- Home

- Blog

- Advanced Technology Development in Epi-Layer Growth for Improving Semiconductor Performance

Advanced Technology Development in Epi-Layer Growth for Improving Semiconductor Performance

By:Admin

The company, which has a proven track record of delivering high-quality semiconductor products, has developed Gan Epi-Layer as a way to enhance the efficiency and power handling capabilities of electronic devices. By utilizing gallium nitride (GaN) materials, the company has been able to create a unique epi-layer that offers significant advantages over traditional silicon-based materials.

One of the key benefits of Gan Epi-Layer is its ability to operate at higher frequencies and voltages, making it ideal for use in advanced electronic applications. This means that electronic devices powered by this technology can deliver faster performance and more reliable operation, while also consuming less power. As a result, the technology has the potential to revolutionize the way electronic devices are designed and manufactured.

In addition to its superior performance characteristics, Gan Epi-Layer also offers a number of other advantages. For example, it is highly resistant to heat and radiation, which makes it well-suited for use in harsh environments. This could make it an attractive option for applications in industries such as aerospace, defense, and telecommunications, where reliability and durability are crucial.

Furthermore, the company has ensured that Gan Epi-Layer can be easily integrated into existing manufacturing processes, making it a cost-effective and practical solution for businesses looking to improve the performance of their electronic products. This means that companies can take advantage of this technology without having to overhaul their entire production systems, making it a highly attractive option for businesses of all sizes.

The potential impact of Gan Epi-Layer extends far beyond the realm of consumer electronics. In fact, the technology has the potential to drive innovation and advancements in a wide range of industries, from healthcare and automotive to energy and infrastructure. By enabling the development of more efficient and reliable electronic devices, Gan Epi-Layer could help to improve the performance and capabilities of a vast array of products and systems.

The company has already begun commercializing Gan Epi-Layer, and has seen strong interest from a variety of industry players. In fact, the technology has already been incorporated into a number of commercial products, demonstrating its real-world potential and proving its viability as a practical solution for businesses.

Looking ahead, the company is committed to further advancing the capabilities of Gan Epi-Layer, and is actively exploring new applications and opportunities for the technology. With its extensive expertise in semiconductor materials and manufacturing, the company is well-positioned to drive the continued development and adoption of this game-changing technology.

In conclusion, Gan Epi-Layer has the potential to revolutionize the way electronic devices are designed and manufactured, offering superior performance, reliability, and efficiency compared to traditional materials. With its wide-ranging applications and potential to drive innovation across multiple industries, this groundbreaking technology is poised to have a profoundly positive impact on the world of electronics. As the company continues to push the boundaries of what is possible with Gan Epi-Layer, we can expect to see even more exciting developments and advancements in the near future.

Company News & Blog

Discover the Benefits of Silicon Carbide Polishing for a Flawless Finish

Silicon Carbide Polishing is a cutting-edge technique that has revolutionized the polishing industry. This method utilizes a combination of silicon carbide powder, water, and a polishing pad to produce a high-gloss finish on a variety of materials, including metals, plastics, and ceramics. The unique properties of silicon carbide make it an ideal material for polishing, as it is extremely hard and durable, allowing for precise and consistent results.One company that has made significant strides in the development of silicon carbide polishing is {}. The company was founded in the early 2000s and has since become a leader in the manufacturing and distribution of advanced polishing solutions. Their commitment to research and development has led to the creation of cutting-edge products that have set new standards in the industry. Their team of experts is dedicated to providing innovative solutions that meet the evolving needs of their customers.The company's silicon carbide polishing products have been widely recognized for their superior performance and reliability. Their proprietary formulation of silicon carbide powder ensures a consistent and uniform polishing action, resulting in a mirror-like finish. This level of precision is particularly valuable in industries such as aerospace, automotive, and electronics, where the quality of the finished product is of utmost importance.One of the key benefits of silicon carbide polishing is its ability to remove surface imperfections and create a smooth, uniform finish. This is essential for ensuring the optimum performance and longevity of components in various applications. Silicon carbide polishing also offers exceptional resistance to wear and tear, making it an ideal choice for high-traffic areas and components subject to heavy use.In addition to its superior performance, silicon carbide polishing is also environmentally friendly. Unlike traditional polishing methods that produce harmful emissions and waste, silicon carbide polishing is a clean and efficient process that minimizes the impact on the environment. This is an important consideration for companies looking to reduce their carbon footprint and operate sustainably.With the growing demand for high-quality surface finishes, the market for silicon carbide polishing is expected to expand significantly in the coming years. This presents an opportunity for companies like {} to further establish themselves as leaders in the industry. By continuing to invest in research and development, as well as maintaining a strong focus on customer satisfaction, they are well-positioned to capitalize on this growing trend.Furthermore, the company's commitment to innovation and excellence has earned them a strong reputation in the industry. They have built long-lasting relationships with a wide range of customers, from small businesses to multinational corporations, who rely on their expertise and products to achieve outstanding results. Their dedication to quality and customer service has set them apart from competitors and positioned them as a trusted partner in the industry.As the demand for silicon carbide polishing continues to grow, {} is poised to capitalize on this opportunity and further solidify their position as a leader in the industry. With their advanced products and commitment to excellence, they are well-equipped to meet the evolving needs of their customers and remain at the forefront of the industry.

