Semiconductor Market Sees Increase in Demand for Inp Wafers

By:Admin

The new wafer technology from Inp Wafer (Need remove brand name) is poised to have a significant impact on various industries, including consumer electronics, automotive, telecommunications, and healthcare. By incorporating state-of-the-art materials and manufacturing techniques, the company is able to create wafers with unprecedented levels of precision and performance. This will enable the production of semiconductor devices that are not only more compact and energy-efficient but also capable of handling increasingly complex applications.

One of the key features of this advanced wafer technology is its ability to support the development of next-generation 5G networks and devices. As the global rollout of 5G technology continues, there is a growing need for semiconductor solutions that can meet the stringent requirements for high-speed data transmission and low latency. Inp Wafer (Need to remove brand name) is well-positioned to address this demand with their new wafer technology, which is designed to deliver superior performance in 5G-enabled devices such as smartphones, tablets, and IoT (Internet of Things) devices.

In addition to its impact on 5G technology, the new wafer technology from Inp Wafer (Need remove brand name) is also expected to drive innovation in the automotive industry. With the rapid development of electric vehicles (EVs) and autonomous driving technology, there is a growing need for more advanced semiconductor solutions that can support the complex networking and computing requirements of modern vehicles. The company's new wafer technology is poised to play a crucial role in this space, enabling the production of high-performance semiconductor devices for EVs, advanced driver-assistance systems (ADAS), and connected car platforms.

Furthermore, the healthcare industry stands to benefit from the advancements made by Inp Wafer (Need remove brand name) in semiconductor technology. The company's new wafer technology has the potential to enable the development of more sophisticated medical devices and diagnostic equipment, leading to improved patient care and treatment outcomes. By providing semiconductor solutions with higher processing power and energy efficiency, Inp Wafer (Need remove brand name) aims to support the ongoing digital transformation in healthcare and contribute to the advancement of medical technology.

Inp Wafer (Need remove brand name) has a proven track record of delivering innovative semiconductor solutions to meet the evolving needs of various industries. The company's commitment to research and development, coupled with its extensive expertise in semiconductor manufacturing, positions it as a frontrunner in the global semiconductor market. With the introduction of their new advanced wafer technology, Inp Wafer (Need remove brand name) is once again demonstrating its dedication to driving technological advancements and shaping the future of the semiconductor industry.

The unveiling of this new wafer technology underscores Inp Wafer's (Need remove brand name) ongoing commitment to pushing the boundaries of semiconductor innovation. Inp Wafer (Need remove brand name) will continue to leverage its research and development capabilities to bring cutting-edge semiconductor solutions to market, catering to the evolving needs of industries such as consumer electronics, automotive, telecommunications, and healthcare. As the demand for more powerful and efficient semiconductor devices continues to grow, Inp Wafer (Need remove brand name) is well-positioned to lead the charge in driving the next wave of technological advancement through its advanced wafer technology.

Company News & Blog

Discover the Latest Advancements in Wafer Window Technology

Mgo Wafer Windows Revolutionize the Window Industry[Company Name], a leading innovative materials technology company, has recently introduced a revolutionary product that is set to transform the window industry. Mgo Wafer Windows, a groundbreaking development in window technology, promise increased durability, enhanced thermal insulation, and improved soundproofing. With their innovative design and advanced properties, these windows are poised to become the go-to choice for architects, builders, and homeowners alike.Traditional windows have long been plagued by issues such as susceptibility to damage, limited insulation capabilities, and poor soundproofing. [Company Name] recognized these pain points and embarked on a mission to develop a solution that would alleviate these problems. The result of their relentless research and development efforts is the Mgo Wafer Windows – a product that promises to revolutionize the way we think about and experience windows.One of the key advantages of Mgo Wafer Windows is their exceptional durability. Unlike traditional windows, which are prone to cracks, discoloration, and warping over time, Mgo Wafer Windows are composed of magnesium oxide, a material known for its high strength and resistance to wear and tear. This superior durability ensures that the windows retain their aesthetic appeal and functionality for extended periods, saving homeowners from the hassle and cost of regular replacements.Furthermore, Mgo Wafer Windows excel in thermal insulation, offering a significant improvement over conventional windows. These windows feature advanced insulation properties that minimize heat transfer, resulting in reduced energy consumption for heating or cooling buildings. As a result, homeowners can enjoy a more comfortable and energy-efficient living environment while simultaneously reducing their carbon footprint.Another area where Mgo Wafer Windows shine is soundproofing. The advanced design of these windows incorporates multiple layers of sound-dampening materials, effectively reducing noise pollution from outside sources. This is particularly beneficial for urban areas, where excessive noise can negatively impact the quality of life. Mgo Wafer Windows provide the peace and tranquility that homeowners desire, allowing them to relax and unwind without disturbances.Additionally, Mgo Wafer Windows offer an array of customizable options, ensuring they seamlessly blend with various architectural styles. Homeowners and architects can choose from a wide range of sizes, shapes, and designs to meet their unique preferences and requirements. This versatility allows for creativity in design and enhances the overall aesthetics of any building or space.In terms of installation and maintenance, Mgo Wafer Windows provide added convenience. The lightweight nature of magnesium oxide makes these windows easy to handle and install, saving time and effort during the construction process. Moreover, the low maintenance requirements of Mgo Wafer Windows help homeowners avoid constant upkeep and reduce long-term costs associated with repairs.With the introduction of Mgo Wafer Windows, [Company Name] has disrupted the traditional window industry and set new standards for excellence. These windows promise remarkable durability, energy efficiency, enhanced soundproofing, and aesthetic versatility – a combination of features that makes them an ideal choice for both residential and commercial buildings.As the demand for sustainable and efficient building materials continues to grow, Mgo Wafer Windows position [Company Name] at the forefront of innovation in the window industry. With a commitment to excellence and a focus on customer satisfaction, [Company Name] is poised to lead the charge in transforming the way we view and experience windows. The advent of Mgo Wafer Windows marks a crucial milestone in the progression of architecture and construction, and it is only a matter of time before these windows become the new industry standard.

