Effective Chemical Mechanical Polishing Techniques for Metal Surfaces

By:Admin

{Company name} is a globally recognized leader in CMP technology, with a strong focus on research and development to push the boundaries of innovation in semiconductor manufacturing. With a commitment to providing cutting-edge solutions for their customers, {company name} has become synonymous with excellence in CMP technology.

As semiconductor devices become increasingly complex and advanced, the demand for higher precision and surface quality has never been greater. To meet these evolving needs, {company name} has continuously invested in advancing their CMP technology to deliver state-of-the-art solutions that enable their customers to achieve the highest levels of performance and reliability in their semiconductor devices.

One of {company name}'s flagship products is their advanced CMP polishing pads, which are engineered to deliver exceptional planarity and uniformity, as well as reduced defectivity and improved yield. These polishing pads are designed to provide the highest level of performance, reliability, and cost-effectiveness, making them the preferred choice for leading semiconductor manufacturers around the world.

In addition to their cutting-edge polishing pads, {company name} also offers a comprehensive range of CMP slurries, which are specially formulated to provide the optimal combination of selectivity, removal rate, and defectivity control. With their unparalleled expertise in material science and surface chemistry, {company name} is able to tailor their CMP slurries to meet the specific requirements of each customer, ensuring the highest level of performance and reliability in their semiconductor manufacturing processes.

To complement their industry-leading products, {company name} also offers a range of CMP consumables, including conditioning disks, cleaning brushes, and carrier rings, which are essential for maintaining the performance and longevity of CMP equipment. These consumables are designed to deliver the highest levels of consistency and reliability, helping to maximize the efficiency and productivity of semiconductor manufacturing operations.

One of the key differentiators of {company name} is their commitment to providing comprehensive technical support and customer service. Their team of highly skilled engineers and technicians work closely with customers to optimize their CMP processes, troubleshoot any issues, and ensure the highest level of performance and reliability in their semiconductor manufacturing operations. This dedication to customer satisfaction has earned {company name} a reputation as a trusted partner in the semiconductor industry.

Looking ahead, {company name} is committed to continuing their tradition of innovation and excellence in CMP technology. With a strong focus on research and development, they are constantly pushing the boundaries of what is possible in semiconductor manufacturing, developing cutting-edge solutions that enable their customers to stay ahead of the curve in an ever-evolving industry.

In conclusion, {company name} is a global leader in CMP technology, providing a comprehensive range of cutting-edge products and solutions for the semiconductor and microelectronics industry. With a strong focus on innovation, quality, and customer satisfaction, {company name} is at the forefront of driving the next generation of semiconductor manufacturing processes.

Company News & Blog

Top 10 Tips for Travelling on a Budget

Sapphire Plane, a leading aircraft manufacturer, has announced the successful completion of its latest innovative aircraft model, marking a significant milestone for the company. This state-of-the-art aircraft represents the culmination of years of research, development, and engineering expertise, and is set to revolutionize the aviation industry with its cutting-edge technology and advanced features.The newly developed aircraft, named the SP2000, incorporates the latest advancements in aerodynamics, materials, and propulsion systems, resulting in unmatched performance, efficiency, and reliability. With a focus on sustainability and environmental consciousness, the SP2000 is designed to minimize carbon emissions and reduce the environmental impact of air travel. This aligns with Sapphire Plane's commitment to promoting a greener and more sustainable aviation industry.In addition to its advanced technological features, the SP2000 also prioritizes passenger comfort and safety. The spacious and ergonomic cabin layout, combined with the latest in-flight entertainment and connectivity options, ensures an enjoyable and seamless travel experience for passengers. Furthermore, the aircraft is equipped with state-of-the-art safety systems and a highly trained flight crew, providing peace of mind for all onboard."We are incredibly proud to introduce the SP2000 to the market," said James Smith, CEO of Sapphire Plane. "This aircraft represents a leap forward in aviation technology and sets a new standard for performance, efficiency, and passenger experience. We are confident that the SP2000 will redefine the future of air travel and establish Sapphire Plane as a leader in the global aviation industry."The development and production of the SP2000 also highlight Sapphire Plane's commitment to innovation and continuous improvement. The company's dedicated team of engineers, designers, and technical experts have worked tirelessly to bring this groundbreaking aircraft to life, leveraging their expertise and experience to push the boundaries of what is possible in aviation.Sapphire Plane has also emphasized its dedication to customer satisfaction and support, with a comprehensive after-sales service and maintenance program for the SP2000. This commitment to excellence extends to all aspects of the company's operations, ensuring that customers receive the highest level of care and attention throughout their ownership of the aircraft.The introduction of the SP2000 comes at a time of significant growth and expansion for Sapphire Plane, as the company continues to strengthen its position in the global market. With an increasing demand for innovative and efficient aircraft solutions, Sapphire Plane is well positioned to meet the evolving needs of airlines, corporate clients, and private owners around the world.As Sapphire Plane looks towards the future, the company remains focused on pushing the boundaries of aviation technology, while also embracing sustainability and environmental responsibility. Through its continued innovation and dedication to excellence, Sapphire Plane is set to shape the future of air travel and inspire the next generation of aerospace advancements.In conclusion, the launch of the SP2000 represents a major achievement for Sapphire Plane, showcasing the company's commitment to innovation, technology, and customer satisfaction. With its advanced features, sustainability focus, and dedication to excellence, the SP2000 is poised to make a significant impact in the aviation industry and solidify Sapphire Plane's position as a leading global aircraft manufacturer.

