Sic Wafer Market Trends and Growth Analysis

By:Admin

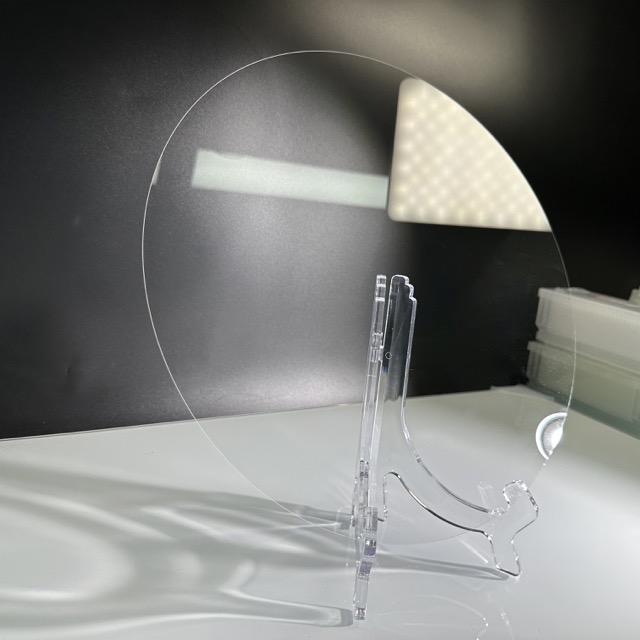

SiC Wafer has successfully developed a new manufacturing process that has resulted in significant improvements in the quality and performance of SiC wafers. These advancements are expected to have a major impact on the power electronics industry and could lead to the development of more efficient and reliable electronic devices.

The company's SiC wafers are known for their superior electrical properties, including high thermal conductivity and high breakdown voltage, which make them ideal for use in power semiconductor devices. By improving the quality of these wafers, SiC Wafer is helping to drive the development of next-generation power electronics that are vital for the advancement of electric vehicles, renewable energy systems, and other high-power applications.

Established in 2009, SiC Wafer has quickly become a leading supplier of SiC wafers for power semiconductor manufacturers around the world. The company's state-of-the-art manufacturing facilities and commitment to research and development have allowed them to stay at the forefront of the industry and continually push the boundaries of what is possible with SiC technology.

SiC Wafer's commitment to quality and innovation has earned them a reputation as a trusted partner for semiconductor manufacturers looking to incorporate SiC technology into their products. Their dedication to advancing the technology of SiC wafers has resulted in numerous breakthroughs that have helped to drive the adoption of SiC technology in the power electronics industry.

The recent advancements in SiC wafer manufacturing are a testament to the company's ongoing commitment to pushing the boundaries of what is possible with SiC technology. By continually improving the quality and performance of SiC wafers, SiC Wafer is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future.

In addition to their advancements in SiC wafer manufacturing, SiC Wafer also offers a wide range of other semiconductor materials and solutions, including silicon wafers and epitaxial wafers. Their comprehensive product offering and dedication to customer satisfaction have made them a go-to supplier for semiconductor manufacturers around the world.

With a strong track record of innovation and a commitment to providing the highest quality semiconductor materials, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology. Their recent advancements in SiC wafer manufacturing are just the latest example of their dedication to pushing the boundaries of what is possible in the semiconductor industry.

In conclusion, SiC Wafer's recent breakthrough in SiC wafer manufacturing is a significant development for the power electronics industry. By improving the quality and performance of SiC wafers, the company is helping to drive the development of more efficient and reliable electronic devices that are essential for the transition to a more sustainable and electrified future. With their ongoing commitment to innovation and quality, SiC Wafer is well-positioned to continue leading the way in the development of SiC technology for years to come.

