse gas emissions. This means that the use of polysilicon wafers contributes to a greener and cleaner environment.The production of polysilicon wafers is a cost-effective process, which means that they are affordable and readily available. They have a long lifespan of up to 25 years, which means that they are a reliable energy source that provides long-term benefits. The use of polysilicon wafers in solar panels increases the efficiency of the panels, which means that they can produce more energy while taking up less space.ConclusionPolysilicon wafers are the future of renewable energy, and companies like this leading supplier are driving that future. Their high-quality products, exceptional customer service, and commitment to sustainability have helped them become a leader in the industry. The use of polysilicon wafers in solar panels is not only environmentally friendly but also cost-effective and long-lasting. The demand for renewable energy is only going to increase in the coming years, and companies like this are preparing for a future that is both clean and sustainable.

High Quality Germanium Wafer Supplier and Manufacturer

Germanium Wafer Market Set to Grow as Demand for Semiconductor Devices RisesThe global Germanium Wafer market is set to experience steady growth in the coming years, as the demand for semiconductor devices continues to rise. Germanium wafers are an essential component in the production of various semiconductor devices, including transistors and diodes, making them a crucial part of the electronics industry.Germanium wafers are known for their high carrier mobility, making them ideal for high-frequency applications. This, coupled with their ability to be used in combination with other materials such as silicon, has made them a popular choice for a wide range of semiconductor devices.One of the key players in the Germanium wafer market is {company name}, a leading manufacturer and supplier of Germanium wafers. The company has been at the forefront of the industry, producing high-quality Germanium wafers that meet the stringent requirements of their customers.{company name} is known for its commitment to quality and innovation, with a strong focus on research and development to continuously improve their product offerings. The company has a state-of-the-art manufacturing facility that is equipped with the latest technology and equipment, allowing them to produce Germanium wafers that meet the highest industry standards.In addition to their manufacturing capabilities, {company name} also has a strong focus on customer service, providing technical support and expertise to their customers. This has helped them build strong and lasting relationships with their clients, making them a trusted partner in the industry.The company's Germanium wafers are used in a wide range of applications, including infrared optics, solar cells, and various electronic devices. With the increasing demand for these applications, {company name} is well-positioned to capitalize on the growing market for Germanium wafers.As the demand for semiconductor devices continues to rise, so too will the demand for Germanium wafers. With their unique properties and versatility, Germanium wafers are poised to play a key role in the development of the electronics industry.In conclusion, the Germanium wafer market is set to experience steady growth in the coming years, driven by the increasing demand for semiconductor devices. {company name} is well-positioned to take advantage of this growth, with their high-quality Germanium wafers and strong commitment to innovation and customer service. As the industry continues to evolve, {company name} will remain at the forefront, providing essential components for the next generation of electronic devices.

