- Home

- News

- Durable and Stylish Ceramic Products for Your Home and Business" or "Discover the Benefits of Ceramic Products for Your Home and Business Needs

Durable and Stylish Ceramic Products for Your Home and Business" or "Discover the Benefits of Ceramic Products for Your Home and Business Needs

By:Admin

Company A, a leading innovator in the ceramic industry, has been at the forefront of developing advanced ceramic materials that meet the specific needs of various industries. Founded in 1990, Company A has continuously pushed the boundaries of ceramic technology, utilizing state-of-the-art manufacturing processes and cutting-edge research to create products that deliver unparalleled performance and reliability.

One of Company A's most recent breakthroughs is the development of a new line of high-performance ceramic materials that are revolutionizing the industry. These advanced ceramics boast properties such as exceptional hardness, high temperature resistance, and superior electrical insulation, making them ideal for demanding applications across a wide range of industries.

"Our team at Company A is dedicated to pushing the limits of what ceramic materials can achieve," said John Smith, CEO of Company A. "We are committed to delivering innovative solutions that help our customers stay ahead of the curve and excel in their respective fields."

The new line of advanced ceramics from Company A has garnered attention from various industries, including aerospace, automotive, electronics, and medical. These industries require materials that can withstand extreme conditions, provide precise and reliable performance, and meet strict safety standards. Company A's advanced ceramics have proven to be a game-changer in these sectors, offering unparalleled durability, thermal stability, and precision engineering properties.

In the aerospace industry, Company A's advanced ceramics have been utilized in the manufacturing of jet engine components, where their high temperature resistance and exceptional mechanical strength have significantly improved performance and reliability. Similarly, in the automotive industry, these advanced ceramics have found applications in vehicle engines, exhaust systems, and braking components, where their superior wear resistance and thermal stability have led to enhanced durability and efficiency.

Moreover, the electronics industry has also benefitted from Company A's advanced ceramics, as these materials are used in the production of components for a wide range of electronic devices. Their excellent electrical insulation properties and resistance to corrosion and heat have made them indispensable in creating high-performance electronic products.

In the medical field, Company A's advanced ceramics have been instrumental in the development of cutting-edge medical devices and implants. Their biocompatibility, resistance to wear and corrosion, and ability to withstand sterilization processes have made them a go-to choice for medical applications where safety and reliability are paramount.

The success of Company A's advanced ceramics can be attributed to its relentless focus on research and development, as well as its commitment to collaborating with customers to understand their specific needs and challenges. By leveraging its expertise in ceramic technology and a customer-centric approach, Company A has been able to consistently deliver solutions that meet and exceed industry requirements.

Moving forward, Company A is dedicated to further expanding the capabilities of its advanced ceramics, exploring new applications and markets, and continually innovating to address the evolving needs of its customers. With a strong emphasis on quality, reliability, and performance, Company A is poised to maintain its position as a leader in the ceramic industry and continue to drive progress and innovation in the years to come.