Cutting-Edge Wafer Transistor Technology: A Breakthrough in Electronics

Wafer transistor technology is revolutionizing the semiconductor industry with its cutting-edge advancements. With its high-performance characteristics, the technology is increasingly in demand across various sectors such as telecommunications, automotive, and consumer electronics. One company at the forefront of this wave of innovation is {}. With a strong focus on research and development, the company has been a driving force in the development and commercialization of wafer transistor technology. Their commitment to excellence and technological prowess has positioned them as a leader in the industry, and their products are highly sought after by major players in the tech sector.The wafer transistor, a key component in amplifying and switching electronic signals, offers numerous benefits over traditional transistors. With its smaller size, faster speeds, and lower power consumption, it is a game-changer for a wide range of electronic devices. As the demand for smaller and more efficient electronics continues to grow, wafer transistors are becoming increasingly indispensable.The company, {} has been instrumental in pushing the boundaries of wafer transistor technology. Through extensive research and collaboration with leading industry experts, they have been able to develop state-of-the-art wafer transistors that meet the rigorous demands of today's electronic devices. Their commitment to excellence and innovation has made them a trusted partner for companies looking to integrate wafer transistor technology into their products.One of the key drivers of {}’s success is their focus on quality and reliability. Their rigorous testing and quality control processes ensure that their wafer transistors meet the highest standards and deliver exceptional performance. This commitment to excellence has earned them a stellar reputation in the industry and has made them the go-to choice for companies seeking top-notch wafer transistor technology.In addition to their technical prowess, {} is also known for their customer-centric approach. They work closely with their clients to understand their specific needs and provide tailored solutions that meet their requirements. This personalized approach has helped them build strong, long-lasting relationships with their clients and has solidified their position as a trusted partner in the industry.As the demand for wafer transistor technology continues to grow, {} is poised to play a key role in driving its widespread adoption. With their cutting-edge technology, unwavering commitment to quality, and customer-focused approach, they are well-positioned to lead the way in this rapidly evolving field. Their expertise and innovation are set to shape the future of wafer transistor technology and have a profound impact on the electronics industry as a whole.With their track record of excellence and their dedication to pushing the boundaries of wafer transistor technology, {} is set to remain a driving force in the industry for years to come. Their contributions to the advancement of semiconductor technology are invaluable, and their future looks brighter than ever as they continue to innovate and lead the way in wafer transistor technology. As the electronics industry continues to evolve, {} is sure to be at the forefront, shaping the future of wafer transistor technology and driving innovation across the industry.