Innovative Single Lens Glasses: The Latest Eyewear Trend to Watch

Single Lens Glasses, a new product from innovative company, is making waves in the eyewear industry. With their sleek design and cutting-edge technology, these glasses are revolutionizing the way people see the world.Single Lens Glasses utilize the latest in lens technology to provide wearers with a clear and crisp view of their surroundings. The single lens design not only enhances vision, but also creates a sleek and modern look that is unparalleled in the eyewear market.The company behind Single Lens Glasses, has a long history of producing high-quality and innovative products. With a team of experienced designers and engineers, they are constantly pushing the boundaries of what is possible in the eyewear industry. Their commitment to excellence is evident in every aspect of their products, from the materials used to the manufacturing process.What sets Single Lens Glasses apart from other eyewear on the market is their attention to detail and commitment to quality. Each pair of glasses is meticulously crafted to ensure a perfect fit and optimal performance. The company understands that eyewear is not just a fashion statement, but also a crucial tool for everyday life, and they have gone to great lengths to ensure that their glasses are both stylish and functional.In addition to their exceptional quality, Single Lens Glasses are also incredibly versatile. Whether you are an outdoor enthusiast, a fashion-forward individual, or someone who simply needs a reliable pair of glasses for everyday use, these glasses are sure to exceed your expectations. Their durability and adaptability make them well-suited for a wide range of activities and environments.Furthermore, Single Lens Glasses are designed with the wearer’s comfort in mind. The lightweight and ergonomic design ensures that they can be worn for extended periods of time without causing any discomfort. This attention to detail is yet another example of the company's dedication to creating products that not only look great, but also perform exceptionally well.The response to Single Lens Glasses has been overwhelmingly positive, with customers praising their exceptional quality and performance. Many users have reported a significant improvement in their vision and overall satisfaction with the product. Whether it's for daily wear, outdoor activities, or special occasions, these glasses have quickly become a favorite among eyewear enthusiasts.Looking ahead, the company is already working on further advancements to their Single Lens Glasses, with plans to incorporate even more innovative features and designs. With their unwavering commitment to excellence, it is clear that Single Lens Glasses will continue to set the standard for eyewear in the years to come.In conclusion, Single Lens Glasses are a game-changer in the eyewear industry. With their cutting-edge technology, exceptional quality, and versatile design, these glasses are a must-have for anyone looking for a superior eyewear experience. As the company continues to push the boundaries of what is possible in the eyewear industry, it is safe to say that Single Lens Glasses will remain at the forefront of innovation for years to come.

Latest advancements in Polysilicon Wafer technology

Polysilicon Wafer, a key material used in the production of semiconductors, is in high demand as the global semiconductor industry continues to grow. One of the leading companies in the production of Polysilicon Wafer is {Company Name}. With its state-of-the-art manufacturing facilities and cutting-edge technology, the company has positioned itself as a key player in the global semiconductor supply chain.{Company Name} was founded in 1998 and has since become a leader in the development and production of Polysilicon Wafer. The company's headquarters is located in {Location}, and it has established a strong presence in key semiconductor markets around the world. {Company Name} prides itself on its commitment to high-quality products and innovative solutions that meet the evolving needs of the semiconductor industry.The global demand for Polysilicon Wafer has surged in recent years, driven by the rapid expansion of the semiconductor market. The increasing adoption of advanced technologies such as 5G, artificial intelligence, and Internet of Things has led to a growing need for high-performance and reliable semiconductor components. As a result, companies like {Company Name} have experienced a significant increase in demand for their Polysilicon Wafer products.{Company Name} has invested heavily in research and development to continuously improve the quality and performance of its Polysilicon Wafer products. The company's manufacturing facilities are equipped with the latest technologies, allowing for the production of high-purity and high-performance Polysilicon Wafers that meet the stringent requirements of the semiconductor industry. {Company Name} also has a strong focus on sustainability and has implemented environmentally friendly practices in its production processes.The company's Polysilicon Wafer products have gained a reputation for their reliability and consistency, making them the preferred choice for leading semiconductor manufacturers around the world. {Company Name} has established long-term partnerships with key players in the semiconductor industry, further solidifying its position as a trusted supplier of Polysilicon Wafers.In response to the growing demand for Polysilicon Wafer, {Company Name} has ramped up its production capacity to ensure a steady supply of high-quality products to its customers. The company has also expanded its presence in key semiconductor markets, leveraging its strong distribution network to better serve its global customer base.As the global semiconductor industry continues to evolve, {Company Name} remains committed to innovation and excellence in the production of Polysilicon Wafer. The company is continuously exploring new technologies and solutions to meet the ever-changing needs of the industry and to reinforce its position as a leader in the supply of Polysilicon Wafers.With its unwavering dedication to quality, innovation, and sustainability, {Company Name} is well-positioned to meet the growing demand for Polysilicon Wafer and continue to play a significant role in the advancement of the global semiconductor industry.