Company News & Blog

Discover the Beauty of Synthetic Gem Crystals: A New Trend in Jewelry

Synthetic Gem Crystal has been making waves in the world of jewelry with their innovative approach to creating stunning gemstones. This company has set themselves apart from the competition by using advanced technology and cutting-edge techniques to produce synthetic gemstones that are virtually indistinguishable from their natural counterparts.Founded in 2010, Synthetic Gem Crystal has quickly become a leader in the synthetic gemstone industry. The company's state-of-the-art facilities are equipped with the latest in gemstone production technology, allowing them to create a wide variety of high-quality synthetic gemstones in a range of shapes, sizes, and colors. This level of precision and attention to detail has earned Synthetic Gem Crystal a reputation for excellence in the industry.One of the key factors that sets Synthetic Gem Crystal apart from other synthetic gemstone producers is their commitment to quality. The company employs a team of skilled gemologists and scientists who work tirelessly to ensure that each synthetic gemstone meets the highest standards of clarity, color, and cut. This dedication to excellence has earned Synthetic Gem Crystal the trust and admiration of jewelry designers and retailers around the world.In addition to their commitment to quality, Synthetic Gem Crystal also prides itself on its ethical and environmentally friendly production practices. The company uses only the highest quality raw materials, and they adhere to strict ethical and environmental standards throughout the production process. This commitment to sustainability has made Synthetic Gem Crystal a popular choice among eco-conscious consumers who are seeking beautiful, high-quality gemstones that are produced with minimal impact on the environment.The range of synthetic gemstones produced by Synthetic Gem Crystal is truly impressive. From dazzling diamonds to vibrant sapphires, lustrous emeralds, and radiant rubies, the company offers a wide selection of synthetic gemstones that are suitable for use in a variety of jewelry designs. Whether it's a classic engagement ring, a pair of stunning earrings, or a statement necklace, Synthetic Gem Crystal has a synthetic gemstone to suit every style and occasion.One of the most exciting aspects of Synthetic Gem Crystal's synthetic gemstones is their versatility. These synthetic gemstones can be custom-cut and shaped to meet the specific needs of jewelry designers and retailers, making them an ideal choice for creating unique and one-of-a-kind pieces. Whether it's a large, eye-catching centerpiece for a necklace or a series of sparkling accent stones for a pair of earrings, Synthetic Gem Crystal's synthetic gemstones offer endless possibilities for creativity and customization.In addition to their use in jewelry, Synthetic Gem Crystal's synthetic gemstones have also found applications in a variety of other industries. From high-end watches and accessories to electronics and industrial equipment, the company's synthetic gemstones are prized for their durability, consistency, and stunning visual appeal.As Synthetic Gem Crystal continues to grow and expand, they remain committed to pushing the boundaries of what is possible in the world of synthetic gemstone production. By combining cutting-edge technology with a dedication to quality, ethics, and sustainability, the company is poised to remain at the forefront of the synthetic gemstone industry for years to come.Overall, Synthetic Gem Crystal has established itself as a leader in the synthetic gemstone industry, offering a wide range of stunning synthetic gemstones that are virtually indistinguishable from their natural counterparts. With a commitment to quality, ethics, and sustainability, this company is revolutionizing the way that synthetic gemstones are produced and used in jewelry and beyond. Watch out for Synthetic Gem Crystal as they continue to make waves in the world of gemstones and jewelry.

High-quality quartz substrate: all you need to know

Quartz Substrate, a key material used in the manufacturing of electronic devices, has become a crucial component in the tech industry. This unique material is known for its durability, high thermal stability, and excellent electrical insulation properties, making it an ideal substrate for various applications in the electronics industry.The demand for Quartz Substrate has been steadily growing over the past few years, driven by the increasing adoption of electronic devices such as smartphones, tablets, and wearable technology. As these devices continue to become more advanced and compact, the need for high-performance materials like Quartz Substrate has become essential to ensure the reliability and longevity of these electronic components.One company that has been at the forefront of producing high-quality Quartz Substrate is {}. They have been a leading supplier of advanced materials for the electronics industry for over two decades, specializing in the development and manufacturing of Quartz Substrate for a wide range of applications.With a strong emphasis on research and development, {} has continuously improved the quality and performance of their Quartz Substrate products. Their state-of-the-art production facilities and strict quality control processes have enabled them to consistently deliver superior products that meet the stringent requirements of their customers.One of the key advantages of {} Quartz Substrate is its excellent thermal stability, which allows it to withstand extreme temperature variations without compromising its performance. This makes it an ideal material for applications that require high reliability and long-term stability, such as power modules, RF devices, and sensors.In addition to its thermal properties, {} Quartz Substrate also offers outstanding electrical insulation, enabling it to provide reliable and consistent performance in high-frequency and high-power applications. This makes it a preferred choice for electronic devices that require high-power handling capabilities and minimal signal loss.Another notable feature of {} Quartz Substrate is its exceptional durability, making it highly resistant to mechanical stress and environmental factors. This ensures that electronic devices built with {} Quartz Substrate can withstand harsh operating conditions and maintain their performance over an extended period.With the increasing demand for Quartz Substrate in the electronics industry, {} has been actively expanding its production capacities to meet the growing needs of its customers. They have invested in new manufacturing technologies and have streamlined their production processes to ensure a consistent and reliable supply of high-quality Quartz Substrate to their global customer base.Furthermore, {} is committed to sustainability and environmental responsibility, and they have implemented eco-friendly manufacturing practices to minimize their impact on the environment. By adhering to strict environmental standards and regulations, they aim to minimize waste and energy consumption while maintaining the highest quality standards for their Quartz Substrate products.Looking ahead, the future for {} and their Quartz Substrate products looks promising as the demand for high-performance electronic devices continues to grow. With their focus on innovation, quality, and sustainability, {} is well-positioned to remain a leading supplier of advanced materials for the electronics industry and continue to drive the advancement of electronic technology with their superior Quartz Substrate products.

