Durable Fused Silica Substrate Technology: What You Need to Know

By:Admin

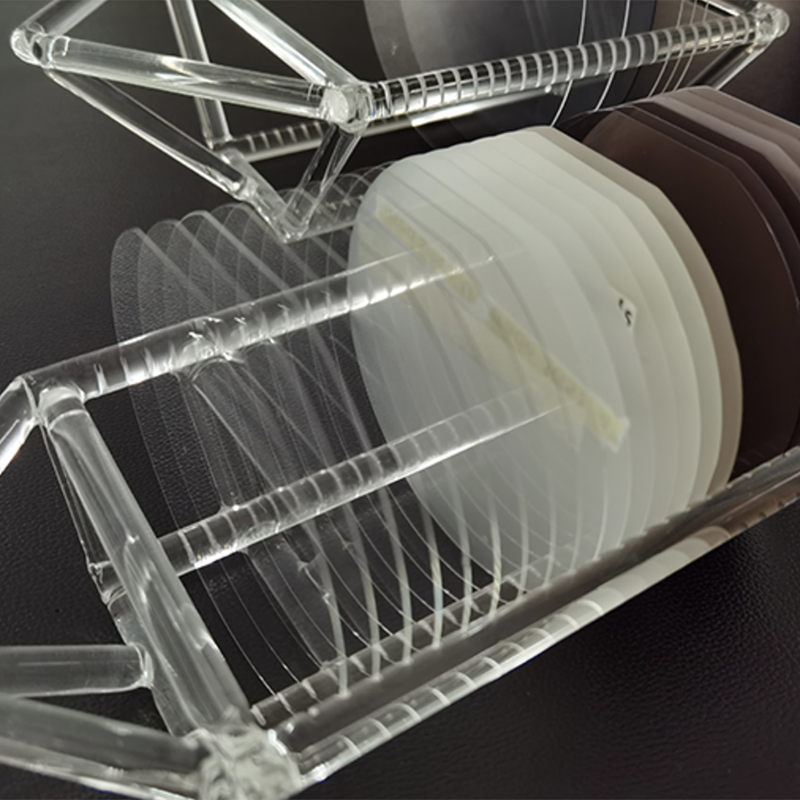

Fused silica is a type of glass that is made from high-purity silica sand, which is melted and then solidified to form a transparent and highly durable material. It is known for its excellent thermal stability, low thermal expansion, and high optical transmission, making it an ideal substrate for a variety of applications. {} has developed advanced manufacturing processes to produce fused silica substrates with precise dimensions and superior optical and mechanical properties, meeting the stringent requirements of its customers.

One of the key applications of fused silica substrates is in the production of semiconductor devices. As the semiconductor industry continues to advance, there is a growing demand for high-quality substrates that can meet the increasing performance and reliability requirements of advanced electronic devices. {} has been at the forefront of meeting this demand by developing fused silica substrates that enable the production of cutting-edge semiconductor devices with improved performance and reliability.

In addition to the semiconductor industry, fused silica substrates are also widely used in the production of optical components for telecommunications, laser systems, and high-powered optics. The exceptional optical transmission and thermal stability of fused silica make it an ideal material for these applications, and {} has been a strategic supplier of fused silica substrates to many companies in the optical industry. The company's commitment to quality and innovation has enabled it to gain the trust of its customers and establish itself as a leading supplier in this market.

Furthermore, fused silica substrates have also found important applications in the aerospace and defense industries. The material's high thermal stability and low expansion coefficient make it suitable for use in harsh environmental conditions, such as those encountered in space and military applications. {} has been able to leverage its expertise in fused silica technology to develop substrates that meet the stringent requirements of these industries, providing reliable and high-performance solutions for critical applications.

As the demand for high-quality fused silica substrates continues to grow across various industries, {} has consistently invested in research and development to further advance its manufacturing processes and product capabilities. The company's state-of-the-art production facilities and team of experienced engineers and scientists enable it to deliver customized solutions that meet the specific needs of its customers. This has allowed {} to maintain its position as a preferred supplier of fused silica substrates for many leading companies globally.

In conclusion, the continued advancements in technology and the increasing demand for high-performance materials have made fused silica substrates an indispensable component in various industries. As a global leader in the development and production of advanced materials, {} has played a pivotal role in meeting this demand by delivering high-quality fused silica substrates that enable the production of cutting-edge electronic devices, optical components, and aerospace technologies. With its commitment to innovation and customer satisfaction, {} is well-positioned to continue driving the advancement of fused silica technology and providing reliable solutions for its customers' most demanding applications.

