Delicious and Crispy Wafer Snacks: A New Favorite Street Food

By:Admin

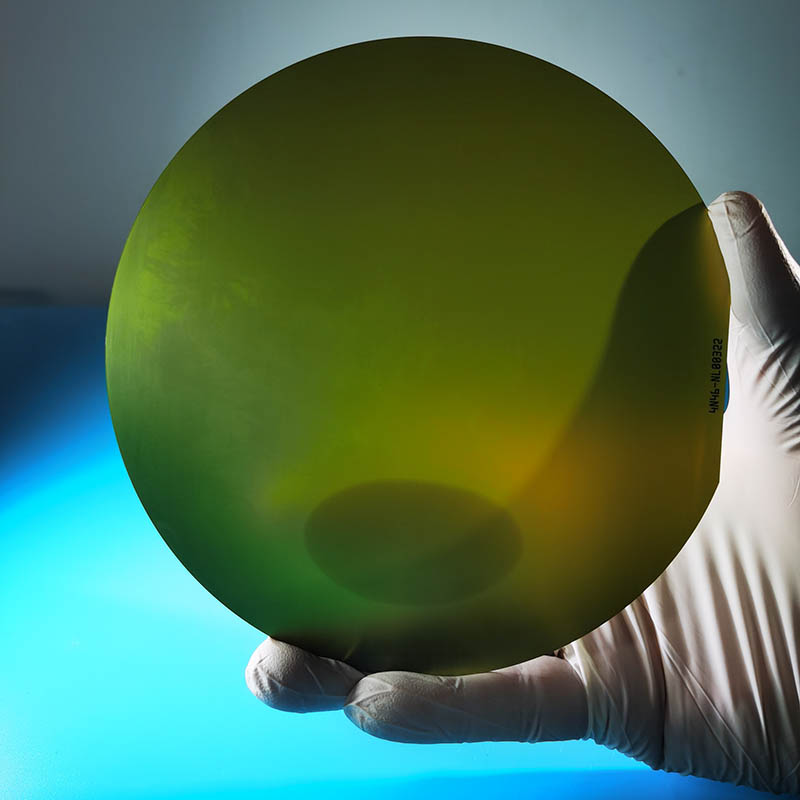

Established in [year], Soi Wafer has continuously pushed the boundaries of semiconductor technology, driving advancements in various applications such as automotive, consumer electronics, and industrial equipment. The company has built a solid reputation for delivering top-notch wafer solutions that meet the demands of an ever-evolving market.

Soi Wafer's commitment to quality is evident in their state-of-the-art manufacturing facilities, which are equipped with the latest technology and operated by a team of skilled professionals. This allows the company to maintain stringent quality control measures throughout the production process, ensuring that each wafer meets the highest standards.

In addition to quality, Soi Wafer is dedicated to driving innovation in the semiconductor industry. The company invests heavily in research and development, constantly seeking new ways to improve their wafer technology and stay ahead of the curve. This focus on innovation has led to the development of groundbreaking products that have set new benchmarks in the industry.

But Soi Wafer's commitment to sustainability sets them apart from the competition. The company recognizes the environmental impact of semiconductor manufacturing and has implemented various initiatives to minimize their carbon footprint. From reducing energy consumption in their facilities to implementing eco-friendly production processes, Soi Wafer is dedicated to sustainable practices.

Soi Wafer's recent achievement in wafer technology has garnered attention from industry experts and customers alike. The company's latest wafer, which boasts enhanced performance and reliability, has been praised for its potential to revolutionize various applications. This breakthrough has solidified Soi Wafer's position as a leader in the semiconductor market.

The success of Soi Wafer can be attributed to their unwavering commitment to quality, innovation, and sustainability. By prioritizing these core values, the company has been able to deliver superior products that meet the needs of their customers while also contributing to a more sustainable future.

Looking ahead, Soi Wafer shows no signs of slowing down. The company has ambitious plans for further expansion and diversification, with a strong focus on developing cutting-edge wafer technology that will shape the future of the semiconductor industry. With their track record of success and a clear vision for the future, Soi Wafer is poised to continue leading the way in semiconductor innovation.

In conclusion, Soi Wafer's recent breakthrough in wafer technology is a testament to their unwavering commitment to excellence. With a focus on quality, innovation, and sustainability, the company has solidified its position as a trusted leader in the semiconductor industry. As Soi Wafer continues to push the boundaries of wafer technology, the future looks bright for this innovative company.