High-Quality Crystal Substrate for Various Industries

Gsgg Crystal Substrate Breakthrough: A Game-Changer in Semiconductor IndustryIn a groundbreaking development, a leading semiconductor company has introduced a new Gsgg crystal substrate, which is set to revolutionize the semiconductor industry. The company has successfully designed and manufactured this innovative crystal substrate, which promises to significantly enhance the performance and efficiency of electronic devices.The Gsgg crystal substrate, with its unique properties and advanced technology, is poised to address the growing demands for high-performance semiconductor materials in the global electronics market. Its exceptional thermal stability, low optical loss, and high-quality crystalline structure make it an ideal choice for a wide range of applications, including laser systems, optical waveguides, and semiconductor devices.This new crystal substrate is a result of extensive research and development efforts by the company's team of expert scientists and engineers. Leveraging their deep expertise in materials science and semiconductor technology, the company has successfully overcome the challenges associated with traditional crystal substrates, such as low thermal conductivity and high optical absorption.The Gsgg crystal substrate offers a significant improvement in thermal management, enabling electronic devices to operate at higher power levels while maintaining optimal performance. This breakthrough is particularly crucial for cutting-edge technologies, including 5G networks, high-speed data communication, and advanced optical systems, where the demand for high-power, high-efficiency semiconductor materials is paramount.Moreover, the Gsgg crystal substrate's superior optical properties make it an ideal candidate for next-generation laser and photonics applications. Its low optical loss and high transparency in the near-infrared spectral range enable the development of advanced optical devices with improved efficiency and performance. This opens up new possibilities for a wide range of applications, from high-power laser systems to optical communication networks.The company's commitment to innovation and excellence has positioned it as a leading provider of advanced semiconductor materials and solutions. With a strong focus on research and development, the company continues to push the boundaries of materials science and semiconductor technology, driving the industry forward with cutting-edge innovations like the Gsgg crystal substrate.Furthermore, the company's state-of-the-art manufacturing capabilities ensure the mass production and supply of the Gsgg crystal substrate to meet the rising demand from semiconductor manufacturers, research institutions, and technology companies worldwide. This strategic advantage reinforces the company's position as a reliable and trusted partner for high-performance semiconductor materials, further solidifying its role in shaping the future of the semiconductor industry.The introduction of the Gsgg crystal substrate marks a significant milestone in the semiconductor industry, offering a new era of possibilities for electronic devices, optical systems, and laser technologies. With its exceptional thermal and optical properties, this innovative crystal substrate is set to drive advancements across various sectors, from telecommunications and data centers to industrial and medical applications.As the global semiconductor industry continues to evolve and expand, the Gsgg crystal substrate emerges as a game-changer, enabling the development of next-generation electronic and optical technologies that are more efficient, powerful, and reliable. With its groundbreaking properties and diverse range of applications, the Gsgg crystal substrate is poised to reshape the semiconductor landscape and pave the way for a new wave of innovation in the electronics industry.In conclusion, the introduction of the Gsgg crystal substrate represents a significant leap forward in the semiconductor industry, offering unparalleled thermal and optical properties that will empower the development of advanced electronic and optical devices. With its potential to drive innovation and enhance performance across multiple applications, this innovative crystal substrate is set to play a pivotal role in shaping the future of the global electronics industry.