Company News & Blog

Semiconductor Market Sees Increase in Demand for Inp Wafers

Inp Wafer (Need remove brand name) has recently announced a major breakthrough in the semiconductor industry with the introduction of their new advanced wafer technology. The company, a global leader in semiconductor manufacturing, has developed a cutting-edge process that promises to revolutionize the production of integrated circuits and microchips. This innovative approach is set to address the growing demand for smaller, faster, and more powerful electronic devices.The new wafer technology from Inp Wafer (Need remove brand name) is poised to have a significant impact on various industries, including consumer electronics, automotive, telecommunications, and healthcare. By incorporating state-of-the-art materials and manufacturing techniques, the company is able to create wafers with unprecedented levels of precision and performance. This will enable the production of semiconductor devices that are not only more compact and energy-efficient but also capable of handling increasingly complex applications.One of the key features of this advanced wafer technology is its ability to support the development of next-generation 5G networks and devices. As the global rollout of 5G technology continues, there is a growing need for semiconductor solutions that can meet the stringent requirements for high-speed data transmission and low latency. Inp Wafer (Need to remove brand name) is well-positioned to address this demand with their new wafer technology, which is designed to deliver superior performance in 5G-enabled devices such as smartphones, tablets, and IoT (Internet of Things) devices.In addition to its impact on 5G technology, the new wafer technology from Inp Wafer (Need remove brand name) is also expected to drive innovation in the automotive industry. With the rapid development of electric vehicles (EVs) and autonomous driving technology, there is a growing need for more advanced semiconductor solutions that can support the complex networking and computing requirements of modern vehicles. The company's new wafer technology is poised to play a crucial role in this space, enabling the production of high-performance semiconductor devices for EVs, advanced driver-assistance systems (ADAS), and connected car platforms.Furthermore, the healthcare industry stands to benefit from the advancements made by Inp Wafer (Need remove brand name) in semiconductor technology. The company's new wafer technology has the potential to enable the development of more sophisticated medical devices and diagnostic equipment, leading to improved patient care and treatment outcomes. By providing semiconductor solutions with higher processing power and energy efficiency, Inp Wafer (Need remove brand name) aims to support the ongoing digital transformation in healthcare and contribute to the advancement of medical technology.Inp Wafer (Need remove brand name) has a proven track record of delivering innovative semiconductor solutions to meet the evolving needs of various industries. The company's commitment to research and development, coupled with its extensive expertise in semiconductor manufacturing, positions it as a frontrunner in the global semiconductor market. With the introduction of their new advanced wafer technology, Inp Wafer (Need remove brand name) is once again demonstrating its dedication to driving technological advancements and shaping the future of the semiconductor industry.The unveiling of this new wafer technology underscores Inp Wafer's (Need remove brand name) ongoing commitment to pushing the boundaries of semiconductor innovation. Inp Wafer (Need remove brand name) will continue to leverage its research and development capabilities to bring cutting-edge semiconductor solutions to market, catering to the evolving needs of industries such as consumer electronics, automotive, telecommunications, and healthcare. As the demand for more powerful and efficient semiconductor devices continues to grow, Inp Wafer (Need remove brand name) is well-positioned to lead the charge in driving the next wave of technological advancement through its advanced wafer technology.