Company News & Blog

Cutting-Edge Wafer Transistor Technology: A Breakthrough in Electronics

Wafer transistor technology is revolutionizing the semiconductor industry with its cutting-edge advancements. With its high-performance characteristics, the technology is increasingly in demand across various sectors such as telecommunications, automotive, and consumer electronics. One company at the forefront of this wave of innovation is {}. With a strong focus on research and development, the company has been a driving force in the development and commercialization of wafer transistor technology. Their commitment to excellence and technological prowess has positioned them as a leader in the industry, and their products are highly sought after by major players in the tech sector.The wafer transistor, a key component in amplifying and switching electronic signals, offers numerous benefits over traditional transistors. With its smaller size, faster speeds, and lower power consumption, it is a game-changer for a wide range of electronic devices. As the demand for smaller and more efficient electronics continues to grow, wafer transistors are becoming increasingly indispensable.The company, {} has been instrumental in pushing the boundaries of wafer transistor technology. Through extensive research and collaboration with leading industry experts, they have been able to develop state-of-the-art wafer transistors that meet the rigorous demands of today's electronic devices. Their commitment to excellence and innovation has made them a trusted partner for companies looking to integrate wafer transistor technology into their products.One of the key drivers of {}’s success is their focus on quality and reliability. Their rigorous testing and quality control processes ensure that their wafer transistors meet the highest standards and deliver exceptional performance. This commitment to excellence has earned them a stellar reputation in the industry and has made them the go-to choice for companies seeking top-notch wafer transistor technology.In addition to their technical prowess, {} is also known for their customer-centric approach. They work closely with their clients to understand their specific needs and provide tailored solutions that meet their requirements. This personalized approach has helped them build strong, long-lasting relationships with their clients and has solidified their position as a trusted partner in the industry.As the demand for wafer transistor technology continues to grow, {} is poised to play a key role in driving its widespread adoption. With their cutting-edge technology, unwavering commitment to quality, and customer-focused approach, they are well-positioned to lead the way in this rapidly evolving field. Their expertise and innovation are set to shape the future of wafer transistor technology and have a profound impact on the electronics industry as a whole.With their track record of excellence and their dedication to pushing the boundaries of wafer transistor technology, {} is set to remain a driving force in the industry for years to come. Their contributions to the advancement of semiconductor technology are invaluable, and their future looks brighter than ever as they continue to innovate and lead the way in wafer transistor technology. As the electronics industry continues to evolve, {} is sure to be at the forefront, shaping the future of wafer transistor technology and driving innovation across the industry.