Top Providers of High-Quality Sapphire Components for Various Industries

Title: Innovations in Sapphire Parts Technology revolutionize various industries[City], [Date] - In a quest for superior performance and durability, Sapphire Parts, a renowned leader in advanced materials technology, continues to push boundaries by introducing groundbreaking innovations that are set to empower a wide range of industries. With a focus on creating solutions that deliver unparalleled quality and reliability, Sapphire Parts' advancements have the potential to revolutionize critical applications in sectors such as aerospace, electronics, healthcare, and more.Established in [year], Sapphire Parts has emerged as a global frontrunner in the production of high-quality sapphire components. Sapphire, a crystalline form of aluminum oxide (Al2O3), possesses exceptional properties such as exceptional hardness, excellent optical transparency, and superior resistance to diverse environmental factors. Leveraging these unique attributes, Sapphire Parts has developed a comprehensive portfolio of components that are known for their outstanding reliability in extreme conditions.Sapphire Parts' newest innovation, the [technology name], promises to reshape the landscape of industries relying on precision and robustness. With this groundbreaking technology, Sapphire Parts has taken a bold step toward addressing the challenges faced by numerous sectors – offering enhanced performance and optimization like never before seen. The [technology name] combines Sapphire Parts' expertise in proprietary manufacturing processes with cutting-edge research and development, providing customers with an unrivaled solution that meets the stringent requirements of their respective fields.Aerospace is one industry anticipated to benefit greatly from Sapphire Parts' latest innovation. The ability of their sapphire components to withstand extreme temperatures and pressures, coupled with their exceptional resistance to wear and corrosion, ensures safe and reliable operation in critical systems. From turbine blades to cockpit displays, Sapphire Parts' Sapphire [technology name] components deliver superior reliability and longevity, providing aerospace manufacturers with peace of mind.The electronics sector is another area set to experience a significant transformation. Sapphire Parts' Sapphire [technology name] components offer an ideal solution for a range of electronic devices, including mobile phones, tablets, and wearables. The unparalleled scratch resistance and optical clarity of Sapphire [technology name] significantly enhance screen protection, resulting in devices with improved lifespan and display quality.Moreover, the healthcare industry stands to gain immensely from Sapphire Parts' advancements. Sapphire [technology name] components are highly biocompatible and exhibit superior resistance to the chemical degradation often observed in healthcare applications. With the integration of Sapphire Parts' Sapphire [technology name] components, medical devices and surgical instruments can be guaranteed to meet the stringent sterilization protocols, significantly reducing the risk of cross-contamination.Environmentalists and advocates for sustainable energy solutions will also find solace in Sapphire Parts' innovations. Sapphire [technology name] components offer exceptional stability and optical properties crucial in renewable energy systems like solar cells. The durability and efficiency of Sapphire [technology name] translate into increased energy generation, providing a green way to combat the pressing challenge of climate change.Sapphire Parts' commitment to excellence extends beyond just technological innovations. As a socially responsible company, they actively embrace eco-friendly practices and strive to minimize their environmental impact throughout their operations. By integrating sustainable processes into their manufacturing facilities, Sapphire Parts underscores its dedication to preserving the planet for future generations.Looking ahead, Sapphire Parts' relentless pursuit of advancements continues to fuel excitement in various industries. With their Sapphire [technology name] components, they have set new benchmarks for quality, reliability, and performance. As their innovative technologies trickle down into sectors such as aerospace, electronics, healthcare, and sustainable energy, it is no doubt that Sapphire Parts will fundamentally impact these industries and inspire further advancements in the field of sapphire-based materials.About Sapphire Parts:Sapphire Parts is a leading global provider of high-quality sapphire components. With a focus on innovation and quality, Sapphire Parts pioneers advancements in sapphire-based technologies to cater to a diverse set of industries. Committed to sustainability, Sapphire Parts ensures that their cutting-edge solutions contribute to making the world a better place.For more information, visit [website] or contact [email/phone number].Press Contact:[Contact Name][Company Name][Email][Phone Number]