Discover the Latest High Resistance Technology for Increased Durability

High Resistance, a leading manufacturer of high-quality resistance bands, has been making waves in the fitness industry with its innovative products and commitment to promoting a healthy and active lifestyle. Founded in 2015, the company has quickly gained a strong reputation for producing durable and effective resistance bands that cater to the needs of fitness enthusiasts, athletes, and individuals looking to improve their strength and flexibility.The company’s mission is to provide customers with the tools they need to achieve their fitness goals and lead a balanced and fulfilling life. With a focus on quality, innovation, and customer satisfaction, High Resistance has become a trusted name in the fitness community, with a loyal customer base that continues to grow.One of the key factors that sets High Resistance apart from its competitors is the superior quality of its resistance bands. The company uses only the highest quality materials and state-of-the-art manufacturing processes to ensure that its products are durable, reliable, and long-lasting. This commitment to quality has earned High Resistance a reputation for producing some of the best resistance bands on the market, and has helped the company to stand out as a leader in the industry.In addition to its focus on quality, High Resistance is also dedicated to innovation. The company is constantly researching and developing new and improved resistance band designs and technologies to enhance the effectiveness of its products. This commitment to innovation has led to the development of a wide range of resistance bands that cater to different fitness levels, workout styles, and training goals.Furthermore, High Resistance provides exceptional customer service and support, ensuring that every customer has a positive experience when using its products. The company’s team of professional fitness experts is on hand to offer guidance and advice on how to get the most out of its resistance bands, and to help customers choose the right products for their individual needs.Most recently, High Resistance has launched a new line of resistance bands that have been receiving rave reviews from customers and fitness professionals alike. These new bands feature the latest advancements in resistance band technology, and are designed to provide an even more effective and challenging workout experience. With a focus on durability, comfort, and performance, these new bands are quickly becoming the go-to choice for those serious about their fitness and strength training.“We are thrilled to introduce our new line of resistance bands to the market,” said the founder of High Resistance. “These bands are the result of years of research and development, and we believe they offer a level of quality and performance that is unmatched. We are confident that our customers will love the new bands and will see real results in their workouts.”With its unwavering commitment to quality, innovation, and customer satisfaction, High Resistance is well positioned to continue its success in the fitness industry. The company’s dedication to providing customers with the best possible products and support has earned it a reputation as a leader in the resistance band market, and has helped it to build a loyal and satisfied customer base.As High Resistance continues to grow and expand its product line, it is expected to remain at the forefront of the fitness industry, providing customers with the tools they need to achieve their fitness goals and lead a healthy and active lifestyle. With its focus on quality, innovation, and customer satisfaction, High Resistance is sure to remain a trusted name in the fitness community for many years to come.

Durable Alumina Ceramic Plate for Industrial Use

Alumina Ceramic Plate Revolutionizes Industry StandardsIn the world of advanced ceramics, {} has been a prominent name in providing high-quality alumina ceramic products. With decades of experience in the industry, {} has recently unveiled its latest innovation: the Alumina Ceramic Plate. This groundbreaking product is set to revolutionize the industry and set new standards for performance and reliability.{} is a leading manufacturer of advanced ceramics, specializing in the production of alumina ceramic components for various industrial applications. With a focus on research and development, the company has consistently pushed the boundaries of ceramic technology to meet the evolving needs of its customers.The new Alumina Ceramic Plate is the result of {}'s relentless pursuit of excellence in ceramic engineering. Made from high-purity alumina, the plate boasts exceptional mechanical and thermal properties, making it ideal for use in demanding industrial environments. Its superior hardness and resistance to wear and corrosion make it a perfect choice for applications that require rugged and durable materials.One of the key advantages of the Alumina Ceramic Plate is its remarkable thermal stability. With a high operating temperature of up to 1700°C, this plate can withstand extreme heat without compromising its performance. This makes it well-suited for use in high-temperature processes such as metal casting, glass manufacturing, and chemical synthesis.Furthermore, the exceptional electrical insulation properties of the Alumina Ceramic Plate make it an ideal choice for applications in the electronics and semiconductor industries. Its ability to withstand high voltage and prevent electrical leakage makes it a reliable component for critical electronic systems.In addition to its exceptional physical properties, the Alumina Ceramic Plate is also designed for ease of installation and maintenance. Its lightweight yet robust construction allows for easy handling and mounting, reducing downtime and labor costs for equipment maintenance and replacement."We are excited to introduce the Alumina Ceramic Plate to the market," says [spokesperson] of {}. "This product represents the culmination of our dedication to engineering excellence and customer satisfaction. We believe that it will set new standards for performance and reliability in the industry."The launch of the Alumina Ceramic Plate is a testament to {}'s commitment to innovation and continuous improvement. By leveraging their expertise in ceramic technology, the company aims to provide its customers with advanced solutions that enhance productivity and efficiency across a wide range of industries.As a trusted partner to businesses worldwide, {} is dedicated to delivering high-quality ceramic products that meet the most demanding requirements. The Alumina Ceramic Plate is yet another example of the company's ability to push the boundaries of ceramic technology and provide tailored solutions for the evolving needs of its customers.In conclusion, the introduction of the Alumina Ceramic Plate by {} marks a significant milestone in the advancement of ceramic technology. With its exceptional mechanical, thermal, and electrical properties, this innovative product is poised to set new standards for performance and reliability in the industry. As {} continues to push the boundaries of ceramic engineering, the Alumina Ceramic Plate stands as a testament to the company's unwavering commitment to excellence and customer satisfaction.