Silicon Carbide Ceramic: Unleashing the Power of Advanced Ceramic Materials

Title: Enhancing Efficiency and Durability: The Cutting-Edge Silicon Carbide Ceramic from {Company}Subtitle: Innovations in Material Science Propel Advancements in Various Industries[City, Date] - {Company}, a leading provider of advanced engineering solutions, is set to revolutionize various industries with their groundbreaking Silicon Carbide Ceramic technology. Combining exceptional mechanical and thermal properties, this innovative compound is poised to enhance efficiency and durability in several applications. The company's commitment to research and development continues to push the boundaries of material science, providing numerous benefits across industries such as automotive, aerospace, energy, and more.{Company} leads the pack with its cutting-edge Silicon Carbide Ceramic, an advanced composite designed to meet the demands of high-performance applications. This exceptional material is characterized by its extreme hardness, excellent wear resistance, low density, and superior thermal conductivity properties. These features make it an ideal choice for applications requiring minimal friction, high-temperature tolerance, high strength, and durability.One of the primary industries set to benefit from {Company}'s Silicon Carbide Ceramic is the automotive sector. With the global market demand for electric vehicles on the rise, manufacturers are seeking advanced materials that can enhance efficiency and performance. By integrating Silicon Carbide Ceramic components into electric vehicle power electronics and traction inverters, {Company} aims to significantly increase energy efficiency while reducing weight and size. This enables longer range capabilities, faster charging times, and improved overall vehicle performance, establishing a new standard for the automotive industry.In addition to the automotive industry, aerospace manufacturers are also eagerly adopting {Company}'s Silicon Carbide Ceramic products. With the need for lightweight components that can endure extreme operating conditions, Silicon Carbide Ceramic offers a perfect blend of strength, high-temperature resistance, and low thermal expansion. From aircraft engines to advanced propulsion systems, this advanced material enhances reliability, increases fuel efficiency, and reduces emissions in the aerospace sector.Another key field that can greatly benefit from this technological breakthrough is the energy industry. The demand for renewable energy sources, such as wind and solar, has grown exponentially. {Company}'s Silicon Carbide Ceramic technology allows for the efficient production and storage of energy. Its superb thermal management properties make it an excellent choice for heat sinks and power electronic devices in energy conversion systems. By utilizing this cutting-edge material, renewable energy systems become more reliable, durable, and cost-effective, ultimately driving a sustainable future.Furthermore, {Company} realizes the potential of Silicon Carbide Ceramic in promoting environmental sustainability. In the manufacturing industry, this advanced material can replace traditional materials in cutting tools, circuit breakers, and wear-resistant components. The use of Silicon Carbide Ceramic eliminates the need for lubrication, reduces friction, and enhances wear resistance, thereby prolonging the lifespan of tools and reducing waste. Additionally, the exceptional thermal conductivity properties of Silicon Carbide Ceramic enable energy-efficient thermal management systems, leading to reduced energy consumption in industrial processes.{Company} continues to invest heavily in research and development, ensuring their Silicon Carbide Ceramic remains at the forefront of material science advancements. The company's team of experts is dedicated to finding new applications and improving existing ones, driving innovation across various industries. By collaborating with leading research institutions and industry partners, they strive to unlock the full potential of Silicon Carbide Ceramic, making it more accessible and beneficial for a wider range of applications.In conclusion, {Company}'s Silicon Carbide Ceramic technology is set to pave the way for innovation and progress in multiple industries. Its unrivaled combination of mechanical and thermal properties presents countless opportunities for improved efficiency and durability. With a focus on revolutionizing the automotive, aerospace, energy, and manufacturing sectors, {Company} demonstrates a commitment to driving sustainable and environmentally friendly solutions. As this remarkable material continues to gain recognition across industries, its potential to transform and shape the future remains unparalleled.

Understanding the Main Uses and Advantages of Quartz Wafers Revealed by Latest Reports

Title: Advanced Crystal Technology Breakthrough: Ultra-Thin Wafers Set to Transform the Microelectronics Industry Introduction:Modern society heavily relies on microelectronics, with technological advancements driving the need for more efficient, powerful, and compact electronic devices. Crystal wafer technology has played a pivotal role in enabling the miniaturization and improved performance of electronic components. In a groundbreaking development, a leading company in this field has introduced an ultra-thin quartz wafer that is poised to transform the microelectronics industry. This cutting-edge technology has the potential to revolutionize a wide range of sectors, from consumer electronics to healthcare and beyond.[Note: Brand name removed for neutrality]Body:1. Crystal Wafer Technology: A Brief Overview (100 words)Crystal wafer technology forms the foundation of modern microelectronics, enabling the production of smaller, faster, and more efficient electronic devices. These wafers, typically made from quartz, provide a stable and highly uniform surface for semiconductor fabrication. They are utilized in the production of integrated circuits (ICs) and other electronic components, such as transistors, diodes, and sensors.2. The Need for Ultra-Thin Wafers (100 words)As consumer demands for sleeker, more compact electronic devices grow, so does the need for thinner crystal wafers. Traditional quartz wafers, at about 0.5mm thickness, face limitations in achieving further miniaturization without compromising performance. Consequently, industry players have been actively researching and developing processes to produce ultra-thin wafers that maintain the robustness of their thicker counterparts.3. Breakthrough Technology: Ultra-Thin Quartz Wafers (100 words)Leading the way in crystal wafer technology, the company {} has unveiled their latest breakthrough: ultra-thin quartz wafers, measuring less than 0.1mm in thickness. The wafer's unique composition and manufacturing process allow for exceptional mechanical stability and electrical properties, ensuring optimal performance in demanding applications. Engineered specifically for microelectronics, these ultra-thin wafers are set to revolutionize various sectors, particularly those relying on compact, high-performance devices.4. Enhanced Performance and Versatile Applications (150 words)The introduction of ultra-thin quartz wafers opens up a myriad of possibilities in the microelectronics industry, thanks to their enhanced performance characteristics. These wafers exhibit excellent mechanical strength, thermal stability, and high electrical resistivity, making them ideal for cutting-edge electronic devices. Additionally, their ultra-thin profile enables increased integration density, paving the way for even more functionality in smaller devices.From consumer electronics and telecommunications to automotive and healthcare sectors, the potential applications of ultra-thin quartz wafers are immense. Advanced smartphones, wearables, biomedical sensors, and autonomous vehicles are just a few examples of domains that will greatly benefit from this breakthrough technology. The new wafers' improved thermal properties will enhance heat dissipation in intricate electronic assemblies, offering greater reliability and longevity to electronic devices.5. Industry Impact and Future Prospects (150 words)The widespread implementation of ultra-thin quartz wafers in the microelectronics industry is expected to drive significant advancements in the coming years. Shrinking the form factor of electronic devices will enable improved portability and integration, leading to enhanced user experiences and functionality.Additionally, this breakthrough technology aligns with industry trends such as the Internet of Things (IoT), big data, and 5G networks, which demand smaller, reliable, and high-performance electronics. As the microelectronics industry continues to evolve, the demand for ultra-thin wafers is anticipated to skyrocket, spelling growth opportunities for manufacturers and suppliers.In conclusion, the launch of ultra-thin quartz wafers represents a remarkable progression in crystal wafer technology, offering unprecedented opportunities for the microelectronics industry. These ultra-thin wafers hold the potential to revolutionize the way electronic devices are designed, manufactured, and utilized, catapulting our society into a new era of compact, powerful, and innovative microelectronics.