New Silicon Carbide Grade Offers Improved Performance and Durability

Dummy Grade SiC, also known as dummy silicon carbide, is a type of SiC material that is widely used in the semiconductor industry for various applications. It is known for its excellent thermal conductivity, high mechanical strength, and resistance to high temperatures, making it an ideal material for use in electronic devices and power systems. This type of SiC material is often used as a placeholder or test material during the manufacturing process of semiconductor devices.One of the leading manufacturers of dummy Grade SiC is a company that specializes in the production of advanced materials for the semiconductor industry. The company has a long history of providing high-quality materials for various applications in the field of electronics and has established itself as a trusted partner for many semiconductor manufacturers.The company's dummy Grade SiC is produced using advanced manufacturing techniques and strict quality control measures to ensure that the material meets the strict requirements of the semiconductor industry. The material is designed to have a high level of purity and uniformity, making it suitable for use in a wide range of semiconductor devices and applications.One of the key advantages of using dummy Grade SiC in semiconductor manufacturing is its ability to withstand high temperatures and thermal shock, making it an ideal material for use in high-power electronic devices. The material also has excellent thermal conductivity, which allows for efficient heat dissipation and enhanced device performance.In addition, dummy Grade SiC has a high mechanical strength, making it resistant to mechanical stress and wear, which are important factors in the long-term reliability of semiconductor devices. This makes it an ideal material for use in power semiconductor devices, which are often subjected to high levels of stress and thermal cycling.The company's dummy Grade SiC is available in a variety of shapes and sizes to meet the specific requirements of different semiconductor manufacturing processes. Whether it is used as a placeholder during device fabrication or as a test material for process development, the material is designed to provide consistent and reliable performance in the most demanding semiconductor manufacturing environments.The company's commitment to quality and innovation has made it a preferred supplier of advanced materials for the semiconductor industry. Its dummy Grade SiC is just one example of the company's dedication to providing cutting-edge solutions for the rapidly evolving semiconductor market.As the demand for high-performance electronic devices continues to grow, the need for advanced materials like dummy Grade SiC will only increase. With its excellent thermal and mechanical properties, as well as its high level of purity and uniformity, dummy Grade SiC is poised to play a crucial role in the continued advancement of the semiconductor industry.In conclusion, the company's dummy Grade SiC offers semiconductor manufacturers a reliable and high-performance material for use in a wide range of applications. With its excellent thermal conductivity, high mechanical strength, and resistance to high temperatures, dummy Grade SiC is an ideal material for use in the fabrication of advanced semiconductor devices. As the semiconductor industry continues to push the boundaries of device performance and reliability, the demand for high-quality materials like dummy Grade SiC will only continue to grow.