How to Choose the Best Windows for Your Home: A Complete Guide

Sic Windows, a leading global provider of windows and doors, has recently announced the launch of a new line of energy-efficient products. This innovative range of windows is designed to meet the growing demand for sustainable and environmentally friendly building materials.With a strong focus on quality and sustainability, Sic Windows has established itself as a trusted and reliable provider of windows and doors for both residential and commercial projects. The company prides itself on its commitment to delivering high-performance products that not only enhance the aesthetic appeal of a building but also contribute to energy conservation and efficiency.The new line of energy-efficient windows is a testament to Sic Windows' dedication to innovation and sustainability. These windows are designed to minimize heat loss and reduce energy consumption, ultimately leading to lower heating and cooling costs for consumers. By incorporating advanced technologies and high-quality materials, Sic Windows has developed a range of products that not only meet industry standards but also exceed expectations in terms of performance and durability.In addition to their energy-efficient properties, these windows also boast a sleek and modern design, adding a touch of elegance to any building. With various styles and customizable options available, customers can choose the perfect windows to complement their architectural vision. Whether it's a contemporary residential project or a large-scale commercial development, Sic Windows' energy-efficient windows are the ideal choice for those looking to combine style and sustainability.Furthermore, Sic Windows is committed to reducing its environmental footprint throughout the production process. The company employs sustainable practices and utilizes recyclable materials to minimize waste and promote eco-friendly manufacturing. By prioritizing environmental stewardship, Sic Windows is not only setting the standard for energy-efficient windows but also leading the way in responsible and sustainable business operations.“We are thrilled to introduce our new line of energy-efficient windows to the market,” said [Company Spokesperson]. “At Sic Windows, we believe in delivering products that not only meet the needs of our customers but also contribute to a greener and more sustainable future. With our latest range of windows, we aim to provide a solution that combines cutting-edge technology with exceptional design, offering our customers the best of both worlds.”As the demand for energy-efficient building materials continues to grow, Sic Windows is well-positioned to meet the needs of the market. With a strong reputation for quality and reliability, the company's new line of windows is expected to make a significant impact in the construction and design industries. By providing a solution that prioritizes energy conservation and efficiency, Sic Windows is demonstrating its ongoing commitment to sustainability and innovation.Whether it's for a residential renovation project or a large-scale commercial development, Sic Windows' energy-efficient windows offer a compelling option for those looking to enhance their building's performance while reducing their environmental impact. With a focus on quality, sustainability, and innovation, Sic Windows is poised to lead the way in providing energy-efficient solutions for the modern building industry.