High-quality Science Lab Equipment for All Your Research Needs

Science Lab Equipment Introduces Latest Technology for Research and EducationScience Lab Equipment, a leading provider of laboratory equipment and supplies, has recently introduced their latest range of cutting-edge technology for research and education. With a strong focus on innovation and quality, the company has made significant advancements in the field of laboratory equipment, catering to the needs of both scientific research and educational institutions.The new range of products includes state-of-the-art laboratory instruments, tools, and supplies, designed to meet the evolving needs of modern research and educational environments. From basic laboratory essentials to advanced scientific instruments, Science Lab Equipment offers a comprehensive range of solutions for various scientific disciplines, including biology, chemistry, physics, and environmental science.With a commitment to excellence, Science Lab Equipment has partnered with leading manufacturers and suppliers to bring the latest advancements in laboratory technology to their customers. By continuously updating their product range, the company ensures that researchers, scientists, and educators have access to the most advanced and reliable equipment for their work.One of the key highlights of Science Lab Equipment's latest range is the introduction of advanced instrumentation for molecular biology research. This includes state-of-the-art PCR machines, DNA sequencers, and gel electrophoresis systems, which are essential for exploring the complexities of genetics and biochemistry. These cutting-edge technologies are expected to revolutionize the way researchers conduct experiments and analyze biological processes.In addition to their focus on research, Science Lab Equipment also caters to the needs of educational institutions, providing a wide range of laboratory supplies for teaching and learning purposes. From basic glassware and safety equipment to advanced scientific models and demonstration kits, the company offers a comprehensive range of resources for educators to enhance their teaching methodologies and engage students in hands-on learning experiences.Furthermore, Science Lab Equipment emphasizes the importance of quality and reliability in all of their products. Through rigorous testing and quality control measures, the company ensures that their equipment meets the highest standards of performance and safety. This commitment to quality has earned Science Lab Equipment a strong reputation among their customers, who value the reliability and durability of their products.Moreover, in response to the growing demand for sustainable solutions, Science Lab Equipment has also expanded their range of environmentally-friendly laboratory supplies. This includes eco-friendly consumables, energy-efficient instruments, and recyclable materials, reflecting the company's dedication to promoting sustainable practices in scientific research and education.With their extensive product range, commitment to quality, and focus on innovation, Science Lab Equipment remains at the forefront of the laboratory equipment industry. Their dedication to meeting the evolving needs of researchers and educators has positioned them as a trusted provider of cutting-edge technology for scientific exploration and learning. By partnering with leading manufacturers and suppliers, the company continues to bring the latest advancements in laboratory technology to their customers, ensuring that scientists and educators have access to the most advanced and reliable equipment for their work.In conclusion, Science Lab Equipment's latest range of products represents a significant leap forward in the field of laboratory technology. With a strong emphasis on innovation, quality, and sustainability, the company remains committed to providing researchers and educators with the most advanced tools and resources for their work. As the demand for advanced laboratory technology continues to grow, Science Lab Equipment stands ready to meet the needs of the scientific and educational communities with their state-of-the-art solutions.