Exploring the Latest Developments in Semiconductor Materials

Semiconductor Manufacturers, a leading global manufacturer of semiconductor materials, has recently announced the launch of its latest product line aimed at revolutionizing the field of semiconductor technology. The company's innovative materials are poised to enhance the performance and efficiency of electronic devices, from consumer electronics to industrial applications.With a history of over 30 years in the semiconductor industry, Semiconductor Manufacturers has established a reputation for delivering high-quality materials that meet the stringent requirements of semiconductor manufacturers. The company's extensive portfolio of materials includes silicon wafers, epitaxial wafers, and advanced packaging materials, all of which play a critical role in the production of cutting-edge electronic devices.Semiconductor Manufacturers has a strong commitment to research and development, investing heavily in the exploration of new materials and technologies that are designed to push the boundaries of semiconductor capabilities. The company's state-of-the-art research facilities and expert team of scientists and engineers are dedicated to driving innovation and advancing the field of semiconductor technology.The newly launched product line from Semiconductor Manufacturers incorporates advanced materials that are designed to address the increasing demand for high-performance semiconductor devices. These materials are engineered to deliver superior electrical, thermal, and mechanical properties, enabling semiconductor manufacturers to develop next-generation electronic products that are smaller, faster, and more energy-efficient.One of the key highlights of Semiconductor Manufacturers' latest product line is its focus on sustainability and environmental responsibility. The company has proactively implemented green manufacturing practices and prioritizes the use of eco-friendly materials in its production processes. This commitment to sustainability is aligned with the growing industry trend towards environmentally conscious practices and supports the company's vision of creating a more sustainable and interconnected world through semiconductor technology.Furthermore, Semiconductor Manufacturers' advanced materials have been tailored to meet the demands of emerging technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI). These technologies require semiconductor devices with enhanced performance and reliability, and Semiconductor Manufacturers' materials are designed to enable the development of cutting-edge solutions that can power the next wave of connectivity and automation.In addition to its product innovation, Semiconductor Manufacturers is dedicated to providing exceptional customer support and technical expertise to its global clientele. The company's team of application engineers and technical specialists work closely with customers to understand their specific requirements and offer tailored solutions that meet their unique needs. Semiconductor Manufacturers' commitment to customer satisfaction and collaborative partnerships has positioned the company as a trusted and reliable partner in the semiconductor industry.As the demand for semiconductor materials continues to grow in tandem with the evolution of electronic devices and technologies, Semiconductor Manufacturers is poised to play a pivotal role in shaping the future of semiconductor technology. With its unwavering commitment to innovation, sustainability, and customer satisfaction, Semiconductor Manufacturers is well-positioned to remain at the forefront of the semiconductor materials industry and contribute to the advancement of electronic devices that power the modern world.