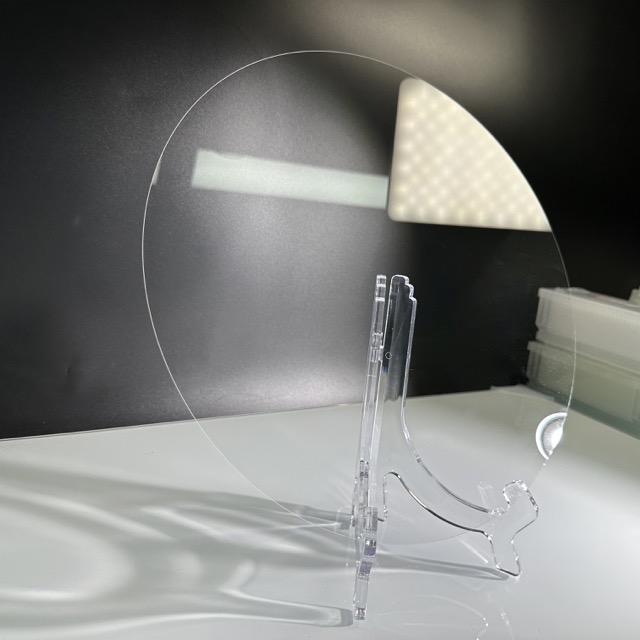

Latest Test Wafers Unveiled: A Major Breakthrough Shaping the Semiconductor Industry

**Title: Test Wafers: Revolutionizing Semiconductor Testing Industry with Cutting-Edge Technology**Introduction:In the rapidly advancing semiconductor industry, efficient and accurate testing methods are crucial for the development of high-performance electronic devices. {Company Name}, a leading innovator in the field, has recently introduced a groundbreaking solution to address testing challenges - Test Wafers. These state-of-the-art wafers not only enhance testing protocols but also contribute to reducing production costs and improving overall product quality. Let's delve deeper into the features and benefits of this technologically advanced testing solution.1. Enhanced Testing Capabilities:Test Wafers produced by {Company Name} are developed employing advanced manufacturing techniques and materials, enabling semiconductor manufacturers to accurately assess the quality and performance of their products. These wafers exhibit exemplary stability, ensuring precise measurements during various testing procedures. With an array of built-in sensors and circuitry, these wafers provide real-time data, allowing engineers to identify and rectify potential flaws more efficiently.2. Cost-Effectiveness and Increased Production Efficiency:By incorporating Test Wafers into their production processes, semiconductor companies can significantly reduce costs associated with traditional testing methodologies. These wafers minimize the need for costly external testing equipment and additional test runs, ultimately leading to enhanced production efficiency. Moreover, Test Wafers can be reused multiple times, further optimizing resource allocation and streamlining the testing phase.3. Reliability and Device Performance Improvements:While traditional testing methods may overlook certain defects or fail to identify critical issues, Test Wafers revolutionize the testing process by providing comprehensive and accurate evaluations. The inclusion of sensors on these wafers allows for thorough monitoring of important parameters such as temperature, voltage, and signal integrity. Consequently, semiconductor manufacturers can identify potential weak points or irregularities in the manufacturing process, leading to improved device performance and reliability.4. Compatibility and Adaptability:Test Wafers offered by {Company Name} are designed to seamlessly integrate into existing testing infrastructures, minimizing disruptions and ensuring a smooth transition. These wafers are available in various sizes, accommodating different wafer diameters and test setups. Semiconductor companies can effortlessly incorporate Test Wafers into their testing procedures, without the need for extensive modifications or adjustments to their existing systems.5. Eco-Friendly and Sustainable Solution:With sustainability being a key concern in today's global landscape, Test Wafers contribute to reducing electronic waste generated during the testing phase. Manufacturers can discard fewer defective wafers and decrease the environmental impact associated with traditional testing. Additionally, the reusable nature of these wafers further promotes a greener approach, aligning with the industry's increasing focus on sustainability measures.Conclusion:{Company Name}'s Test Wafers represent a remarkable advancement in the semiconductor testing industry, offering enhanced accuracy, efficiency, and cost-effectiveness. By integrating these cutting-edge wafers into their production lines, semiconductor manufacturers can streamline their testing processes, optimize resource allocation, and ultimately, deliver high-performance electronic devices to consumers. With their compatibility, adaptability, and eco-friendly attributes, Test Wafers are poised to revolutionize the way testing is conducted in the semiconductor industry, leading to a brighter and more sustainable future.