Innovative Single Lens Glasses: The Latest Eyewear Trend to Watch

Single Lens Glasses, a new product from innovative company, is making waves in the eyewear industry. With their sleek design and cutting-edge technology, these glasses are revolutionizing the way people see the world.Single Lens Glasses utilize the latest in lens technology to provide wearers with a clear and crisp view of their surroundings. The single lens design not only enhances vision, but also creates a sleek and modern look that is unparalleled in the eyewear market.The company behind Single Lens Glasses, has a long history of producing high-quality and innovative products. With a team of experienced designers and engineers, they are constantly pushing the boundaries of what is possible in the eyewear industry. Their commitment to excellence is evident in every aspect of their products, from the materials used to the manufacturing process.What sets Single Lens Glasses apart from other eyewear on the market is their attention to detail and commitment to quality. Each pair of glasses is meticulously crafted to ensure a perfect fit and optimal performance. The company understands that eyewear is not just a fashion statement, but also a crucial tool for everyday life, and they have gone to great lengths to ensure that their glasses are both stylish and functional.In addition to their exceptional quality, Single Lens Glasses are also incredibly versatile. Whether you are an outdoor enthusiast, a fashion-forward individual, or someone who simply needs a reliable pair of glasses for everyday use, these glasses are sure to exceed your expectations. Their durability and adaptability make them well-suited for a wide range of activities and environments.Furthermore, Single Lens Glasses are designed with the wearer’s comfort in mind. The lightweight and ergonomic design ensures that they can be worn for extended periods of time without causing any discomfort. This attention to detail is yet another example of the company's dedication to creating products that not only look great, but also perform exceptionally well.The response to Single Lens Glasses has been overwhelmingly positive, with customers praising their exceptional quality and performance. Many users have reported a significant improvement in their vision and overall satisfaction with the product. Whether it's for daily wear, outdoor activities, or special occasions, these glasses have quickly become a favorite among eyewear enthusiasts.Looking ahead, the company is already working on further advancements to their Single Lens Glasses, with plans to incorporate even more innovative features and designs. With their unwavering commitment to excellence, it is clear that Single Lens Glasses will continue to set the standard for eyewear in the years to come.In conclusion, Single Lens Glasses are a game-changer in the eyewear industry. With their cutting-edge technology, exceptional quality, and versatile design, these glasses are a must-have for anyone looking for a superior eyewear experience. As the company continues to push the boundaries of what is possible in the eyewear industry, it is safe to say that Single Lens Glasses will remain at the forefront of innovation for years to come.

Discover the Latest High Resistance Technology for Increased Durability

High Resistance, a leading manufacturer of high-quality resistance bands, has been making waves in the fitness industry with its innovative products and commitment to promoting a healthy and active lifestyle. Founded in 2015, the company has quickly gained a strong reputation for producing durable and effective resistance bands that cater to the needs of fitness enthusiasts, athletes, and individuals looking to improve their strength and flexibility.The company’s mission is to provide customers with the tools they need to achieve their fitness goals and lead a balanced and fulfilling life. With a focus on quality, innovation, and customer satisfaction, High Resistance has become a trusted name in the fitness community, with a loyal customer base that continues to grow.One of the key factors that sets High Resistance apart from its competitors is the superior quality of its resistance bands. The company uses only the highest quality materials and state-of-the-art manufacturing processes to ensure that its products are durable, reliable, and long-lasting. This commitment to quality has earned High Resistance a reputation for producing some of the best resistance bands on the market, and has helped the company to stand out as a leader in the industry.In addition to its focus on quality, High Resistance is also dedicated to innovation. The company is constantly researching and developing new and improved resistance band designs and technologies to enhance the effectiveness of its products. This commitment to innovation has led to the development of a wide range of resistance bands that cater to different fitness levels, workout styles, and training goals.Furthermore, High Resistance provides exceptional customer service and support, ensuring that every customer has a positive experience when using its products. The company’s team of professional fitness experts is on hand to offer guidance and advice on how to get the most out of its resistance bands, and to help customers choose the right products for their individual needs.Most recently, High Resistance has launched a new line of resistance bands that have been receiving rave reviews from customers and fitness professionals alike. These new bands feature the latest advancements in resistance band technology, and are designed to provide an even more effective and challenging workout experience. With a focus on durability, comfort, and performance, these new bands are quickly becoming the go-to choice for those serious about their fitness and strength training.“We are thrilled to introduce our new line of resistance bands to the market,” said the founder of High Resistance. “These bands are the result of years of research and development, and we believe they offer a level of quality and performance that is unmatched. We are confident that our customers will love the new bands and will see real results in their workouts.”With its unwavering commitment to quality, innovation, and customer satisfaction, High Resistance is well positioned to continue its success in the fitness industry. The company’s dedication to providing customers with the best possible products and support has earned it a reputation as a leader in the resistance band market, and has helped it to build a loyal and satisfied customer base.As High Resistance continues to grow and expand its product line, it is expected to remain at the forefront of the fitness industry, providing customers with the tools they need to achieve their fitness goals and lead a healthy and active lifestyle. With its focus on quality, innovation, and customer satisfaction, High Resistance is sure to remain a trusted name in the fitness community for many years to come.