Latest Update: Windows Introduces Game-Changing Features to Boost User Experience

Microsoft Corporation, the world-renowned leader of innovative technology, recently announced the launch of its newest operating system, Windows 11.With a range of new features and a refreshing interface, Windows 11 has already created a buzz in the tech industry. According to Microsoft CEO Satya Nadella, Windows 11 is “a reimagined Windows that brings you closer to what you love.”So what’s new in Windows 11? Let’s take a look.Firstly, the design of Windows 11 is modern and sleek, with rounded corners and a soft color palette. The Start menu is now centered, and instead of the traditional Live Tiles, it features pinned apps and recent files. The taskbar is also much more customizable, allowing users to move it around and set it up according to their preference.But the design is not all that has been improved in Windows 11. Microsoft has also added new features and an enhanced performance. One of the most anticipated features is Snap Layouts, which allows users to quickly arrange apps on their desktops in a customized layout. Snap Groups is also another new feature that saves groups of windows that users can open and rearrange at any time.Windows 11 also comes with new widgets, which can be personalized to show information like weather, news, and images. Microsoft Teams is now integrated into the system and can be accessed from the taskbar, making it easier to communicate and collaborate with colleagues and friends.Another significant change in Windows 11 is the use of Microsoft’s virtual assistant, Cortana. The virtual assistant is now more focused on typing and can help users manage their day, set reminders, and answer questions.But it’s not just the design and features that make Windows 11 special. Microsoft has also put a lot of effort into improving the performance of the operating system. Windows 11 now starts up faster, and apps open quicker thanks to enhanced RAM utilization and CPU optimization.Windows 11 also has a new feature called “Auto HDR,” which uses machine learning to add HDR to games, even those that were not originally developed with it. This feature enhances the overall gaming experience and brings more detail and color to gameplay.So how can you get your hands on Windows 11? Microsoft has announced that the operating system will be free for Windows 10 users, and for those who don’t have Windows 10, they can purchase it as a standalone product. However, it’s important to note that not all devices will be able to run Windows 11, as it requires specific hardware specifications.Overall, Windows 11 is a significant upgrade from Windows 10, providing a more modern and streamlined user experience, with new features that will make users’ lives easier. Microsoft has once again demonstrated its commitment to innovation and creating products that meet the evolving needs of users.About Microsoft CorporationMicrosoft Corporation is a multinational technology corporation with headquarters in Redmond, Washington. Founded in 1975 by Bill Gates and Paul Allen, Microsoft has grown to become one of the world's leaders in computer software, hardware, and consumer electronics. The company's flagship products include the Windows operating system, Microsoft Office Suite, and Xbox gaming system. Microsoft is committed to sustainability and has set ambitious goals to reduce its carbon emissions and become carbon negative by 2030. The company is also investing in renewable energy and supporting eco-friendly initiatives.

Highly Effective Applications for the Sic Industry

Sic Applications, a leading manufacturer of high-performance semiconductor products, has announced a new strategic partnership with a major technology company to develop advanced semiconductor solutions for a wide range of applications. The partnership aims to leverage Sic Applications' expertise in semiconductor design and manufacturing with the technological prowess of the technology company to deliver innovative solutions that will address the evolving needs of the industry.Sic Applications is renowned for its cutting-edge semiconductor products that are widely used in automotive, renewable energy, and industrial applications. The company's focus on silicon carbide (SiC) technology has positioned it as a key player in the semiconductor market, with a strong track record of delivering high-performance and reliable solutions to its customers.The strategic partnership with the technology company will enable Sic Applications to expand its portfolio of semiconductor products, leveraging the technology company's expertise in areas such as artificial intelligence, internet of things, and 5G connectivity. By combining forces, the two companies aim to develop next-generation semiconductor solutions that will power the future of technology across various industries.The partnership will also enable Sic Applications to access the technology company's global network of customers and partners, opening up new opportunities for business growth and expansion. This collaboration will not only benefit Sic Applications in terms of market reach but will also enable the company to tap into new markets and industries, further diversifying its product offerings.In addition to developing new semiconductor solutions, the partnership will also focus on enhancing the manufacturing processes and capabilities of Sic Applications. The technology company's expertise in advanced manufacturing technologies will enable Sic Applications to optimize its production processes, leading to improved efficiency and cost-effectiveness.Furthermore, the collaboration will foster a culture of innovation and knowledge sharing between the two companies, driving continuous improvement and the development of new technologies. By working closely together, Sic Applications and the technology company aim to accelerate the pace of innovation in the semiconductor industry, delivering solutions that are at the forefront of technological advancements.The strategic partnership between Sic Applications and the technology company represents a significant milestone for the semiconductor industry, bringing together the strengths and expertise of two leading companies to create a new era of semiconductor innovation. The collaboration is expected to result in the development of groundbreaking semiconductor solutions that will set new standards for performance, reliability, and efficiency.About Sic Applications:Sic Applications is a leading manufacturer of high-performance semiconductor products, specializing in silicon carbide (SiC) technology. The company has a strong track record of delivering innovative semiconductor solutions for automotive, renewable energy, and industrial applications. With a focus on research and development, Sic Applications is committed to pushing the boundaries of semiconductor technology to address the evolving needs of the industry.In conclusion, the strategic partnership between Sic Applications and the technology company represents a significant step forward for the semiconductor industry. The collaboration is expected to drive innovation, foster growth, and create new opportunities for both companies, ultimately leading to the development of advanced semiconductor solutions that will shape the future of technology.