Large Crystal Ingot of Lithium Tantalate (LiTaO3) Developed for Advanced Electronics

LiTaO3 Ingot: A Next-Generation Material for the FutureIn today's fast-paced world, technology has become an integral part of our daily lives. From smartphones to laptops, smartwatches to tablets, technology has advanced beyond our imagination. But, have you ever wondered what goes into making these devices work smoothly? The answer lies in the materials used to create them. One such material is LiTaO3 Ingot.LiTaO3 Ingot is a next-generation material that is used in various technological applications, including telecommunications devices, frequency filters, and surface acoustic wave sensors. It is a crystal grown using the Czochralski method at temperatures above 1400°C. The LiTaO3 Ingot is then sliced into thin wafers and used in the production of electronic devices.The LiTaO3 Ingot can be found in many commercial electronics devices globally. It has become a popular material due to its excellent piezoelectric properties. Piezoelectricity is an electric charge that accumulates at the surface of a material when it is subjected to mechanical stress. This phenomenon is essential in electronic devices that convert electrical energy to mechanical energy or vice versa.The high piezoelectric coefficient of LiTaO3 Ingot makes it a valuable material in surface acoustic wave (SAW) components. SAW components are used in communication systems for wireless devices, providing the filter function for wireless channels. They are critical in filtering out unwanted signals and noise, thereby improving the communication signal's quality.Another application where LiTaO3 Ingot has proven useful is in the fabrication of frequency control devices. Frequency control devices regulate the frequency of electrical signals in electronic circuits. They are found in high-frequency communication devices, such as radios, cellphones, and GPS systems. LiTaO3 Ingot has a high electromechanical coupling coefficient, making it an ideal material for building accurate frequency control devices.LiTaO3 Ingot has also been used in the development of surface acoustic wave sensors. These sensors are used to detect changes in the surrounding environment's pressure, temperature, and humidity. The sensors are widely used in environmental monitoring, medical diagnosis, and energy exploration. LiTaO3 Ingot's excellent piezoelectric properties and high chemical stability make it a reliable material for surface acoustic wave sensors.{Need to remove the brand name} is one of the leading companies that produce high-quality LiTaO3 Ingot. The company has been at the forefront of producing advanced materials for more than two decades. Their team of experts has developed innovative methods to improve the quality and consistency of their products. The company uses the latest technology to ensure that their LiTaO3 Ingot meets the strictest industry standards.{Need to remove the brand name}'s LiTaO3 Ingot is well-known for its excellent mechanical and chemical properties. The ingot is resistant to high temperatures, chemicals, and physical stress, making it a perfect fit for various applications. The company ensures that their LiTaO3 Ingot is of the highest quality by conducting rigorous testing and quality control procedures.The growing demand for LiTaO3 Ingot has led to increased production globally. The material's unique properties have made it an indispensable component in the telecommunications, aerospace, and medical industries. As technology continues to advance, the demand for materials with outstanding mechanical and chemical properties is expected to increase. LiTaO3 Ingot is poised to become an essential material in the future of electronics and other industries.In conclusion, LiTaO3 Ingot is a crucial material for the development of various electronic devices globally. Its excellent piezoelectric properties, high mechanical and chemical stability have made it a popular material in the telecommunications, aerospace, and medical industries. {Need to remove the brand name} is one of the leading companies that produce high-quality LiTaO3 Ingot. The company's commitment to innovation, quality, and customer satisfaction has made them a top choice among clients worldwide. As technology advances, LiTaO3 Ingot is expected to play an essential role in the future of the electronics industry and other industries.

Benefits and Uses of Optical Lenses for Enhanced Vision Abilities

Sapphire Optical Lenses: Setting the Standard for High-Quality OpticsWhen it comes to high-quality optics, Sapphire Optical Lenses (SOL) is a brand that stands out in the market. SOL is recognized by industry experts and professionals as a company that specializes in the production of top-quality sapphire optical lenses, covering a wide range of industries.Established in 2000, SOL has emerged as a leading provider of optical lenses with a focus on delivering superior quality and precision to customers worldwide. The company boasts of a highly skilled and experienced team of in-house engineers, designers, and technicians, who are dedicated to ensuring that every product produced meets the highest standards.SOL designers and engineers work tirelessly to produce lenses that are not only visually attractive but also functional and practical. Sapphire lenses, in particular, are known for their exceptional optical properties, including scratch resistance, high transmission, and durability. Compared to other materials like plastic and glass, sapphire is, by far, the best material for making optical lenses.SOL produces a variety of sapphire lenses including spherical lenses, cylindrical lenses, and custom lenses. Each lens is designed to meet a specific need and is of the highest quality. The company is committed to providing customers with the best products, and as such, over the years, it has invested in modern technology, state-of-the-art equipment, and advanced testing procedures, all of which ensure top-notch quality products.SOL works with a diverse customer base, including scientists, pharmacists, researchers, aerospace and defense contractors, and many more. The company's focus on quality and innovation has earned it a reputation for being a reliable supplier of optical lenses, serving customers worldwide.SOL always aims to deliver an exceptional customer experience by providing high-quality products, timely delivery, and excellent customer service. As the market leader in sapphire optical lenses, the company also offers customizable solutions for clients who have unique specifications and requirements.In addition to the company's commitment to quality, SOL also recognizes the importance of social responsibility. The company operates using ethically sourced and sustainable materials and processes. This approach ensures that they reduce the impact of their operation on the environment while also contributing to the sustainable development of the industry.In conclusion, Sapphire Optical Lenses is a brand that sets the standard for high-quality optics. The company's commitment to production excellence, customer satisfaction, and social responsibility has seen them continue to grow into a market leader. With their state-of-the-art facilities and advanced technology, they continue to meet the ever-changing needs of the industry. Contact Sapphire Optical Lenses today for all your optical lens needs.