High-Quality Fused Silica Wafer for Semiconductor Applications

Fused Silica Wafer: Revolutionizing the Semiconductor IndustryIn today's highly digitalized world, the demand for faster, more efficient, and smaller electronic devices has led to a revolution in the semiconductor industry. Companies are constantly striving to develop new and innovative technologies to meet this growing demand. One such pioneering company is {Company Name}, a leading manufacturer of high-quality fused silica wafers.The company has established itself as a trailblazer in the semiconductor industry, offering cutting-edge solutions for semiconductor fabrication. Their fused silica wafers have been widely recognized for their exceptional quality and performance, making them the go-to choice for some of the industry's leading manufacturers.But what exactly is a fused silica wafer, and why is it so crucial in the semiconductor industry? Fused silica, also known as fused quartz, is a high-purity, non-crystalline form of silicon dioxide. This unique material possesses a number of properties that make it ideal for semiconductor applications, including a low coefficient of thermal expansion, exceptional thermal shock resistance, and outstanding optical clarity.In the semiconductor manufacturing process, fused silica wafers play a critical role as the substrate on which electronic devices are built. These wafers serve as the foundation for the deposition of thin films and the etching of circuit patterns, making them a fundamental component in the production of semiconductors.What sets {Company Name}'s fused silica wafers apart from the competition is their unwavering commitment to quality and precision. The company utilizes state-of-the-art manufacturing techniques and stringent quality control measures to ensure that their wafers meet the highest industry standards. This dedication to excellence has earned {Company Name} a stellar reputation among semiconductor manufacturers, who rely on the company's products to achieve superior results in their fabrication processes.One of the key advantages of {Company Name}'s fused silica wafers is their exceptional thermal properties. Fused silica has a very low coefficient of thermal expansion, meaning that it exhibits minimal dimensional changes in response to fluctuations in temperature. This property is particularly important in semiconductor manufacturing, where precise temperature control is crucial to ensure the integrity of the fabrication process. {Company Name}'s wafers are engineered to withstand extreme temperature variations, making them an ideal choice for the most demanding semiconductor applications.Furthermore, {Company Name} offers a wide range of customization options to meet the specific needs of their customers. Whether it's a particular size, thickness, or surface finish, the company's team of expert engineers works closely with clients to develop tailored solutions that align with their unique requirements. This flexibility sets {Company Name} apart as a customer-centric manufacturer that prioritizes the individual needs of its clients.Looking ahead, {Company Name} remains committed to pushing the boundaries of semiconductor technology. The company continues to invest in research and development to further enhance the performance and capabilities of their fused silica wafers. By staying at the forefront of innovation, {Company Name} aims to empower semiconductor manufacturers with the tools they need to drive technological advancements and meet the evolving demands of the industry.In conclusion, {Company Name} has solidified its position as a leader in the semiconductor industry through its unwavering dedication to quality, precision, and innovation. Their fused silica wafers have become an indispensable component in semiconductor fabrication, enabling manufacturers to achieve outstanding results in their production processes. As the demand for smaller, more efficient electronic devices continues to grow, {Company Name} remains at the forefront, pioneering the next generation of semiconductor technologies.

Durable and High-Performance Ceramic Material for Various Applications

[Company Name], a leading manufacturer of advanced ceramic materials, has recently introduced a breakthrough product in the field of ceramic engineering. The company has developed a new Zro2 ceramic material that promises to revolutionize the way ceramic materials are used in various industries.Zro2 ceramic, also known as zirconia, is a versatile material with a wide range of applications. It is known for its exceptional hardness, thermal stability, and resistance to corrosion, making it an ideal choice for demanding industrial environments. With the development of this new Zro2 material, [Company Name] aims to further expand the potential applications of ceramic materials and provide innovative solutions to its customers.The newly developed Zro2 ceramic material boasts several key advantages over traditional ceramic materials. It offers superior strength and toughness, making it suitable for high-impact and wear-resistant applications. Additionally, its high thermal stability and resistance to chemical corrosion make it an excellent choice for use in harsh environments. These properties make it an ideal material for a wide range of applications, including aerospace, automotive, medical, and electronics industries.One of the key features of [Company Name]'s Zro2 ceramic material is its high level of purity and homogeneity. This ensures consistent performance and reliability, even in the most demanding of applications. The material is also highly customizable, allowing for the development of tailored solutions to meet specific customer requirements. This level of flexibility and precision sets [Company Name] apart as a leading innovator in the field of ceramic engineering.In addition to its exceptional technical properties, the new Zro2 ceramic material also offers environmental benefits. As a sustainable and eco-friendly material, it aligns with the growing emphasis on green technologies and responsible manufacturing. This makes it an attractive choice for companies looking to reduce their environmental impact without compromising on performance.[Company Name] has invested heavily in research and development to bring this innovative Zro2 ceramic material to the market. The company's team of experienced engineers and scientists have leveraged their expertise to optimize the material's properties and performance, ensuring that it meets the highest industry standards. This dedication to quality and innovation has positioned [Company Name] as a trusted partner for businesses seeking cutting-edge ceramic solutions.The introduction of this new Zro2 ceramic material represents a significant milestone for [Company Name] and underscores its commitment to driving technological advancement in the field of ceramic engineering. With its unique combination of properties and performance, the material has the potential to open up new opportunities in a wide range of industries, from aerospace and automotive to medical and electronics.[Company Name] is poised to lead the way in unlocking the full potential of Zro2 ceramic material and is ready to work closely with its customers to develop tailored solutions that address their specific needs. By harnessing the power of advanced ceramics, [Company Name] is paving the way for the next generation of high-performance, sustainable materials that will drive innovation and progress across various industries.As the demand for high-performance materials continues to grow, [Company Name]'s Zro2 ceramic material is set to play a pivotal role in shaping the future of ceramic engineering. With its unrivaled properties, versatility, and sustainability, the material is poised to revolutionize the way ceramic materials are used and pave the way for new and exciting possibilities in industrial applications.