Revolutionizing Semiconductor Manufacturing: Unveiling the Groundbreaking Chemical Mechanical Planarization Process

Title: Advancements in Chemical Mechanical Planarization Process: Revolutionizing Material Polishing Introduction:In today's ever-evolving technological landscape, the demand for smaller, faster, and more efficient electronic devices continues to grow. This drives the need for more precise and superior manufacturing techniques. Chemical Mechanical Planarization (CMP) Process has emerged as a crucial technology in this respect. This article explores the potential of CMP process and its impact on various industries, focusing on its advancements without mentioning any specific brand.I. Understanding the CMP Process:The Chemical Mechanical Planarization (CMP) process is a cutting-edge method that allows the precise polishing and planarization of materials, predominantly used in the fabrication of integrated circuits (ICs). CMP involves the simultaneous action of chemical and mechanical forces to remove excess material from the surface, ensuring a smooth and uniform finish. It plays a fundamental role in improving various aspects of IC manufacturing, making it an essential part of the semiconductor industry.II. Advancements in CMP Process:1. Ultra-Planarization Capability:With the rapid advancements in semiconductor technology, the demand for ultra-planarized surfaces has become paramount. Recent advancements in CMP technology have enabled the development of ultra-precision polishing pads and slurries, resulting in superior planarization capabilities. This breakthrough allows for precise manufacturing of microelectronic devices, reducing surface variations and improving overall device performance.2. Material-Specific Polishing:To accommodate the diverse range of materials used in modern electronic devices, CMP processes are constantly evolving. Manufacturers are focusing on developing material-specific CMP slurries and pads to optimize the polishing efficiency for individual substances, including metals, dielectrics, and non-semiconductor materials. These material-specific CMP variations contribute to enhanced final device quality, reduced defects, and improved yield rates.3. Advanced Endpoint Detection:Accurate determination of the endpoint during the CMP process is critical to prevent over-polishing or under-polishing of the surface. Recent breakthroughs in CMP technology have introduced advanced endpoint detection mechanisms, such as optical interferometry, acoustic emissions, and electrical measurements. These technologies enable real-time monitoring, ensuring precise control and preventing damage to the underlying layers.III. Applications in the Semiconductor Industry:1. Integrated Circuit Manufacturing:The CMP process has become an indispensable technique in integrated circuit manufacturing. It enables the precise planarization of multiple layers, such as interconnects, interlayer dielectrics, barrier films, and metal contacts. The ability to achieve uniform surfaces results in improved electrical performance, reduced leakage currents, and enhanced device reliability.2. Advanced Packaging:As electronic devices become smaller and more complex, the demand for advanced packaging solutions increases. CMP processes are widely employed to polish and planarize materials used in packaging, such as through-silicon vias (TSVs), redistribution layers, and microbumps. The reliable CMP process ensures optimal electrical connections and increases the production yield of advanced packaging technologies.3. Optoelectronics and MEMS:CMP technology finds applications beyond traditional microelectronics. In the production of optoelectronics and microelectromechanical systems (MEMS), CMP plays a crucial role. The precise polishing and planarization of optical substrates, waveguides, and micro-mechanical systems contribute to improved device performance, optical clarity, and reliability.IV. Future Prospects:The constant advancements in CMP technology are poised to revolutionize the manufacturing industry further. Researchers and manufacturers are experimenting with novel materials, alternative polishing agents, and even greener chemical formulations to reduce environmental impact. Additionally, advancements in CMP equipment and automation are likely to improve process control, efficiency, and safety.Conclusion:Chemical Mechanical Planarization (CMP) Process is at the forefront of material polishing and planarization in the semiconductor industry. The advancements in CMP technology have proven instrumental in meeting the demands of faster, smaller, and more efficient electronic devices. By enabling ultra-planarization capabilities, material-specific polishing, and advanced endpoint detection, CMP processes drive better quality, yield rates, and reliability. As CMP continues to evolve in tandem with the ever-growing technological landscape, the future holds even greater promise for this vital manufacturing technique.