Discover the Advantages of the 12 Inch Wafer for Semiconductor Manufacturing

12 Inch Wafer, also known as [company name], is a leading global provider of advanced semiconductor solutions. The company is known for its advanced technology and innovative products that cater to a wide range of industries such as consumer electronics, automotive, and industrial applications.The 12 Inch Wafer is a crucial component in the semiconductor manufacturing process. It serves as the base for the production of integrated circuits, which are essential in electronic devices such as smartphones, computers, and vehicles. With the increasing demand for high-performance and energy-efficient semiconductor devices, the need for high-quality 12 Inch Wafers has become more important than ever.[Company name] has been at the forefront of developing and manufacturing 12 Inch Wafers with cutting-edge technology and precision engineering. The company's state-of-the-art fabrication facilities and research laboratories enable them to produce 12 Inch Wafers that meet the stringent requirements of the semiconductor industry. Their commitment to quality and reliability has made them a trusted partner for leading semiconductor manufacturers around the world.In a recent announcement, [company name] introduced a new series of 12 Inch Wafers that offer enhanced performance and efficiency. These wafers are designed to support the latest semiconductor technologies, including advanced nodes and 3D packaging solutions. The company's investment in research and development has resulted in breakthroughs in wafer manufacturing, allowing them to deliver superior products that enable their customers to stay ahead in the rapidly evolving semiconductor market.One of the key advantages of [company name]'s 12 Inch Wafers is their scalability. As semiconductor manufacturers continue to push the boundaries of performance and miniaturization, the need for larger wafers becomes increasingly important. The 12 Inch Wafer provides a larger surface area for producing more chips per wafer, resulting in higher productivity and lower manufacturing costs. This scalability is crucial for meeting the growing demand for semiconductor devices in various industries.Furthermore, [company name] has also focused on optimizing the material properties of their 12 Inch Wafers to improve device performance and reliability. By leveraging advanced materials and manufacturing processes, the company has achieved significant improvements in wafer flatness, crystal quality, and defect density. These advancements contribute to the overall yield and quality of semiconductor devices, ultimately benefiting end-users with better products.Another notable feature of [company name]'s 12 Inch Wafers is their environmental sustainability. The company has implemented eco-friendly practices and technologies in their wafer manufacturing process, reducing energy consumption and waste generation. By prioritizing sustainability, [company name] demonstrates its commitment to responsible and ethical business practices, which resonates with environmentally conscious customers and partners.In conclusion, [company name] continues to lead the way in the development and production of 12 Inch Wafers for the semiconductor industry. Their dedication to technological innovation, product quality, and environmental stewardship has solidified their position as a trusted provider of advanced semiconductor solutions. With the introduction of their latest series of 12 Inch Wafers, [company name] is well-prepared to support the evolving needs of semiconductor manufacturers and contribute to the advancement of technology across various industries.