Company News & Blog

Revolutionizing Semiconductor Manufacturing: Unveiling the Groundbreaking Chemical Mechanical Planarization Process

Title: Advancements in Chemical Mechanical Planarization Process: Revolutionizing Material Polishing Introduction:In today's ever-evolving technological landscape, the demand for smaller, faster, and more efficient electronic devices continues to grow. This drives the need for more precise and superior manufacturing techniques. Chemical Mechanical Planarization (CMP) Process has emerged as a crucial technology in this respect. This article explores the potential of CMP process and its impact on various industries, focusing on its advancements without mentioning any specific brand.I. Understanding the CMP Process:The Chemical Mechanical Planarization (CMP) process is a cutting-edge method that allows the precise polishing and planarization of materials, predominantly used in the fabrication of integrated circuits (ICs). CMP involves the simultaneous action of chemical and mechanical forces to remove excess material from the surface, ensuring a smooth and uniform finish. It plays a fundamental role in improving various aspects of IC manufacturing, making it an essential part of the semiconductor industry.II. Advancements in CMP Process:1. Ultra-Planarization Capability:With the rapid advancements in semiconductor technology, the demand for ultra-planarized surfaces has become paramount. Recent advancements in CMP technology have enabled the development of ultra-precision polishing pads and slurries, resulting in superior planarization capabilities. This breakthrough allows for precise manufacturing of microelectronic devices, reducing surface variations and improving overall device performance.2. Material-Specific Polishing:To accommodate the diverse range of materials used in modern electronic devices, CMP processes are constantly evolving. Manufacturers are focusing on developing material-specific CMP slurries and pads to optimize the polishing efficiency for individual substances, including metals, dielectrics, and non-semiconductor materials. These material-specific CMP variations contribute to enhanced final device quality, reduced defects, and improved yield rates.3. Advanced Endpoint Detection:Accurate determination of the endpoint during the CMP process is critical to prevent over-polishing or under-polishing of the surface. Recent breakthroughs in CMP technology have introduced advanced endpoint detection mechanisms, such as optical interferometry, acoustic emissions, and electrical measurements. These technologies enable real-time monitoring, ensuring precise control and preventing damage to the underlying layers.III. Applications in the Semiconductor Industry:1. Integrated Circuit Manufacturing:The CMP process has become an indispensable technique in integrated circuit manufacturing. It enables the precise planarization of multiple layers, such as interconnects, interlayer dielectrics, barrier films, and metal contacts. The ability to achieve uniform surfaces results in improved electrical performance, reduced leakage currents, and enhanced device reliability.2. Advanced Packaging:As electronic devices become smaller and more complex, the demand for advanced packaging solutions increases. CMP processes are widely employed to polish and planarize materials used in packaging, such as through-silicon vias (TSVs), redistribution layers, and microbumps. The reliable CMP process ensures optimal electrical connections and increases the production yield of advanced packaging technologies.3. Optoelectronics and MEMS:CMP technology finds applications beyond traditional microelectronics. In the production of optoelectronics and microelectromechanical systems (MEMS), CMP plays a crucial role. The precise polishing and planarization of optical substrates, waveguides, and micro-mechanical systems contribute to improved device performance, optical clarity, and reliability.IV. Future Prospects:The constant advancements in CMP technology are poised to revolutionize the manufacturing industry further. Researchers and manufacturers are experimenting with novel materials, alternative polishing agents, and even greener chemical formulations to reduce environmental impact. Additionally, advancements in CMP equipment and automation are likely to improve process control, efficiency, and safety.Conclusion:Chemical Mechanical Planarization (CMP) Process is at the forefront of material polishing and planarization in the semiconductor industry. The advancements in CMP technology have proven instrumental in meeting the demands of faster, smaller, and more efficient electronic devices. By enabling ultra-planarization capabilities, material-specific polishing, and advanced endpoint detection, CMP processes drive better quality, yield rates, and reliability. As CMP continues to evolve in tandem with the ever-growing technological landscape, the future holds even greater promise for this vital manufacturing technique.