Latest Breakthrough in Optical Wafer Technology Unveiled in Recent News

Optical Wafer Company Revolutionizes Semiconductor IndustryOptical wafers are a critical component in the production of semiconductors, and one company has been making waves in the industry with its innovative technology and unparalleled quality. Based in the heart of Silicon Valley, this company has been at the forefront of optical wafer production for over 25 years, serving as a trusted partner for some of the largest semiconductor manufacturers in the world.The company's success can be attributed to its commitment to delivering the highest quality products while continuously pushing the boundaries of innovation. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, they have been able to consistently develop cutting-edge optical wafer solutions that meet the ever-evolving demands of the semiconductor industry.One of the company's most notable achievements is the development of a proprietary process that allows for the production of ultra-thin optical wafers with unprecedented precision and uniformity. This breakthrough has enabled semiconductor manufacturers to achieve higher performance and efficiency in their products, ultimately driving the advancement of technology across various industries.Moreover, the company's dedication to sustainability and environmental responsibility has also set them apart from their competitors. By implementing stringent quality control measures and environmentally-friendly manufacturing processes, they have been able to minimize waste and reduce their carbon footprint, making them a preferred partner for businesses with a focus on corporate social responsibility.In addition to their technological and environmental advancements, the company has also been recognized for their exceptional customer service and support. They work closely with their clients to understand their specific needs and provide customized solutions that address their unique challenges. This customer-centric approach has helped them establish long-standing relationships with leading semiconductor manufacturers, further solidifying their position as a trusted industry partner.Looking ahead, the company is poised to continue leading the way in optical wafer production, with plans to further enhance their manufacturing capabilities and develop new, innovative products that will drive the next generation of semiconductor technology. With a strong focus on research and development, they are committed to staying ahead of the curve and delivering solutions that will shape the future of the semiconductor industry.As the demand for high-performance semiconductors continues to grow, the role of optical wafers in enabling this advancement becomes increasingly crucial. With their unwavering commitment to excellence, innovation, and sustainability, this company is well-positioned to play a pivotal role in shaping the future of the semiconductor industry, and their continued success is sure to be a key driver in the advancement of technology across the globe.In conclusion, the Optical Wafer company has established itself as a leader in the semiconductor industry, with a track record of delivering high-quality, innovative products and unparalleled customer service. Their commitment to excellence, sustainability, and continuous innovation has positioned them as a trusted partner for the world's leading semiconductor manufacturers, and their future looks brighter than ever as they continue to drive the advancement of technology.

Breakthrough in Crystalline Material: SrTiO3 Wafer Holds Potential for Revolutionary Applications

A new technology using SrTiO3 wafers promises to revolutionize the semiconductor industry by improving the efficiency and performance of electronic devices. SrTiO3 is a unique material with exceptional electrical and optical properties that make it ideal for use in electronic devices such as computers, smartphones, and other digital devices.SrTiO3 is a complex oxide compound made up of Strontium, Titanium, and Oxygen. It exhibits semiconducting properties, which is why it’s relevant to the electronics industry. The technology is particularly useful in the development of advanced semiconductor devices such as MOSFETs, solar cells, and transistors, among others.SrTiO3 wafers have been in use in the semiconductor industry for years, but scientists have been exploring ways to make the compound material more efficient and precise. New research shows that combining SrTiO3 with other materials, such as hafnium oxide, can produce even more remarkable results.The company behind this breakthrough development is a leading producer of high-quality wafers for the electronics industry. The company has been a pioneer in the development of semiconductor-grade crystals, and its technological advancements continue to push the boundaries of what is possible within the industry.The SrTiO3 wafer technology has significant implications for the future of the electronics industry. Manufacturers can use the technology to develop devices that are more powerful, efficient, and affordable. The use of SrTiO3 wafers in the manufacturing process ensures that electronic components are more reliable and can operate at higher temperatures.The technology also has significant benefits for solar cell technology. SrTiO3-based solar cells have higher conversion efficiencies than conventional cells, making them more desirable for use in photovoltaic systems. The use of this technology in solar panels could lead to the development of more efficient and cost-effective solar panels, helping bring clean energy to millions of people worldwide.The innovative SrTiO3 wafer technology has many applications, including in the automotive, healthcare, and aerospace industries. Researchers are exploring new uses for the technology and hope to discover new applications that will further revolutionize the electronics industry in the coming years.The company's patented manufacturing process for SrTiO3 wafers ensures the production of high-quality materials that meet strict industry standards. The company's wafers are currently being used in research and development laboratories around the world, and several companies have already adopted the technology in their manufacturing processes.The use of SrTiO3 wafers in electronic devices is set to increase in the coming years as the technology becomes more widespread and affordable. The introduction of this technology has significant implications for the electronics industry, and researchers are excited by its potential to transform the industry's future.In conclusion, the emergence of SrTiO3 wafers has set the semiconductor industry on a path towards a new generation of electronic devices. The technology has significant implications for the development of powerful, efficient, and affordable electronic devices, solar cell technology, and many other applications. With continued research and development, the technology has the potential to revolutionize the electronics industry for years to come.