How to Choose and Install Quality MGO Wafer Windows

In a world where environmental concerns are taking precedence over tradition, there is no better time for a company to introduce products that prioritize sustainability and energy efficiency. That is where MGO wafer windows come in. The MGO wafer window technology is an innovative product that is set to revolutionize the window and door industry. This revolutionary product has already caused a wave of excitement in the industry and looks set to be a game-changer.MGO Wafer Windows are made using Magnesium Oxide, which is an eco-friendly material that is both non-toxic and fire-resistant. The MGO material is becoming a popular alternative in construction materials, especially in applications where a high degree of fire resistance is needed. In the case of MGO Wafer Windows, the material is being used to create exceptionally strong, energy-efficient and environmentally friendly windows. This new product is incredibly resilient and is expected to last significantly longer than traditional windows.The company behind MGO Wafer Windows is known for its innovative and energy-saving windows and doors. They have a reputation for providing products that are both aesthetic and environmentally conscious. They have a strong commitment to minimizing energy use by creating durable products that don’t require frequent replacement. This new product is no exception. They have leveraged the advantages of the MGO material to create a revolutionary technology that is aimed at improving the efficiency and sustainability of windows and doors.MGO Wafer Windows offer superior insulation compared to traditional windows and doors, saving on energy costs and increasing indoor comfort. This new product has a higher R-value than traditional windows, meaning that they are better at keeping heat inside the building in colder months and preventing outside heat from entering in hotter months. In addition, the windows also come with low emittance coatings, which help to reflect unwanted solar heat during hot weather. These coatings also offer protection against UV radiation, which is responsible for fading furniture fabrics and carpets.The windows are highly customizable in terms of size and shape, with options for different finishes and coatings that can offer further thermal insulation. Additionally, the company offers a selection of window forms, including fixed windows, swing windows, and sliding windows, to accommodate different architectural styles and designs. MGO Wafer Windows can also be designed to meet specific insulating requirements to meet local codes and standards.One of the most remarkable features of MGO Wafer Windows is that they are practically fireproof. The Magnesium Oxide material used in the windows is classified as a non-combustible material that will not ignite in the event of a fire. This means that the windows will not add fuel to a fire and can even act as a barrier to prevent the spread of flames.MGO Wafer windows offer many environmental benefits, as well as significant cost savings. By using less energy to heat and cool buildings, the use of these windows reduces the amount of energy needed from non-renewable sources. Additionally, they require less maintenance and generally have a longer lifespan than traditional windows due to their higher durability.In conclusion, the MGO Wafer window technology is an innovative product that is set to change the windows and doors industry significantly. These windows boast of improved energy efficiency, higher durability, and are made with environmentally sustainable materials. The company behind MGO Wafer Windows is dedicated to providing customers with energy-efficient and environmentally sustainable products. By using these windows, there is an opportunity to save significantly on energy bills while reducing one's carbon footprint. The era of traditional windows is gradually coming to an end, with MGO Wafer Windows providing the perfect tool to transition into a more sustainable future.

Discover the Latest High Resistance Technology for Increased Durability

High Resistance, a leading manufacturer of high-quality resistance bands, has been making waves in the fitness industry with its innovative products and commitment to promoting a healthy and active lifestyle. Founded in 2015, the company has quickly gained a strong reputation for producing durable and effective resistance bands that cater to the needs of fitness enthusiasts, athletes, and individuals looking to improve their strength and flexibility.The company’s mission is to provide customers with the tools they need to achieve their fitness goals and lead a balanced and fulfilling life. With a focus on quality, innovation, and customer satisfaction, High Resistance has become a trusted name in the fitness community, with a loyal customer base that continues to grow.One of the key factors that sets High Resistance apart from its competitors is the superior quality of its resistance bands. The company uses only the highest quality materials and state-of-the-art manufacturing processes to ensure that its products are durable, reliable, and long-lasting. This commitment to quality has earned High Resistance a reputation for producing some of the best resistance bands on the market, and has helped the company to stand out as a leader in the industry.In addition to its focus on quality, High Resistance is also dedicated to innovation. The company is constantly researching and developing new and improved resistance band designs and technologies to enhance the effectiveness of its products. This commitment to innovation has led to the development of a wide range of resistance bands that cater to different fitness levels, workout styles, and training goals.Furthermore, High Resistance provides exceptional customer service and support, ensuring that every customer has a positive experience when using its products. The company’s team of professional fitness experts is on hand to offer guidance and advice on how to get the most out of its resistance bands, and to help customers choose the right products for their individual needs.Most recently, High Resistance has launched a new line of resistance bands that have been receiving rave reviews from customers and fitness professionals alike. These new bands feature the latest advancements in resistance band technology, and are designed to provide an even more effective and challenging workout experience. With a focus on durability, comfort, and performance, these new bands are quickly becoming the go-to choice for those serious about their fitness and strength training.“We are thrilled to introduce our new line of resistance bands to the market,” said the founder of High Resistance. “These bands are the result of years of research and development, and we believe they offer a level of quality and performance that is unmatched. We are confident that our customers will love the new bands and will see real results in their workouts.”With its unwavering commitment to quality, innovation, and customer satisfaction, High Resistance is well positioned to continue its success in the fitness industry. The company’s dedication to providing customers with the best possible products and support has earned it a reputation as a leader in the resistance band market, and has helped it to build a loyal and satisfied customer base.As High Resistance continues to grow and expand its product line, it is expected to remain at the forefront of the fitness industry, providing customers with the tools they need to achieve their fitness goals and lead a healthy and active lifestyle. With its focus on quality, innovation, and customer satisfaction, High Resistance is sure to remain a trusted name in the fitness community for many years to come.