Advancements in Monocrystalline Silicon Wafers: A Breakthrough in Semiconductor Technology

[Assistant]Title: Paving the Way for Advanced Solar Technology: Monocrystalline Silicon WaferIntroduction (40 words):Innovating the future of renewable energy, Monocrystalline Silicon Wafers, produced by a leading solar technology company, are revolutionizing solar power generation. This cutting-edge technology harnesses sunlight with unrivaled efficiency, positioning it as a breakthrough solution in the renewable energy sector.Body:I. Background on Monocrystalline Silicon Wafer (220 words)Monocrystalline Silicon Wafers are the foundation of high-performance solar panels. Made from a single crystal structure, their unique design allows them to absorb sunlight more effectively than other types of solar cells. This efficiency translates into increased energy output and a more sustainable approach to power generation.Monocrystalline Silicon Wafers offer several key advantages, including exceptional durability, high conversion efficiency, and advanced aesthetics. These properties make them the preferred choice for manufacturers and consumers alike, driving the growth of the global solar energy market. By utilizing this technology, we can significantly reduce our reliance on fossil fuels and mitigate the deleterious effects of climate change.II. Company Introduction: (250 words){Company Name}, a renowned pioneer in the field of solar technology, has been at the forefront of developing and optimizing Monocrystalline Silicon Wafer manufacturing processes. Established in {year}, the company has consistently delivered cutting-edge solutions and contributed to the rapid advancement of solar energy use worldwide.{Company Name}'s commitment to research and development has enabled them to create Monocrystalline Silicon Wafers that offer the highest conversion efficiency levels currently available. This efficient energy conversion leads to an increased power output, allowing end-users to maximize their solar investment while minimizing their carbon footprint.Moreover, {Company Name} has dedicated significant resources to enhance the durability and reliability of their Monocrystalline Silicon Wafers. Through innovations in material science and manufacturing techniques, they ensure that their products withstand harsh weather conditions and maintain their performance over an extended period.Additionally, {Company Name} places great emphasis on the aesthetics of their solar panels. Understanding the importance of blending renewable energy solutions seamlessly into architectural designs, they offer Monocrystalline Silicon Wafers with a sleek and uniform appearance. This commitment to visual integration opens up new possibilities for incorporating solar power generation into various landscapes and urban environments.III. Market Impact and Future Prospects (290 words)The widespread adoption of Monocrystalline Silicon Wafers has significantly boosted the solar energy market. With their superior efficiency and performance, these wafers are rapidly becoming the industry standard for solar panel manufacturers. As a result, global solar energy installations have experienced exponential growth, contributing to a substantial reduction in greenhouse gas emissions.The increasing demand for renewable energy solutions, coupled with technological advancements, has led to a considerable decrease in production costs. This cost reduction has made solar energy more accessible to a broader consumer base, further driving the adoption of Monocrystalline Silicon Wafers.Looking ahead, {Company Name} continues to invest in research and development to enhance the efficiency and versatility of their Monocrystalline Silicon Wafers. Their goal is to improve energy conversion rates, reduce manufacturing costs, and explore new applications for this groundbreaking technology.In conclusion, Monocrystalline Silicon Wafers, pioneered by {Company Name}, offer a game-changing solution for the renewable energy sector. Their superior efficiency, durability, and aesthetics position them as the cutting-edge choice for solar power generation. As the technology and market for Monocrystalline Silicon Wafers continue to evolve rapidly, we can anticipate a brighter and more sustainable future powered by the sun.