High-quality Gallium Arsenide Wafer for Electronic Applications

Semiconductor technology is advancing rapidly, and one company is at the forefront of this innovation with its cutting-edge Gallium Arsenide wafers. These wafers offer superior performance and have the potential to revolutionize various industries, from telecommunications to aerospace. The company, which has been a leader in the semiconductor industry for over [X] years, is committed to pushing the boundaries of what is possible with Gallium Arsenide technology.Gallium Arsenide wafers are semiconductor materials that have several advantages over traditional silicon wafers. They offer higher electron mobility, which results in faster electronic devices, and they can operate at higher temperatures, making them ideal for high-power applications. Additionally, Gallium Arsenide has a direct bandgap, which allows it to emit light more efficiently than silicon. This makes it a perfect material for optoelectronic devices such as LEDs and solar cells.The company has perfected the manufacturing process for Gallium Arsenide wafers, ensuring that they meet the highest quality standards. Their wafers are available in various sizes and thicknesses, making them suitable for a wide range of applications. Whether it's for advanced wireless communication systems, high-speed data transfer, or satellite technology, these wafers are poised to enable the next generation of electronic devices.One of the most exciting potential applications for Gallium Arsenide wafers is in the development of 5G technology. With the demand for faster and more reliable wireless communication growing rapidly, 5G networks are set to revolutionize the way we connect and communicate. Gallium Arsenide wafers can enable the high-frequency operation required for 5G devices, making them an essential component in the rollout of this next-generation technology.In addition to telecommunications, Gallium Arsenide wafers have the potential to drive advancements in aerospace and defense. The superior performance of these wafers makes them ideal for radar and communication systems used in military and aerospace applications. Their ability to operate at higher frequencies and temperatures makes them a key enabler for sophisticated electronic systems in these critical fields.The company's commitment to research and development has positioned them as a leader in Gallium Arsenide technology. They continue to invest in refining their manufacturing processes and expanding their product offerings to meet the evolving needs of the semiconductor industry. Their team of experienced engineers and scientists are dedicated to pushing the boundaries of what is possible with Gallium Arsenide, driving innovation and shaping the future of electronic devices.As the demand for faster, more efficient electronic devices continues to grow, the importance of advanced semiconductor materials like Gallium Arsenide cannot be overstated. The unique properties of this material make it a key enabler for the development of cutting-edge technologies in various industries. With their expertise and commitment to excellence, the company is well-positioned to drive the widespread adoption of Gallium Arsenide wafers and shape the future of semiconductor technology.