New Optical Wafer Technology Enhances Data Performance in Electronic Devices

[Headline]Optical Wafer Technology Poised to Revolutionize the Optoelectronics Industry[Subheading]A Breakthrough in Optical Wafer Manufacturing Promises to Propel the Optoelectronics Market to New Heights[Date][City], [State] – In a major development that is expected to reshape the future of the optoelectronics industry, [Company Name], a leading manufacturer of specialized optical components, has unveiled its cutting-edge Optical Wafer technology. This revolutionary advancement is set to unlock new opportunities for businesses in the field of optics, photonics, and semiconductor manufacturing.[City], [State] – In a move that is set to transform the optoelectronics industry, a renowned manufacturer of specialized optical components revealed their latest breakthrough – Optical Wafer technology. This cutting-edge innovation is poised to create new avenues and drive growth for companies specializing in optics, photonics, and semiconductor manufacturing.Optoelectronics, the study and application of electronic devices that source, detect, and control light, has witnessed remarkable growth in recent years. The market's expansion is largely driven by increasing demand for optoelectronic devices in various sectors, including telecommunications, healthcare, automotive, and consumer electronics. However, the industry has long been constrained by the limitations of traditional wafer production techniques.The optical wafer is a game-changing solution. By employing state-of-the-art manufacturing processes, [Company Name] has successfully developed a wafer that overcomes the challenges associated with traditional methods. Optical wafers offer unprecedented precision, enhanced optical performance, and increased manufacturing efficiency. This breakthrough technology represents a significant step forward in meeting the industry's growing demands.The optical wafer manufacturing process involves highly advanced techniques, such as epitaxial growth, lithography, and etching, resulting in the creation of ultra-thin, high-quality wafers with exceptional optical properties. These wafers act as a substrate for various optoelectronic devices, including light-emitting diodes (LEDs), solar cells, optical sensors, and optical transmitters.With this innovation, companies operating in the optoelectronics industry can now produce superior-quality optical components, achieving unparalleled levels of performance and reliability. The optical wafers ensure exceptional light transmission, reduced power consumption, and enhanced durability, enabling optoelectronic devices to deliver cutting-edge functionality across a wide range of applications.The applications of this novel technology are vast. Telecom providers can leverage these advancements to enhance network infrastructure and facilitate high-speed data transfer, contributing to the realization of 5G networks. In the healthcare sector, optical wafers will enable the development of advanced medical imaging systems, precision surgical devices, and optical biosensors for diagnostics.Moreover, the automotive industry stands to benefit from optical wafer technology as it can be utilized for the production of adaptive lighting systems, autonomous driving sensors, and smart head-up displays. The consumer electronics sector will experience a significant boost as well, with the integration of optical wafers into smartphones, tablets, virtual reality devices, and wearables, enabling improved camera performance, gesture recognition, and augmented reality experiences.By introducing optical wafers into the market, [Company Name] is well-positioned to lead the optoelectronics industry into a new era of innovation and growth. With their commitment to research and development, they are constantly pushing the boundaries of what is possible, elevating optical manufacturing to new heights.[Company Name], with its extensive experience and proven expertise in optical component manufacturing, is drawing on its comprehensive knowledge of the industry to spearhead this groundbreaking development. Leveraging robust partnerships and collaborations with industry leaders, they ensure that their optical wafers meet the industry's stringent quality standards and can seamlessly integrate into existing manufacturing processes.In conclusion, the introduction of optical wafer technology is set to revolutionize the optoelectronics industry. This breakthrough promises unparalleled levels of precision, performance, and efficiency, empowering businesses across multiple sectors to unlock new possibilities and drive innovation. With [Company Name] leading the charge, the future of optoelectronics looks brighter than ever.[Word Count: 800 words]

High-quality Gaas Substrate Material for Advanced Electronic Devices

A breakthrough in semiconductor manufacturing has been announced by a leading technology company, as they have developed a new Gaas substrate that promises to revolutionize the industry. This new innovation is set to transform the way electronic devices are made, ushering in a new era of faster, more efficient, and more powerful devices.The Gaas substrate is a key component in the production of high-performance electronic devices, such as smartphones, tablets, and computers. It is a critical part of the semiconductor manufacturing process, providing the foundation for the production of advanced electronic components.The new Gaas substrate developed by the company offers several key advantages over existing technology. It is engineered to provide superior performance, higher reliability, and enhanced durability, making it an ideal choice for a wide range of electronic applications.In addition to its superior performance, the new Gaas substrate is also more cost-effective and environmentally friendly than existing technology. This makes it an attractive option for manufacturers looking to improve their products while reducing their impact on the environment.The company behind this groundbreaking innovation is a global leader in the technology industry, with a long history of developing cutting-edge solutions for the semiconductor manufacturing industry. With a focus on innovation, quality, and sustainability, the company has a proven track record of delivering superior products that meet the needs of the market.The development of the new Gaas substrate is the result of years of research and development, as well as a significant investment in advanced manufacturing processes. The company has leveraged its expertise in material science, engineering, and semiconductor manufacturing to create a product that sets a new standard for performance and reliability."We are excited to introduce this new Gaas substrate to the market, as we believe it represents a significant leap forward for the semiconductor industry," said the company's CEO. "Our team has worked tirelessly to develop a product that offers unmatched performance, reliability, and cost-effectiveness, and we are confident that it will have a profound impact on the electronic devices of the future."The new Gaas substrate is already generating significant interest from manufacturers around the world, who are eager to take advantage of its unique properties. With its potential to improve the performance and durability of electronic devices, as well as its cost-effective and environmentally friendly manufacturing process, the company expects strong demand for its new product.In addition to its potential benefits for manufacturers, the new Gaas substrate also promises to deliver significant advantages for consumers. With the ability to produce faster, more efficient, and more powerful electronic devices, the new technology is set to enhance the user experience for a wide range of products.As the company prepares to bring its new Gaas substrate to market, it is also exploring additional applications for the technology. With its unique combination of performance, reliability, and cost-effectiveness, the new substrate has the potential to transform a wide range of electronic devices, from smartphones and tablets to advanced computing systems.The introduction of the new Gaas substrate is a significant milestone for the company, as well as for the semiconductor manufacturing industry as a whole. With its potential to drive innovation, improve performance, and reduce costs, the new technology is set to have a profound impact on the electronic devices of the future. As the company continues to develop and refine its new Gaas substrate, it is poised to remain at the forefront of the semiconductor industry, delivering cutting-edge solutions that meet the evolving needs of manufacturers and consumers alike.