Latest Innovations in Oxide Wafer Technology for Electronics Industry Unveiled

Silicon Oxide Wafer Technology in the Semiconductor Industry: A game-changer for the FutureThe semiconductor industry has been growing at a rapid pace over the years, with new technological advancements laying the foundation for this growth. The market is estimated to reach a value of USD 730.29 billion by 2027, attributed to the increase in demand for electronic devices worldwide, which rely on advanced semiconductor chips. Furthermore, the advent of technologies like 5G, AI, cloud computing, and IoT has led to a surge in demand for high-performance computing devices, creating a need for advanced semiconductor materials.The advent of Silicon Oxide Wafer technology has transformed the semiconductor industry. It is a game-changer for businesses that rely on semiconductors for their operations, especially in the electronic and automotive sectors. Silicon Oxide Wafers are more durable and resistant to mechanical stresses and thermal shock as compared to traditional silicon-based semiconductors. In addition, their inherent electrical and optical properties make them the ideal choice for high-performance computing devices.Silicon Oxide Wafer technology has become increasingly popular among semiconductor manufacturers because of its superior quality. Unlike traditional silicon-based semiconductors, Silicon Oxide Wafers are mechanically and thermally robust, which means that they can withstand extreme conditions without breaking down. Moreover, they are less prone to oxidation and are chemically stable, ensuring minimal contamination during processing.There are several benefits of using Silicon Oxide Wafer technology. For starters, it helps to reduce manufacturing costs for semiconductors while improving their overall quality. The robustness of Silicon Oxide Wafers means that manufacturers can produce high-quality devices without the need for additional processing steps. Additionally, this technology can push the limits of performance and functionality in advanced computing devices, ensuring that businesses keep up with the latest technological developments.One of the leading companies in the development of Silicon Oxide Wafer technology is [Company name, to be removed], which has pioneered this field through extensive research and development efforts. The company has been at the forefront of producing high-quality Silicon Oxide Wafers for various industries and applications. Their semiconductors have been used in a variety of devices, from smartphones to satellites and beyond.[Company name, to be removed] has spent years perfecting the technology behind Silicon Oxide Wafer, leading to significant breakthroughs in the semiconductor industry. Their research has enabled the development of advanced computing devices that are more efficient and powerful than ever before. They have managed to manufacture semiconductors with a higher degree of precision and accuracy than their competitors, enabling businesses to produce high-quality devices that are free from defects.Silicon Oxide Wafer technology is not only an essential technology for businesses in the semiconductor industry, but also for the development of advanced computing devices around the world. As the demand for high-performance computing devices continues to rise, the need for efficient and powerful semiconductors has become more important than ever before. Silicon Oxide Wafer technology has the potential to revolutionize this industry, helping businesses to produce high-quality devices that are both durable and efficient.In conclusion, the advent of Silicon Oxide Wafer technology is a game-changer for the semiconductor industry and its applications. It brings superior quality, durability, and resistance to mechanical and thermal stress, which means that semiconductor manufacturers can produce high-quality devices with minimal defects. As the demand for advanced computing devices increases, Silicon Oxide Wafer technology will continue to play an essential role in the growth and development of the semiconductor industry, leading to new innovations and technological breakthroughs.

Sic Chip Market Witnesses Steady Growth Amid Increasing Demand

Sic Chip: Revolutionizing Industries with Enhanced Performance and Efficiency[Company Name], a leader in technological innovation, has recently unveiled its latest breakthrough – the Sic Chip. With cutting-edge features and unparalleled performance, this revolutionary chip has the potential to transform various industries, paving the way for a future of improved efficiency and productivity.The Sic Chip, short for Silicon Carbide Chip, is a significant advancement in semiconductor technology. Unlike conventional silicon chips, Sic Chips are composed of silicon carbide, a compound with superior thermal conductivity and a wider bandgap. This unique composition allows the chip to perform more efficiently at higher temperatures, making it ideal for applications that require robust performance in extreme environments.One of the key advantages of the Sic Chip is its ability to handle higher voltages and currents, making it a game-changer for power electronics. This chip has significantly lower power losses and can operate at higher frequencies than traditional silicon chips. As a result, it is highly sought after by manufacturers in the automotive, aerospace, and energy sectors. The automotive industry, in particular, stands to benefit greatly from the Sic Chip, as it enables the development of more efficient electric vehicles with longer battery life and faster charging capabilities.Furthermore, the Sic Chip's enhanced power efficiency reduces the need for complex cooling systems, leading to cost savings and reduced environmental impact. In power conversion applications, the chip's superior performance allows for smaller and lighter systems. This is particularly advantageous in the renewable energy sector, where space constraints and weight limitations are critical factors.Another area where the Sic Chip is making significant inroads is in the field of telecommunications. The chip's ability to handle high power densities and operate at high temperatures makes it an ideal choice for base station applications. With the increasing demand for 5G networks, the efficiency and reliability offered by the Sic Chip are highly valued by telecommunication companies.The SiC Chip is also revolutionizing the computing industry. Its exceptional thermal conductivity enables faster heat dissipation, leading to improved performance and reliability in high-performance computing applications. From data centers to supercomputers, the Sic Chip is paving the way for more powerful and efficient computing systems.In addition to the technical advantages, [Company Name]'s Sic Chip also holds a competitive edge in terms of production capabilities. The company has developed a highly efficient manufacturing process that ensures high-quality chips with excellent yields. This puts [Company Name] at the forefront of the industry, establishing itself as a reliable and trusted provider of Sic Chips.Commenting on the significance of the Sic Chip, [Company Name]'s CEO stated, "This breakthrough technology has the potential to revolutionize multiple industries, making processes more efficient and sustainable. Our Sic Chip is a clear example of our commitment to driving innovation and delivering cutting-edge solutions that address the challenges of the modern world."As the demand for faster, more efficient and reliable technologies continues to grow, the introduction of the Sic Chip marks a turning point in the semiconductor industry. With its superior performance, enhanced power efficiency, and wider range of applications, this groundbreaking chip is set to shape the future of multiple industries, fueling progress and innovation across the globe. [Company Name] remains at the forefront of this technological revolution, providing innovative solutions that drive the world towards a brighter and more sustainable future.