Discover the Latest Advances in Solar Silicon Wafer Technology

Solar energy has been gaining traction as a sustainable and renewable source of energy. One of the key components in harnessing solar energy is the solar silicon wafer. These wafers are used to convert sunlight into electricity and are essential in the production of solar panels.In this regard, [Company Name] has been at the forefront of manufacturing high-quality solar silicon wafers. Established in [year], [Company Name] has become a leading player in the solar energy industry, specializing in the production of silicon wafers that are used in photovoltaic cells. With a strong emphasis on technological innovation and sustainable manufacturing practices, [Company Name] has positioned itself as a trusted and reliable supplier of solar silicon wafers.The company's dedication to excellence is evident in its state-of-the-art manufacturing facilities, where it employs the latest technologies and processes to produce premium quality silicon wafers. With a focus on quality control and performance testing, [Company Name] ensures that its products meet the highest industry standards. This commitment to quality has earned [Company Name] a reputation for reliability and excellence in the solar energy sector.Moreover, [Company Name] is committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing processes and has implemented measures to minimize its carbon footprint, making it a socially responsible choice for businesses and consumers looking to reduce their environmental impact.In addition to its advanced manufacturing capabilities, [Company Name] has a team of experienced professionals who are dedicated to delivering exceptional customer service and technical support. Whether it's providing technical expertise, offering product recommendations, or assisting with custom orders, [Company Name]'s team is committed to ensuring a positive experience for its customers.One of the key factors that set [Company Name] apart from its competitors is its ability to customize silicon wafers to meet specific customer requirements. This flexibility allows the company to cater to a wide range of applications and projects, making it a preferred choice for businesses and organizations looking for tailored solutions.As the demand for solar energy continues to grow, [Company Name] remains dedicated to advancing its technology and expanding its product offerings. Through ongoing research and development, the company aims to further improve the efficiency and performance of its silicon wafers, contributing to the widespread adoption of solar energy as a viable alternative to traditional power sources.Furthermore, [Company Name] is committed to fostering partnerships and collaborations within the solar energy industry. By working closely with other companies, research institutions, and organizations, [Company Name] seeks to contribute to the advancement of solar technology and promote the adoption of sustainable energy solutions on a global scale.With its unwavering commitment to quality, innovation, and sustainability, [Company Name] is well-positioned to meet the evolving needs of the solar energy market and make a significant impact in the transition towards a more sustainable energy future.In conclusion, [Company Name] continues to be a driving force in the solar energy industry, with its high-quality silicon wafers and dedication to sustainable practices. By consistently delivering exceptional products and services, [Company Name] has established itself as a trusted partner for businesses and organizations looking to harness the power of solar energy. As the demand for renewable energy sources continues to grow, [Company Name] is poised to play a pivotal role in shaping the future of solar technology and contributing to a more sustainable world.

Rare Earth Material Gadolinium Gallium Garnet: Uses, Properties and Applications

Gadolinium Gallium Garnet (GGG) is a synthetic crystalline material that is used in a wide range of applications, including magneto-optical devices, microwave isolators, and optical modulators. It is known for its exceptional physical and chemical properties, making it an ideal choice for various technological and scientific uses. With its high thermal stability, excellent optical transparency, and strong magneto-optical properties, GGG is a versatile material that has found its way into numerous industries.One company that has been at the forefront of GGG research and production is {}. Founded in 1995, {} has a long history of expertise in the development and manufacturing of advanced materials, including GGG. The company prides itself on its dedication to research and innovation, and its commitment to providing high-quality materials to meet the needs of its customers.With state-of-the-art facilities and a team of experienced scientists and engineers, {} has been able to produce GGG crystals with exceptional purity and uniformity, making them ideal for a wide range of applications. The company's GGG crystals exhibit high optical transparency over a broad wavelength range, making them suitable for use in various optical devices and components. In addition, they also possess excellent magneto-optical properties, allowing for efficient modulation of light in magneto-optical devices.One of the key advantages of {}'s GGG crystals is their high thermal stability, which makes them resistant to thermal shock and capable of withstanding high temperatures. This property makes them ideal for use in harsh environments, such as high-power laser systems and microwave applications. Furthermore, {}'s GGG crystals exhibit high mechanical strength, ensuring their durability and longevity in demanding applications.As a leading supplier of GGG crystals, {} has been able to cater to the diverse needs of its customers in various industries, including telecommunications, aerospace, and scientific research. The company offers a wide range of GGG products, including single crystals, wafers, and custom-made components, tailored to meet specific customer requirements. With a focus on quality and precision, {} has established itself as a trusted partner for businesses and researchers seeking reliable GGG materials.In addition to its commitment to quality, {} is also dedicated to sustainability and environmental responsibility. The company's manufacturing processes adhere to strict environmental standards, ensuring minimal impact on the environment. Furthermore, {} is actively involved in research and development efforts aimed at finding greener and more sustainable approaches to material production.Looking ahead, {} is poised to continue its leadership in the field of GGG research and production. The company remains committed to staying at the forefront of technological advancements and meeting the evolving needs of its customers. With ongoing investments in research and development, {} is well-positioned to offer cutting-edge GGG materials that will drive innovation in various industries.As GGG continues to find new applications and opportunities in the marketplace, {} is poised to play a pivotal role in shaping the future of this versatile material. With its dedication to excellence and innovation, {} is set to remain a trusted partner for businesses and researchers seeking high-quality GGG materials for their applications.In conclusion, Gadolinium Gallium Garnet (GGG) is a remarkable material with a wide range of applications, and {} is a leading supplier of high-quality GGG crystals. With its focus on research, innovation, and sustainability, {} is well-positioned to continue its legacy of excellence in GGG production and advance the possibilities of this remarkable material.