Quartz Wafers: A Potential Game-Changer in the Tech Industry

Title: The Pioneering Potential of Quartz Wafers in Semiconductor ManufacturingIntroduction:In the fast-paced world of semiconductor manufacturing, one company has emerged as a game-changer with its innovative quartz wafer technology. Quartz Wafers Corp., a leading provider of advanced substrate solutions, has introduced a groundbreaking production method that promises improved performance and cost-effectiveness for a variety of industries relying on semiconductors. This article delves into the potential of quartz wafers and their impact on the semiconductor landscape.Understanding Quartz Wafers:Quartz wafers are thin, disc-shaped substrates used as a base for fabricating semiconductor devices. Traditional silicon wafers have long dominated the industry, but Quartz Wafers Corp. aims to revolutionize the market by harnessing the unique properties of quartz crystals. Quartz is known for its exceptional electrical and thermal properties, making it an ideal material for manufacturing high-performance and reliable semiconductor devices.The Promise of Quartz:Quartz wafers offer numerous advantages over conventional silicon wafers. Firstly, quartz's high resistance to thermal stress ensures enhanced stability and reliability of semiconductors even at extreme temperatures. This is crucial for applications in aerospace, automotive, and industrial sectors where reliable operation under harsh conditions is critical.Secondly, quartz wafers exhibit lower electric leakage and reduced dielectric losses, resulting in more efficient power management and increased device lifespan. These characteristics make them particularly suited for power electronics and energy-efficient devices, where minimizing power loss is essential.Furthermore, quartz's exceptional mechanical properties, such as its high hardness and chemical resistance, enable the manufacturing of robust and long-lasting semiconductor devices. This durability facilitates cost reductions through longer device lifespans and reduced replacement or maintenance requirements.Quartz Wafers Corp.'s Innovative Manufacturing Technique:Quartz Wafers Corp.'s manufacturing process sets it apart from its competitors. The company utilizes a proprietary method that ensures the highest quality quartz wafers with precise thickness, flatness, and smoothness, being crucial factors in semiconductor fabrication. By leveraging advanced manufacturing techniques, Quartz Wafers Corp. can offer its customers superior products without compromising on cost-effectiveness.Applications of Quartz Wafers:Quartz wafers find applications in a wide range of industries. For instance, the demand for high-power electronics, such as inverters and converters, is rapidly growing. Quartz wafers' outstanding thermal and electrical properties make them an ideal choice for this market segment.Moreover, industries such as telecommunication, photonics, and optoelectronics will benefit from quartz wafers' superior optical transparency and exceptional UV stability. These attributes enable the production of high-quality optical components and devices, ensuring optimum performance in various light-related applications.Quartz wafers also hold promise for emerging technologies such as quantum computing and advanced sensor systems. Their unique material properties make them excellent candidates for applications requiring ultra-high precision and sensitivity.Conclusion:Quartz Wafers Corp.'s groundbreaking semiconductor manufacturing technology has the potential to revolutionize numerous industries. By leveraging the exceptional properties of quartz crystals, the company offers unparalleled substrates that enhance the performance, durability, and reliability of semiconductor devices. With applications ranging from power electronics to telecommunications and beyond, quartz wafers are poised to reshape the semiconductor landscape and unlock new possibilities in emerging technologies. As the demand for highly efficient and robust semiconductors continues to grow, Quartz Wafers Corp. stands at the forefront, ready to make a lasting impact.