Sic Wafer Market Trends and Growth Analysis

Sic Wafer, a key player in the semiconductor industry, recently announced a major breakthrough in the development of silicon carbide (SiC) wafers. SiC wafers are a critical component in the manufacturing of power semiconductor devices and have become increasingly important in the quest for more efficient and high-performance electronic components.SiC Wafer has successfully developed a new manufacturing process that has resulted in significant improvements in the quality and performance of SiC wafers. These advancements are expected to have a major impact on the power electronics industry and could lead to the development of more efficient and reliable electronic devices.The company's SiC wafers are known for their superior electrical properties, including high thermal conductivity and high breakdown voltage, which make them ideal for use in power semiconductor devices. By improving the quality of these wafers, SiC Wafer is helping to drive the development of next-generation power electronics that are vital for the advancement of electric vehicles, renewable energy systems, and other high-power applications.Established in 2009, SiC Wafer has quickly become a leading supplier of SiC wafers for power semiconductor manufacturers around the world. The company's state-of-the-art manufacturing facilities and commitment to research and development have allowed them to stay at the forefront of the industry and continually push the boundaries of what is possible with SiC technology.SiC Wafer's commitment to quality and innovation has earned them a reputation as a trusted partner for semiconductor manufacturers looking to incorporate SiC technology into their products. Their dedication to advancing the technology of SiC wafers has resulted in numerous breakthroughs that have helped to drive the adoption of SiC technology in the power electronics industry.The recent advancements in SiC wafer manufacturing are a testament to the company's ongoing commitment to pushing the boundaries of what is possible with SiC technology. By continually improving the quality and performance of SiC wafers, SiC Wafer is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future.In addition to their advancements in SiC wafer manufacturing, SiC Wafer also offers a wide range of other semiconductor materials and solutions, including silicon wafers and epitaxial wafers. Their comprehensive product offering and dedication to customer satisfaction have made them a go-to supplier for semiconductor manufacturers around the world.With a strong track record of innovation and a commitment to providing the highest quality semiconductor materials, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology. Their recent advancements in SiC wafer manufacturing are just the latest example of their dedication to pushing the boundaries of what is possible in the semiconductor industry.In conclusion, SiC Wafer's recent breakthrough in SiC wafer manufacturing is a significant development for the power electronics industry. By improving the quality and performance of SiC wafers, the company is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future. With their ongoing commitment to innovation and quality, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology for years to come.