High-performance Galliumarsenide: The Future of Semiconductors

Galliumarsenide, a new revolutionary material in the world of technology, is set to transform the way we think about electronic devices. This compound, which is a combination of gallium and arsenic, has been making headlines recently for its incredible potential in the field of semiconductor technology. With its high electron mobility and superior performance characteristics, galliumarsenide is poised to be a game-changer in the industry.One company that is at the forefront of harnessing the power of galliumarsenide is a leading semiconductor manufacturer. The company has been a pioneer in developing cutting-edge technologies and has been at the forefront of innovation in the industry for decades.The company has been investing heavily in research and development to explore the potential of galliumarsenide and has recently made significant strides in utilizing this material to create high-performance electronic devices. Their team of scientists and engineers have been working tirelessly to unlock the full potential of galliumarsenide and have already achieved groundbreaking results.One of the key advantages of galliumarsenide is its superior electron mobility, which allows for faster and more efficient electronic devices. This property makes galliumarsenide an ideal material for high-speed communications, wireless networks, and other applications that require rapid data transfer.Additionally, galliumarsenide also boasts a higher breakdown voltage than traditional silicon semiconductors, making it more durable and reliable in demanding operating conditions. This makes it an attractive option for a wide range of applications, including aerospace, defense, and telecommunications.The company's commitment to innovation and its expertise in semiconductor manufacturing have uniquely positioned them to lead the way in utilizing galliumarsenide in commercial applications. By leveraging their extensive experience and cutting-edge facilities, the company has been able to develop advanced galliumarsenide-based devices that outperform traditional silicon-based counterparts.Furthermore, the company's dedication to sustainability and environmental responsibility has also played a significant role in their advancements in galliumarsenide technology. They have implemented eco-friendly manufacturing processes and have made significant strides in reducing their carbon footprint, making their galliumarsenide products not only high-performance but also environmentally friendly.As the demand for faster and more efficient electronic devices continues to grow, the potential of galliumarsenide is becoming increasingly apparent. The company's work in harnessing the power of this revolutionary material has the potential to transform the semiconductor industry and open up new possibilities for the next generation of electronic devices.With their expertise, resources, and commitment to innovation, the company is well-positioned to lead the charge in the commercialization of galliumarsenide technology. Their groundbreaking advancements in this field are a testament to their dedication to pushing the boundaries of what is possible in the world of semiconductor technology.In conclusion, galliumarsenide has the potential to revolutionize the semiconductor industry, and one company is leading the way in harnessing its power. With their expertise, commitment to sustainability, and groundbreaking advancements in galliumarsenide technology, the company is poised to shape the future of electronic devices and solidify their position as a trailblazer in the industry. As the world continues to demand faster, more efficient, and reliable electronic devices, the potential of galliumarsenide is more promising than ever.