Discover the Latest Advancements in Wafer Window Technology

Mgo Wafer Windows Revolutionize the Window Industry[Company Name], a leading innovative materials technology company, has recently introduced a revolutionary product that is set to transform the window industry. Mgo Wafer Windows, a groundbreaking development in window technology, promise increased durability, enhanced thermal insulation, and improved soundproofing. With their innovative design and advanced properties, these windows are poised to become the go-to choice for architects, builders, and homeowners alike.Traditional windows have long been plagued by issues such as susceptibility to damage, limited insulation capabilities, and poor soundproofing. [Company Name] recognized these pain points and embarked on a mission to develop a solution that would alleviate these problems. The result of their relentless research and development efforts is the Mgo Wafer Windows – a product that promises to revolutionize the way we think about and experience windows.One of the key advantages of Mgo Wafer Windows is their exceptional durability. Unlike traditional windows, which are prone to cracks, discoloration, and warping over time, Mgo Wafer Windows are composed of magnesium oxide, a material known for its high strength and resistance to wear and tear. This superior durability ensures that the windows retain their aesthetic appeal and functionality for extended periods, saving homeowners from the hassle and cost of regular replacements.Furthermore, Mgo Wafer Windows excel in thermal insulation, offering a significant improvement over conventional windows. These windows feature advanced insulation properties that minimize heat transfer, resulting in reduced energy consumption for heating or cooling buildings. As a result, homeowners can enjoy a more comfortable and energy-efficient living environment while simultaneously reducing their carbon footprint.Another area where Mgo Wafer Windows shine is soundproofing. The advanced design of these windows incorporates multiple layers of sound-dampening materials, effectively reducing noise pollution from outside sources. This is particularly beneficial for urban areas, where excessive noise can negatively impact the quality of life. Mgo Wafer Windows provide the peace and tranquility that homeowners desire, allowing them to relax and unwind without disturbances.Additionally, Mgo Wafer Windows offer an array of customizable options, ensuring they seamlessly blend with various architectural styles. Homeowners and architects can choose from a wide range of sizes, shapes, and designs to meet their unique preferences and requirements. This versatility allows for creativity in design and enhances the overall aesthetics of any building or space.In terms of installation and maintenance, Mgo Wafer Windows provide added convenience. The lightweight nature of magnesium oxide makes these windows easy to handle and install, saving time and effort during the construction process. Moreover, the low maintenance requirements of Mgo Wafer Windows help homeowners avoid constant upkeep and reduce long-term costs associated with repairs.With the introduction of Mgo Wafer Windows, [Company Name] has disrupted the traditional window industry and set new standards for excellence. These windows promise remarkable durability, energy efficiency, enhanced soundproofing, and aesthetic versatility – a combination of features that makes them an ideal choice for both residential and commercial buildings.As the demand for sustainable and efficient building materials continues to grow, Mgo Wafer Windows position [Company Name] at the forefront of innovation in the window industry. With a commitment to excellence and a focus on customer satisfaction, [Company Name] is poised to lead the charge in transforming the way we view and experience windows. The advent of Mgo Wafer Windows marks a crucial milestone in the progression of architecture and construction, and it is only a matter of time before these windows become the new industry standard.