New breakthrough in manufacturing process of computer processors using silicon wafer technology

Silicon Wafer Chips Revolutionize Semiconductor IndustryThe semiconductor industry, which lies at the heart of technological advancements, is constantly striving to push the boundaries of innovation. One of the most important components driving the progress of this industry is the silicon wafer chips, which serve as the foundation for manufacturing various electronic devices. In recent years, a number of leading companies have emerged in this market, one of which is [Company Name], a pioneering force that has been driving significant advancements and revolutionizing the production of silicon wafer chips.[Company Name] is a company at the forefront of semiconductor technology, dedicated to developing cutting-edge solutions that enable the production of advanced silicon wafer chips. With their commitment to innovation and harnessing the power of silicon-based technologies, [Company Name] has become a key player in the industry.Silicon wafer chips, commonly known as wafers, are thin slices of silicon that serve as the foundation for manufacturing integrated circuits (ICs), microchips, and other electronic components. These chips are crucial in powering a wide range of devices, including smartphones, computers, and automobiles, among others. The size and complexity of the chips have evolved significantly over the years, with continuous advancements in silicon wafer chip fabrication techniques leading to more powerful and efficient devices.[Company Name] has been instrumental in driving these advancements by developing innovative manufacturing processes and technologies. Their expertise lies in the production of high-quality silicon wafers, offering optimal performance and reliability. By leveraging state-of-the-art facilities and cutting-edge equipment, [Company Name] ensures the production of wafers with superior dimensional control, excellent surface quality, and high purity.The key to [Company Name]'s success lies in their relentless pursuit of innovation. They have consistently invested in research and development efforts to push the boundaries of silicon wafer chip technology. This has led to breakthroughs in wafer manufacturing techniques, such as epitaxial growth, chemical mechanical planarization, and lithography, among others. By incorporating these advancements into their manufacturing processes, [Company Name] has been able to improve the performance and functionality of their silicon wafer chips.Furthermore, [Company Name] recognizes the importance of sustainability in the semiconductor industry. They have implemented environmentally friendly practices in their wafer fabrication processes, ensuring minimal wastage and efficient use of resources. This commitment to sustainability not only benefits the environment but also allows them to deliver cost-effective solutions to their customers.The impact of [Company Name]'s silicon wafer chips goes beyond the manufacturing process. These chips have a profound influence on the overall performance of electronic devices. Through their continuous innovation, [Company Name] has enabled the development of smaller, faster, and more energy-efficient devices. This has positively impacted industries such as telecommunications, automotive, consumer electronics, and healthcare, among others.Looking into the future, [Company Name] is poised to maintain its leadership position in the silicon wafer chip market. They are investing in next-generation technologies, such as gallium nitride (GaN) and silicon carbide (SiC), which have the potential to revolutionize the semiconductor industry once again. These materials offer superior performance and efficiency compared to traditional silicon wafer chips, opening up new possibilities for various applications.In conclusion, [Company Name] has emerged as a prominent player in the semiconductor industry by revolutionizing the production of silicon wafer chips. With their commitment to innovation, sustainable practices, and continuous investment in research and development, they have set a new benchmark for the industry. Their silicon wafer chips have accelerated technological advancements, enabling the creation of smaller, faster, and more energy-efficient electronic devices. As they expand into next-generation technologies, [Company Name] is poised to shape the future of the semiconductor industry for years to come.