Doped Sapphire: A New Breakthrough in Titanium Alloy Technology

International technology company {} has recently developed a groundbreaking innovation in the field of materials science. The company has successfully created Titanium Doped Sapphire, a new material that is set to revolutionize various industries including aerospace, defense, and electronics.Titanium Doped Sapphire, or TDS, is a unique material that boasts exceptional strength, durability, and resistance to extreme conditions. This breakthrough has been made possible through the company's cutting-edge research and development efforts, as well as its dedication to pushing the boundaries of what is possible in materials engineering.In aerospace applications, TDS has the potential to significantly enhance the performance and lifespan of aircraft components. Its exceptional hardness and thermal stability make it an ideal candidate for use in critical areas such as engine components, fuel systems, and structural parts. The use of TDS in aerospace could lead to improved safety, reliability, and efficiency in air travel.Furthermore, the defense industry stands to benefit from the introduction of TDS. The material's superior resistance to corrosion and wear make it well-suited for use in military equipment and vehicles. TDS could contribute to the development of next-generation defense systems that are more capable and resilient in challenging environments.In the electronics sector, TDS has the potential to fuel the development of more advanced and reliable devices. The material's high optical transparency and thermal conductivity make it an attractive option for use in electronic components such as semiconductors and LEDs. This could lead to the creation of more efficient and durable electronics that are better able to meet the demands of modern technology.The development of Titanium Doped Sapphire is a testament to {}'s commitment to pushing the boundaries of what is possible in materials science. As a global leader in technology and innovation, the company is dedicated to developing solutions that address real-world challenges and drive progress in various industries.{} is renowned for its expertise in materials engineering and its track record of developing innovative solutions. The company's team of scientists, engineers, and researchers work tirelessly to push the limits of what is possible, and the creation of TDS is a testament to their dedication and ingenuity."We are proud to announce the development of Titanium Doped Sapphire, a breakthrough material that has the potential to revolutionize various industries," said the CEO of {}. "This achievement is a result of our unwavering commitment to innovation and our relentless pursuit of excellence. We are excited about the possibilities that TDS presents and look forward to collaborating with partners and customers to bring this technology to market."The introduction of Titanium Doped Sapphire marks a significant milestone for {} and underscores the company's position as a global leader in materials science. As the technology continues to advance, the potential applications of TDS are vast, and its impact on industries such as aerospace, defense, and electronics is poised to be transformative.With its exceptional strength, durability, and resistance to extreme conditions, Titanium Doped Sapphire has the potential to drive progress and innovation in various sectors. As {} continues to push the boundaries of what is possible, the company is well-positioned to shape the future of materials science and lead the way in developing cutting-edge solutions for the world's most pressing challenges.