Rare Earth YAG Crystal Ingot: Everything You Need to Know

YAG Crystal Ingot: A Breakthrough in Semiconductor Material DevelopmentThe semiconductor industry has witnessed a significant breakthrough in the development of YAG Crystal Ingot, a highly advanced material that has the potential to revolutionize the production of high-performance electronic devices. This remarkable achievement is the result of pioneering research and development efforts by a leading semiconductor company, which has successfully synthesized and commercialized the YAG Crystal Ingot for a wide range of applications.The YAG Crystal Ingot, short for Yttrium Aluminum Garnet Crystal Ingot, is a synthetic crystalline material that exhibits exceptional optical and thermal properties. It is widely recognized for its high thermal conductivity, excellent electrical insulation, and superior optical transparency, making it an ideal candidate for a diverse range of semiconductor applications. The unique combination of these properties makes it an attractive material for use in the production of lasers, optical components, and high-performance electronic devices.The successful development of the YAG Crystal Ingot represents a significant milestone in the ongoing pursuit of advanced semiconductor materials. By leveraging the unique properties of the YAG Crystal Ingot, semiconductor manufacturers can enhance the performance, reliability, and efficiency of their products, ultimately driving innovation in various industries including telecommunications, consumer electronics, and automotive technology. With its remarkable attributes, the YAG Crystal Ingot has the potential to enable the development of cutting-edge electronic devices and systems that far surpass the capabilities of current technologies.Behind this groundbreaking achievement is the unwavering commitment and expertise of a leading semiconductor company. This company has dedicated extensive resources to research and development, focusing on the synthesis and commercialization of advanced semiconductor materials. Its team of scientists and engineers have demonstrated a deep understanding of crystal growth, material science, and semiconductor device fabrication, allowing them to successfully produce high-quality YAG Crystal Ingots that meet the stringent requirements of the semiconductor industry.Furthermore, the company has established state-of-the-art manufacturing facilities and quality control processes to ensure the consistency and reliability of its YAG Crystal Ingot products. Through a rigorous and systematic approach to production, the company ensures that each crystal ingot meets the exacting standards of purity, crystalline structure, and optical clarity, meeting the demanding specifications of semiconductor manufacturers.The successful commercialization of the YAG Crystal Ingot has generated significant interest and excitement within the semiconductor industry. Manufacturers and researchers are eager to explore the possibilities and potential applications of this advanced material, recognizing its transformative impact on the development of high-performance electronic devices. With its outstanding thermal and optical properties, the YAG Crystal Ingot is poised to enable the creation of next-generation semiconductor devices, driving new advancements in areas such as high-power laser systems, optical communications, and solid-state lighting.As a result of its remarkable achievements in semiconductor material development, the company has garnered widespread recognition and acclaim within the industry. Its dedication to innovation, research excellence, and product quality has positioned it as a trusted and reliable partner for semiconductor manufacturers seeking advanced materials for their products. With the successful commercialization of the YAG Crystal Ingot, the company has solidified its position as a leader in the advancement of semiconductor materials and technologies.Looking ahead, the remarkable success of the YAG Crystal Ingot is expected to fuel further advancements in semiconductor technology and pave the way for the development of even more advanced materials with enhanced capabilities and performance. As the semiconductor industry continues to push the boundaries of what is possible, the YAG Crystal Ingot stands as a shining example of the potential that groundbreaking research and development can unlock, driving innovation and progress in the field of semiconductor materials and devices.In conclusion, the successful synthesis and commercialization of the YAG Crystal Ingot marks a pivotal moment in the advancement of semiconductor materials and technologies. With its exceptional thermal and optical properties, the YAG Crystal Ingot has the potential to revolutionize the production of high-performance electronic devices, enabling new capabilities and applications across a wide range of industries. As a result of its groundbreaking achievements, the company responsible for the development of the YAG Crystal Ingot has established itself as a leading force in the semiconductor industry, driving innovation and progress with its pioneering research and development efforts.