The importance of Silica Sio2 in various industries

[Company Introduction] The company is a leading manufacturer and supplier of high-quality silica Sio2 products. With a strong focus on research and development, the company has been consistently at the forefront of innovation in the industry. Their extensive range of products caters to various sectors such as rubber, plastics, coatings, and adhesives, among others. With a commitment to quality and customer satisfaction, the company has established a strong presence in both domestic and international markets.[News Content]Silica Sio2, commonly known as silica, is a versatile and essential mineral that finds widespread applications across various industries. From its use as a reinforcing filler in rubber products to its role as a flow aid in pharmaceuticals, the significance of silica in modern manufacturing processes cannot be overstated. In this regard, the company has been a key player in meeting the growing demand for high-quality silica products.The company's silica Sio2 products are known for their exceptional purity and consistency, making them the material of choice for a wide range of applications. Their state-of-the-art manufacturing facilities and stringent quality control measures ensure that the silica products meet the highest industry standards. This, combined with their technical expertise and customer-centric approach, has earned the company a stellar reputation in the market.One of the key areas where the company has made significant strides is in the development of silica-based solutions for the rubber industry. Silica is widely used as a reinforcing agent in rubber compounds, imparting strength, abrasion resistance, and tear resistance to the final products. The company's silica Sio2 products for rubber applications are designed to enhance the performance and durability of tires, conveyor belts, hoses, and various other rubber products.Furthermore, the company's silica products have also found extensive use in the plastics industry. Silica is used as a filler and reinforcement agent in plastic compounds, improving their mechanical properties and dimensional stability. The company offers a diverse range of silica products specifically tailored to meet the unique requirements of the plastics industry, catering to applications such as film and sheet extrusion, injection molding, and compounding.In the realm of coatings and adhesives, silica Sio2 plays a crucial role in enhancing the performance of various formulations. The company's silica products are widely used as matting agents, thickeners, and rheology modifiers in coatings, paints, and adhesives. Their high-purity silica grades contribute to improved durability, scratch resistance, and overall quality of the coatings and adhesives, thereby meeting the stringent demands of the industry.Notably, the company has also diversified its product portfolio to include specialty silica products catering to niche markets such as pharmaceuticals, personal care, and agriculture. With their in-depth understanding of material science and applications expertise, the company has been able to develop customized silica solutions to address the evolving needs of these industries, thereby expanding their market presence and customer base.Looking ahead, the company remains committed to driving innovation and excellence in the field of silica Sio2 products. With a strong focus on sustainability and environmental responsibility, they are investing in research and development to create eco-friendly silica solutions that align with the evolving regulatory requirements and industry trends. Moreover, by strengthening their global distribution network and forging strategic partnerships, the company is poised to further consolidate its position as a leading provider of high-quality silica products worldwide.

High Performance Siliciumcarbid Wafer for Advanced Electronics

Silicon Carbide Wafer: A Groundbreaking Innovation in Semiconductor TechnologySilicon carbide (SiC) wafers have been making waves in the semiconductor industry due to their potential to revolutionize the way electronic devices are designed and manufactured. With superior electrical and thermal properties compared to traditional silicon wafers, SiC wafers are enabling the development of higher performance and more efficient electronic components.The company behind the groundbreaking innovation in SiC wafer technology is a leading semiconductor manufacturer with a strong track record of producing high-quality and advanced semiconductor materials. With a commitment to research and development, they have been at the forefront of bringing cutting-edge semiconductor solutions to the market.The introduction of SiC wafers into the semiconductor industry represents a significant advancement in material science and semiconductor technology. SiC wafers offer many advantages over traditional silicon wafers, including higher thermal conductivity, lower power losses, and increased temperature resistance. These unique properties make SiC wafers an ideal choice for applications in power electronics, electric vehicles, renewable energy systems, and wireless communication devices.One of the key benefits of SiC wafers is their ability to operate at higher temperatures compared to silicon wafers. This is particularly important for power electronic devices, where the ability to handle high temperatures can significantly improve overall system efficiency and reliability. As a result, SiC wafers are driving innovation in power conversion systems, enabling the development of more compact, energy-efficient, and environmentally friendly electronic devices.Furthermore, SiC wafers have demonstrated superior electrical performance, including higher electron mobility and breakdown voltage, which are essential for high-power and high-frequency electronic applications. This has led to increased interest and adoption of SiC wafers in industries such as automotive, aerospace, and telecommunications, where advanced semiconductor materials are crucial for achieving next-generation performance targets.The company's expertise in manufacturing high-quality SiC wafers has positioned them as a trusted partner for semiconductor companies looking to leverage the benefits of SiC technology. Their state-of-the-art production facilities and rigorous quality control processes ensure that their SiC wafers meet the stringent requirements of the semiconductor industry, enabling their customers to design and manufacture advanced electronic devices with confidence.In addition to producing SiC wafers, the company is also actively engaged in collaborative research and development efforts to further enhance the performance and functionality of SiC-based semiconductor devices. This includes working with industry partners and academic institutions to explore new applications for SiC technology and develop innovative solutions that address the evolving needs of the semiconductor market.As the demand for high-performance electronic devices continues to grow, SiC wafers are poised to play a pivotal role in shaping the future of semiconductor technology. With their exceptional material properties and the company's expertise in semiconductor manufacturing, SiC wafers are unlocking new possibilities for designing and producing advanced electronic components that are smaller, faster, and more efficient.Overall, the introduction of SiC wafers represents a significant milestone in the semiconductor industry, offering a glimpse into the future of electronic devices that are powered by advanced materials and cutting-edge technology. As the company continues to push the boundaries of SiC technology, it is evident that SiC wafers will continue to drive innovation and change the landscape of the semiconductor industry for years to come.