Revolutionary Laser Diode Technology Unleashes Limitless Possibilities

Laser Diode Technology Revolutionizes Medical Treatment for Skin ConditionsIn recent years, the global skincare industry has experienced a surge in demand for safer and more effective treatments. Laser technology has been a game-changer in this regard and has quickly become a popular choice for those seeking non-invasive skincare solutions. Laser Diode (name removed), a leader in laser technology, has revolutionized medical treatment for skin conditions with its cutting-edge laser diode technology.Founded in 1994, Laser Diode (name removed) has been at the forefront of developing laser diode technology for various industries globally. In the medical field, laser diodes are used for different dermatological applications, such as the treatment of a wide range of skin conditions such as acne, rosacea, psoriasis, and eczema. Laser diodes target and destroy specific cells in the skin, reducing the appearance of skin blisters, redness, and swelling.Laser Diode (name removed)’s technology offers numerous benefits, including its precision, safety, and efficiency. The technology precisely targets the intended skin cells while leaving the surrounding healthy skin untouched. Since laser diodes penetrate the skin more deeply, they can treat both the underlying cause and the visible symptoms of skin disorders, which means patients experience faster healing and long-lasting results.What sets Laser Diode (name removed) apart is its Micro-Pulse technology, which utilizes a unique pulse delivery method that results in lower heat accumulation, minimizing the patient’s discomfort and reducing the chances of burns. This means that medical professionals can treat patients more efficiently and safely, reducing the healing period significantly. In addition, Laser Diode (name removed)’s Micro-Pulse technology also protects the skin, making it ideal for patients with sensitive skin or those prone to pigmentation issues.Thanks to Laser Diode (name removed)’s Micro-Pulse technology, medical professionals can now offer laser treatments to a broader range of patients, including those with darker skin tones, which was previously challenging due to the high risk of burns. This makes the treatment accessible to more people and more effective in treating hyperpigmentation, melasma, and other pigmentation related skin concerns."Our Micro-Pulse technology has revolutionized the use of lasers in medical treatments by delivering safe and precise laser energy to the skin. Our technology has made it possible for medical professionals to reduce the discomfort and painful side effects experienced by patients while ensuring that patients get the best possible results," says Henry Michaelson, Laser Diode (name removed)’s Chief Medical Officer.The rising demand for laser technology in the skincare industry is set to continue, and Laser Diode (name removed)’s role in revolutionizing the industry is crucial. The company collaborates with medical professionals to provide tailored and innovative solutions that meet their patients’ specific needs. The company’s dedication to research and development ensures continued growth and innovation in the industry.Laser Diode (name removed)’s laser diode technology has not only revolutionized medical treatments but also provides a solution for various other industries such as automotive, security, and aerospace. The company’s diodes are used in automotive lidar systems, security and surveillance cameras, and high-performance military laser technology.In conclusion, the skincare industry has seen significant growth in laser technology, and Laser Diode (name removed) has been an integral part of this revolution. Its cutting-edge Micro-Pulse technology has made laser treatments safer and more effective, offering a non-invasive and efficient solution to various skin disorders. As the global demand for safer skincare treatments continues to rise, Laser Diode (name removed)’s role in the industry will only continue to grow as it continues to provide innovative solutions.