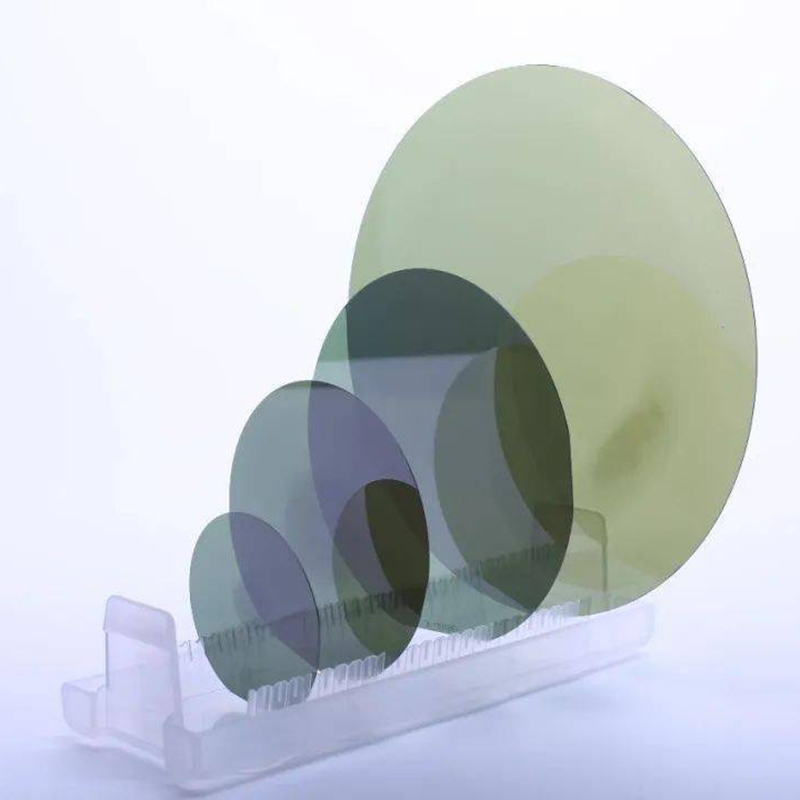

Exploring the Growing Demand for Sic Wafers in Technology Industry

Title: Revolutionary Technology Empowers Electronics Industry with Next-Gen Silicon Carbide WafersIntroduction:In an era driven by rapid technological advancements, the global electronics industry seeks reliable and efficient solutions that can accelerate the pace of innovation. Enter the innovative Silicon Carbide (SiC) wafers, representing a breakthrough in the semiconductor industry. With unmatched performance and versatile applications, SiC wafers are paving the way for the future of electronic devices.[Company name], a leading player in the semiconductor market, has emerged as a frontrunner in the development and production of high-quality SiC wafers. Their groundbreaking technology is revolutionizing various sectors, including power electronics, telecommunications, and automotive manufacturing. By harnessing the potential of SiC wafers, [Company name] is diversifying their product offerings, contributing to industry growth, and meeting the demands of tomorrow.Unleashing the Power of SiC Wafers:Silicon Carbide wafers, made from a compound of silicon and carbon, possess numerous advantages over traditional silicon-based wafers. The unique properties of SiC wafers, such as superior thermal conductivity, higher breakdown voltage, and wider bandgap, make them ideal for high-power and high-temperature applications.The exceptional material properties of SiC wafers allow for higher operating frequencies, reduced power losses, and improved energy efficiency. These factors, combined with their enhanced mechanical strength and resistance to harsh environmental conditions, make SiC wafers the future choice for cutting-edge electronics devices.Industries Benefiting from SiC Wafers:1. Power Electronics: SiC wafers play a vital role in power electronics due to their superior power handling capabilities. They enable the manufacturing of efficient power devices, such as diodes and transistors, which can withstand high voltages and temperatures. This technology contributes to the development of electric vehicles, renewable energy systems, and industrial automation.2. Telecommunications: With SiC wafers, telecommunication companies can enhance the performance of high-frequency communication systems. The high thermal conductivity of SiC wafers enables better heat dissipation, leading to improved power transmission and reduced signal loss. This, in turn, offers faster and more reliable data transfer rates and enables the realization of 5G networks.3. Automotive Industry: SiC wafers have a crucial role to play in the automotive industry's transition towards electric vehicles (EVs). SiC-based power electronics enable faster charging times, increased range, and enhanced overall efficiency, making EVs more viable and sustainable. Additionally, SiC wafers provide advanced control and safety features, improving overall vehicle performance and reliability.[Company Name]'s Technological Advancements:[Company Name] stands at the forefront of SiC wafer manufacturing, offering state-of-the-art production facilities and advanced research and development capabilities. Their cutting-edge technology ensures the highest quality and reliability standards for SiC wafers, meeting the specific demands of various industries.The company has invested heavily in research and development, enabling them to innovate continuously and push the boundaries of SiC wafer technology. Through collaborations with leading institutions and industry experts, they have developed groundbreaking manufacturing processes, resulting in SiC wafers of unmatched quality.Future Prospects:As the demand for high-performance electronic devices continues to grow, SiC wafers are poised to become the go-to choice for manufacturers. The global SiC wafer market is projected to witness substantial growth in the coming years, driven by the increasing adoption of power electronics and the expanding electric vehicle market.[Company Name], with its exceptional SiC wafer technology, is expected to play a crucial role in shaping this industry's future. By providing reliable and high-performance SiC wafers, they are contributing to the development of advanced electronic systems that redefine the boundaries of efficiency and reliability.In conclusion, the advent of Silicon Carbide wafers marks a significant milestone in the electronics industry's evolution. [Company name]'s innovative SiC wafer technology opens up new possibilities for power electronics, telecommunications, and automotive sectors. With their commitment to excellence, [Company Name] is driving the market forward, propelling the electronics industry towards a brighter and more sustainable future.