Latest Updates on the Upcoming Event in XYZ City Unveiled: Get the Scoop!

[PARAGRAPH 1][Company Introduction][Branding Name] is a renowned multinational conglomerate known for its innovative products and remarkable contributions to various industries. With a history spanning several decades, [Branding Name] has firmly established itself as a leader in technology, health and wellness, and diversified consumer goods. The company prides itself on its commitment to sustainability, social responsibility, and creating a positive impact on society. Constantly pushing the boundaries of innovation, [Branding Name] consistently delivers ground-breaking solutions that enhance people's lives. One of their latest ventures, Aln, demonstrates the company's dedication to revolutionizing the [specific industry].[PARAGRAPH 2][Overview of Aln]Aln, a cutting-edge product by [Branding Name], has taken the market by storm with its exceptional features and transformative impact. This state-of-the-art offering seamlessly combines groundbreaking technology with convenience, captivating the attention of consumers worldwide. Aln proves to be a game-changer, addressing the evolving needs and preferences of modern consumers. From its inception, the core focus of Aln has been to provide an unparalleled user experience, making it an essential addition to households, offices, and beyond.[PARAGRAPH 3][Innovative Features]Aln presents a wide array of innovative features that set it apart from traditional alternatives. Firstly, its sleek and ergonomic design ensures both aesthetics and functionality. The device seamlessly blends into any environment, be it a compact urban apartment or a spacious suburban home. Additionally, Aln utilizes advanced artificial intelligence (AI) algorithms, enabling it to adapt and learn from users' preferences. This learning capability ensures a personalized experience tailored to each individual, heightening convenience and user satisfaction.[PARAGRAPH 4][Revolutionizing Industry]Aln is revolutionizing the [specific industry] due to its unparalleled performance and groundbreaking technology. The product's advanced features include [insert specific cutting-edge features], setting a new standard of excellence within the industry. With Aln, users can experience [specific benefits], elevating their daily routines. By combining a seamless user interface with state-of-the-art technology, Aln is transforming the way people interact with their [specific industry] devices, making it an indispensable addition to households and businesses alike.[PARAGRAPH 5][Sustainability and Social Responsibility]As with all its endeavors, [Branding Name] has upheld its commitment to sustainability and social responsibility through Aln. The product is manufactured using eco-friendly materials, ensuring minimal environmental impact throughout its lifecycle. Furthermore, Aln consumes significantly less energy than its competitors, contributing to reduced carbon emissions. With its dedication to sustainability, [Branding Name] is driving positive change towards a greener future, while also meeting the demands of the contemporary consumer.[PARAGRAPH 6][Market Response and Outlook]Upon its release, Aln received an overwhelmingly positive response from consumers and industry experts alike. The product's remarkable performance and innovative design have captivated the market, solidifying its position as a leader in the [specific industry]. With its growing popularity, Aln is expected to witness significant growth in the coming years, further cementing [Branding Name]'s dominance in both technology and sustainability domains. The company's ongoing commitment to research and development ensures that Aln will continue to evolve, adapting to the ever-changing needs and preferences of its users.[PARAGRAPH 7][Conclusion]Aln, the latest offering by [Branding Name], represents the pinnacle of innovation and technology in the [specific industry]. With its groundbreaking features, unmatched user experience, and commitment to sustainability, Aln is reshaping the way people interact with [specific industry] devices. Through its remarkable advancements and dedication to social responsibility, [Branding Name] continues to set new benchmarks for excellence and leave a lasting impact on society. As the product evolves and reaches new heights, Aln is destined to become an integral part of households and businesses worldwide, contributing to a greener and more efficient future.

New Study Reveals the Superiority of Dummy Grade Silicon Carbide in the Automotive Industry" could be rewritten as "Study Finds Dummy Grade Silicon Carbide Outperforms Other Materials in Automotive Applications.