Understanding the Main Uses and Advantages of Quartz Wafers Revealed by Latest Reports

Title: Advanced Crystal Technology Breakthrough: Ultra-Thin Wafers Set to Transform the Microelectronics Industry Introduction:Modern society heavily relies on microelectronics, with technological advancements driving the need for more efficient, powerful, and compact electronic devices. Crystal wafer technology has played a pivotal role in enabling the miniaturization and improved performance of electronic components. In a groundbreaking development, a leading company in this field has introduced an ultra-thin quartz wafer that is poised to transform the microelectronics industry. This cutting-edge technology has the potential to revolutionize a wide range of sectors, from consumer electronics to healthcare and beyond.[Note: Brand name removed for neutrality]Body:1. Crystal Wafer Technology: A Brief Overview (100 words)Crystal wafer technology forms the foundation of modern microelectronics, enabling the production of smaller, faster, and more efficient electronic devices. These wafers, typically made from quartz, provide a stable and highly uniform surface for semiconductor fabrication. They are utilized in the production of integrated circuits (ICs) and other electronic components, such as transistors, diodes, and sensors.2. The Need for Ultra-Thin Wafers (100 words)As consumer demands for sleeker, more compact electronic devices grow, so does the need for thinner crystal wafers. Traditional quartz wafers, at about 0.5mm thickness, face limitations in achieving further miniaturization without compromising performance. Consequently, industry players have been actively researching and developing processes to produce ultra-thin wafers that maintain the robustness of their thicker counterparts.3. Breakthrough Technology: Ultra-Thin Quartz Wafers (100 words)Leading the way in crystal wafer technology, the company {} has unveiled their latest breakthrough: ultra-thin quartz wafers, measuring less than 0.1mm in thickness. The wafer's unique composition and manufacturing process allow for exceptional mechanical stability and electrical properties, ensuring optimal performance in demanding applications. Engineered specifically for microelectronics, these ultra-thin wafers are set to revolutionize various sectors, particularly those relying on compact, high-performance devices.4. Enhanced Performance and Versatile Applications (150 words)The introduction of ultra-thin quartz wafers opens up a myriad of possibilities in the microelectronics industry, thanks to their enhanced performance characteristics. These wafers exhibit excellent mechanical strength, thermal stability, and high electrical resistivity, making them ideal for cutting-edge electronic devices. Additionally, their ultra-thin profile enables increased integration density, paving the way for even more functionality in smaller devices.From consumer electronics and telecommunications to automotive and healthcare sectors, the potential applications of ultra-thin quartz wafers are immense. Advanced smartphones, wearables, biomedical sensors, and autonomous vehicles are just a few examples of domains that will greatly benefit from this breakthrough technology. The new wafers' improved thermal properties will enhance heat dissipation in intricate electronic assemblies, offering greater reliability and longevity to electronic devices.5. Industry Impact and Future Prospects (150 words)The widespread implementation of ultra-thin quartz wafers in the microelectronics industry is expected to drive significant advancements in the coming years. Shrinking the form factor of electronic devices will enable improved portability and integration, leading to enhanced user experiences and functionality.Additionally, this breakthrough technology aligns with industry trends such as the Internet of Things (IoT), big data, and 5G networks, which demand smaller, reliable, and high-performance electronics. As the microelectronics industry continues to evolve, the demand for ultra-thin wafers is anticipated to skyrocket, spelling growth opportunities for manufacturers and suppliers.In conclusion, the launch of ultra-thin quartz wafers represents a remarkable progression in crystal wafer technology, offering unprecedented opportunities for the microelectronics industry. These ultra-thin wafers hold the potential to revolutionize the way electronic devices are designed, manufactured, and utilized, catapulting our society into a new era of compact, powerful, and innovative microelectronics.