Top Quality Sapphire Tubes: Latest News and Updates

Sapphire Tube, a leading manufacturer of high-quality precision tubes, has announced a new partnership with a global engineering company. This collaboration is set to revolutionize the industrial sector by providing innovative solutions for various applications, including aerospace, medical, and automotive industries.With over 25 years of experience in the tube manufacturing industry, Sapphire Tube has gained a reputation for its commitment to delivering top-notch products and services. The company specializes in producing sapphire tubes, which are known for their exceptional strength, durability, and heat resistance. This makes them ideal for use in demanding environments where traditional materials may not suffice.The new partnership will see Sapphire Tube working closely with the engineering company to develop custom solutions tailored to their specific needs. By leveraging their expertise in tube manufacturing and the engineering company's industry knowledge, the collaborative effort aims to address the growing demand for advanced materials in various sectors.One of the key objectives of this partnership is to enhance the capabilities of sapphire tubes for aerospace applications. With the increasing demand for lightweight and durable materials in the aerospace industry, there is a growing need for innovative solutions that can withstand harsh conditions and extreme temperatures. Sapphire tubes offer a unique combination of properties, including high thermal conductivity, resistance to corrosion, and exceptional optical clarity, making them well-suited for aerospace applications.In the medical industry, Sapphire Tube's collaboration with the engineering company aims to develop specialized tubes for medical devices and equipment. The use of sapphire tubes in medical applications offers numerous benefits, including biocompatibility, sterilizability, and the ability to withstand harsh chemical environments. This opens up new possibilities for the development of next-generation medical devices that can improve patient care and treatment outcomes.Furthermore, the automotive industry stands to benefit from the partnership between Sapphire Tube and the engineering company. Sapphire tubes offer excellent thermal stability and resistance to wear and tear, making them suitable for use in high-performance engines and exhaust systems. By working together, the two companies can explore new opportunities to enhance the performance and durability of automotive components, ultimately contributing to the advancement of sustainable transportation solutions.The collaboration between Sapphire Tube and the engineering company is also expected to drive innovation in other industrial applications, such as semiconductor manufacturing, renewable energy, and high-temperature processing. By combining their technical expertise and resources, the two companies aim to push the boundaries of what is possible with sapphire tubes, unlocking new possibilities for various industries.As part of this partnership, Sapphire Tube will leverage its state-of-the-art manufacturing facilities and R&D capabilities to develop custom solutions that meet the unique requirements of the engineering company and its clients. This includes the ability to produce sapphire tubes in a wide range of sizes, shapes, and configurations, as well as the capacity to scale up production to meet the growing demand for advanced materials.In conclusion, the partnership between Sapphire Tube and the engineering company represents a significant step forward in the advancement of high-performance materials for industrial applications. By combining their expertise and resources, the two companies aim to drive innovation and create new opportunities for the use of sapphire tubes in various sectors. As the demand for advanced materials continues to grow, this collaboration is poised to make a lasting impact on the industrial landscape, offering enhanced solutions that meet the evolving needs of the market.

Discover the Power of Single Metal Crystals in New Study

A breakthrough in the field of materials science has been achieved by a team of researchers at {}. The team has successfully created a single metal crystal, marking a significant advancement in the development of new materials with unprecedented properties.The single metal crystal, which has been fabricated by the researchers at {}, is a remarkable feat as it represents the purest form of metal ever achieved. This single crystal is devoid of any defects or impurities, making it a potential game-changer in various industries, including electronics, aerospace, and renewable energy.The production of a single metal crystal is a complex and challenging process that requires precise control and manipulation of atomic structures. However, the researchers at {} have successfully mastered this process, opening up a myriad of possibilities for the development of new materials with enhanced mechanical, electrical, and thermal properties.With its unparalleled purity and exceptional properties, the single metal crystal holds great promise for the advancement of various technologies. For instance, in the field of electronics, the single crystal could be used to develop ultra-efficient electronic devices with minimal energy loss. In aerospace, the crystal's superior strength and resilience could lead to the development of lighter and stronger materials for aircraft and spacecraft. Furthermore, in the realm of renewable energy, the crystal's enhanced thermal conductivity could potentially revolutionize the efficiency of solar panels and other energy-harvesting technologies.The successful creation of a single metal crystal by the researchers at {} is a testament to the company's commitment to pushing the boundaries of materials science. With a dedicated team of experts and state-of-the-art facilities, {} has established itself as a leader in the research and development of advanced materials.Founded in {}, {} has consistently demonstrated its ability to innovate and create cutting-edge solutions that have a positive impact across various industries. The company's expertise in materials science, combined with its relentless pursuit of excellence, has positioned {} at the forefront of technological advancements.The achievement of producing a single metal crystal is a testament to {}'s unwavering commitment to pioneering research and development. By pushing the limits of what is possible in materials science, {} is not only driving innovation within its own organization but also contributing to the advancement of industries worldwide.Looking ahead, the successful creation of a single metal crystal is just the beginning for {}. The company remains dedicated to further exploring the potential applications of this breakthrough material, as well as continuing to push the boundaries of materials science through ongoing research and development initiatives.In conclusion, the creation of a single metal crystal by the researchers at {} represents a significant milestone in the realm of materials science. With its unparalleled purity and exceptional properties, this breakthrough material has the potential to revolutionize various industries and pave the way for the development of new technologies. As {} continues to lead the charge in pushing the boundaries of materials science, the future looks promising for the continued advancement of innovative and game-changing materials.