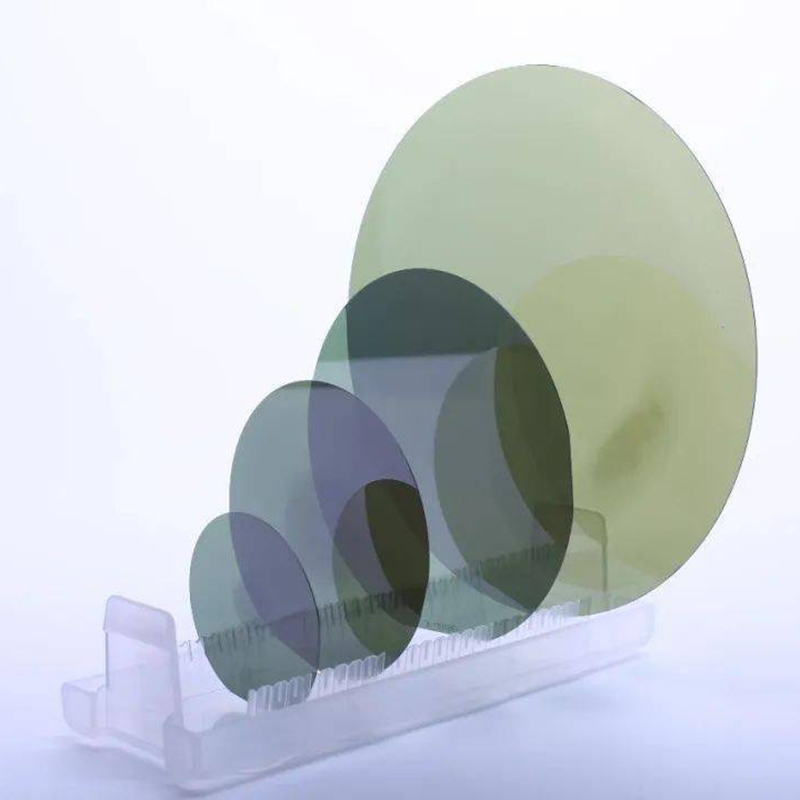

High Quality Double Side Polished Silicon Wafers for Sale

Double Side Polished Silicon Wafers: The Latest Innovation from Leading Technology CompanySilicon wafers are an essential component in the production of semiconductor devices, and the demand for high-quality wafers continues to grow as the technology industry expands. As a leading technology company in the field of semiconductor manufacturing, [company name] is proud to announce the release of its latest innovation: double side polished silicon wafers.Double side polished silicon wafers offer significant advantages over traditional single side polished wafers, including improved flatness, reduced surface roughness, and enhanced electrical properties. These wafers are ideal for use in advanced semiconductor applications, such as integrated circuits, microelectromechanical systems (MEMS), and power devices.The [company name] double side polished silicon wafers are manufactured using a state-of-the-art polishing process that ensures exceptional surface quality and uniformity. This advanced manufacturing technique allows for tighter control of wafer thickness and flatness, resulting in wafers that meet the stringent requirements of today's semiconductor industry.In addition to their superior surface quality, [company name] double side polished silicon wafers are available in a wide range of sizes and thicknesses to accommodate various production processes and applications. Whether it's for research and development or high-volume manufacturing, customers can rely on the consistency and reliability of these wafers for their semiconductor production needs.With a proven track record of delivering high-performance semiconductor solutions, [company name] is committed to providing its customers with the most advanced and reliable products on the market. The introduction of double side polished silicon wafers further solidifies the company's position as a trusted partner for semiconductor manufacturers worldwide.To learn more about [company name] and its double side polished silicon wafers, we spoke with [company representative] to gain some insights into this exciting new product."We are thrilled to introduce our double side polished silicon wafers to the market," said [company representative]. "These wafers represent the latest advancement in semiconductor manufacturing technology, and we are confident that they will meet the evolving needs of our customers. Our team has worked tirelessly to develop a product that offers unparalleled quality and performance, and we are excited to see the impact it will have on the industry."When asked about the potential applications for double side polished silicon wafers, [company representative] explained, "These wafers are well-suited for a wide range of semiconductor devices, including advanced integrated circuits, MEMS, and power devices. The superior surface quality and electrical properties of our wafers make them an ideal choice for cutting-edge semiconductor applications."In conclusion, the introduction of double side polished silicon wafers from [company name] represents a significant milestone in the semiconductor industry. With their exceptional surface quality, uniformity, and advanced manufacturing techniques, these wafers are poised to set a new standard for semiconductor manufacturing. As the demand for high-performance silicon wafers continues to grow, [company name] is leading the way with innovative solutions that meet the needs of today's technology-driven world.