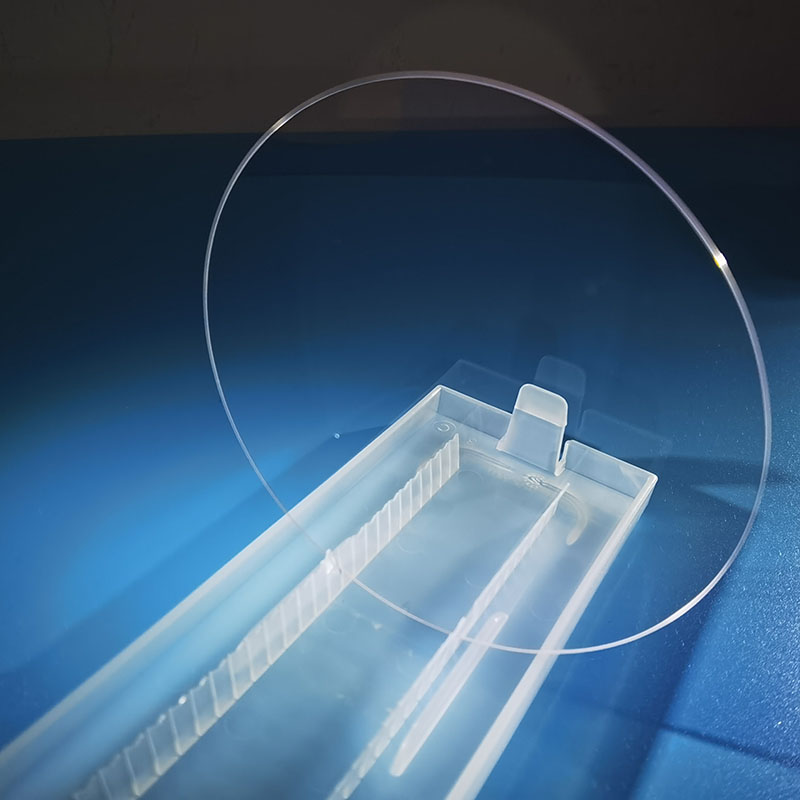

High-quality Fused Silica Substrate for Various Applications

Fused Silica Substrate: The Foundation of Cutting-Edge TechnologyFused silica substrate, also known as fused quartz, is a key component in the manufacturing of advanced optical and electronic systems. Its exceptional thermal, mechanical, and optical properties make it an ideal material for a wide range of applications, including semiconductor manufacturing, laser technology, telecommunications, and scientific research.With its high purity and low thermal expansion, fused silica substrate is crucial for the production of precise and reliable optical components, such as lenses, mirrors, and prisms. Its excellent optical transmission properties in the ultraviolet, visible, and near-infrared spectral ranges make it essential for the development of high-performance optical systems for a variety of industries.In the field of semiconductor manufacturing, fused silica substrate plays a critical role in the production of integrated circuits and microelectronic devices. Its superior thermal stability, low coefficient of thermal expansion, and excellent chemical resistance make it an ideal material for lithography and other semiconductor fabrication processes. Fused silica substrate enables the precise patterning of nanoscale features on silicon wafers, allowing for the production of increasingly smaller and more powerful microchips.Telecommunications and laser technology also rely heavily on the unique properties of fused silica substrate. Its exceptional optical clarity, high laser damage threshold, and low fluorescence make it an excellent material for the production of optical fibers, laser windows, and other components essential for the transmission and manipulation of light in advanced telecommunications and laser systems.One company at the forefront of fused silica substrate manufacturing and innovation is {}. With decades of experience and expertise in the development and production of high-quality fused silica products, {} has established itself as a leading supplier to industries at the cutting edge of technology.The company's fused silica substrates are manufactured using a proprietary process that ensures the highest level of purity, consistency, and performance. Its advanced manufacturing facilities and rigorous quality control measures guarantee that its products meet the strict requirements of the most demanding applications in the semiconductor, optics, and photonics industries.{} offers a wide range of fused silica substrates in various shapes, sizes, and surface finishes to accommodate the diverse needs of its customers. Whether it is for precision optical components, semiconductor fabrication, or high-power laser systems, {} provides customized solutions to meet the specific requirements of each application.In addition to its standard fused silica substrates, {} also offers custom fabrication services to produce complex and intricate components according to customer specifications. Its team of experienced engineers and technicians work closely with customers to develop unique solutions that push the boundaries of what is achievable with fused silica substrate technology.Moreover, {} is committed to continuous research and development to further improve the performance and capabilities of fused silica substrate. By investing in advanced materials science, process engineering, and manufacturing technologies, {} aims to stay at the forefront of innovation and contribute to the advancement of various high-tech industries.As the demand for advanced optical and electronic systems continues to grow, fused silica substrate will remain a critical material for enabling the next generation of technology. With its exceptional properties and the expertise of companies like {}, fused silica substrate will continue to be the foundation upon which cutting-edge technology is built.