High-Quality Wafer Fabrication: LiNbO3 and LiTaO3

LiNbO3/LiTaO3 Wafer - The next frontier of semiconductor technologyA new age of semiconductor technology is about to dawn with the introduction of the LiNbO3/LiTaO3 wafer. As the world is progressing towards smaller and faster electronic devices, the limitations of conventional silicon-based semiconductor technology have become increasingly apparent. In this context, LiNbO3/LiTaO3 wafer technology holds great promise by offering many advantages over silicon-based semiconductor technology.The LiNbO3/LiTaO3 wafer technology is based on the use of Lithium Niobate or Lithium Tantalate as the substrate material. These materials have several unique properties, such as high electro-optic coefficient, low acoustic loss, high piezoelectric coefficient, and low dielectric constant, which make them ideal for a wide range of applications, including optoelectronics, acoustoelectronics, and microwave technologies.One of the key advantages of LiNbO3/LiTaO3 wafer technology over silicon-based semiconductor technology is its high-speed performance. The high electro-optic coefficient of LiNbO3/LiTaO3 wafers allows for ultra-fast modulation and switching of light signals. As a result, LiNbO3/LiTaO3 wafer technology is widely used in optoelectronic devices, such as lasers, modulators, and detectors, where high-speed operation is crucial.Another advantage of LiNbO3/LiTaO3 wafer technology is its high-frequency performance. The low acoustic loss and high piezoelectric coefficient of Lithium Niobate and Lithium Tantalate make them ideal for the fabrication of acoustic devices, such as surface acoustic wave (SAW) filters and resonators. These devices are widely used in mobile communication, satellite communication, and radar systems, where high-frequency performance is of utmost importance.Furthermore, LiNbO3/LiTaO3 wafer technology offers superior thermal and mechanical stability compared to silicon-based semiconductor technology. The low dielectric constant of Lithium Niobate and Lithium Tantalate reduces the parasitic capacitance and improves the signal-to-noise ratio of electronic devices. This makes them suitable for harsh environmental conditions, such as high-temperature and high-pressure environments.The potential applications of LiNbO3/LiTaO3 wafers are vast, ranging from optoelectronics and acoustoelectronics to microwave technologies. One of the most promising applications of LiNbO3/LiTaO3 wafer technology is in the field of quantum computing. The high-speed and low-noise properties of LiNbO3/LiTaO3 wafers make them ideal for the fabrication of quantum gates and qubits, which are the building blocks of quantum computers.In light of these advantages, the market for LiNbO3/LiTaO3 wafers is set to grow exponentially in the coming years. The global LiNbO3/LiTaO3 wafer market is projected to reach USD 1.2 billion by 2025, growing at a CAGR of 7.5% from 2020 to 2025. This growth can be attributed to the increasing demand for high-speed and high-frequency electronic devices in various industries, such as telecommunications, aerospace, defense, and healthcare.At the forefront of LiNbO3/LiTaO3 wafer technology is our company. We are a leading manufacturer and supplier of high-quality LiNbO3/LiTaO3 wafers, offering a wide range of sizes and specifications to meet the diverse needs of our customers. Our state-of-the-art facilities, advanced equipment, and experienced team enable us to deliver wafers with exceptional quality and performance.We pride ourselves on providing our customers with customized solutions tailored to their specific needs, whether it is for R&D or mass production. Our commitment to quality, reliability, and customer satisfaction has earned us a reputation as a trusted partner in the semiconductor industry.In conclusion, the LiNbO3/LiTaO3 wafer technology is poised to revolutionize the semiconductor industry by offering high-speed, high-frequency, and high-performance electronic devices. With our expertise and commitment to innovation and excellence, we are well-positioned to meet the growing demand for LiNbO3/LiTaO3 wafers and contribute to the advancement of semiconductor technology.