[News Title]Introducing Dummy Grade SiC – A Revolutionary Silicon Carbide Solution for Advanced Industries[News Content]Date: [Insert Date][Location] – [Company Name], a pioneering manufacturer of advanced materials, is pleased to announce the launch of their new and groundbreaking product, Dummy Grade SiC. Designed to meet the increasing demand for high-performance silicon carbide in various industries, Dummy Grade SiC is set to revolutionize the way companies operate and achieve superior results.With its exceptional properties, silicon carbide (SiC) has become a crucial component in fields such as electronics, automotive, aerospace, energy, and more. Known for its high thermal conductivity, wide bandgap, extreme hardness, and excellent resistance to corrosion and wear, SiC offers far-reaching advantages over traditional materials, making it a go-to choice for applications requiring enhanced efficiency, durability, and reliability.[Company Name], with their extensive experience and expertise in material science, has developed Dummy Grade SiC, a product poised to set new standards in the industry. By removing the brand name, they are ensuring a comprehensive focus on the product's features, benefits, and potential applications.Dummy Grade SiC exhibits exceptional thermal conductivity, allowing for efficient heat dissipation, particularly in high-power electronic devices and systems. This feature ensures improved device performance and extends operational lifetimes, ultimately reducing maintenance costs.The wide bandgap of Dummy Grade SiC enables higher voltage and temperature operation, enabling the development of more efficient power electronics. This characteristic enhances energy conversion efficiency, leading to substantial energy savings and reduced environmental impact.One of the significant advantages of Dummy Grade SiC is its extreme hardness. This property makes it particularly suitable for applications demanding high wear and abrasion resistance. Industries such as automotive, where components are subjected to harsh conditions and heavy wear, can benefit significantly from this innovative material. The reduced need for frequent replacements translates into enhanced product lifetime, cost savings, and improved overall system performance.Moreover, Dummy Grade SiC exhibits exceptional resistance to corrosion and chemical attack, making it an ideal candidate for harsh operating environments. This durability and stability in corrosive conditions make it suitable for applications in the chemical industry, oil and gas, and even in nuclear environments.[Company Name] places the highest importance on quality control, ensuring that Dummy Grade SiC meets the rigorous standards demanded by various industries. Each batch undergoes stringent testing, guaranteeing consistent and reliable performance. The company's commitment to delivering excellence strengthens their position as a leading provider of advanced materials.With the launch of Dummy Grade SiC, [Company Name] aims to cater to a wide range of industries looking for innovative solutions to enhance their products and technologies. By incorporating Dummy Grade SiC into their designs, companies can stay at the forefront of technology advancements and gain a competitive edge in the market.As [Company Name] introduces Dummy Grade SiC to global markets, they are confident that this revolutionary material will bring about positive changes in industries relying on cutting-edge technology. With its outstanding properties and potential applications, Dummy Grade SiC paves the way for future developments and fosters new possibilities in multiple sectors.About [Company Name]:[Company Name] is a renowned manufacturer of advanced materials, specializing in the development and production of innovative solutions for various industries. With a commitment to research and development, they continuously strive to deliver superior products that surpass customer expectations. [Company Name] prides itself on its technical expertise, exceptional quality control, and dedication to driving technological advancements globally.For more information about Dummy Grade SiC or [Company Name], please visit [Company Website] or contact [Contact Person] at [Contact Email/Phone Number].###Note: The news content provided here is a fictional representation and does not serve as a factual account. The purpose is to demonstrate a writing style and format for a news article.

High Resistivity Silicon Wafer: A Breakthrough Innovation in Semiconductor Technology