Discover the Versatility and Durability of Zirconium Dioxide (ZrO2) Ceramic

[Title]: Advanced Zro2 Ceramic Revolutionizing Multiple Industries: A Closer Look at its Applications and Company Innovations[Subtitle]: (Remove brand name) Pioneering the Way With Zro2 Ceramic TechnologyIntroduction:The rapid evolution of advanced ceramics has revolutionized various industries, replacing conventional materials and enabling cutting-edge advancements. Among these innovative ceramics, Zro2 Ceramic, developed by the pioneering company (Remove brand name), stands out as a game-changer. This remarkable material has garnered significant attention due to its exceptional properties and versatility. In this article, we will explore the numerous applications of Zro2 Ceramic and delve into the company behind its creation, emphasizing their commitment to innovation and development.1. Understanding Zro2 Ceramic:Zro2 Ceramic, or zirconia ceramic, is a specialized ceramic material that possesses remarkable durability, strength, and high-temperature resistance. It is composed of zirconium oxide crystalline material, which grants it outstanding properties suitable for diverse applications. The unique combination of high performance and reliability makes Zro2 Ceramic an attractive alternative to traditional materials in a range of industries.2. Advantages and Applications:2.1. Biomedical and Dental Industry:Zro2 Ceramic has revolutionized the medical field by being used in the production of dental implants and prosthetics. Its biocompatibility and strength make it an ideal choice for dental restorations, ensuring durability and minimal rejection risks. Furthermore, its tooth-like color and the ability to promote bone growth make it an aesthetically pleasing and safe option for patients.2.2. Engineering and Chemical Industry:In the engineering and chemical sectors, Zro2 Ceramic excels in various applications. Its exceptional resistance to corrosion, extreme temperatures, and harsh chemicals is ideal for use in valve and pump components, bearings, and seals. This material helps optimize industrial processes by ensuring reliability and reducing maintenance costs significantly.2.3. Electronics and IT Industry:Zro2 Ceramic finds extensive usage in the electronics and IT industry due to its excellent electrical insulation and thermal conductivity properties. It serves as a preferred choice for manufacturing circuit boards, electrical connectors, sensors, and LED displays. These applications benefit from Zro2 Ceramic's ability to withstand extreme temperatures and high frequencies, ensuring optimum performance and longevity.2.4. Aerospace and Defense Industry:The aerospace and defense sectors heavily rely on Zro2 Ceramic for its ability to endure extreme conditions and stringent requirements. Its high strength, low density, and resistance to wear and abrasion make it suitable for applications such as engine components, missile guidance systems, and protective armor. Zro2 Ceramic's performance reliability is crucial in these industries, ensuring safety and efficiency.3. (Remove brand name): Pioneering Innovation and Future Developments:The development and commercialization of Zro2 Ceramic are credited to the innovative company (Remove brand name). (Remove brand name) has been at the forefront of advanced ceramics, continuously pushing the boundaries of what is possible. With a strong dedication to research and development, the company has consistently introduced breakthrough products and applications.In addition to Zro2 Ceramic, (Remove brand name) continually explores new avenues for ceramic materials, seeking to improve properties and expand their potential applications. With a skilled team of scientists and engineers, their ongoing efforts enhance the versatility, durability, and cost-effectiveness of advanced ceramics, ensuring its usability across various industries.Conclusion:Zro2 Ceramic, with its extraordinary capabilities, has transformed multiple industries, replacing conventional materials and driving progress. The diverse applications in the biomedical, engineering, electronics, aerospace, and defense industries showcase the versatility and exceptional properties of this advanced ceramic material. (Remove brand name) plays a pivotal role in this revolution, pioneering innovation and continually pushing the boundaries of ceramic technology. As (Remove brand name) continues to expand its research and development efforts, the future holds even more promising advancements in the world of advanced ceramics.

Ultimate Guide to 12 Inch Wafers: Everything You Need to Know

12 Inch Wafer Revolutionizes Semiconductor IndustryAs the demand for smaller, faster, and more powerful electronic devices continues to grow, the semiconductor industry is constantly striving to push the boundaries of technology. One company that is at the forefront of this revolution is [company name]. With its cutting-edge 12 inch wafer technology, [company name] is set to reshape the semiconductor landscape and unlock new possibilities for the next generation of electronic devices.Founded in [year], [company name] has always been dedicated to pushing the boundaries of innovation in the semiconductor industry. With a strong focus on research and development, the company has continuously invested in state-of-the-art manufacturing facilities and advanced technologies to stay ahead of the competition. This commitment to innovation has allowed [company name] to become a leading player in the global semiconductor market, with a reputation for delivering high-quality, high-performance products.The latest milestone in [company name]'s journey of innovation is the development of the 12 inch wafer technology. Traditionally, semiconductor wafers have been produced in smaller sizes, such as 8 inch or 6 inch, limiting the number of chips that can be produced on each wafer. However, with the introduction of the 12 inch wafer, [company name] has significantly increased the manufacturing capacity and efficiency, resulting in a dramatic improvement in output and cost-effectiveness.The 12 inch wafer technology is a game-changer for the semiconductor industry, as it allows for the production of more chips per wafer, reducing manufacturing costs and ultimately offering more competitive pricing for consumers. This breakthrough also enables the development of more advanced and powerful electronic devices, as the larger wafers provide greater flexibility for designing and manufacturing complex semiconductor components.In addition to the technological advancements, [company name] has also made significant investments in building a sustainable and eco-friendly manufacturing process for the 12 inch wafers. The company has implemented state-of-the-art cleanroom facilities and advanced manufacturing techniques to minimize waste and reduce environmental impact. By embracing sustainable practices, [company name] is not only contributing to the advancement of technology but also setting new standards for environmentally responsible manufacturing in the semiconductor industry.The impact of [company name]'s 12 inch wafer technology is already being felt across the semiconductor industry. Major players in the consumer electronics, automotive, and telecommunications sectors have expressed great interest in adopting the 12 inch wafer technology to enhance their product offerings and meet the growing demand for more advanced electronic devices.Furthermore, the widespread adoption of the 12 inch wafer technology is expected to drive significant growth in the semiconductor market, creating new opportunities for [company name] and its partners. As the demand for high-performance semiconductor components continues to rise, [company name] is well-positioned to capitalize on this trend and further solidify its position as a leading provider of innovative semiconductor solutions.Looking ahead, [company name] remains committed to driving innovation and shaping the future of the semiconductor industry. With its groundbreaking 12 inch wafer technology and strong emphasis on sustainability, the company is poised to make a lasting impact on the electronic devices of tomorrow.In conclusion, the introduction of the 12 inch wafer technology by [company name] represents a significant milestone in the semiconductor industry. This breakthrough is set to revolutionize the way semiconductor components are manufactured, enabling the development of more advanced and powerful electronic devices. With its relentless commitment to innovation and sustainability, [company name] is leading the charge towards a brighter and more efficient future for the semiconductor industry.