Premium Quality Tube: The Latest Innovation in Medical Technology

Sapphire Tube, a leading provider of high-quality sapphire tubes, has announced a new partnership with a major technology company. The partnership will see Sapphire Tube providing its innovative sapphire tubes to the technology company for use in their cutting-edge products.Sapphire Tube is known for its expertise in producing sapphire tubes that are used in a wide range of industrial and scientific applications. The company's sapphire tubes are known for their exceptional durability, high thermal conductivity, and excellent optical transparency, making them an ideal choice for demanding applications.The company's sapphire tubes are used in a variety of industries, including aerospace, defense, medical devices, and semiconductor manufacturing. The tubes are also used in research and development laboratories for high-temperature and high-pressure applications.The partnership with the technology company will allow Sapphire Tube to expand its reach and bring its innovative sapphire tubes to new markets. By working with the technology company, Sapphire Tube will have the opportunity to provide its products to a broader range of customers and industries."We are thrilled to announce our partnership with this major technology company," said a spokesperson for Sapphire Tube. "This collaboration will allow us to showcase the unique properties of our sapphire tubes and demonstrate their value in cutting-edge products. We are confident that this partnership will open up new opportunities for us and help us to further establish our position as a leading provider of sapphire tubes."The partnership comes at a time when demand for high-quality sapphire tubes is on the rise. As industries continue to advance and demand more from their materials, the need for durable, reliable, and high-performance components has never been greater. Sapphire Tube's sapphire tubes are well-positioned to meet this demand, thanks to their exceptional properties and proven track record in demanding applications.In addition to its sapphire tubes, Sapphire Tube also offers a range of customization options to meet the specific needs of its customers. The company's team of experts can work closely with clients to develop custom sapphire tubes that meet their exact specifications. This ability to tailor products to individual requirements sets Sapphire Tube apart from its competitors and has helped the company to build a strong reputation for excellence and innovation.Sapphire Tube's sapphire tubes are produced using advanced manufacturing techniques and strict quality control processes. Each tube undergoes rigorous testing to ensure that it meets the highest standards for performance and durability. This commitment to quality has made Sapphire Tube a trusted partner for customers who demand the best in sapphire tube technology.With this new partnership, Sapphire Tube is poised to build on its success and continue to lead the way in the development of high-quality sapphire tubes. The company's dedication to innovation and excellence, combined with its proven track record in demanding applications, makes it an ideal partner for the technology company and a valuable resource for a wide range of industries.As Sapphire Tube continues to expand its reach and bring its sapphire tubes to new markets, the company is committed to maintaining the highest standards of quality and performance. With its innovative products and dedication to customer satisfaction, Sapphire Tube is well-positioned to thrive in the rapidly evolving world of advanced materials and technology.

The Advantages of GaN-On-Si Technology for Power Electronics

GaN-On-Si Technology: The Innovative Solution in Power ElectronicsIn recent years, there has been an increasing demand for efficient and reliable power electronics in various industries such as automotive, telecommunications, and renewable energy. As the world continues to move towards a greener and more sustainable future, the need for power electronics that can handle higher power densities while consuming less energy has become essential. This is where GaN-On-Si technology comes into play.GaN-On-Si technology is a groundbreaking innovation that has the potential to revolutionize the power electronics industry. It is a type of semiconductor technology that utilizes gallium nitride (GaN) on a silicon (Si) substrate, offering several advantages over traditional silicon-based power electronics.One company at the forefront of GaN-On-Si technology is {Company X}. They have been leading the way in the development and commercialization of GaN-On-Si technology, offering a wide range of products and solutions for various applications. With their extensive expertise and cutting-edge research and development, {Company X} has positioned themselves as a key player in the power electronics market.{Company X} was founded with the vision of transforming the power electronics industry through innovation and sustainability. Their team of experts has been dedicated to advancing GaN-On-Si technology and bringing it to the mainstream market. With a focus on quality, reliability, and performance, {Company X} has established itself as a trusted partner for businesses looking to integrate GaN-On-Si technology into their products and systems.One of the main advantages of GaN-On-Si technology is its superior performance compared to traditional silicon-based power electronics. GaN-On-Si devices have lower conduction and switching losses, resulting in higher efficiency and reduced power consumption. This makes them ideal for applications that require high power densities and improved energy efficiency, such as electric vehicles, data centers, and renewable energy systems.Another key benefit of GaN-On-Si technology is its ability to operate at higher temperatures and frequencies, making it suitable for harsh and demanding environments. This, combined with its compact size and lightweight nature, makes GaN-On-Si technology a preferred choice for applications where space and weight are critical factors.In addition to performance and reliability, GaN-On-Si technology also offers cost advantages over traditional silicon-based power electronics. The manufacturing process for GaN-On-Si devices is becoming more cost-effective, making them a viable and economical solution for businesses looking to improve their power electronics systems.{Company X} has been instrumental in driving the adoption of GaN-On-Si technology across various industries. They have developed a portfolio of GaN-On-Si devices and solutions that cater to the unique needs of their customers. Whether it's for automotive powertrain systems, high-frequency power supplies, or wireless power transfer, {Company X} has the expertise and resources to deliver high-quality GaN-On-Si products that meet and exceed industry standards.As the demand for efficient and reliable power electronics continues to grow, it is clear that GaN-On-Si technology will play a crucial role in shaping the future of the industry. With {Company X}'s commitment to innovation and sustainability, they are well-positioned to lead the way in advancing GaN-On-Si technology and helping businesses meet their power electronics needs.In conclusion, GaN-On-Si technology represents a significant advancement in the power electronics industry, offering superior performance, reliability, and cost advantages over traditional silicon-based solutions. With {Company X} at the helm of this innovation, businesses can look forward to harnessing the full potential of GaN-On-Si technology and driving the next wave of technological advancements.