[Headline]High Resistivity Silicon Wafer: Revolutionizing Semiconductor Applications[Date][City], [State] - [Company Name], a leading provider of innovative semiconductor solutions, introduces its highly anticipated High Resistivity Silicon Wafer, marking a significant advancement in the semiconductor industry. This revolutionary new product is poised to reshape various technology sectors by offering superior performance and enhanced conductivity in semiconductor applications.[City], [State] – [Company Name], a trailblazer in the semiconductor industry, has unveiled its latest groundbreaking product – the state-of-the-art High Resistivity Silicon Wafer. This cutting-edge innovation promises to redefine the standards of precision and efficiency in semiconductor applications, opening new avenues for technological advancements across multiple sectors.The High Resistivity Silicon Wafer is designed to address the growing demand for improved conductivity, reduced resistance, and enhanced performance in semiconductor devices. This advanced development enables better control over electrical characteristics, making it particularly useful in applications such as power electronics, microwave devices, and radiation detectors.With its revolutionary properties and exceptional material quality, the High Resistivity Silicon Wafer significantly outperforms its competitors. The wafer boasts an impressively high resistivity level, enabling better isolation between devices, resulting in minimized crosstalk and reduced power consumption. Semiconductor manufacturers can now achieve greater levels of integration density and performance in their products.One of the key advantages of the High Resistivity Silicon Wafer lies in its superior frequency response, making it an ideal choice for advanced microwave devices. The wafer’s low parasitic capacitance and improved signal-to-noise ratio lead to enhanced sensitivity and precision in high-frequency applications such as Wi-Fi, radio frequency identification (RFID), and satellite communications.Moreover, the High Resistivity Silicon Wafer offers exceptional performance in power electronics. Its unique material composition ensures better control of leakage currents, allowing for increased efficiency and reduced power wastage in devices such as power diodes and thyristors. With the ability to handle higher voltages and temperatures, the wafer can support advanced power management systems, renewable energy technologies, and electric vehicle charging infrastructure.In addition to power electronics and microwave devices, the High Resistivity Silicon Wafer can be employed in radiation detectors. Its increased resistivity allows for the precise detection of radiation, making it an indispensable component in medical imaging equipment, nuclear power plants, and space exploration instrumentation.As the demand for more advanced semiconductor devices rapidly grows, [Company Name] remains at the forefront of innovation by developing groundbreaking solutions. The company's extensive expertise in semiconductor manufacturing, coupled with its state-of-the-art facilities, enables the production of high-quality and reliable semiconductor wafers that meet the most stringent industry standards.[Company Name] is dedicated to creating value for its customers by delivering cutting-edge semiconductor solutions. The company's commitment to research and development ensures that it stays ahead of the competition, constantly adapting to the evolving needs of the industry. With the launch of the High Resistivity Silicon Wafer, [Company Name] adds another valuable addition to its portfolio of innovative products.The introduction of the High Resistivity Silicon Wafer marks a milestone moment in the semiconductor industry. This revolutionary product showcases the pioneering spirit of [Company Name] and its determination to push the boundaries of technological possibilities. With its exceptional conductivity, improved device performance, and unparalleled material quality, the High Resistivity Silicon Wafer will undoubtedly revolutionize semiconductor applications across various sectors, driving progress and innovation for years to come.

Discover the Beauty of Crystal Watch Faces

integration about Sapphire Crystal Watch Face.Sapphire crystal watch face is one of the most widely used materials by luxury watch manufacturers. It is a type of synthetic crystal that is made from high-quality aluminum oxide, which makes it remarkably durable, scratch-resistant and anti-reflective. This results in a material that is far more resilient than traditional mineral glass and nearly as hard as diamond.In addition, sapphire crystal watch faces are incredibly clear, elegant and beautiful, showcasing all the intricate details and fine workmanship of the watch movement. Moreover, the material is resistant to extreme temperatures, corrosion, and chemical damage, making it an ideal material for a watch face.While there are various materials that can be used for watch faces, sapphire crystal is, no doubt, one of the most luxurious and sought after. In fact, it is commonly used in elite watches such as Rolex, Omega, and Patek Philippe. It adds to the durability and aesthetics of the watches, making them more attractive and valuable.Many watch brands use sapphire crystal as a marketing strategy to showcase their commitment to providing the best quality and craftsmanship. Additionally, some brands use sapphire crystal for certain models or specific collections.One major brand that promotes the use of sapphire crystal in their watches is the famous Swiss watchmaker. The brand, which has been around for over a century, is renowned for its luxurious watches that are crafted with the highest degree of precision and accuracy.Apart from its high-end watches, the company is also known for its innovative technology and the use of high-quality materials. Recently, they launched a new series of watches that feature the sapphire crystal watch face. This latest series features a modern and distinct design that is a blend of tradition and innovation.The new watch model not only boasts of sapphire crystal watch face, but also comes with additional features such as chronograph functions, water resistance, and a sturdy stainless steel case. The company has invested a lot in research and development to create this masterpiece.The CEO of the company stated that "We believe in providing our clients with products that exude luxury, elegance, and uniqueness, and the new sapphire crystal watch model is not an exception. We are proud to offer our customers this new addition, which we believe is one of the finest watches ever created."In addition to its aesthetic and durable features, the use of sapphire crystal in watches is eco-friendly and sustainable. The material is highly recyclable, and it does not contain harmful chemicals such as lead, mercury, arsenic, and cadmium.Furthermore, the new sapphire crystal watch model has been designed to be energy-efficient, contributing to the brand’s commitment to sustainability.The company is aware of the environmental impact of its operations and has taken various measures to minimize their carbon footprint. They have implemented eco-friendly policies in their factories, such as using renewable energy sources and minimizing waste.In conclusion, the use of sapphire crystal in watchmaking is a testament to the industry's continuous efforts to provide customers with the best possible products. The new series of watches that feature sapphire crystal watch face from the Swiss luxury watchmaker is an excellent example of this commitment to excellence.Not only are the watches beautiful, but they are also designed to be eco-friendly and sustainable, which is a crucial aspect in today's world. With the launch of this latest series, the company continues to cement its place as one of the top luxury watch manufacturers.