Essential Information About Semiconductor Epi You Need to Know

Semiconductor Epi, a leading manufacturer of advanced semiconductor materials, has announced a new milestone in their technological advancement with the development of a groundbreaking semiconductor epi product. This innovative product is poised to revolutionize the semiconductor industry with its superior performance and efficiency.Semiconductor Epi has always been at the forefront of semiconductor material research and development. With a team of talented engineers and researchers, the company is dedicated to pushing the boundaries of semiconductor technology. Their relentless pursuit of innovation has led to the creation of cutting-edge products that are shaping the future of the semiconductor industry.The newly developed semiconductor epi product is a testament to Semiconductor Epi's commitment to excellence. It is the result of years of research and development, and represents a significant advancement in semiconductor material technology. This product promises to offer unparalleled performance and reliability, making it an attractive option for semiconductor manufacturers looking to stay ahead of the curve.One of the key features of this new semiconductor epi product is its exceptional quality. Semiconductor Epi has spared no effort in ensuring that the product meets the highest standards of performance and reliability. With rigorous testing and quality control measures in place, customers can have confidence in the consistent and superior performance of this product.In addition to its exceptional quality, the new semiconductor epi product also boasts impressive efficiency. Semiconductor Epi has optimized the manufacturing process to ensure that the product delivers maximum performance while minimizing energy consumption. This not only benefits the environment, but also makes the product a cost-effective solution for semiconductor manufacturers.Furthermore, Semiconductor Epi has taken into consideration the diverse needs of their customers in the semiconductor industry. The new semiconductor epi product is versatile and can be customized to meet specific requirements. Whether it's for high-speed computing applications or advanced communication devices, Semiconductor Epi's product is designed to cater to a wide range of semiconductor manufacturing needs.Semiconductor Epi's commitment to customer satisfaction doesn't stop at product excellence. The company understands the importance of providing exceptional customer support and service. With a team of knowledgeable professionals, Semiconductor Epi is dedicated to assisting customers every step of the way – from product selection to after-sales support.Semiconductor Epi's success in developing the new semiconductor epi product is a testament to their expertise and dedication to innovation. As the semiconductor industry continues to evolve, Semiconductor Epi remains at the forefront, continuously pushing the boundaries of what is possible with semiconductor materials.With the introduction of this groundbreaking semiconductor epi product, Semiconductor Epi has once again proven that they are a driving force in the semiconductor industry. Their commitment to excellence, combined with their focus on customer satisfaction, sets them apart as a leader in semiconductor material technology.In conclusion, Semiconductor Epi's new semiconductor epi product is set to make a significant impact on the semiconductor industry. With its exceptional quality, efficiency, and versatility, it promises to be a game-changer for semiconductor manufacturers. As Semiconductor Epi continues to push the boundaries of semiconductor technology, the company's dedication to innovation and customer satisfaction will undoubtedly solidify their position as a leader in the industry.

Discover the Latest Advances in Optical Lens Glass Technology

Optical Lens Glass, A Revolutionary Breakthrough in Lens TechnologyThe world of lens technology has been revolutionized with the introduction of Optical Lens Glass, a groundbreaking new product that promises to offer unparalleled clarity and precision in optical devices. This innovative material has been developed by a leading optical technology company, {company name}, known for its cutting-edge advancements in the field of optics.Optical Lens Glass is a highly specialized material that has been engineered to provide superior optical performance in a wide range of applications. It offers exceptional clarity and precision, making it ideal for use in cameras, microscopes, telescopes, and other optical devices. The unique properties of this glass make it a game-changer in the world of optics, offering unprecedented levels of performance and reliability.One of the key advantages of Optical Lens Glass is its remarkable ability to minimize optical aberrations, such as distortion and chromatic aberration, which can often compromise the quality of images produced by optical devices. By using this advanced material, manufacturers can ensure that their products deliver the highest levels of optical performance, resulting in clearer, sharper, and more accurate images.Furthermore, Optical Lens Glass boasts excellent light transmission properties, allowing for maximum brightness and contrast in optical devices. This means that images produced with lenses made from this material are incredibly vibrant and true to life, giving users a truly immersive viewing experience.In addition to its optical prowess, Optical Lens Glass also offers exceptional durability and resistance to environmental factors. This makes it an ideal choice for use in harsh and demanding conditions, such as outdoor and industrial settings, where traditional lens materials may be prone to damage or degradation.The development of Optical Lens Glass represents a significant milestone in the ongoing evolution of lens technology. By harnessing the unique properties of this innovative material, {company name} has once again demonstrated its commitment to pushing the boundaries of what is possible in the field of optics.As a leading player in the optical industry, {company name} has a long history of innovation and expertise in developing advanced optical solutions. With a dedicated team of scientists, engineers, and researchers, the company has consistently delivered groundbreaking breakthroughs that have reshaped the optical landscape.The introduction of Optical Lens Glass is a testament to {company name}'s ongoing dedication to driving forward the field of optics. By investing in research and development, the company continues to lead the way in developing cutting-edge optical materials and technologies that have a transformative impact on various industries.Looking ahead, the future of optical technology looks brighter than ever, thanks to the pioneering efforts of companies like {company name}. As the demand for high-performance, precision optics continues to grow across a wide range of industries, products like Optical Lens Glass will play a pivotal role in shaping the next generation of optical devices.In conclusion, the unveiling of Optical Lens Glass represents a major leap forward in the world of lens technology. Through its exceptional optical performance, durability, and resistance to environmental factors, this innovative material promises to set a new standard for optical excellence. With {company name} at the helm of this cutting-edge development, the future of optical technology looks set to reach new heights of innovation and performance.