Exploring the Growing Demand for Sic Wafers in Technology Industry

Title: Revolutionary Technology Empowers Electronics Industry with Next-Gen Silicon Carbide WafersIntroduction:In an era driven by rapid technological advancements, the global electronics industry seeks reliable and efficient solutions that can accelerate the pace of innovation. Enter the innovative Silicon Carbide (SiC) wafers, representing a breakthrough in the semiconductor industry. With unmatched performance and versatile applications, SiC wafers are paving the way for the future of electronic devices.[Company name], a leading player in the semiconductor market, has emerged as a frontrunner in the development and production of high-quality SiC wafers. Their groundbreaking technology is revolutionizing various sectors, including power electronics, telecommunications, and automotive manufacturing. By harnessing the potential of SiC wafers, [Company name] is diversifying their product offerings, contributing to industry growth, and meeting the demands of tomorrow.Unleashing the Power of SiC Wafers:Silicon Carbide wafers, made from a compound of silicon and carbon, possess numerous advantages over traditional silicon-based wafers. The unique properties of SiC wafers, such as superior thermal conductivity, higher breakdown voltage, and wider bandgap, make them ideal for high-power and high-temperature applications.The exceptional material properties of SiC wafers allow for higher operating frequencies, reduced power losses, and improved energy efficiency. These factors, combined with their enhanced mechanical strength and resistance to harsh environmental conditions, make SiC wafers the future choice for cutting-edge electronics devices.Industries Benefiting from SiC Wafers:1. Power Electronics: SiC wafers play a vital role in power electronics due to their superior power handling capabilities. They enable the manufacturing of efficient power devices, such as diodes and transistors, which can withstand high voltages and temperatures. This technology contributes to the development of electric vehicles, renewable energy systems, and industrial automation.2. Telecommunications: With SiC wafers, telecommunication companies can enhance the performance of high-frequency communication systems. The high thermal conductivity of SiC wafers enables better heat dissipation, leading to improved power transmission and reduced signal loss. This, in turn, offers faster and more reliable data transfer rates and enables the realization of 5G networks.3. Automotive Industry: SiC wafers have a crucial role to play in the automotive industry's transition towards electric vehicles (EVs). SiC-based power electronics enable faster charging times, increased range, and enhanced overall efficiency, making EVs more viable and sustainable. Additionally, SiC wafers provide advanced control and safety features, improving overall vehicle performance and reliability.[Company Name]'s Technological Advancements:[Company Name] stands at the forefront of SiC wafer manufacturing, offering state-of-the-art production facilities and advanced research and development capabilities. Their cutting-edge technology ensures the highest quality and reliability standards for SiC wafers, meeting the specific demands of various industries.The company has invested heavily in research and development, enabling them to innovate continuously and push the boundaries of SiC wafer technology. Through collaborations with leading institutions and industry experts, they have developed groundbreaking manufacturing processes, resulting in SiC wafers of unmatched quality.Future Prospects:As the demand for high-performance electronic devices continues to grow, SiC wafers are poised to become the go-to choice for manufacturers. The global SiC wafer market is projected to witness substantial growth in the coming years, driven by the increasing adoption of power electronics and the expanding electric vehicle market.[Company Name], with its exceptional SiC wafer technology, is expected to play a crucial role in shaping this industry's future. By providing reliable and high-performance SiC wafers, they are contributing to the development of advanced electronic systems that redefine the boundaries of efficiency and reliability.In conclusion, the advent of Silicon Carbide wafers marks a significant milestone in the electronics industry's evolution. [Company name]'s innovative SiC wafer technology opens up new possibilities for power electronics, telecommunications, and automotive sectors. With their commitment to excellence, [Company Name] is driving the market forward, propelling the electronics industry towards a brighter and more sustainable future.