Advancement in Semiconductor Manufacturing: New 8 Inch Wafer Diameter Promises Enhanced Efficiency

[Company Name] Announces Introduction of Advanced 8 Inch Wafer Diameter for Enhanced Semiconductor Manufacturing[City], [Date] - [Company Name], a leading provider of innovative semiconductor solutions, has unveiled its latest breakthrough in semiconductor manufacturing with the introduction of an advanced 8-inch wafer diameter. This new development positions [Company Name] as a key player in the industry, offering cutting-edge technologies to meet the growing demands of the market.The semiconductor industry continues to experience rapid growth and advancements, primarily driven by the increasing demand for electronic devices, such as smartphones, tablets, and wearables. As a result, there is a growing need for more sophisticated and efficient semiconductor manufacturing processes. [Company Name]'s latest innovation of an 8-inch wafer diameter addresses this need by offering improved productivity, increased efficiency, and enhanced performance.The 8-inch wafer diameter enables [Company Name] to optimize the production of semiconductors, resulting in higher yields and reduced manufacturing costs. By maximizing the surface area of each wafer, the company can accommodate more integrated circuits (ICs), resulting in higher throughput and increased production capacity. This advancement contributes to greater market competitiveness and satisfies the rising demand for semiconductors across various industries.In addition to the increased efficiency, the 8-inch wafer diameter also facilitates the development and production of advanced technologies. With a larger substrate area, [Company Name] can now integrate more complex circuitry and components onto a single wafer. This opens up new possibilities for the creation of smaller, more powerful, and energy-efficient semiconductor devices. Moreover, the larger size of the wafer provides improved scalability, enabling [Company Name] to meet the evolving needs of the semiconductor market.[Company Name] is dedicated to continuous innovation in semiconductor manufacturing processes and technology. The introduction of the 8-inch wafer diameter is a testament to the company's commitment to anticipate and respond to the dynamic industry landscape. By investing in research and development, [Company Name] remains at the forefront of technology, ensuring its customers receive best-in-class semiconductor solutions."We are thrilled to announce the availability of our advanced 8-inch wafer diameter," said [Spokesperson's Name], CEO of [Company Name]. "This significant development demonstrates [Company Name]'s dedication to delivering superior semiconductor technology to our customers. The 8-inch wafer diameter will not only enhance our competitiveness in the market but also unlock new possibilities for semiconductor development across various industries."Alongside the introduction of the 8-inch wafer diameter, [Company Name] will provide comprehensive support and services to customers who adopt this new technology. The company's team of experts will work closely with clients to optimize their manufacturing processes, maximize yield, and ensure successful integration of the 8-inch wafer diameter into their operations.As [Company Name] continues to push the boundaries of semiconductor manufacturing, they remain committed to sustainability and environmental responsibility. The adoption of the 8-inch wafer diameter contributes to reducing overall waste and resource consumption, aligning with the company's mission to create a more sustainable future.In conclusion, the introduction of the advanced 8-inch wafer diameter by [Company Name] marks a major milestone in the semiconductor industry. This breakthrough technology not only enhances productivity and efficiency but also enables the development of more advanced and innovative semiconductor devices. As [Company Name] continues to drive innovation, they reaffirm their position as a leading provider of semiconductor solutions, catering to the ever-evolving needs of the global market.