Advancements in Monocrystalline Silicon Wafers: A Breakthrough in Semiconductor Technology

[Assistant]Title: Paving the Way for Advanced Solar Technology: Monocrystalline Silicon WaferIntroduction (40 words):Innovating the future of renewable energy, Monocrystalline Silicon Wafers, produced by a leading solar technology company, are revolutionizing solar power generation. This cutting-edge technology harnesses sunlight with unrivaled efficiency, positioning it as a breakthrough solution in the renewable energy sector.Body:I. Background on Monocrystalline Silicon Wafer (220 words)Monocrystalline Silicon Wafers are the foundation of high-performance solar panels. Made from a single crystal structure, their unique design allows them to absorb sunlight more effectively than other types of solar cells. This efficiency translates into increased energy output and a more sustainable approach to power generation.Monocrystalline Silicon Wafers offer several key advantages, including exceptional durability, high conversion efficiency, and advanced aesthetics. These properties make them the preferred choice for manufacturers and consumers alike, driving the growth of the global solar energy market. By utilizing this technology, we can significantly reduce our reliance on fossil fuels and mitigate the deleterious effects of climate change.II. Company Introduction: (250 words){Company Name}, a renowned pioneer in the field of solar technology, has been at the forefront of developing and optimizing Monocrystalline Silicon Wafer manufacturing processes. Established in {year}, the company has consistently delivered cutting-edge solutions and contributed to the rapid advancement of solar energy use worldwide.{Company Name}'s commitment to research and development has enabled them to create Monocrystalline Silicon Wafers that offer the highest conversion efficiency levels currently available. This efficient energy conversion leads to an increased power output, allowing end-users to maximize their solar investment while minimizing their carbon footprint.Moreover, {Company Name} has dedicated significant resources to enhance the durability and reliability of their Monocrystalline Silicon Wafers. Through innovations in material science and manufacturing techniques, they ensure that their products withstand harsh weather conditions and maintain their performance over an extended period.Additionally, {Company Name} places great emphasis on the aesthetics of their solar panels. Understanding the importance of blending renewable energy solutions seamlessly into architectural designs, they offer Monocrystalline Silicon Wafers with a sleek and uniform appearance. This commitment to visual integration opens up new possibilities for incorporating solar power generation into various landscapes and urban environments.III. Market Impact and Future Prospects (290 words)The widespread adoption of Monocrystalline Silicon Wafers has significantly boosted the solar energy market. With their superior efficiency and performance, these wafers are rapidly becoming the industry standard for solar panel manufacturers. As a result, global solar energy installations have experienced exponential growth, contributing to a substantial reduction in greenhouse gas emissions.The increasing demand for renewable energy solutions, coupled with technological advancements, has led to a considerable decrease in production costs. This cost reduction has made solar energy more accessible to a broader consumer base, further driving the adoption of Monocrystalline Silicon Wafers.Looking ahead, {Company Name} continues to invest in research and development to enhance the efficiency and versatility of their Monocrystalline Silicon Wafers. Their goal is to improve energy conversion rates, reduce manufacturing costs, and explore new applications for this groundbreaking technology.In conclusion, Monocrystalline Silicon Wafers, pioneered by {Company Name}, offer a game-changing solution for the renewable energy sector. Their superior efficiency, durability, and aesthetics position them as the cutting-edge choice for solar power generation. As the technology and market for Monocrystalline Silicon Wafers continue to evolve rapidly, we can anticipate a brighter and more sustainable future powered by the sun.