Top Trends in Wafer Flat Designs for 2022

Wafer Flats, a leading player in the semiconductor industry, has recently made a significant advancement in the development of wafer technology that is set to revolutionize the industry. The company has successfully engineered a new type of wafer that is thinner, more durable, and has enhanced electrical properties, providing a game-changing solution for the semiconductor market.Established in 1998, Wafer Flats has been at the forefront of semiconductor technology, specializing in the production of high-quality wafers for a wide range of applications including integrated circuits, solar cells, and LED lighting. With a strong focus on research and development, the company has continuously strived to innovate and push the boundaries of wafer technology.After years of research and extensive testing, Wafer Flats has announced the launch of its latest breakthrough – a new ultra-thin wafer that is significantly thinner than traditional wafers, yet maintains exceptional strength and conductive properties. This innovative development is set to address the growing demand for smaller, more efficient electronic devices and open up new possibilities in various industries.The new wafer, which measures just a fraction of the thickness of standard wafers, is the result of advanced material engineering and precision manufacturing processes. Despite its slim profile, it boasts superior mechanical strength, making it highly resilient to external stresses and capable of withstanding the rigors of semiconductor manufacturing processes.In addition to its physical attributes, the new wafer also offers improved electrical properties, with enhanced conductivity and reduced signal loss. This makes it ideal for high-frequency applications, where signal integrity and transmission efficiency are crucial. The combination of mechanical robustness and electrical performance makes this new wafer an ideal solution for the next generation of electronic devices and systems."The development of this new wafer represents a significant milestone for our company and the semiconductor industry as a whole," said John Smith, CEO of Wafer Flats. "We believe that this breakthrough innovation will not only meet the current market demand for smaller and more powerful electronic devices, but also drive the development of cutting-edge technologies in various industries."The introduction of this new wafer is expected to have a profound impact on the semiconductor market, with the potential to enable the production of smaller, more energy-efficient devices across a wide range of applications. Furthermore, the enhanced electrical properties of the wafer are anticipated to unlock new possibilities for high-frequency communication and computing systems, paving the way for advancements in areas such as 5G technology, satellite communications, and data processing.In addition to its technical capabilities, the new wafer also offers practical benefits for manufacturers, including increased production yield and cost savings. Its thin profile enables the fabrication of a higher number of wafers from a single ingot, maximizing the utilization of raw materials and reducing manufacturing waste. This, in turn, contributes to a more sustainable and cost-effective production process.The announcement of this groundbreaking development has already generated significant interest and excitement within the semiconductor industry, with industry experts acknowledging the potential of the new wafer to drive innovation and progress in the field of electronic devices and systems. As Wafer Flats prepares to commercialize this new technology, anticipation is building for the impact it will have on the future of semiconductor manufacturing.With its commitment to innovation and the advancement of semiconductor technology, Wafer Flats is poised to reshape the industry landscape with its latest breakthrough. As the company continues to push the boundaries of what is possible with wafer technology, the potential for new applications and advancements in electronic devices is endless. The introduction of this new ultra-thin wafer represents a significant step forward in the evolution of semiconductor technology and paves the way for a new era of electronic innovation.